Magnetic Shielding Designs For Compact Atomic Clock Modules

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Atomic Clock Magnetic Shielding Background and Objectives

Atomic clocks represent one of the most precise timekeeping technologies developed by humanity, with applications spanning from global navigation satellite systems to fundamental physics research. The evolution of magnetic shielding for atomic clocks traces back to the mid-20th century when the first atomic frequency standards were developed. Initially, these devices were large laboratory instruments where space constraints were not a primary concern. However, as applications expanded into aerospace, telecommunications, and portable systems, the need for compact yet highly effective magnetic shielding became paramount.

The technological trajectory has been marked by continuous refinement of shielding materials and designs, moving from simple ferromagnetic enclosures to sophisticated multi-layer configurations incorporating advanced materials like mu-metal, permalloy, and metglas. This progression has been driven by the fundamental requirement that atomic clocks operate in environments with minimal magnetic field interference, as external fields can significantly perturb the quantum states used for timekeeping, degrading clock performance.

Current technological objectives in magnetic shielding for compact atomic clock modules focus on several critical parameters. First, achieving shielding factors exceeding 10^4 to 10^5 while maintaining minimal volume and mass represents a primary goal. Second, designs must address the challenge of access ports for optical, electrical, and vacuum connections without compromising shielding integrity. Third, thermal management considerations have become increasingly important as compact designs create heat dissipation challenges that can affect both shielding properties and clock stability.

The miniaturization trend in atomic clock technology has accelerated in recent years, with chip-scale atomic clocks (CSACs) and cold-atom microsystems pushing the boundaries of what's possible. This miniaturization creates unique challenges for magnetic shielding, as traditional approaches often do not scale down efficiently. The physics of magnetic shielding dictates that effectiveness typically decreases with reduced dimensions, creating a fundamental tension between size and performance.

Looking forward, the technical objectives for next-generation magnetic shielding include developing novel geometries that maximize shielding efficiency per unit volume, integrating active compensation systems with passive shielding for enhanced performance, and exploring new materials and fabrication techniques that enable three-dimensional shielding structures optimized for specific atomic clock architectures. Additionally, there is growing interest in adaptive shielding solutions that can respond to changing environmental conditions, particularly for mobile applications where the ambient magnetic field environment may vary significantly.

The technological trajectory has been marked by continuous refinement of shielding materials and designs, moving from simple ferromagnetic enclosures to sophisticated multi-layer configurations incorporating advanced materials like mu-metal, permalloy, and metglas. This progression has been driven by the fundamental requirement that atomic clocks operate in environments with minimal magnetic field interference, as external fields can significantly perturb the quantum states used for timekeeping, degrading clock performance.

Current technological objectives in magnetic shielding for compact atomic clock modules focus on several critical parameters. First, achieving shielding factors exceeding 10^4 to 10^5 while maintaining minimal volume and mass represents a primary goal. Second, designs must address the challenge of access ports for optical, electrical, and vacuum connections without compromising shielding integrity. Third, thermal management considerations have become increasingly important as compact designs create heat dissipation challenges that can affect both shielding properties and clock stability.

The miniaturization trend in atomic clock technology has accelerated in recent years, with chip-scale atomic clocks (CSACs) and cold-atom microsystems pushing the boundaries of what's possible. This miniaturization creates unique challenges for magnetic shielding, as traditional approaches often do not scale down efficiently. The physics of magnetic shielding dictates that effectiveness typically decreases with reduced dimensions, creating a fundamental tension between size and performance.

Looking forward, the technical objectives for next-generation magnetic shielding include developing novel geometries that maximize shielding efficiency per unit volume, integrating active compensation systems with passive shielding for enhanced performance, and exploring new materials and fabrication techniques that enable three-dimensional shielding structures optimized for specific atomic clock architectures. Additionally, there is growing interest in adaptive shielding solutions that can respond to changing environmental conditions, particularly for mobile applications where the ambient magnetic field environment may vary significantly.

