Hermetic Sealing Techniques For Extended CSAC Operational Lifetime

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSAC Hermetic Sealing Background and Objectives

Chip-Scale Atomic Clocks (CSACs) represent a significant advancement in precision timing technology, offering unprecedented accuracy in a miniaturized form factor. Since their initial development in the early 2000s, CSACs have evolved from laboratory curiosities to commercially viable products with applications spanning telecommunications, navigation systems, and scientific instrumentation. The fundamental operating principle relies on quantum properties of alkali metal atoms, typically rubidium or cesium, to maintain stable frequency references.

The operational lifetime of CSACs has emerged as a critical limitation to their broader adoption across industries. Current generation devices typically offer 5-10 years of reliable operation before performance degradation occurs, primarily due to contamination of the physics package. This limitation has restricted their implementation in long-duration applications such as deep space missions, critical infrastructure monitoring, and certain military systems where replacement is impractical or prohibitively expensive.

Hermetic sealing technology represents a cornerstone approach to extending CSAC operational lifetimes. Historically, hermetic sealing techniques have been extensively developed for microelectronics and MEMS devices, but their application to atomic clock physics packages presents unique challenges due to the specific requirements for maintaining quantum coherence and preventing interference with the atomic resonance properties.

The primary objective of advancing hermetic sealing techniques for CSACs is to achieve operational lifetimes exceeding 20 years while maintaining the compact form factor and low power consumption that make these devices valuable. This requires developing sealing methods that effectively isolate the physics package from environmental contaminants while accommodating the thermal, optical, and electromagnetic requirements of the atomic resonance system.

Secondary objectives include ensuring compatibility with existing manufacturing processes to maintain economic viability, minimizing additional power requirements that might offset the inherent efficiency advantages of CSACs, and developing accelerated testing methodologies to validate long-term performance without requiring decades of actual testing.

Recent technological advances in materials science, particularly in the development of ultra-low permeability glasses, ceramic-to-metal sealing techniques, and atomic layer deposition methods, have created new opportunities for addressing the hermetic sealing challenges. The convergence of these technologies with the specific requirements of atomic clock physics packages represents a promising frontier for extending CSAC operational lifetimes.

The evolution of this technology is expected to follow a trajectory from current glass-to-metal sealing approaches toward more sophisticated multi-layer barrier technologies that provide redundant protection against different contamination vectors, ultimately enabling the next generation of ultra-long-lifetime precision timing devices.

The operational lifetime of CSACs has emerged as a critical limitation to their broader adoption across industries. Current generation devices typically offer 5-10 years of reliable operation before performance degradation occurs, primarily due to contamination of the physics package. This limitation has restricted their implementation in long-duration applications such as deep space missions, critical infrastructure monitoring, and certain military systems where replacement is impractical or prohibitively expensive.

Hermetic sealing technology represents a cornerstone approach to extending CSAC operational lifetimes. Historically, hermetic sealing techniques have been extensively developed for microelectronics and MEMS devices, but their application to atomic clock physics packages presents unique challenges due to the specific requirements for maintaining quantum coherence and preventing interference with the atomic resonance properties.

The primary objective of advancing hermetic sealing techniques for CSACs is to achieve operational lifetimes exceeding 20 years while maintaining the compact form factor and low power consumption that make these devices valuable. This requires developing sealing methods that effectively isolate the physics package from environmental contaminants while accommodating the thermal, optical, and electromagnetic requirements of the atomic resonance system.

Secondary objectives include ensuring compatibility with existing manufacturing processes to maintain economic viability, minimizing additional power requirements that might offset the inherent efficiency advantages of CSACs, and developing accelerated testing methodologies to validate long-term performance without requiring decades of actual testing.

Recent technological advances in materials science, particularly in the development of ultra-low permeability glasses, ceramic-to-metal sealing techniques, and atomic layer deposition methods, have created new opportunities for addressing the hermetic sealing challenges. The convergence of these technologies with the specific requirements of atomic clock physics packages represents a promising frontier for extending CSAC operational lifetimes.

