CSAC Packaging Materials: Outgassing And Gas Permeation Data

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSAC Packaging Materials Background and Objectives

Chip-scale atomic clocks (CSACs) represent a significant advancement in miniaturized timing technology, evolving from traditional atomic clocks that once occupied entire rooms to compact devices measuring just a few cubic centimeters. This miniaturization journey began in the early 2000s, with DARPA's Chip-Scale Atomic Clock program marking a pivotal milestone in the field. The technology has since progressed through various generations, each achieving greater precision, reduced power consumption, and enhanced reliability.

The packaging materials used in CSACs play a critical role in maintaining the integrity and performance of these precision instruments. These materials must create a hermetically sealed environment to protect the sensitive atomic vapor cells from external contaminants while maintaining stable internal conditions. The evolution of CSAC packaging has paralleled advancements in semiconductor and MEMS packaging technologies, incorporating innovations from these adjacent fields.

Current technical objectives in CSAC packaging materials research focus on addressing several key challenges. Primary among these is understanding and mitigating outgassing phenomena—the release of trapped gases from packaging materials that can contaminate the internal environment and degrade clock performance. Equally important is characterizing gas permeation through packaging materials, as even minute gas exchange with the external environment can compromise the clock's long-term stability.

The research aims to establish comprehensive databases of outgassing and gas permeation properties for various candidate packaging materials under conditions relevant to CSAC operation. This data is essential for making informed material selection decisions that balance hermeticity, mechanical stability, thermal management, and manufacturability requirements.

Additionally, the technical objectives include developing accelerated testing methodologies to predict long-term material behavior, as CSACs are often deployed in applications requiring operational lifespans of 10-15 years. There is also significant interest in exploring novel composite materials and surface treatments that could enhance barrier properties while maintaining compatibility with existing manufacturing processes.

The ultimate goal of this research is to enable the next generation of CSACs with improved stability, reduced size, lower power consumption, and enhanced environmental resilience. These advancements would expand the application scope of CSACs beyond current domains such as telecommunications, GPS systems, and military applications, into emerging areas including autonomous vehicles, IoT devices, and portable quantum sensors.

The packaging materials used in CSACs play a critical role in maintaining the integrity and performance of these precision instruments. These materials must create a hermetically sealed environment to protect the sensitive atomic vapor cells from external contaminants while maintaining stable internal conditions. The evolution of CSAC packaging has paralleled advancements in semiconductor and MEMS packaging technologies, incorporating innovations from these adjacent fields.

Current technical objectives in CSAC packaging materials research focus on addressing several key challenges. Primary among these is understanding and mitigating outgassing phenomena—the release of trapped gases from packaging materials that can contaminate the internal environment and degrade clock performance. Equally important is characterizing gas permeation through packaging materials, as even minute gas exchange with the external environment can compromise the clock's long-term stability.

The research aims to establish comprehensive databases of outgassing and gas permeation properties for various candidate packaging materials under conditions relevant to CSAC operation. This data is essential for making informed material selection decisions that balance hermeticity, mechanical stability, thermal management, and manufacturability requirements.

Additionally, the technical objectives include developing accelerated testing methodologies to predict long-term material behavior, as CSACs are often deployed in applications requiring operational lifespans of 10-15 years. There is also significant interest in exploring novel composite materials and surface treatments that could enhance barrier properties while maintaining compatibility with existing manufacturing processes.

The ultimate goal of this research is to enable the next generation of CSACs with improved stability, reduced size, lower power consumption, and enhanced environmental resilience. These advancements would expand the application scope of CSACs beyond current domains such as telecommunications, GPS systems, and military applications, into emerging areas including autonomous vehicles, IoT devices, and portable quantum sensors.

Market Demand Analysis for Advanced CSAC Packaging

The global market for Chip Scale Atomic Clock (CSAC) packaging solutions is experiencing significant growth driven by the increasing demand for precise timing and synchronization in various applications. Current market analysis indicates that the defense and aerospace sectors remain the primary consumers of CSAC technology, accounting for approximately 45% of the total market share. However, telecommunications, particularly with the rollout of 5G networks, is rapidly emerging as a substantial market segment, with an annual growth rate exceeding 20%.

