Design Guidelines For Minimizing Creasing Effect Of Ultra-Thin Glass (UTG) In Flexible Displays

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UTG Technology Background and Objectives

Ultra-Thin Glass (UTG) technology represents a significant breakthrough in the evolution of flexible display materials. Originating from traditional glass manufacturing techniques, UTG has undergone substantial refinement over the past decade to achieve thicknesses below 100 micrometers while maintaining essential glass properties. This remarkable advancement has positioned UTG as a critical component in next-generation flexible and foldable display devices, offering superior optical clarity, scratch resistance, and durability compared to polymer alternatives.

The development trajectory of UTG has been characterized by progressive improvements in manufacturing processes, particularly in areas of chemical strengthening, precision thinning, and handling techniques for ultra-thin substrates. Early iterations faced significant challenges with brittleness and yield rates, but recent technological breakthroughs have enabled commercial viability, particularly for mobile device applications requiring both flexibility and premium display quality.

Current market trends indicate an accelerating shift toward foldable and rollable display technologies across consumer electronics, with major manufacturers investing heavily in UTG integration. This shift is driven by consumer demand for devices that combine portability with expanded screen real estate, without compromising on display performance or durability.

Despite significant progress, the creasing effect remains one of the most persistent technical challenges in UTG implementation. When UTG is folded or bent repeatedly, visible and tactile deformations can develop along the fold axis, compromising both aesthetic appeal and functional performance. These creases not only affect user experience but can eventually lead to structural failures in the glass substrate, limiting device longevity.

The primary technical objective in UTG development is to establish comprehensive design guidelines that minimize or eliminate the creasing effect while maintaining the material's optical and mechanical advantages. This involves optimizing several interdependent parameters including glass composition, thickness profiles, supporting layer structures, and folding radius limitations.

Secondary objectives include enhancing UTG's resistance to impact damage, improving manufacturing scalability to reduce costs, and developing standardized testing methodologies to evaluate creasing behavior under various usage conditions. The ultimate goal is to enable UTG implementation in increasingly demanding applications, including devices with multiple folding axes or more extreme folding radii.

As the industry progresses toward more sophisticated flexible display applications, addressing the creasing effect in UTG has become a critical determinant of market success, driving collaborative research efforts across materials science, mechanical engineering, and manufacturing technology domains.

The development trajectory of UTG has been characterized by progressive improvements in manufacturing processes, particularly in areas of chemical strengthening, precision thinning, and handling techniques for ultra-thin substrates. Early iterations faced significant challenges with brittleness and yield rates, but recent technological breakthroughs have enabled commercial viability, particularly for mobile device applications requiring both flexibility and premium display quality.

Current market trends indicate an accelerating shift toward foldable and rollable display technologies across consumer electronics, with major manufacturers investing heavily in UTG integration. This shift is driven by consumer demand for devices that combine portability with expanded screen real estate, without compromising on display performance or durability.

Despite significant progress, the creasing effect remains one of the most persistent technical challenges in UTG implementation. When UTG is folded or bent repeatedly, visible and tactile deformations can develop along the fold axis, compromising both aesthetic appeal and functional performance. These creases not only affect user experience but can eventually lead to structural failures in the glass substrate, limiting device longevity.

The primary technical objective in UTG development is to establish comprehensive design guidelines that minimize or eliminate the creasing effect while maintaining the material's optical and mechanical advantages. This involves optimizing several interdependent parameters including glass composition, thickness profiles, supporting layer structures, and folding radius limitations.

Secondary objectives include enhancing UTG's resistance to impact damage, improving manufacturing scalability to reduce costs, and developing standardized testing methodologies to evaluate creasing behavior under various usage conditions. The ultimate goal is to enable UTG implementation in increasingly demanding applications, including devices with multiple folding axes or more extreme folding radii.

As the industry progresses toward more sophisticated flexible display applications, addressing the creasing effect in UTG has become a critical determinant of market success, driving collaborative research efforts across materials science, mechanical engineering, and manufacturing technology domains.

Market Demand for Foldable Display Solutions

The global market for foldable displays has witnessed exponential growth since the introduction of the first commercial foldable smartphones in 2019. According to industry reports, the foldable display market reached approximately $16 billion in 2022 and is projected to grow at a CAGR of 24.3% through 2028. This remarkable growth trajectory underscores the significant consumer interest in devices that offer larger screen real estate while maintaining portability.