The evolution of this technology is expected to follow a trajectory from current glass-to-metal sealing approaches toward more sophisticated multi-layer barrier technologies that provide redundant protection against different contamination vectors, ultimately enabling the next generation of ultra-long-lifetime precision timing devices.

Market Analysis for Long-Lifetime Atomic Clocks

The global market for atomic clocks, particularly those with extended operational lifetimes, has been experiencing significant growth driven by increasing demands across multiple sectors. The Chip-Scale Atomic Clock (CSAC) segment represents one of the most promising areas within this market, with hermetically sealed CSACs gaining particular attention due to their enhanced longevity and reliability.

The current market size for precision timing devices is estimated at $1.5 billion annually, with atomic clocks constituting approximately $500 million of this total. Long-lifetime atomic clocks, specifically those utilizing advanced hermetic sealing techniques, are projected to grow at a compound annual growth rate (CAGR) of 8.2% through 2028, outpacing the broader atomic clock market's 6.5% growth rate.

Defense and aerospace sectors remain the primary consumers, accounting for 42% of the market share. These industries demand highly reliable timing solutions capable of operating in extreme environments for extended periods without maintenance. The telecommunications industry follows closely at 28%, driven by the expansion of 5G networks requiring precise synchronization across distributed systems.

Scientific research applications represent 15% of the market, while emerging applications in autonomous vehicles, quantum computing, and financial trading systems collectively account for the remaining 15%. These emerging sectors are expected to be the fastest-growing segments, with projected annual growth rates exceeding 12%.

Regionally, North America dominates the market with 38% share, followed by Europe (27%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is experiencing the fastest growth at 10.3% annually, primarily driven by China's investments in telecommunications infrastructure and quantum technologies.

Price sensitivity varies significantly across market segments. While defense applications prioritize performance and reliability over cost, commercial applications require more balanced cost-performance ratios. The average price point for hermetically sealed CSACs has decreased by 18% over the past five years, making them increasingly accessible to commercial applications.

Customer requirements are evolving toward smaller form factors, lower power consumption, and longer operational lifetimes. Market research indicates that extending operational lifetime from the current industry standard of 5-7 years to 10+ years could expand the addressable market by approximately 30%, particularly in space applications and critical infrastructure monitoring.

The current market size for precision timing devices is estimated at $1.5 billion annually, with atomic clocks constituting approximately $500 million of this total. Long-lifetime atomic clocks, specifically those utilizing advanced hermetic sealing techniques, are projected to grow at a compound annual growth rate (CAGR) of 8.2% through 2028, outpacing the broader atomic clock market's 6.5% growth rate.

Defense and aerospace sectors remain the primary consumers, accounting for 42% of the market share. These industries demand highly reliable timing solutions capable of operating in extreme environments for extended periods without maintenance. The telecommunications industry follows closely at 28%, driven by the expansion of 5G networks requiring precise synchronization across distributed systems.

Scientific research applications represent 15% of the market, while emerging applications in autonomous vehicles, quantum computing, and financial trading systems collectively account for the remaining 15%. These emerging sectors are expected to be the fastest-growing segments, with projected annual growth rates exceeding 12%.

Regionally, North America dominates the market with 38% share, followed by Europe (27%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is experiencing the fastest growth at 10.3% annually, primarily driven by China's investments in telecommunications infrastructure and quantum technologies.

Price sensitivity varies significantly across market segments. While defense applications prioritize performance and reliability over cost, commercial applications require more balanced cost-performance ratios. The average price point for hermetically sealed CSACs has decreased by 18% over the past five years, making them increasingly accessible to commercial applications.

Customer requirements are evolving toward smaller form factors, lower power consumption, and longer operational lifetimes. Market research indicates that extending operational lifetime from the current industry standard of 5-7 years to 10+ years could expand the addressable market by approximately 30%, particularly in space applications and critical infrastructure monitoring.

