Failure Modes And Root-Cause Analysis For Crack Initiation In Ultra-Thin Glass (UTG) In Flexible Displays

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UTG Crack Initiation Background and Objectives

Ultra-thin glass (UTG) has emerged as a revolutionary material in the display industry, particularly for flexible and foldable devices. The evolution of UTG technology can be traced back to the early 2010s when display manufacturers began exploring alternatives to plastic substrates that could offer better scratch resistance while maintaining flexibility. The trajectory of UTG development has been characterized by progressive improvements in manufacturing techniques, thickness reduction, and enhanced mechanical properties.

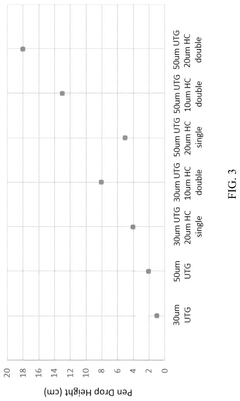

The current technological landscape shows UTG thickness has been reduced from initial 100μm to below 30μm in commercial applications, with research prototypes reaching as thin as 10μm. This remarkable thinning process has enabled unprecedented flexibility while preserving the inherent advantages of glass, including superior optical clarity, chemical stability, and barrier properties against oxygen and moisture.

Despite these advancements, crack initiation in UTG remains a critical challenge that threatens the reliability and longevity of flexible display devices. The primary objective of investigating failure modes and root causes of crack initiation is to establish a comprehensive understanding of the mechanical behavior of UTG under various stress conditions typical in flexible display applications.

This technical research aims to identify and categorize the fundamental failure mechanisms in UTG, including stress concentration points, microstructural defects, and environmental factors that contribute to crack formation. By developing predictive models for crack initiation and propagation, we seek to establish design guidelines that can significantly improve UTG durability in commercial applications.

Additionally, this research intends to explore the correlation between manufacturing processes and crack susceptibility, with particular emphasis on edge finishing techniques, chemical strengthening parameters, and handling protocols during device assembly. Understanding these relationships will enable optimization of the entire UTG production and integration workflow.

The ultimate goal is to develop a systematic approach for enhancing UTG reliability through material composition modifications, structural design improvements, and process optimizations. This includes establishing standardized testing methodologies that accurately simulate real-world usage conditions and predict long-term performance, thereby accelerating the development cycle for next-generation flexible display technologies.

By addressing these objectives, we aim to overcome the current limitations of UTG technology and facilitate wider adoption in consumer electronics, potentially expanding into new application domains where the combination of flexibility and durability is paramount.

The current technological landscape shows UTG thickness has been reduced from initial 100μm to below 30μm in commercial applications, with research prototypes reaching as thin as 10μm. This remarkable thinning process has enabled unprecedented flexibility while preserving the inherent advantages of glass, including superior optical clarity, chemical stability, and barrier properties against oxygen and moisture.

Despite these advancements, crack initiation in UTG remains a critical challenge that threatens the reliability and longevity of flexible display devices. The primary objective of investigating failure modes and root causes of crack initiation is to establish a comprehensive understanding of the mechanical behavior of UTG under various stress conditions typical in flexible display applications.

This technical research aims to identify and categorize the fundamental failure mechanisms in UTG, including stress concentration points, microstructural defects, and environmental factors that contribute to crack formation. By developing predictive models for crack initiation and propagation, we seek to establish design guidelines that can significantly improve UTG durability in commercial applications.

Additionally, this research intends to explore the correlation between manufacturing processes and crack susceptibility, with particular emphasis on edge finishing techniques, chemical strengthening parameters, and handling protocols during device assembly. Understanding these relationships will enable optimization of the entire UTG production and integration workflow.

The ultimate goal is to develop a systematic approach for enhancing UTG reliability through material composition modifications, structural design improvements, and process optimizations. This includes establishing standardized testing methodologies that accurately simulate real-world usage conditions and predict long-term performance, thereby accelerating the development cycle for next-generation flexible display technologies.

By addressing these objectives, we aim to overcome the current limitations of UTG technology and facilitate wider adoption in consumer electronics, potentially expanding into new application domains where the combination of flexibility and durability is paramount.

Market Demand for Flexible Display Technologies

The flexible display market has witnessed exponential growth over the past decade, driven by consumer demand for more versatile, durable, and innovative electronic devices. Market research indicates that the global flexible display market was valued at approximately $23.1 billion in 2022 and is projected to reach $42.5 billion by 2027, representing a compound annual growth rate (CAGR) of 12.9%. This remarkable growth trajectory underscores the significant market potential for technologies addressing failure modes in ultra-thin glass (UTG) components.

Smartphone manufacturers constitute the largest segment of flexible display adopters, accounting for nearly 60% of the total market share. Major players like Samsung, Huawei, and Motorola have launched multiple generations of foldable devices, each iteration addressing previous limitations while expanding functionality. Industry analysts predict that by 2025, foldable smartphones could represent 7% of premium smartphone shipments globally.