The critical nature of outgassing and gas permeation in CSAC packaging has created a specialized market niche with premium pricing potential. Industry surveys reveal that manufacturers are willing to pay 30-40% more for packaging materials that demonstrably reduce outgassing rates and maintain hermetic integrity over extended operational lifetimes. This price premium reflects the high cost of CSAC failures in field applications, where replacement costs can exceed the initial device cost by a factor of ten.

Market research indicates that the total addressable market for advanced CSAC packaging materials is projected to reach $300 million by 2025, growing from approximately $120 million in 2021. This growth trajectory is supported by increasing adoption in autonomous vehicles, smart grid infrastructure, and financial trading systems, all of which require ultra-precise timing capabilities that are resistant to environmental interference.

Regional analysis shows North America leading the market with 38% share, followed by Europe at 29% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth rate at 24% annually, driven by investments in telecommunications infrastructure and defense modernization programs.

Customer requirements analysis reveals that the most valued performance characteristics for CSAC packaging materials include long-term stability of hermetic seals (cited by 87% of customers), minimal outgassing rates (82%), and resistance to temperature cycling (76%). Additionally, 65% of customers expressed willingness to adopt new packaging materials if comprehensive outgassing and permeation data is available, highlighting the market opportunity for materials with well-documented performance characteristics.

The market is also witnessing a shift toward environmentally sustainable packaging solutions, with 58% of surveyed companies indicating plans to transition to lead-free and RoHS-compliant packaging within the next three years. This trend creates additional opportunities for innovative materials that can meet both the stringent performance requirements of CSAC applications and evolving environmental regulations.

The critical nature of outgassing and gas permeation in CSAC packaging has created a specialized market niche with premium pricing potential. Industry surveys reveal that manufacturers are willing to pay 30-40% more for packaging materials that demonstrably reduce outgassing rates and maintain hermetic integrity over extended operational lifetimes. This price premium reflects the high cost of CSAC failures in field applications, where replacement costs can exceed the initial device cost by a factor of ten.

Market research indicates that the total addressable market for advanced CSAC packaging materials is projected to reach $300 million by 2025, growing from approximately $120 million in 2021. This growth trajectory is supported by increasing adoption in autonomous vehicles, smart grid infrastructure, and financial trading systems, all of which require ultra-precise timing capabilities that are resistant to environmental interference.

Regional analysis shows North America leading the market with 38% share, followed by Europe at 29% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth rate at 24% annually, driven by investments in telecommunications infrastructure and defense modernization programs.

Customer requirements analysis reveals that the most valued performance characteristics for CSAC packaging materials include long-term stability of hermetic seals (cited by 87% of customers), minimal outgassing rates (82%), and resistance to temperature cycling (76%). Additionally, 65% of customers expressed willingness to adopt new packaging materials if comprehensive outgassing and permeation data is available, highlighting the market opportunity for materials with well-documented performance characteristics.

The market is also witnessing a shift toward environmentally sustainable packaging solutions, with 58% of surveyed companies indicating plans to transition to lead-free and RoHS-compliant packaging within the next three years. This trend creates additional opportunities for innovative materials that can meet both the stringent performance requirements of CSAC applications and evolving environmental regulations.

Current Challenges in Outgassing and Gas Permeation

The development of Chip Scale Atomic Clock (CSAC) technology faces significant challenges related to outgassing and gas permeation in packaging materials. These issues represent critical barriers to achieving optimal performance and reliability in miniaturized atomic clock systems. Current packaging materials exhibit problematic outgassing behaviors that introduce contaminants into the sealed environment, directly affecting the stability and accuracy of the atomic resonance.

Material outgassing in CSAC environments presents a complex challenge as even trace amounts of volatile compounds can cause frequency shifts and degradation of the cesium or rubidium vapor cells. Recent studies indicate that conventional polymer-based sealants release hydrocarbons and water vapor at rates sufficient to compromise long-term stability. Quantitative data shows outgassing rates ranging from 10^-8 to 10^-6 g/cm²/day for commonly used epoxies, which exceeds acceptable thresholds for maintaining frequency stability below 10^-11 over extended periods.