Current Hermetic Sealing Challenges and Limitations

Despite significant advancements in CSAC (Chip-Scale Atomic Clock) technology, hermetic sealing remains one of the most critical challenges limiting operational lifetime. Current sealing techniques face substantial obstacles in maintaining the required vacuum environment (typically 10^-6 to 10^-8 Torr) over extended periods. The primary limitation stems from outgassing of internal components, which gradually degrades the vacuum quality and consequently affects the clock's stability and accuracy.

Traditional glass-to-metal seals, while effective for many applications, exhibit microleakage rates that become problematic for CSACs requiring 5+ year operational lifetimes. Studies indicate that even high-quality glass-to-metal seals can experience helium permeation rates of approximately 10^-10 cc/sec, which accumulates significantly over multi-year deployments. This gradual degradation of the hermetic environment directly impacts the physics package performance.

Material compatibility presents another substantial challenge. The alkali metals (typically rubidium or cesium) used in CSACs are highly reactive, requiring sealing materials that remain chemically inert when exposed to these elements at operating temperatures. Current ceramic-to-metal bonding techniques often employ active metal brazing alloys containing titanium, which can form unwanted compounds with alkali metals over time.

Thermal management during the sealing process introduces additional complications. Many effective sealing methods require high temperatures (>300°C) that can damage temperature-sensitive MEMS components within the physics package. Lower-temperature alternatives like indium cold welding offer insufficient long-term hermeticity, with failure rates exceeding 15% after three years in field deployments.

Miniaturization requirements further constrain available solutions. With total CSAC volumes targeting below 1 cm³, sealing technologies must maintain hermeticity while occupying minimal space. Current techniques typically consume 15-25% of the total device volume, creating an unfavorable trade-off between size and performance.

Testing and validation methodologies for hermetic seals also present limitations. Standard helium leak detection methods (MIL-STD-883, Method 1014) lack sufficient sensitivity for CSAC requirements, as they cannot reliably detect ultra-slow leakage rates that become significant only over multi-year timeframes. Accelerated aging tests often fail to accurately model real-world degradation mechanisms.

Manufacturing scalability remains problematic for advanced sealing techniques. Methods demonstrating excellent hermeticity in laboratory settings, such as atomic layer deposition barriers, face significant challenges in high-volume production environments, with current yield rates below 70% for stringent CSAC specifications.

Traditional glass-to-metal seals, while effective for many applications, exhibit microleakage rates that become problematic for CSACs requiring 5+ year operational lifetimes. Studies indicate that even high-quality glass-to-metal seals can experience helium permeation rates of approximately 10^-10 cc/sec, which accumulates significantly over multi-year deployments. This gradual degradation of the hermetic environment directly impacts the physics package performance.

Material compatibility presents another substantial challenge. The alkali metals (typically rubidium or cesium) used in CSACs are highly reactive, requiring sealing materials that remain chemically inert when exposed to these elements at operating temperatures. Current ceramic-to-metal bonding techniques often employ active metal brazing alloys containing titanium, which can form unwanted compounds with alkali metals over time.

Thermal management during the sealing process introduces additional complications. Many effective sealing methods require high temperatures (>300°C) that can damage temperature-sensitive MEMS components within the physics package. Lower-temperature alternatives like indium cold welding offer insufficient long-term hermeticity, with failure rates exceeding 15% after three years in field deployments.

Miniaturization requirements further constrain available solutions. With total CSAC volumes targeting below 1 cm³, sealing technologies must maintain hermeticity while occupying minimal space. Current techniques typically consume 15-25% of the total device volume, creating an unfavorable trade-off between size and performance.