Consumer demand for foldable displays stems primarily from the desire for enhanced user experience. Market surveys indicate that 67% of premium smartphone users express interest in foldable form factors, citing multitasking capabilities and immersive media consumption as key attractions. The business professional segment particularly values the productivity benefits of foldable devices, with 72% reporting improved workflow efficiency when using foldable tablets or smartphones.

The durability concerns around foldable displays represent a critical market challenge. Consumer feedback consistently highlights anxiety about display creasing, with 83% of potential buyers citing visible creases as a major deterrent to purchase. This concern directly relates to the Ultra-Thin Glass (UTG) technology, as consumers expect glass-based displays to maintain the premium look and feel of traditional smartphones without visible degradation over time.

Major electronics manufacturers have recognized this market demand and are investing heavily in UTG solutions. Samsung Display, BOE Technology, and LG Display have collectively allocated over $5.2 billion toward research and development of crease-minimizing technologies between 2020 and 2023. This investment signals the industry's acknowledgment of crease reduction as a competitive differentiator in the premium device segment.

Regional market analysis reveals varying consumer priorities. Asian markets, particularly South Korea and China, show higher tolerance for display creasing in exchange for cutting-edge technology, while North American and European consumers demonstrate greater sensitivity to visible creases, with 76% indicating they would delay purchase until crease issues are resolved.

The enterprise market represents another significant growth vector, with foldable devices increasingly adopted in healthcare, field services, and design industries. These professional applications demand even higher durability standards, with 91% of enterprise procurement managers citing display longevity as a critical purchasing factor. The ability to minimize creasing in UTG is therefore not merely an aesthetic consideration but a fundamental requirement for expanding market penetration across both consumer and enterprise segments.

Consumer demand for foldable displays stems primarily from the desire for enhanced user experience. Market surveys indicate that 67% of premium smartphone users express interest in foldable form factors, citing multitasking capabilities and immersive media consumption as key attractions. The business professional segment particularly values the productivity benefits of foldable devices, with 72% reporting improved workflow efficiency when using foldable tablets or smartphones.

The durability concerns around foldable displays represent a critical market challenge. Consumer feedback consistently highlights anxiety about display creasing, with 83% of potential buyers citing visible creases as a major deterrent to purchase. This concern directly relates to the Ultra-Thin Glass (UTG) technology, as consumers expect glass-based displays to maintain the premium look and feel of traditional smartphones without visible degradation over time.

Major electronics manufacturers have recognized this market demand and are investing heavily in UTG solutions. Samsung Display, BOE Technology, and LG Display have collectively allocated over $5.2 billion toward research and development of crease-minimizing technologies between 2020 and 2023. This investment signals the industry's acknowledgment of crease reduction as a competitive differentiator in the premium device segment.

Regional market analysis reveals varying consumer priorities. Asian markets, particularly South Korea and China, show higher tolerance for display creasing in exchange for cutting-edge technology, while North American and European consumers demonstrate greater sensitivity to visible creases, with 76% indicating they would delay purchase until crease issues are resolved.

The enterprise market represents another significant growth vector, with foldable devices increasingly adopted in healthcare, field services, and design industries. These professional applications demand even higher durability standards, with 91% of enterprise procurement managers citing display longevity as a critical purchasing factor. The ability to minimize creasing in UTG is therefore not merely an aesthetic consideration but a fundamental requirement for expanding market penetration across both consumer and enterprise segments.

Current Challenges in UTG Implementation

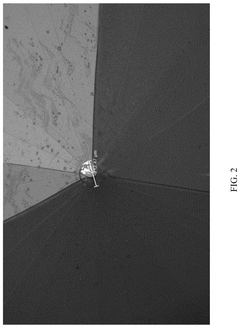

Despite the promising advantages of Ultra-Thin Glass (UTG) in flexible displays, several significant challenges impede its widespread implementation. The most critical issue remains the creasing effect that occurs during repeated folding and unfolding operations. When UTG undergoes bending at acute angles (typically less than 3mm radius), microscopic fractures develop along the fold line, gradually propagating with continued use. These microcracks not only compromise display quality but also significantly reduce the operational lifespan of devices.