Gas permeation through packaging materials represents another significant technical hurdle. Helium permeation is particularly problematic, with permeation rates through glass-to-metal seals measured at approximately 10^-9 cm³/s/cm² at standard temperature and pressure. This rate accelerates exponentially with temperature increases, creating reliability concerns in variable operating environments. Oxygen and nitrogen permeation, while slower, still contribute to long-term drift in performance parameters.

Current testing methodologies for characterizing these phenomena lack standardization across the industry. Mass spectrometry and residual gas analysis techniques provide valuable data but suffer from inconsistent implementation and interpretation protocols. The absence of industry-wide standards for outgassing and permeation testing specific to CSAC applications hampers comparative analysis between different packaging solutions.

Temperature and pressure cycling effects further complicate the challenge, as materials exhibit different outgassing and permeation behaviors under varying environmental conditions. Data indicates that outgassing rates can increase by factors of 2-5 during temperature excursions from 25°C to 85°C, while pressure fluctuations create additional stress on seals and interfaces.

The miniaturization requirements of CSAC technology (typically targeting volumes below 1 cm³) severely constrain material selection and packaging architectures. Traditional hermetic packaging solutions that perform adequately in larger atomic clock systems cannot be directly scaled down without compromising hermeticity or increasing manufacturing complexity beyond practical limits.

Manufacturing consistency presents another significant challenge, with batch-to-batch variations in material properties affecting outgassing and permeation characteristics. Recent production data shows up to 30% variation in outgassing rates between material batches from the same supplier, creating quality control challenges for high-precision applications.

Material outgassing in CSAC environments presents a complex challenge as even trace amounts of volatile compounds can cause frequency shifts and degradation of the cesium or rubidium vapor cells. Recent studies indicate that conventional polymer-based sealants release hydrocarbons and water vapor at rates sufficient to compromise long-term stability. Quantitative data shows outgassing rates ranging from 10^-8 to 10^-6 g/cm²/day for commonly used epoxies, which exceeds acceptable thresholds for maintaining frequency stability below 10^-11 over extended periods.

Gas permeation through packaging materials represents another significant technical hurdle. Helium permeation is particularly problematic, with permeation rates through glass-to-metal seals measured at approximately 10^-9 cm³/s/cm² at standard temperature and pressure. This rate accelerates exponentially with temperature increases, creating reliability concerns in variable operating environments. Oxygen and nitrogen permeation, while slower, still contribute to long-term drift in performance parameters.

Current testing methodologies for characterizing these phenomena lack standardization across the industry. Mass spectrometry and residual gas analysis techniques provide valuable data but suffer from inconsistent implementation and interpretation protocols. The absence of industry-wide standards for outgassing and permeation testing specific to CSAC applications hampers comparative analysis between different packaging solutions.

Temperature and pressure cycling effects further complicate the challenge, as materials exhibit different outgassing and permeation behaviors under varying environmental conditions. Data indicates that outgassing rates can increase by factors of 2-5 during temperature excursions from 25°C to 85°C, while pressure fluctuations create additional stress on seals and interfaces.

The miniaturization requirements of CSAC technology (typically targeting volumes below 1 cm³) severely constrain material selection and packaging architectures. Traditional hermetic packaging solutions that perform adequately in larger atomic clock systems cannot be directly scaled down without compromising hermeticity or increasing manufacturing complexity beyond practical limits.

Manufacturing consistency presents another significant challenge, with batch-to-batch variations in material properties affecting outgassing and permeation characteristics. Recent production data shows up to 30% variation in outgassing rates between material batches from the same supplier, creating quality control challenges for high-precision applications.