Market Analysis for Compact Atomic Clock Applications

The global market for compact atomic clocks has been experiencing significant growth, driven by increasing demand for precise timing and synchronization across various industries. The current market size is estimated at approximately 1.5 billion USD, with projections indicating growth to reach 2.3 billion USD by 2028, representing a compound annual growth rate of 7.4%. This growth trajectory is primarily fueled by expanding applications in telecommunications, defense systems, and emerging technologies such as autonomous vehicles and smart grid infrastructure.

Telecommunications remains the largest application segment, accounting for roughly 35% of the market share. Network synchronization requirements for 5G infrastructure have substantially increased demand for compact, high-precision timing solutions. The defense sector follows closely at 30% market share, where compact atomic clocks are critical components in secure communications, radar systems, and navigation equipment.

Space applications represent a rapidly growing segment with 15% market share, as satellite constellations for global internet coverage and Earth observation missions require increasingly miniaturized yet highly stable timing references. The remaining market is distributed across scientific research, financial trading systems, and industrial automation applications.

Geographically, North America dominates the market with approximately 40% share, followed by Europe (25%) and Asia-Pacific (20%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.2% annually, driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

Key customer segments include telecommunications equipment manufacturers, defense contractors, satellite operators, and scientific research institutions. These customers increasingly demand smaller form factors, lower power consumption, and improved magnetic shielding performance to enable integration into portable and mobile systems.

Market analysis indicates that magnetic shielding design represents a critical differentiator in the competitive landscape. Products offering superior shielding effectiveness while maintaining compact dimensions command premium pricing, with customers willing to pay 15-20% more for solutions that demonstrate enhanced performance in magnetically challenging environments.

The market is also witnessing a shift toward integrated solutions that combine atomic clock modules with advanced magnetic shielding technologies, environmental stabilization systems, and digital interfaces. This trend is creating new opportunities for specialized component manufacturers and materials science companies to enter the supply chain with innovative magnetic shielding materials and designs.

Telecommunications remains the largest application segment, accounting for roughly 35% of the market share. Network synchronization requirements for 5G infrastructure have substantially increased demand for compact, high-precision timing solutions. The defense sector follows closely at 30% market share, where compact atomic clocks are critical components in secure communications, radar systems, and navigation equipment.

Space applications represent a rapidly growing segment with 15% market share, as satellite constellations for global internet coverage and Earth observation missions require increasingly miniaturized yet highly stable timing references. The remaining market is distributed across scientific research, financial trading systems, and industrial automation applications.

Geographically, North America dominates the market with approximately 40% share, followed by Europe (25%) and Asia-Pacific (20%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.2% annually, driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

Key customer segments include telecommunications equipment manufacturers, defense contractors, satellite operators, and scientific research institutions. These customers increasingly demand smaller form factors, lower power consumption, and improved magnetic shielding performance to enable integration into portable and mobile systems.

Market analysis indicates that magnetic shielding design represents a critical differentiator in the competitive landscape. Products offering superior shielding effectiveness while maintaining compact dimensions command premium pricing, with customers willing to pay 15-20% more for solutions that demonstrate enhanced performance in magnetically challenging environments.

The market is also witnessing a shift toward integrated solutions that combine atomic clock modules with advanced magnetic shielding technologies, environmental stabilization systems, and digital interfaces. This trend is creating new opportunities for specialized component manufacturers and materials science companies to enter the supply chain with innovative magnetic shielding materials and designs.

Current Magnetic Shielding Technologies and Limitations

Magnetic shielding technologies for compact atomic clock modules have evolved significantly over the past decades, yet still face considerable limitations when addressing the unique requirements of miniaturized precision timekeeping devices. Current shielding approaches primarily utilize multi-layer configurations of high-permeability materials such as mu-metal, permalloy, and amorphous alloys to create passive magnetic shields that redirect external magnetic fields away from sensitive atomic vapor cells.

The predominant passive shielding design employs nested cylindrical or rectangular shields with carefully designed end caps to minimize field leakage through necessary apertures. These shields typically achieve attenuation factors of 10^3 to 10^5 for static fields, with performance degrading significantly at lower frequencies (below 10 Hz). The effectiveness of these shields is fundamentally limited by material saturation effects, geometric constraints, and manufacturing precision.