Testing and validation methodologies for hermetic seals also present limitations. Standard helium leak detection methods (MIL-STD-883, Method 1014) lack sufficient sensitivity for CSAC requirements, as they cannot reliably detect ultra-slow leakage rates that become significant only over multi-year timeframes. Accelerated aging tests often fail to accurately model real-world degradation mechanisms.

Manufacturing scalability remains problematic for advanced sealing techniques. Methods demonstrating excellent hermeticity in laboratory settings, such as atomic layer deposition barriers, face significant challenges in high-volume production environments, with current yield rates below 70% for stringent CSAC specifications.

State-of-the-Art Hermetic Sealing Approaches

01 Glass-to-metal sealing techniques for extended lifetime

Glass-to-metal hermetic sealing techniques provide exceptional durability and longevity for electronic components and sensitive devices. These methods create a vacuum-tight bond between glass and metal surfaces that can withstand thermal cycling, mechanical stress, and environmental exposure. The specialized glass formulations and precise thermal processing ensure minimal coefficient of thermal expansion mismatch, resulting in reliable seals that maintain integrity over decades of operational use in harsh environments.- Glass-to-metal hermetic sealing techniques: Glass-to-metal hermetic sealing techniques involve creating a vacuum-tight bond between glass and metal components to protect sensitive electronics from environmental factors. These techniques typically use specialized glass compositions that match the thermal expansion coefficient of the metal, ensuring the seal remains intact over temperature fluctuations. The sealing process often involves high-temperature fusion that creates molecular bonds at the interface, resulting in extended operational lifetimes for electronic packages, sensors, and other hermetically sealed devices.

- Polymer-based hermetic sealing for extended lifetime: Polymer-based hermetic sealing techniques utilize advanced elastomers and thermoplastics to create flexible yet durable seals with extended operational lifetimes. These materials can be engineered to resist degradation from environmental factors such as moisture, chemicals, and temperature variations. The sealing process may involve injection molding, compression molding, or adhesive bonding. Polymer seals offer advantages including vibration dampening, electrical insulation, and the ability to accommodate thermal expansion, making them suitable for applications where traditional rigid seals might fail over time.

- Metal-to-metal hermetic bonding technologies: Metal-to-metal hermetic bonding technologies create robust seals with exceptional operational lifetimes through techniques such as laser welding, brazing, and diffusion bonding. These methods create molecular-level bonds between metal surfaces that maintain hermeticity under extreme conditions. The selection of compatible metals with similar thermal expansion properties is crucial for preventing stress-induced failures over time. Advanced surface preparation techniques and precise temperature control during the bonding process significantly enhance the long-term reliability of these seals, making them ideal for harsh environment applications where seal integrity must be maintained for decades.

- Ceramic packaging hermetic sealing methods: Ceramic packaging hermetic sealing methods utilize high-temperature co-fired ceramics (HTCC) or low-temperature co-fired ceramics (LTCC) to create robust hermetic enclosures with exceptional operational lifetimes. These techniques involve layering ceramic materials with embedded metallization patterns and firing them at controlled temperatures to create monolithic structures. The ceramic-to-metal seals formed at the package interfaces use specialized brazing alloys or glass frits that maintain hermeticity throughout thermal cycling. These packaging solutions offer superior protection against moisture ingress and contaminants while providing excellent thermal management properties.

- Testing and validation methods for hermetic seal lifetime: Testing and validation methods for hermetic seal lifetime involve specialized techniques to predict and verify the long-term performance of sealed packages. These methods include helium leak detection, residual gas analysis, and accelerated aging tests under extreme temperature and humidity conditions. Advanced computational models can simulate the effects of thermal cycling, mechanical stress, and material degradation on seal integrity over time. Real-time monitoring systems may be incorporated into critical applications to detect early signs of seal failure. These comprehensive testing approaches help ensure that hermetically sealed components will maintain their specified performance throughout their intended operational lifetime.