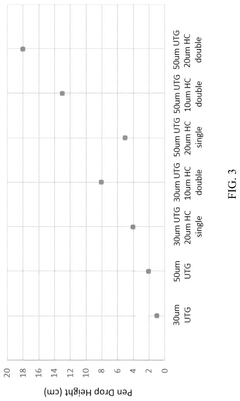

Material composition presents another substantial challenge. Current UTG formulations struggle to achieve the optimal balance between flexibility and durability. While increasing flexibility often requires reducing thickness (below 30μm), this simultaneously decreases impact resistance and structural integrity. Industry testing reveals that UTG below 100μm thickness exhibits a 30-40% higher fracture rate compared to conventional display glass.

Manufacturing scalability poses significant barriers to mass production. The specialized processes required for UTG production—including precision etching, chemical strengthening, and ultra-thin lamination—demand extremely controlled environments with contamination levels below 10 particles per cubic meter. Current yield rates for premium-quality UTG hover around 65-70%, substantially lower than the 85-90% standard for conventional display glass manufacturing.

Cost factors further complicate UTG implementation. The specialized materials and precision manufacturing processes increase production costs by approximately 200-300% compared to conventional display technologies. This cost premium makes UTG implementation economically challenging for mid-range consumer electronics, limiting its application primarily to premium devices.

Integration challenges with other display components also present significant hurdles. The touch sensor layer, polarizer, and protective films must maintain functionality while conforming to the same bending radius as the UTG. Current adhesive technologies struggle to maintain bond strength through repeated folding cycles, with delamination occurring after approximately 100,000-200,000 fold operations—below the industry target of 300,000 cycles.

Temperature sensitivity represents another critical limitation. UTG exhibits significant changes in mechanical properties across typical operating temperature ranges (-20°C to 60°C). At lower temperatures, brittleness increases dramatically, with fracture resistance decreasing by up to 40% at 0°C compared to room temperature performance. This temperature sensitivity restricts the practical deployment of UTG in diverse environmental conditions.

Material composition presents another substantial challenge. Current UTG formulations struggle to achieve the optimal balance between flexibility and durability. While increasing flexibility often requires reducing thickness (below 30μm), this simultaneously decreases impact resistance and structural integrity. Industry testing reveals that UTG below 100μm thickness exhibits a 30-40% higher fracture rate compared to conventional display glass.

Manufacturing scalability poses significant barriers to mass production. The specialized processes required for UTG production—including precision etching, chemical strengthening, and ultra-thin lamination—demand extremely controlled environments with contamination levels below 10 particles per cubic meter. Current yield rates for premium-quality UTG hover around 65-70%, substantially lower than the 85-90% standard for conventional display glass manufacturing.

Cost factors further complicate UTG implementation. The specialized materials and precision manufacturing processes increase production costs by approximately 200-300% compared to conventional display technologies. This cost premium makes UTG implementation economically challenging for mid-range consumer electronics, limiting its application primarily to premium devices.

Integration challenges with other display components also present significant hurdles. The touch sensor layer, polarizer, and protective films must maintain functionality while conforming to the same bending radius as the UTG. Current adhesive technologies struggle to maintain bond strength through repeated folding cycles, with delamination occurring after approximately 100,000-200,000 fold operations—below the industry target of 300,000 cycles.

Temperature sensitivity represents another critical limitation. UTG exhibits significant changes in mechanical properties across typical operating temperature ranges (-20°C to 60°C). At lower temperatures, brittleness increases dramatically, with fracture resistance decreasing by up to 40% at 0°C compared to room temperature performance. This temperature sensitivity restricts the practical deployment of UTG in diverse environmental conditions.

Current Anti-Creasing Technical Solutions

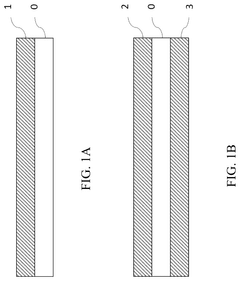

01 UTG structure design to prevent creasing

Ultra-thin glass (UTG) structures can be designed with specific layers and configurations to prevent creasing effects when folded. These designs may include reinforcement layers, buffer layers, or special structural arrangements that distribute stress more evenly across the folding area. By optimizing the thickness and composition of different layers, the resistance to creasing can be significantly improved while maintaining the flexibility required for foldable displays.- UTG structure design to prevent creasing: Ultra-thin glass (UTG) structures can be designed with specific layers and configurations to prevent creasing effects when folded. These designs may include reinforcement layers, support films, or specialized adhesive layers that distribute stress more evenly across the glass surface. The thickness and composition of these layers are carefully engineered to maintain the flexibility of the UTG while minimizing the risk of creasing or damage during repeated folding operations.