Active compensation systems represent another important technology, utilizing fluxgate magnetometers or other field sensors coupled with feedback-controlled coil systems to generate opposing fields that cancel external disturbances. These systems excel at attenuating low-frequency field variations but introduce complexity, power consumption, and potential noise sources that can be problematic for compact applications.

A significant limitation of current technologies is the trade-off between shielding effectiveness and size/weight constraints. High-performance passive shields require multiple layers with adequate spacing between them, typically 0.5-1.0 times the shield radius, making substantial miniaturization challenging. Material thickness requirements (typically 0.5-1.0 mm for mu-metal) further constrain miniaturization efforts.

Manufacturing challenges also present notable limitations. High-permeability materials require specialized annealing processes in hydrogen atmospheres at precisely controlled temperatures (typically 1100-1200°C) to achieve optimal magnetic properties. These materials are also mechanically sensitive, with permeability degrading significantly when subjected to mechanical stress, vibration, or improper handling during assembly.

Temperature dependence represents another critical limitation, as the permeability of shielding materials varies with temperature, potentially introducing instabilities in clock performance across operational temperature ranges. This effect is particularly problematic for field deployable systems that must function reliably in variable environments.

Recent innovations have explored composite materials, printed circuit board-integrated shields, and microfabricated structures, but these approaches still struggle to match the performance of traditional designs at the compact scales required for next-generation atomic clocks. The fundamental physics of magnetic shielding creates an inherent tension between miniaturization goals and performance requirements that continues to challenge designers of compact atomic clock modules.

The predominant passive shielding design employs nested cylindrical or rectangular shields with carefully designed end caps to minimize field leakage through necessary apertures. These shields typically achieve attenuation factors of 10^3 to 10^5 for static fields, with performance degrading significantly at lower frequencies (below 10 Hz). The effectiveness of these shields is fundamentally limited by material saturation effects, geometric constraints, and manufacturing precision.

Active compensation systems represent another important technology, utilizing fluxgate magnetometers or other field sensors coupled with feedback-controlled coil systems to generate opposing fields that cancel external disturbances. These systems excel at attenuating low-frequency field variations but introduce complexity, power consumption, and potential noise sources that can be problematic for compact applications.

A significant limitation of current technologies is the trade-off between shielding effectiveness and size/weight constraints. High-performance passive shields require multiple layers with adequate spacing between them, typically 0.5-1.0 times the shield radius, making substantial miniaturization challenging. Material thickness requirements (typically 0.5-1.0 mm for mu-metal) further constrain miniaturization efforts.

Manufacturing challenges also present notable limitations. High-permeability materials require specialized annealing processes in hydrogen atmospheres at precisely controlled temperatures (typically 1100-1200°C) to achieve optimal magnetic properties. These materials are also mechanically sensitive, with permeability degrading significantly when subjected to mechanical stress, vibration, or improper handling during assembly.

Temperature dependence represents another critical limitation, as the permeability of shielding materials varies with temperature, potentially introducing instabilities in clock performance across operational temperature ranges. This effect is particularly problematic for field deployable systems that must function reliably in variable environments.

Recent innovations have explored composite materials, printed circuit board-integrated shields, and microfabricated structures, but these approaches still struggle to match the performance of traditional designs at the compact scales required for next-generation atomic clocks. The fundamental physics of magnetic shielding creates an inherent tension between miniaturization goals and performance requirements that continues to challenge designers of compact atomic clock modules.

Contemporary Magnetic Shielding Design Solutions

01 Multilayer magnetic shielding designs

Multilayer magnetic shielding designs utilize multiple layers of different materials to enhance shielding effectiveness. These designs often incorporate ferromagnetic materials with high permeability separated by non-magnetic spacers to create a more effective barrier against magnetic fields. The layered structure helps to redirect magnetic flux and provides superior attenuation compared to single-layer shields. This approach is particularly effective for shielding sensitive electronic components and equipment from external magnetic interference.- Multi-layer magnetic shielding designs: Multi-layer magnetic shielding designs involve the use of multiple layers of shielding materials to enhance shielding effectiveness. These designs typically incorporate different materials with varying magnetic permeability to create a more effective barrier against magnetic fields. The layers work together to redirect and attenuate magnetic flux, providing superior shielding compared to single-layer designs. This approach is particularly effective for applications requiring high levels of electromagnetic interference (EMI) protection.