Current Outgassing and Permeation Measurement Solutions

01 Outgassing detection and measurement techniques

Various techniques and methods are employed to detect and measure outgassing from packaging materials used in CSAC (Chip Scale Atomic Clock) applications. These include mass spectrometry, gas chromatography, and specialized sensors that can detect trace amounts of gases released from materials. These measurement techniques are crucial for ensuring the reliability and longevity of sensitive components within sealed packages by identifying potential contaminants before they cause damage.- Outgassing measurement and detection methods: Various methods and devices are used to measure and detect outgassing from packaging materials. These include specialized sensors, gas chromatography techniques, and mass spectrometry systems that can identify and quantify gases released from materials. These detection systems are crucial for ensuring that packaging materials meet required standards for applications where outgassing could affect product integrity or performance.

- Gas permeation testing for packaging materials: Testing methods for evaluating gas permeation through packaging materials involve specialized equipment that measures the rate at which gases pass through barrier materials. These tests are essential for determining the effectiveness of packaging in protecting contents from external gases or preventing internal gases from escaping. The testing procedures often involve controlled environments and precise measurement techniques to ensure accurate permeation data.

- Advanced packaging materials with low outgassing properties: Development of advanced packaging materials focuses on reducing outgassing through specialized formulations and manufacturing processes. These materials are designed to minimize the release of volatile compounds that could contaminate sensitive components. Innovations include modified polymers, composite structures, and specially treated surfaces that maintain structural integrity while reducing gas emissions under various environmental conditions.

- Gas barrier technologies for CSAC applications: Gas barrier technologies specifically designed for Chip Scale Atomic Clock (CSAC) applications focus on preventing gas permeation that could affect the precision of atomic timekeeping components. These technologies incorporate multiple layers of barrier materials, specialized sealants, and innovative bonding techniques to create hermetic or near-hermetic packaging solutions that maintain the required internal atmosphere for optimal CSAC performance.

- Environmental conditioning and material purification: Processes for conditioning and purifying packaging materials to reduce outgassing involve specialized treatments such as vacuum baking, plasma cleaning, and chemical purification. These methods remove residual solvents, monomers, and other volatile compounds before the materials are used in sensitive applications. The conditioning processes are tailored to specific material types and end-use requirements to achieve optimal outgassing performance.

02 Gas permeation barrier materials and coatings

Advanced barrier materials and coatings are developed to minimize gas permeation in CSAC packaging. These materials include specialized polymers, metal films, and composite structures that provide effective barriers against moisture, oxygen, and other gases that could compromise the functionality of sensitive components. The barrier properties can be enhanced through various treatment methods and multi-layer structures to achieve the required hermeticity levels for long-term stability of atomic clock components.Expand Specific Solutions03 Hermetic sealing technologies for CSAC packaging

Hermetic sealing technologies are essential for CSAC packaging to prevent gas exchange between the internal cavity and external environment. These technologies include glass-to-metal seals, ceramic-to-metal seals, and advanced welding techniques that create gas-tight enclosures. The sealing methods are designed to maintain vacuum integrity or specific gas environments required for optimal operation of atomic clock components while preventing contamination from external gases.Expand Specific Solutions04 Testing methods for package hermeticity and leak detection

Specialized testing methods are employed to evaluate the hermeticity and detect leaks in CSAC packaging. These include helium leak testing, residual gas analysis, and pressure decay measurements that can identify even microscopic leaks in sealed packages. Advanced testing protocols ensure that packages meet the stringent requirements for gas impermeability necessary for maintaining the precise internal environment required for atomic clock operation.Expand Specific Solutions05 Material selection and qualification for low outgassing applications

The selection and qualification of materials for CSAC packaging focuses on identifying components with minimal outgassing properties. This involves rigorous testing of candidate materials under various temperature and vacuum conditions to measure their outgassing rates and composition of released gases. Materials that pass these qualification tests are then incorporated into packaging designs to ensure long-term stability and reliability of the sensitive atomic clock components by minimizing potential contamination sources.Expand Specific Solutions