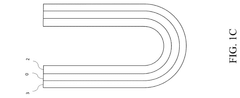

- Folding mechanism optimization for UTG displays: The folding mechanism design plays a crucial role in preventing creasing effects in UTG displays. Optimized hinge structures, bending radius controls, and support systems can significantly reduce stress concentration on the glass during folding operations. These mechanisms often incorporate elastic components or variable-radius designs that ensure the glass bends along a gradual curve rather than a sharp crease, thereby preserving the integrity of the ultra-thin glass surface.

- Surface treatment methods for UTG: Various surface treatment methods can be applied to ultra-thin glass to enhance its resistance to creasing effects. These treatments may include chemical strengthening processes, specialized coatings, or surface modification techniques that improve the mechanical properties of the glass. By altering the surface characteristics of the UTG, these treatments can increase flexibility, reduce friction, and minimize the visibility of any creasing that might occur during folding operations.

- Composite materials integration with UTG: Integrating composite materials with ultra-thin glass can significantly reduce creasing effects. These composites may combine polymer layers, specialized adhesives, or other flexible materials with the glass to create a hybrid structure that maintains transparency while improving folding performance. The composite approach allows for the distribution of mechanical stress across multiple materials, preventing stress concentration that would otherwise lead to visible creasing in the glass layer.

- Manufacturing processes to minimize UTG creasing: Advanced manufacturing processes have been developed specifically to minimize creasing effects in ultra-thin glass. These processes may include specialized tempering techniques, controlled cooling methods, precision lamination procedures, or innovative glass forming technologies. By optimizing the manufacturing parameters such as temperature profiles, pressure distribution, and processing time, the inherent resistance of UTG to creasing can be significantly improved, resulting in more durable and visually appealing flexible display components.

02 Protective films and coatings for UTG

Applying specialized protective films and coatings to ultra-thin glass can enhance its resistance to creasing. These protective layers may include polymer films, hard coatings, or composite materials that provide additional support while maintaining optical clarity. The coatings can be designed to absorb stress during folding operations, thereby reducing the likelihood of permanent creases forming in the glass substrate.Expand Specific Solutions03 Folding mechanism design for UTG displays

The design of folding mechanisms plays a crucial role in preventing creasing effects in ultra-thin glass displays. Innovative hinge designs, support structures, and folding radius controls can minimize stress concentration at the folding area. These mechanisms may incorporate variable curvature designs or dynamic support systems that adjust during the folding process to maintain an optimal bending radius for the glass.Expand Specific Solutions04 Manufacturing processes to enhance UTG flexibility

Specialized manufacturing processes can be employed to enhance the flexibility of ultra-thin glass while reducing its susceptibility to creasing. These processes may include chemical strengthening, thermal treatments, or ion exchange techniques that modify the glass structure at a molecular level. By optimizing these manufacturing parameters, the glass can achieve improved bending properties while maintaining its resistance to permanent deformation.Expand Specific Solutions05 Composite UTG materials and stress distribution techniques

Developing composite materials that combine ultra-thin glass with other flexible materials can help distribute stress more effectively and prevent creasing. These composites may incorporate polymer interlayers, nano-materials, or specialized adhesives that work together to absorb and distribute bending forces. Additionally, techniques for controlling stress distribution across the glass surface during folding can significantly reduce the formation of visible creases.Expand Specific Solutions