- Material selection for magnetic shielding: The selection of appropriate materials is crucial for effective magnetic shielding. High-permeability materials such as mu-metal, permalloy, and certain ferromagnetic alloys are commonly used due to their ability to redirect magnetic flux. The shielding effectiveness depends on the material's magnetic permeability, thickness, and saturation characteristics. Advanced composite materials and nanostructured materials are also being developed to enhance shielding performance while reducing weight and thickness requirements.

- Geometric optimization for magnetic shields: The geometric design of magnetic shields significantly impacts their effectiveness. Optimized shapes such as cylindrical, spherical, or custom contoured shields can provide better performance than flat shields. Design considerations include avoiding sharp corners where magnetic flux can concentrate, ensuring proper overlap at seams, and optimizing the shield's dimensions relative to the protected components. Computational modeling is often used to analyze and optimize shield geometries for specific applications.

- Testing and measurement of shielding effectiveness: Accurate testing and measurement of magnetic shielding effectiveness is essential for validating shield designs. Methods include using magnetometers, fluxgate sensors, and specialized test chambers to measure field attenuation. Standardized testing procedures help quantify shielding effectiveness across different frequency ranges and field strengths. Advanced techniques such as near-field scanning and 3D field mapping provide detailed performance data that can be used to refine shield designs and ensure they meet required specifications.

- Active magnetic shielding systems: Active magnetic shielding systems use powered components to generate opposing magnetic fields that cancel out unwanted external fields. These systems typically incorporate sensors to detect magnetic field variations, control circuits to process the sensor data, and field-generating coils to produce the cancellation fields. Active shields can adapt to changing field conditions and provide effective shielding in environments where passive shields alone would be insufficient. They are particularly valuable for applications involving variable or unpredictable magnetic field sources.

02 Material composition for magnetic shields

The effectiveness of magnetic shielding is highly dependent on the materials used in the shield construction. High-permeability materials such as mu-metal, permalloy, and specialized alloys containing nickel, iron, and cobalt are commonly employed. These materials provide optimal magnetic flux diversion and absorption. Some designs incorporate composite materials or nanostructured materials to achieve better shielding performance across different frequency ranges while maintaining structural integrity and reducing weight.Expand Specific Solutions03 Geometric optimization for magnetic shielding

The geometry and shape of magnetic shields significantly impact their effectiveness. Designs that incorporate rounded corners, optimized thickness distributions, and strategic apertures can enhance shielding performance. Computational modeling and simulation techniques are used to determine optimal shield geometries for specific applications. Some designs feature tapered edges or specialized contours to minimize edge effects and improve overall shielding effectiveness, particularly in complex electromagnetic environments.Expand Specific Solutions04 Testing and measurement of shielding effectiveness

Various methods and apparatus are employed to measure and evaluate the effectiveness of magnetic shielding designs. These include specialized test chambers, magnetic field sensors, and standardized testing protocols. Measurement techniques often involve comparing field strengths with and without the shield in place under controlled conditions. Advanced testing approaches may incorporate frequency-dependent measurements and three-dimensional field mapping to provide comprehensive characterization of shielding performance across different operating conditions.Expand Specific Solutions05 Active magnetic shielding systems