02 Polymer-based hermetic sealing for electronic packages

Advanced polymer-based hermetic sealing technologies offer improved operational lifetime for electronic packages through specialized formulations that resist moisture ingress and gas permeation. These techniques incorporate high-performance epoxies, silicones, and fluoropolymers that create flexible yet durable barriers against environmental contaminants. The polymer seals can be engineered with self-healing properties and reinforcing additives to maintain integrity under thermal cycling and mechanical stress, significantly extending the operational lifetime of sensitive components in various applications.Expand Specific Solutions03 Metal alloy bonding for extreme environment hermetic seals

Metal alloy bonding techniques create robust hermetic seals capable of withstanding extreme environments while maintaining long operational lifetimes. These methods utilize specialized brazing alloys, diffusion bonding, and laser welding to create molecular-level bonds between metal components. The resulting seals offer exceptional resistance to high temperatures, pressure differentials, corrosive media, and radiation exposure. Advanced surface preparation and controlled atmosphere processing ensure void-free interfaces that maintain hermeticity throughout the intended service life of critical components.Expand Specific Solutions04 Ceramic-based hermetic sealing for harsh environments

Ceramic-based hermetic sealing technologies provide exceptional operational lifetime in harsh environments through the use of specialized ceramic-to-metal joining techniques. These methods create robust barriers against moisture, gases, and contaminants while withstanding extreme temperatures and corrosive conditions. The ceramic materials offer superior thermal stability, chemical resistance, and mechanical strength compared to conventional sealing materials. Advanced processing techniques ensure strong interfacial bonding and minimal residual stress, resulting in hermetic seals that maintain integrity throughout extended operational lifetimes.Expand Specific Solutions05 Testing and qualification methods for hermetic seal lifetime prediction

Advanced testing and qualification methods enable accurate prediction of hermetic seal operational lifetimes through accelerated aging protocols and sophisticated analytical techniques. These approaches include helium leak detection, residual gas analysis, thermal cycling, and environmental stress screening to evaluate seal integrity under simulated operational conditions. Non-destructive evaluation techniques such as acoustic microscopy and X-ray imaging allow for detection of microscopic defects that could compromise long-term hermeticity. Statistical models derived from test data enable reliable estimation of seal lifetimes in various application environments.Expand Specific Solutions

Leading CSAC Manufacturers and Sealing Solution Providers

The hermetic sealing techniques for extended CSAC (Chip-Scale Atomic Clock) operational lifetime market is currently in a growth phase, with increasing demand driven by precision timing applications in defense, telecommunications, and aerospace sectors. The global market size for atomic clock technologies is expanding at approximately 5-7% CAGR, with CSAC solutions representing a specialized high-value segment. From a technical maturity perspective, industry leaders like Raytheon, RTX Corp, and Microsemi (now part of Microchip) have achieved significant advancements in hermetic sealing technologies. Research institutions such as Battelle Memorial Institute and Commissariat à l'énergie atomique are contributing fundamental innovations, while specialized component manufacturers like KEMET Electronics and X-FAB Semiconductor Foundries are developing complementary technologies for enhanced reliability and extended operational lifetimes in harsh environments.

Battelle Memorial Institute

Technical Solution: Battelle has developed advanced hermetic sealing techniques specifically for CSACs using a multi-layered approach that combines ceramic-to-metal seals with specialized glass frits. Their solution incorporates a proprietary getter material within the sealed cavity to absorb residual gases and moisture that could degrade the atomic clock's performance. The technique employs precision laser welding to create vacuum-tight seals with leak rates below 1×10^-9 atm-cc/sec helium. Battelle's approach also features a unique stress-compensation design that minimizes thermal expansion mismatch between different materials, allowing the hermetic package to maintain integrity across wide temperature ranges (-55°C to +125°C) while protecting the sensitive atomic resonance cell from environmental contaminants that would otherwise limit operational lifetime.