Key Players in UTG Manufacturing Ecosystem

The ultra-thin glass (UTG) market for flexible displays is currently in a growth phase, with increasing demand driven by foldable smartphones and wearable devices. The market size is expanding rapidly, projected to reach significant value by 2025 as major players invest in production capacity. Technologically, UTG is maturing but still faces challenges in minimizing creasing effects. Leading companies like Samsung Display, Corning, and BOE Technology have made substantial progress in UTG development, while Chinese manufacturers including Dongxu Technology and CNBM are rapidly advancing their capabilities. Collaboration between display manufacturers (Samsung Electronics, Huawei, OPPO) and glass specialists (Corning, Schott) is accelerating innovation in crease-resistant UTG solutions through specialized coating technologies and composite material structures.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a multi-layered UTG structure with optimized thickness distribution to minimize creasing effects. Their approach involves a composite design where the UTG layer (typically 30μm thick) is combined with a polymer layer underneath that serves as a stress buffer. Samsung's design incorporates a neutral plane engineering concept, where the glass layer is positioned at a calculated distance from the folding axis to minimize tensile stress during bending. They've also implemented a variable radius folding mechanism that distributes stress more evenly across the folding area rather than concentrating it at a single point. Additionally, Samsung has developed specialized nano-coating technologies that enhance the UTG's flexibility while maintaining its hardness properties, allowing for a bending radius as small as 1.4mm while significantly reducing visible creasing.

Strengths: Industry-leading UTG technology with proven commercial implementation in multiple generations of foldable devices. Their multi-layered approach effectively balances durability with flexibility. Weaknesses: The complex manufacturing process results in higher production costs and potential yield issues. The technology still shows visible creasing after extended use cycles (typically noticeable after 200,000+ folds).

Corning, Inc.

Technical Solution: Corning has pioneered a proprietary "Willow Glass" technology specifically designed for flexible display applications. Their approach focuses on the glass composition itself, developing specialized formulations that maintain transparency and durability while enabling flexibility. Corning's UTG solution employs a fusion draw process that creates inherently thin glass with exceptional surface quality and thickness uniformity (down to 100μm and potentially thinner). To address creasing, they've developed a stress-relief layer system that works in conjunction with the glass, absorbing deformation energy during bending. Their design guidelines emphasize the importance of glass edge treatment, with specialized polishing techniques to eliminate micro-cracks that could propagate during bending. Corning has also developed computational models that predict stress distribution during folding, allowing for optimization of supporting structures and adhesive layers to minimize stress concentration at the fold area.

Strengths: Superior optical clarity and surface quality compared to polymer alternatives, with excellent scratch resistance. Their glass formulation expertise provides unique material properties optimized for flexibility. Weaknesses: Their solutions typically require thicker glass than competitors (limiting the minimum bending radius achievable) and need additional protective layers that add to the overall display thickness.

Critical Patents in UTG Creasing Mitigation

Foldable ultrathin glass with transparent, impact-resistant hard coating

PatentActiveUS12116308B2

Innovation

- A single-layer hard coating composed of silsesquioxane with a silicon-oxygen core framework directly bonded to the ultrathin tempered glass substrate, providing a surface hardness of at least 7H, hydrophobic properties, and improved impact resistance without the need for an adhesive layer, achieved through chemical tempering and specific molecular weight ranges of the silsesquioxane.

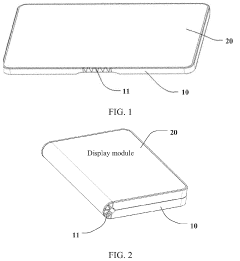

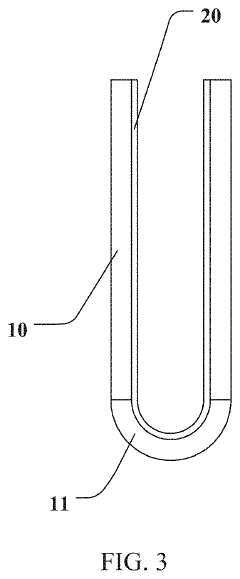

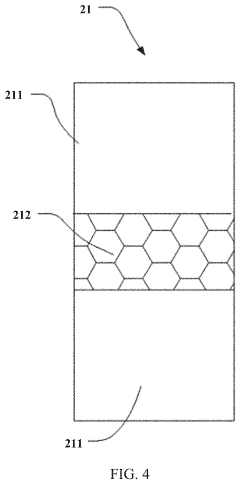

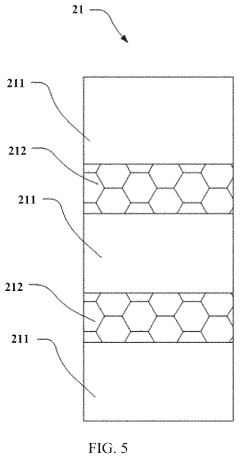

Flexible Display Cover, Flexible Display Module, And Flexible Display Apparatus

PatentActiveUS20220118744A1

Innovation

- A flexible display cover comprising a glass layer with a hardened layer and a flexible protective layer, where the glass layer is chemically strengthened and coated with a hardened material to enhance scratch and impact resistance, and an anti-shatter layer is optionally included to prevent glass fragmentation.