Key Industry Players in CSAC Materials Development

The CSAC (Chip Scale Atomic Clock) packaging materials market is currently in a growth phase, with increasing demand driven by applications in telecommunications, defense, and aerospace sectors. The market is characterized by moderate competition among established players focusing on addressing outgassing and gas permeation challenges. Key competitors include Applied Materials and Robert Bosch GmbH, who leverage their semiconductor expertise, while research organizations like Fraunhofer-Gesellschaft and Commissariat à l'énergie atomique provide technological innovations. Companies such as Dai Nippon Printing and Eastman Chemical contribute specialized packaging solutions. The technology is approaching maturity in traditional applications but continues to evolve for emerging miniaturized applications, with ongoing research focused on improving hermetic sealing properties and reducing material degradation over time.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed a comprehensive materials evaluation framework specifically for CSAC packaging applications, focusing on both outgassing and gas permeation characteristics. Their approach combines multi-stage thermal vacuum outgassing tests with helium permeation analysis to identify materials suitable for long-term atomic clock stability. The organization has created a proprietary database of over 200 packaging materials with detailed outgassing profiles measured at temperatures ranging from -40°C to +125°C, covering the full operational range of military and space-grade CSACs. Their research has identified specific fluoropolymer composites that demonstrate outgassing rates below 10^-10 g/cm²/day while maintaining hermetic sealing properties with helium leak rates below 10^-9 atm·cm³/s. CEA's testing methodology includes accelerated aging protocols that simulate 10+ years of operational conditions to predict long-term material stability and outgassing behavior, essential for applications requiring decade-long CSAC performance without drift.

Strengths: Extensive materials database specifically for atomic clock applications; sophisticated aging models that accurately predict long-term outgassing behavior; strong scientific foundation with peer-reviewed methodologies. Weaknesses: Testing infrastructure requires significant investment; some proprietary materials formulations remain restricted to specific government applications and aren't commercially available.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich has pioneered advanced analytical techniques for characterizing outgassing and gas permeation in CSAC packaging materials. Their approach combines ultra-high vacuum mass spectrometry with surface analysis techniques to identify specific molecular species released during outgassing. The research center has developed a specialized testing protocol that simulates the exact environmental conditions experienced by CSACs in various applications, including space, defense, and telecommunications systems. Their materials science division has created a comprehensive database documenting the outgassing rates and permeation coefficients for over 150 candidate packaging materials, with particular focus on ceramic-to-metal seals and glass-to-metal interfaces critical for CSAC hermetic packaging. Their research has identified specific glass compositions that demonstrate outgassing rates below 10^-11 g/cm²/day while maintaining excellent thermal stability across the -55°C to +125°C military temperature range. Additionally, they've developed specialized barrier coatings that can reduce hydrogen permeation by up to three orders of magnitude compared to conventional packaging materials.

Strengths: Exceptional measurement sensitivity capable of detecting outgassing species at sub-ppb levels; comprehensive understanding of material-gas interactions at the molecular level; innovative barrier coating technologies. Weaknesses: Testing methodologies require specialized equipment not widely available in commercial settings; some advanced materials remain in experimental stages with limited production scalability.

Critical Materials Science Innovations for CSAC Packaging

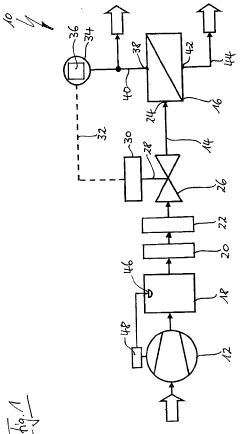

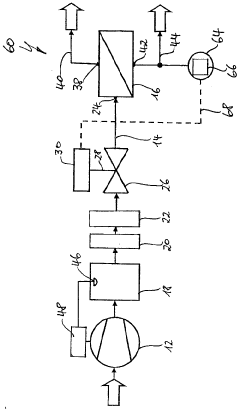

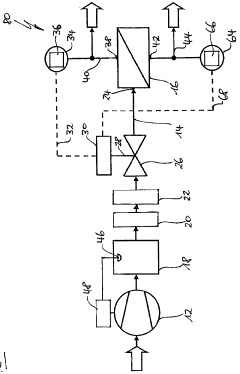

Gas-permeation system comprises a pressure source connected with membrane separation unit exhibiting first and second product gas outlet lines via mixed gas line, and sensor unit attached on product gas outlet line to detect gas parameter

PatentInactiveDE102010003507A1

Innovation

- Incorporating a buffer volume and a controllable valve in the gas permeation system, regulated by a sensor unit and control device, allows precise control of gas volume flow without the need for a variable-speed compressor, using a controllable valve and a buffer volume to stabilize input pressure.