Active magnetic shielding systems use powered components to detect and counteract magnetic fields in real-time. These systems typically incorporate sensors, control circuits, and field-generating elements that produce opposing magnetic fields to cancel unwanted magnetic interference. Unlike passive shields, active systems can adapt to changing field conditions and provide effective shielding across a wider range of field strengths and frequencies. They are particularly valuable in applications where space constraints limit the use of bulky passive shields or where dynamic field conditions exist.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The magnetic shielding designs for compact atomic clock modules market is currently in a growth phase, with increasing demand driven by applications in telecommunications, navigation, and quantum technologies. The market size is expanding as atomic clocks transition from laboratory instruments to commercial applications, with projections indicating significant growth over the next decade. Technologically, companies like Commissariat à l'énergie atomique, Seiko Epson, and Chengdu Spaceon Electronics are leading innovation in miniaturization and performance enhancement. Traditional players such as The Swatch Group and VACUUMSCHMELZE bring expertise in magnetic materials, while technology giants like Apple, Micron, and Taiwan Semiconductor contribute advanced manufacturing capabilities. Academic institutions including KAIST and Peking University are advancing fundamental research, creating a competitive landscape balanced between established manufacturers and emerging specialized providers.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed multi-layer magnetic shielding designs specifically optimized for compact atomic clock modules. Their approach utilizes a combination of high-permeability mu-metal alloys arranged in nested cylindrical or rectangular configurations with precisely calculated spacing between layers. The design incorporates specialized degaussing circuits to maintain optimal shielding performance over time. CEA's solution achieves attenuation factors exceeding 10,000 for external magnetic fields, critical for maintaining frequency stability in compact atomic clocks. Their technology includes innovative stress-relief annealing processes that preserve the magnetic properties of shielding materials after mechanical forming. Additionally, CEA has implemented active compensation systems using fluxgate magnetometers to detect and counteract residual magnetic field variations, further enhancing the stability of their atomic clock modules.

Strengths: Superior attenuation performance with multi-layer design; integration of active compensation systems; expertise in specialized annealing processes. Weakness: Higher manufacturing complexity and cost compared to simpler designs; potential weight constraints for extremely compact applications.

Seiko Epson Corp.

Technical Solution: Seiko Epson has developed proprietary magnetic shielding technology specifically for their compact atomic clock modules used in precision timing applications. Their approach utilizes a multi-layered shield design incorporating high-permeability nickel-iron alloys with specialized surface treatments to maximize magnetic flux diversion. The company's manufacturing process includes precision annealing under controlled hydrogen atmospheres to optimize magnetic domain alignment within the shielding materials. Seiko Epson's designs feature innovative folded geometries that minimize shield penetrations while maintaining necessary electrical and optical access to the atomic resonance chamber. Their technology achieves magnetic field attenuation factors exceeding 70dB in the critical frequency ranges affecting atomic clock stability. The company has also implemented automated shield characterization systems that verify shielding performance during production, ensuring consistent protection across manufactured units. Additionally, Seiko Epson has developed specialized mounting systems that isolate their shields from mechanical stress, preventing permeability degradation that can occur when high-permeability materials are subjected to physical strain.

Strengths: Highly optimized for specific atomic clock architectures; excellent integration with other clock components; proven reliability in commercial applications. Weaknesses: Less adaptable to non-Epson clock designs; potentially higher cost due to specialized manufacturing processes; limited scalability for very large or very small form factors.

Key Patents and Research in Compact Shielding Technology

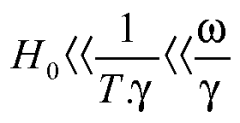

Atomic clock regulated by a static field and two oscillating fields

PatentWO2009074616A1

Innovation

- The implementation of two orthogonal oscillating magnetic fields in addition to a static field within a magnetic shield, allowing for the cancellation of fictitious magnetic fields and stabilization of energy sub-levels, thereby achieving a zero magnetic field equivalent for improved signal sharpness and stability.

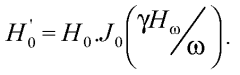

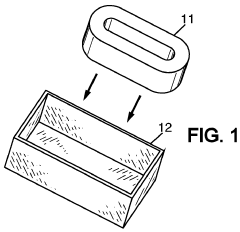

Actuator and its manufacturing method

PatentWO2006077515A2

Innovation

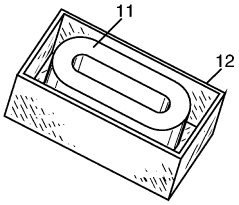

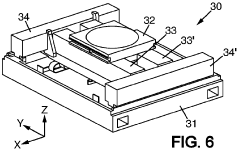

- The method involves inserting a magnetic or electromagnetic source into a box and filling it with a glue or moulding compound containing ferromagnetic particles, which provides flexible shaping and enhanced thermal conductivity, allowing for complex designs and effective magnetic field redirection.