Material Science Advancements for UTG

The evolution of Ultra-Thin Glass (UTG) represents a significant breakthrough in material science for flexible display technologies. Recent advancements have focused on modifying the chemical composition of UTG to enhance its flexibility while maintaining structural integrity. Researchers have successfully incorporated alkali metal ions, particularly lithium and sodium, into the glass matrix, which has proven effective in reducing the formation of stress points during bending cycles.

Surface treatment technologies have also evolved considerably, with ion exchange processes emerging as a critical method for strengthening UTG. This process, often referred to as chemical tempering, involves replacing smaller ions in the glass surface with larger ones, creating a compressive stress layer that significantly improves crack resistance while maintaining flexibility. Advanced coating technologies using hybrid organic-inorganic materials have demonstrated promising results in enhancing the scratch resistance of UTG without compromising its bendability.

Nano-composite integration represents another frontier in UTG development. By embedding nanoparticles such as silica or alumina within the glass matrix, researchers have achieved UTG variants with improved mechanical properties. These nano-reinforced glasses exhibit superior resistance to creasing while maintaining optical clarity, addressing one of the primary challenges in flexible display applications.

Manufacturing processes have similarly undergone substantial refinement, with float glass techniques being modified specifically for ultra-thin applications. The development of precision drawing methods has enabled the production of glass sheets with thicknesses below 30 micrometers while maintaining uniform thickness distribution—a critical factor in preventing localized stress concentrations that lead to creasing.

Lamination technologies have advanced to allow multi-layer UTG structures with engineered interfaces that distribute bending stresses more effectively. These composite structures incorporate gradient layers with varying elastic properties, effectively dissipating strain energy during folding operations and minimizing visible crease formation.

Atomic layer deposition (ALD) techniques have been adapted for UTG applications, enabling the creation of nanometer-scale protective layers that enhance durability without adding significant thickness. These ultra-thin coatings provide chemical protection while maintaining the mechanical flexibility of the underlying glass substrate.

Recent research has also explored the potential of self-healing materials as additives or coatings for UTG. Preliminary studies indicate that incorporating certain polymeric compounds can enable limited self-repair of microscopic damage, potentially extending the usable lifetime of flexible displays by preventing the propagation of minor defects into visible creases.

Surface treatment technologies have also evolved considerably, with ion exchange processes emerging as a critical method for strengthening UTG. This process, often referred to as chemical tempering, involves replacing smaller ions in the glass surface with larger ones, creating a compressive stress layer that significantly improves crack resistance while maintaining flexibility. Advanced coating technologies using hybrid organic-inorganic materials have demonstrated promising results in enhancing the scratch resistance of UTG without compromising its bendability.

Nano-composite integration represents another frontier in UTG development. By embedding nanoparticles such as silica or alumina within the glass matrix, researchers have achieved UTG variants with improved mechanical properties. These nano-reinforced glasses exhibit superior resistance to creasing while maintaining optical clarity, addressing one of the primary challenges in flexible display applications.

Manufacturing processes have similarly undergone substantial refinement, with float glass techniques being modified specifically for ultra-thin applications. The development of precision drawing methods has enabled the production of glass sheets with thicknesses below 30 micrometers while maintaining uniform thickness distribution—a critical factor in preventing localized stress concentrations that lead to creasing.

Lamination technologies have advanced to allow multi-layer UTG structures with engineered interfaces that distribute bending stresses more effectively. These composite structures incorporate gradient layers with varying elastic properties, effectively dissipating strain energy during folding operations and minimizing visible crease formation.

Atomic layer deposition (ALD) techniques have been adapted for UTG applications, enabling the creation of nanometer-scale protective layers that enhance durability without adding significant thickness. These ultra-thin coatings provide chemical protection while maintaining the mechanical flexibility of the underlying glass substrate.

Recent research has also explored the potential of self-healing materials as additives or coatings for UTG. Preliminary studies indicate that incorporating certain polymeric compounds can enable limited self-repair of microscopic damage, potentially extending the usable lifetime of flexible displays by preventing the propagation of minor defects into visible creases.