Environmental Impact of CSAC Packaging Materials

The environmental impact of CSAC (Chip Scale Atomic Clock) packaging materials represents a critical consideration in the development and deployment of these precision timing devices. The materials used in CSAC packaging, particularly those related to outgassing and gas permeation properties, have significant environmental implications throughout their lifecycle.

Outgassing from polymers and adhesives used in CSAC packaging introduces volatile organic compounds (VOCs) into the environment during manufacturing, operation, and disposal phases. These emissions contribute to air pollution and may have adverse effects on both indoor air quality in production facilities and broader atmospheric conditions. Studies indicate that certain high-performance polymers used in hermetic sealing applications can release fluorinated compounds that persist in the environment for extended periods.

Gas permeation characteristics of packaging materials also influence environmental sustainability. Materials with poor barrier properties necessitate more frequent replacement of CSACs, increasing electronic waste generation. Conversely, highly effective barrier materials often incorporate complex multi-layer structures that combine metals, ceramics, and specialized polymers, making recycling and end-of-life management challenging.

The manufacturing processes for advanced gas barrier materials typically require energy-intensive production methods and specialized chemical treatments. These processes generate significant carbon footprints and may involve hazardous chemicals that require careful handling and disposal. For instance, the production of metallized ceramic packages with low helium permeability consumes approximately 3-5 times more energy than standard plastic packaging alternatives.

Recent environmental assessments have revealed that the rare earth elements and specialty metals used in some high-performance CSAC packaging contribute to resource depletion and mining-related environmental degradation. The extraction and processing of these materials often occurs in regions with limited environmental regulations, exacerbating ecological impacts through habitat destruction, water pollution, and soil contamination.

Regulatory frameworks increasingly address these environmental concerns, with standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) imposing limitations on certain materials used in electronic packaging. These regulations have spurred research into environmentally friendly alternatives that maintain the necessary outgassing and permeation properties while reducing ecological footprints.

Emerging sustainable approaches include bio-based polymers with enhanced gas barrier properties, recyclable composite materials, and design-for-disassembly strategies that facilitate material recovery at end-of-life. These innovations aim to balance the stringent technical requirements of CSAC packaging with growing environmental imperatives, though significant challenges remain in achieving performance parity with conventional materials.

Outgassing from polymers and adhesives used in CSAC packaging introduces volatile organic compounds (VOCs) into the environment during manufacturing, operation, and disposal phases. These emissions contribute to air pollution and may have adverse effects on both indoor air quality in production facilities and broader atmospheric conditions. Studies indicate that certain high-performance polymers used in hermetic sealing applications can release fluorinated compounds that persist in the environment for extended periods.

Gas permeation characteristics of packaging materials also influence environmental sustainability. Materials with poor barrier properties necessitate more frequent replacement of CSACs, increasing electronic waste generation. Conversely, highly effective barrier materials often incorporate complex multi-layer structures that combine metals, ceramics, and specialized polymers, making recycling and end-of-life management challenging.

The manufacturing processes for advanced gas barrier materials typically require energy-intensive production methods and specialized chemical treatments. These processes generate significant carbon footprints and may involve hazardous chemicals that require careful handling and disposal. For instance, the production of metallized ceramic packages with low helium permeability consumes approximately 3-5 times more energy than standard plastic packaging alternatives.

Recent environmental assessments have revealed that the rare earth elements and specialty metals used in some high-performance CSAC packaging contribute to resource depletion and mining-related environmental degradation. The extraction and processing of these materials often occurs in regions with limited environmental regulations, exacerbating ecological impacts through habitat destruction, water pollution, and soil contamination.

Regulatory frameworks increasingly address these environmental concerns, with standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) imposing limitations on certain materials used in electronic packaging. These regulations have spurred research into environmentally friendly alternatives that maintain the necessary outgassing and permeation properties while reducing ecological footprints.