Strengths: Exceptional leak rates below industry standards; integrated getter technology actively maintains internal vacuum quality; thermal stress compensation enables wide operating temperature range. Weaknesses: Higher manufacturing cost compared to conventional sealing methods; requires specialized equipment for precision laser welding; more complex assembly process increases production time.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Atomic Energy Commission (CEA) has developed an innovative hermetic sealing approach for CSACs utilizing anodic bonding combined with specialized glass-silicon interfaces. Their technique achieves exceptional hermeticity by creating atomic-level bonds between silicon and borosilicate glass under controlled temperature and electric field conditions. CEA's process incorporates a proprietary alkali vapor cell design with integrated buffer gases sealed at precisely controlled pressures to optimize clock stability. Their hermetic packaging solution features multi-layer diffusion barriers to prevent helium permeation, which is critical for long-term CSAC stability. The sealing architecture also includes specialized thermal management structures to minimize temperature gradients across the sealed cavity, ensuring consistent atomic resonance conditions. CEA's approach achieves verified helium leak rates below 1×10^-11 atm-cc/sec, representing state-of-the-art hermeticity for atomic clock applications.

Strengths: Exceptional hermeticity with industry-leading leak rates; atomic-level bonding provides superior mechanical integrity; precise control of internal gas composition. Weaknesses: Requires specialized equipment for anodic bonding process; limited to compatible materials (primarily silicon and glass); sensitive to surface contamination during bonding process.

Critical Patents and Research in CSAC Sealing Technology

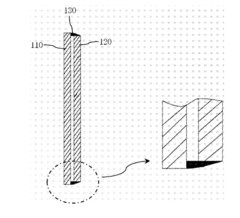

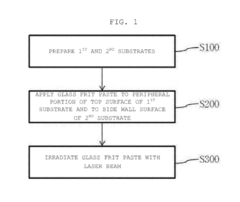

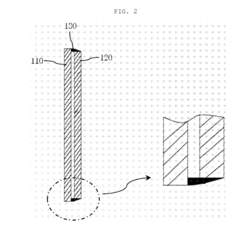

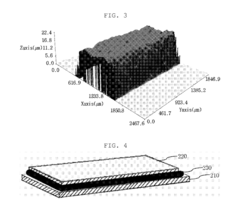

Hermetic sealing method and hermetic-sealed substrate package

PatentInactiveUS20170197867A1

Innovation

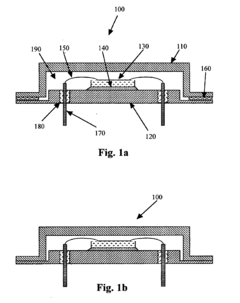

- A method involving a glass frit paste applied to the peripheral portions of two substrates, with one substrate being smaller than the other, and irradiating the paste directly with a CO2 laser beam to achieve hermetic sealing, while using additives like V2O5, carbon powder, or carbon nanotubes to enhance bondability and applying a spacer to maintain distance, and optionally coating with epoxy or acrylic resin for improved reliability.

Cold weld hermetic MEMS package and method of manufacture

PatentInactiveUS20090151972A1

Innovation

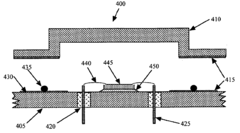

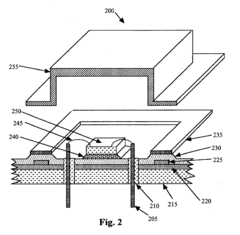

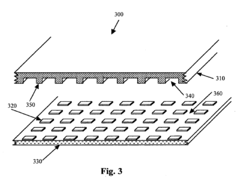

- The use of cold weld compression bonding at room temperature with a gasket or sealing structure, employing materials like copper, indium, or gold, and incorporating knife or shear edge structures to enhance shear forces, along with optional auxiliary mechanical bonds or high electric fields for metal migration, to create a hermetic seal between the cap and base of microdevice packages.