Reliability Testing Standards for Foldable Displays

Reliability testing standards for foldable displays incorporating Ultra-Thin Glass (UTG) technology have evolved significantly to address the unique challenges posed by flexible form factors. These standards focus on evaluating the durability and performance of displays under various stress conditions that simulate real-world usage patterns.

The International Electrotechnical Commission (IEC) has developed specific testing protocols for foldable displays, including IEC 62715-6-1 which addresses mechanical reliability testing methods. This standard encompasses folding cycle tests, requiring displays to withstand between 100,000 to 200,000 folding cycles without significant degradation in optical performance or mechanical integrity.

ASTM International has complemented these efforts with standards focusing on material properties relevant to UTG implementation, particularly ASTM D7027 which evaluates scratch resistance—a critical parameter for UTG surfaces exposed to daily handling. Similarly, the Japanese Electronics and Information Technology Industries Association (JEITA) has established ET-7407 specifically for evaluating the reliability of flexible display modules.

Temperature variation testing represents another crucial aspect of reliability standards, with tests typically conducted between -30°C and 85°C to ensure UTG maintains structural integrity across diverse environmental conditions. These thermal cycle tests are particularly important for identifying potential delamination issues between the UTG and polymer layers in composite structures.

Impact resistance testing has been standardized through drop tests from heights of 1.0-1.5 meters, simulating accidental falls. For UTG-specific evaluation, modified ball drop tests using smaller diameter (5-8mm) steel balls at lower heights have been developed to better represent realistic impact scenarios without catastrophic failure.

Humidity resistance testing requires exposure to 85% relative humidity at 60°C for 500-1000 hours, evaluating potential moisture ingress effects on adhesive layers surrounding the UTG. This test is particularly relevant for identifying potential delamination risks at the glass-polymer interfaces.

Optical performance degradation measurements have been standardized to quantify the impact of folding stress on display quality. These include luminance uniformity (maximum 15% variation across the fold area), color shift (ΔE < 3 across the fold), and contrast ratio maintenance (minimum 80% of original value after reliability testing).

Industry consortiums like the Flexible Display Alliance have proposed supplementary testing protocols specifically addressing UTG crease formation, recommending multi-angle optical evaluation at 0°, 45°, and 90° viewing angles to comprehensively characterize the visual impact of creasing under various viewing conditions.

The International Electrotechnical Commission (IEC) has developed specific testing protocols for foldable displays, including IEC 62715-6-1 which addresses mechanical reliability testing methods. This standard encompasses folding cycle tests, requiring displays to withstand between 100,000 to 200,000 folding cycles without significant degradation in optical performance or mechanical integrity.

ASTM International has complemented these efforts with standards focusing on material properties relevant to UTG implementation, particularly ASTM D7027 which evaluates scratch resistance—a critical parameter for UTG surfaces exposed to daily handling. Similarly, the Japanese Electronics and Information Technology Industries Association (JEITA) has established ET-7407 specifically for evaluating the reliability of flexible display modules.

Temperature variation testing represents another crucial aspect of reliability standards, with tests typically conducted between -30°C and 85°C to ensure UTG maintains structural integrity across diverse environmental conditions. These thermal cycle tests are particularly important for identifying potential delamination issues between the UTG and polymer layers in composite structures.

Impact resistance testing has been standardized through drop tests from heights of 1.0-1.5 meters, simulating accidental falls. For UTG-specific evaluation, modified ball drop tests using smaller diameter (5-8mm) steel balls at lower heights have been developed to better represent realistic impact scenarios without catastrophic failure.

Humidity resistance testing requires exposure to 85% relative humidity at 60°C for 500-1000 hours, evaluating potential moisture ingress effects on adhesive layers surrounding the UTG. This test is particularly relevant for identifying potential delamination risks at the glass-polymer interfaces.

Optical performance degradation measurements have been standardized to quantify the impact of folding stress on display quality. These include luminance uniformity (maximum 15% variation across the fold area), color shift (ΔE < 3 across the fold), and contrast ratio maintenance (minimum 80% of original value after reliability testing).

Industry consortiums like the Flexible Display Alliance have proposed supplementary testing protocols specifically addressing UTG crease formation, recommending multi-angle optical evaluation at 0°, 45°, and 90° viewing angles to comprehensively characterize the visual impact of creasing under various viewing conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!