Emerging sustainable approaches include bio-based polymers with enhanced gas barrier properties, recyclable composite materials, and design-for-disassembly strategies that facilitate material recovery at end-of-life. These innovations aim to balance the stringent technical requirements of CSAC packaging with growing environmental imperatives, though significant challenges remain in achieving performance parity with conventional materials.

Reliability Testing Standards for CSAC Packaging Systems

Reliability testing standards for CSAC (Chip-Scale Atomic Clock) packaging systems have evolved significantly to address the unique challenges posed by these miniaturized atomic timekeeping devices. These standards focus primarily on ensuring the long-term stability and performance of CSACs by controlling outgassing and gas permeation effects that can compromise clock accuracy and operational lifetime.

The most widely adopted standards include MIL-STD-883 Method 1018 for internal gas analysis, which has been specifically adapted for the ultra-small internal volumes of CSAC packages. This standard prescribes precise methodologies for measuring trace gases within hermetically sealed packages, with particular emphasis on detecting helium, hydrogen, and hydrocarbon contaminants that can affect the physics package performance.

ASTM F1269 for helium fine leak testing has been modified to accommodate the extremely low leak rate requirements of CSACs, typically requiring detection capabilities in the 10^-12 atm-cc/sec range. This represents a significant advancement over conventional electronic package testing, reflecting the critical nature of maintaining gas composition within CSAC cells.

For outgassing characterization, ASTM E595 provides the framework for measuring Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) from packaging materials. CSAC-specific implementations of this standard typically require TML values below 0.5% and CVCM below 0.05%, substantially more stringent than requirements for conventional electronics.

Gas permeation testing follows modified versions of ASTM D1434, with particular attention to helium permeation rates through polymer-based seals and adhesives. The test conditions have been adapted to reflect the operational temperature range of CSACs (-40°C to +85°C) rather than standard ambient conditions.

Accelerated aging protocols combine elements from MIL-STD-883 Method 1008 (High Temperature Storage) and JEDEC JESD22-A101, but with extended durations to account for the expected 10+ year operational lifetime of CSACs. These tests typically incorporate periodic performance verification of frequency stability to correlate material degradation with functional impacts.

Industry consortia including SEMI and JEDEC have established working groups specifically focused on developing next-generation standards for quantum timing devices, with particular emphasis on standardizing outgassing and permeation test methodologies for the unique requirements of alkali metal vapor cells used in CSACs.

The most widely adopted standards include MIL-STD-883 Method 1018 for internal gas analysis, which has been specifically adapted for the ultra-small internal volumes of CSAC packages. This standard prescribes precise methodologies for measuring trace gases within hermetically sealed packages, with particular emphasis on detecting helium, hydrogen, and hydrocarbon contaminants that can affect the physics package performance.

ASTM F1269 for helium fine leak testing has been modified to accommodate the extremely low leak rate requirements of CSACs, typically requiring detection capabilities in the 10^-12 atm-cc/sec range. This represents a significant advancement over conventional electronic package testing, reflecting the critical nature of maintaining gas composition within CSAC cells.

For outgassing characterization, ASTM E595 provides the framework for measuring Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) from packaging materials. CSAC-specific implementations of this standard typically require TML values below 0.5% and CVCM below 0.05%, substantially more stringent than requirements for conventional electronics.

Gas permeation testing follows modified versions of ASTM D1434, with particular attention to helium permeation rates through polymer-based seals and adhesives. The test conditions have been adapted to reflect the operational temperature range of CSACs (-40°C to +85°C) rather than standard ambient conditions.

Accelerated aging protocols combine elements from MIL-STD-883 Method 1008 (High Temperature Storage) and JEDEC JESD22-A101, but with extended durations to account for the expected 10+ year operational lifetime of CSACs. These tests typically incorporate periodic performance verification of frequency stability to correlate material degradation with functional impacts.

Industry consortia including SEMI and JEDEC have established working groups specifically focused on developing next-generation standards for quantum timing devices, with particular emphasis on standardizing outgassing and permeation test methodologies for the unique requirements of alkali metal vapor cells used in CSACs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!