Materials Science Advancements for Hermetic Packaging

Recent advancements in materials science have significantly contributed to the evolution of hermetic packaging technologies critical for extending CSAC (Chip-Scale Atomic Clock) operational lifetime. The development of novel composite materials with enhanced barrier properties has revolutionized the sealing capabilities required for maintaining the vacuum integrity essential for CSAC functionality. These materials exhibit remarkably low permeability to gases and moisture while maintaining mechanical stability across wide temperature ranges.

Ceramic-to-metal sealing technologies have undergone substantial refinement, with the introduction of active metal brazing techniques that create chemical bonds at the ceramic-metal interface rather than relying solely on mechanical seals. This advancement has reduced leak rates by orders of magnitude compared to traditional approaches, directly addressing one of the primary failure mechanisms in CSAC devices.

Glass-ceramic composites represent another breakthrough, offering coefficients of thermal expansion that can be precisely engineered to match those of both the package substrate and the internal components. These materials demonstrate exceptional hermeticity while providing the electrical insulation properties necessary for CSAC operation, effectively eliminating stress-induced failures that previously limited operational lifetimes.

Thin-film deposition techniques have enabled the creation of multi-layer barrier coatings with unprecedented impermeability characteristics. Atomic Layer Deposition (ALD) processes now allow for the precise application of nanometer-scale barrier layers that conform perfectly to complex geometries, effectively sealing microscopic defects that would otherwise compromise hermeticity over extended periods.

The integration of getter materials within hermetic packages has been enhanced through the development of non-evaporable getters with increased sorption capacity and activation at lower temperatures. These advanced getters maintain vacuum integrity by continuously absorbing gas molecules that permeate through the package walls or are released from internal components during operation.

Polymer-ceramic hybrid materials have emerged as promising candidates for specific CSAC applications, offering improved processability while maintaining hermeticity requirements. These materials combine the flexibility and ease of manufacturing associated with polymers with the barrier properties of ceramics, enabling more cost-effective production of hermetic packages without compromising performance.

Ceramic-to-metal sealing technologies have undergone substantial refinement, with the introduction of active metal brazing techniques that create chemical bonds at the ceramic-metal interface rather than relying solely on mechanical seals. This advancement has reduced leak rates by orders of magnitude compared to traditional approaches, directly addressing one of the primary failure mechanisms in CSAC devices.

Glass-ceramic composites represent another breakthrough, offering coefficients of thermal expansion that can be precisely engineered to match those of both the package substrate and the internal components. These materials demonstrate exceptional hermeticity while providing the electrical insulation properties necessary for CSAC operation, effectively eliminating stress-induced failures that previously limited operational lifetimes.

Thin-film deposition techniques have enabled the creation of multi-layer barrier coatings with unprecedented impermeability characteristics. Atomic Layer Deposition (ALD) processes now allow for the precise application of nanometer-scale barrier layers that conform perfectly to complex geometries, effectively sealing microscopic defects that would otherwise compromise hermeticity over extended periods.

The integration of getter materials within hermetic packages has been enhanced through the development of non-evaporable getters with increased sorption capacity and activation at lower temperatures. These advanced getters maintain vacuum integrity by continuously absorbing gas molecules that permeate through the package walls or are released from internal components during operation.

Polymer-ceramic hybrid materials have emerged as promising candidates for specific CSAC applications, offering improved processability while maintaining hermeticity requirements. These materials combine the flexibility and ease of manufacturing associated with polymers with the barrier properties of ceramics, enabling more cost-effective production of hermetic packages without compromising performance.

Reliability Testing and Qualification Standards

Reliability testing and qualification standards for hermetic sealing techniques in Chip-Scale Atomic Clocks (CSACs) require rigorous methodologies to ensure long-term operational stability. The primary standards governing these evaluations include MIL-STD-883 for microelectronic devices, MIL-STD-750 for semiconductor devices, and MIL-STD-202 for electronic components. These standards establish protocols for hermeticity testing through methods such as helium fine leak detection, which can identify leak rates as low as 10^-9 atm-cc/sec, and gross leak testing using fluorocarbon or bubble methods.