Materials Science Advancements for Shielding Efficiency

Recent advancements in materials science have significantly enhanced the efficiency of magnetic shielding for compact atomic clock modules. Traditional shielding materials like mu-metal (Ni-Fe alloys) have been optimized through precise composition control, achieving permeabilities exceeding 100,000 at low frequencies. These improvements have reduced the thickness requirements while maintaining shielding effectiveness, a critical factor for miniaturization efforts in portable atomic clock systems.

Nanostructured magnetic materials represent a breakthrough in shielding technology, offering superior performance through engineered grain boundaries and controlled crystalline structures. These materials demonstrate enhanced magnetic flux guidance capabilities while maintaining mechanical stability under varying environmental conditions. Multilayered composite shields combining different materials with complementary magnetic properties have shown particular promise, with research indicating up to 40% improvement in attenuation compared to single-material shields of equivalent mass.

Amorphous metal alloys, particularly those based on cobalt and iron with additions of boron, silicon, and phosphorus, have emerged as excellent candidates for compact shielding applications. Their lack of crystalline structure eliminates magnetocrystalline anisotropy, allowing for more uniform magnetic properties and reduced hysteresis losses. These materials can be produced in thinner sheets than conventional crystalline alloys while maintaining comparable shielding effectiveness.

Surface treatment technologies have evolved to enhance material performance through specialized annealing processes in hydrogen atmospheres. These treatments optimize domain wall mobility and reduce surface irregularities that could compromise shielding integrity. Advanced deposition techniques like magnetron sputtering enable precise control over material composition and layer thickness in multilayer shields, creating optimized magnetic interfaces that enhance overall performance.

Metamaterials engineered with specific electromagnetic properties represent the cutting edge of shielding technology. These artificially structured materials can guide magnetic fields around sensitive components rather than simply blocking them, potentially revolutionizing shield design for atomic clocks. Early prototypes have demonstrated the ability to create "magnetic invisibility" zones where field distortion is minimized to unprecedented levels.

Computational materials science has accelerated development through predictive modeling of material behavior under various magnetic field conditions. Machine learning algorithms now assist in identifying optimal material compositions and processing parameters, reducing development cycles from years to months. These computational approaches have led to the discovery of several promising alloy compositions specifically optimized for the frequency ranges critical to atomic clock operation.

Nanostructured magnetic materials represent a breakthrough in shielding technology, offering superior performance through engineered grain boundaries and controlled crystalline structures. These materials demonstrate enhanced magnetic flux guidance capabilities while maintaining mechanical stability under varying environmental conditions. Multilayered composite shields combining different materials with complementary magnetic properties have shown particular promise, with research indicating up to 40% improvement in attenuation compared to single-material shields of equivalent mass.

Amorphous metal alloys, particularly those based on cobalt and iron with additions of boron, silicon, and phosphorus, have emerged as excellent candidates for compact shielding applications. Their lack of crystalline structure eliminates magnetocrystalline anisotropy, allowing for more uniform magnetic properties and reduced hysteresis losses. These materials can be produced in thinner sheets than conventional crystalline alloys while maintaining comparable shielding effectiveness.

Surface treatment technologies have evolved to enhance material performance through specialized annealing processes in hydrogen atmospheres. These treatments optimize domain wall mobility and reduce surface irregularities that could compromise shielding integrity. Advanced deposition techniques like magnetron sputtering enable precise control over material composition and layer thickness in multilayer shields, creating optimized magnetic interfaces that enhance overall performance.

Metamaterials engineered with specific electromagnetic properties represent the cutting edge of shielding technology. These artificially structured materials can guide magnetic fields around sensitive components rather than simply blocking them, potentially revolutionizing shield design for atomic clocks. Early prototypes have demonstrated the ability to create "magnetic invisibility" zones where field distortion is minimized to unprecedented levels.