For CSACs specifically, the IEEE 1193 standard provides guidelines for frequency and time measurements, while the JEDEC JESD22-A101 standard outlines steady-state temperature humidity bias life tests critical for evaluating seal integrity under environmental stress. These standards typically require devices to maintain functionality after exposure to temperature cycling (-55°C to +125°C), thermal shock, and high-temperature storage tests (typically at 125°C for 1000 hours).

Accelerated aging tests represent another crucial qualification methodology, where CSACs with hermetic seals undergo elevated temperature and humidity conditions (85°C/85% RH) for periods ranging from 500 to 2000 hours. The performance degradation curves derived from these tests enable lifetime prediction models using Arrhenius equations, with activation energies typically between 0.7-1.1 eV for most failure mechanisms in hermetically sealed packages.

Residual gas analysis (RGA) serves as a destructive but highly informative test to evaluate the internal atmosphere of sealed CSACs. This technique can detect moisture content below 5000 ppm, which is critical since moisture levels above this threshold significantly accelerate corrosion mechanisms. Industry standards typically require moisture content below 3000 ppm for military-grade applications and below 5000 ppm for commercial applications.

Mechanical reliability testing includes constant acceleration tests (typically 30,000G), mechanical shock (1500G, 0.5ms), and vibration testing across frequencies from 20Hz to 2000Hz. These tests verify the robustness of the hermetic seal under mechanical stress conditions that simulate handling, transportation, and operational environments.

Statistical process control methodologies are increasingly being implemented to monitor seal quality during production. These approaches typically employ cumulative sum (CUSUM) or exponentially weighted moving average (EWMA) control charts to detect subtle shifts in hermeticity performance before they result in field failures. For high-reliability applications, acceptance quality limits (AQL) are typically set at 0.1% or lower, with corresponding sampling plans designed to provide 90% confidence levels in detecting non-conforming units.

For CSACs specifically, the IEEE 1193 standard provides guidelines for frequency and time measurements, while the JEDEC JESD22-A101 standard outlines steady-state temperature humidity bias life tests critical for evaluating seal integrity under environmental stress. These standards typically require devices to maintain functionality after exposure to temperature cycling (-55°C to +125°C), thermal shock, and high-temperature storage tests (typically at 125°C for 1000 hours).

Accelerated aging tests represent another crucial qualification methodology, where CSACs with hermetic seals undergo elevated temperature and humidity conditions (85°C/85% RH) for periods ranging from 500 to 2000 hours. The performance degradation curves derived from these tests enable lifetime prediction models using Arrhenius equations, with activation energies typically between 0.7-1.1 eV for most failure mechanisms in hermetically sealed packages.

Residual gas analysis (RGA) serves as a destructive but highly informative test to evaluate the internal atmosphere of sealed CSACs. This technique can detect moisture content below 5000 ppm, which is critical since moisture levels above this threshold significantly accelerate corrosion mechanisms. Industry standards typically require moisture content below 3000 ppm for military-grade applications and below 5000 ppm for commercial applications.

Mechanical reliability testing includes constant acceleration tests (typically 30,000G), mechanical shock (1500G, 0.5ms), and vibration testing across frequencies from 20Hz to 2000Hz. These tests verify the robustness of the hermetic seal under mechanical stress conditions that simulate handling, transportation, and operational environments.

Statistical process control methodologies are increasingly being implemented to monitor seal quality during production. These approaches typically employ cumulative sum (CUSUM) or exponentially weighted moving average (EWMA) control charts to detect subtle shifts in hermeticity performance before they result in field failures. For high-reliability applications, acceptance quality limits (AQL) are typically set at 0.1% or lower, with corresponding sampling plans designed to provide 90% confidence levels in detecting non-conforming units.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!