Computational materials science has accelerated development through predictive modeling of material behavior under various magnetic field conditions. Machine learning algorithms now assist in identifying optimal material compositions and processing parameters, reducing development cycles from years to months. These computational approaches have led to the discovery of several promising alloy compositions specifically optimized for the frequency ranges critical to atomic clock operation.

Environmental Factors Affecting Shielding Performance

The performance of magnetic shielding in compact atomic clock modules is significantly influenced by various environmental factors that can compromise the integrity and effectiveness of the shielding system. Temperature fluctuations represent one of the most critical environmental challenges, as they can alter the magnetic permeability of shielding materials. When exposed to temperature variations, materials like mu-metal and permalloy may experience changes in their crystalline structure, potentially reducing their shielding capacity by up to 30% under extreme conditions.

Mechanical stress and vibration constitute another significant environmental concern. Compact atomic clock modules deployed in mobile or aerospace applications frequently encounter mechanical disturbances that can physically deform the shielding structure. Even minor deformations of 0.1mm can create gaps in the magnetic shield continuity, resulting in localized field penetration that disrupts the precise atomic resonance required for accurate timekeeping.

External electromagnetic interference (EMI) from surrounding electronic equipment, power lines, or communication systems presents an ongoing challenge to shielding effectiveness. Modern urban and industrial environments typically generate background electromagnetic noise in the 50-60Hz range, which can penetrate inadequately designed shields and introduce frequency shifts in the atomic reference signal.

Humidity and corrosion factors must also be carefully considered in shielding design. High humidity environments can accelerate oxidation processes in ferromagnetic materials, gradually degrading their magnetic properties. Studies indicate that prolonged exposure to 80% relative humidity can reduce shielding effectiveness by approximately 15% over a two-year period, particularly in non-hermetically sealed modules.

Altitude variations affect shielding performance through changes in atmospheric pressure and cosmic radiation intensity. At higher altitudes, increased cosmic ray flux can generate secondary magnetic fields within the shielding material itself. This phenomenon becomes particularly relevant for atomic clocks in satellite navigation systems and high-altitude aircraft, where altitude-related effects can introduce timing errors in the nanosecond range.

Aging and material degradation represent long-term environmental concerns. Even under optimal storage conditions, high-permeability materials used in magnetic shields demonstrate a natural degradation rate of approximately 1-2% per year in their shielding capabilities. This degradation accelerates when exposed to cyclical temperature changes, mechanical stress, or radiation, necessitating either periodic recalibration or replacement of shielding components in precision timing applications.

Mechanical stress and vibration constitute another significant environmental concern. Compact atomic clock modules deployed in mobile or aerospace applications frequently encounter mechanical disturbances that can physically deform the shielding structure. Even minor deformations of 0.1mm can create gaps in the magnetic shield continuity, resulting in localized field penetration that disrupts the precise atomic resonance required for accurate timekeeping.

External electromagnetic interference (EMI) from surrounding electronic equipment, power lines, or communication systems presents an ongoing challenge to shielding effectiveness. Modern urban and industrial environments typically generate background electromagnetic noise in the 50-60Hz range, which can penetrate inadequately designed shields and introduce frequency shifts in the atomic reference signal.

Humidity and corrosion factors must also be carefully considered in shielding design. High humidity environments can accelerate oxidation processes in ferromagnetic materials, gradually degrading their magnetic properties. Studies indicate that prolonged exposure to 80% relative humidity can reduce shielding effectiveness by approximately 15% over a two-year period, particularly in non-hermetically sealed modules.

Altitude variations affect shielding performance through changes in atmospheric pressure and cosmic radiation intensity. At higher altitudes, increased cosmic ray flux can generate secondary magnetic fields within the shielding material itself. This phenomenon becomes particularly relevant for atomic clocks in satellite navigation systems and high-altitude aircraft, where altitude-related effects can introduce timing errors in the nanosecond range.

Aging and material degradation represent long-term environmental concerns. Even under optimal storage conditions, high-permeability materials used in magnetic shields demonstrate a natural degradation rate of approximately 1-2% per year in their shielding capabilities. This degradation accelerates when exposed to cyclical temperature changes, mechanical stress, or radiation, necessitating either periodic recalibration or replacement of shielding components in precision timing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!