Beyond smartphones, flexible displays are gaining traction in wearable technology, automotive interfaces, and smart home devices. The wearable segment, including smartwatches and fitness trackers, is experiencing particularly robust growth with a CAGR of 15.2%, as consumers increasingly prioritize health monitoring capabilities and seamless connectivity.

A critical market driver is consumer expectation for device durability. Recent surveys indicate that 78% of potential buyers consider durability as a "very important" factor when purchasing foldable devices. This highlights the commercial significance of addressing crack initiation in UTG, as device failure due to screen damage represents the primary concern among consumers hesitant to adopt flexible display technology.

Enterprise adoption presents another substantial market opportunity. Corporate procurement of foldable devices is projected to grow at 18.3% annually through 2026, with businesses valuing the productivity benefits of larger, flexible screens in portable form factors. However, enterprise adoption remains contingent upon demonstrable device longevity and reliability.

Regional analysis reveals Asia-Pacific as the dominant market for flexible displays, accounting for 43% of global demand, followed by North America (27%) and Europe (21%). China and South Korea lead manufacturing capacity, though significant investments in production facilities are occurring globally as demand intensifies.

The market landscape clearly indicates that solving the technical challenges of crack initiation in UTG would address a critical barrier to wider flexible display adoption. Consumers and enterprise customers alike demonstrate willingness to pay premium prices for flexible display devices, provided manufacturers can guarantee reasonable durability standards and operational lifespans comparable to conventional devices.

Smartphone manufacturers constitute the largest segment of flexible display adopters, accounting for nearly 60% of the total market share. Major players like Samsung, Huawei, and Motorola have launched multiple generations of foldable devices, each iteration addressing previous limitations while expanding functionality. Industry analysts predict that by 2025, foldable smartphones could represent 7% of premium smartphone shipments globally.

Beyond smartphones, flexible displays are gaining traction in wearable technology, automotive interfaces, and smart home devices. The wearable segment, including smartwatches and fitness trackers, is experiencing particularly robust growth with a CAGR of 15.2%, as consumers increasingly prioritize health monitoring capabilities and seamless connectivity.

A critical market driver is consumer expectation for device durability. Recent surveys indicate that 78% of potential buyers consider durability as a "very important" factor when purchasing foldable devices. This highlights the commercial significance of addressing crack initiation in UTG, as device failure due to screen damage represents the primary concern among consumers hesitant to adopt flexible display technology.

Enterprise adoption presents another substantial market opportunity. Corporate procurement of foldable devices is projected to grow at 18.3% annually through 2026, with businesses valuing the productivity benefits of larger, flexible screens in portable form factors. However, enterprise adoption remains contingent upon demonstrable device longevity and reliability.

Regional analysis reveals Asia-Pacific as the dominant market for flexible displays, accounting for 43% of global demand, followed by North America (27%) and Europe (21%). China and South Korea lead manufacturing capacity, though significant investments in production facilities are occurring globally as demand intensifies.

The market landscape clearly indicates that solving the technical challenges of crack initiation in UTG would address a critical barrier to wider flexible display adoption. Consumers and enterprise customers alike demonstrate willingness to pay premium prices for flexible display devices, provided manufacturers can guarantee reasonable durability standards and operational lifespans comparable to conventional devices.

Current Challenges in UTG Durability

Ultra-thin glass (UTG) in flexible displays faces significant durability challenges that impede widespread commercial adoption. The primary concern is crack initiation under various stress conditions, which occurs at much lower thresholds compared to conventional glass due to UTG's reduced thickness (typically below 100 μm). This fundamental vulnerability stems from the inverse relationship between glass thickness and bending stress susceptibility.

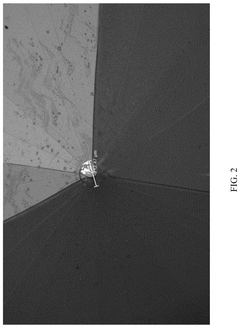

Surface defects represent a critical failure point in UTG applications. Microscopic flaws, including scratches, microcracks, and chemical imperfections introduced during manufacturing, handling, or chemical strengthening processes, serve as stress concentration points. These defects, often invisible to the naked eye, can propagate rapidly under minimal stress, leading to catastrophic failure.

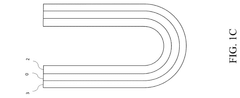

Repeated folding and unfolding actions in flexible display applications create cyclic stress patterns that accelerate fatigue-induced microcrack formation. Current UTG implementations typically demonstrate durability ranging from 100,000 to 200,000 fold cycles before visible damage occurs—insufficient for long-term consumer device reliability where 5+ years of daily use is expected.

Edge finishing quality presents another significant challenge. The glass edges, particularly vulnerable to chipping and microcrack formation, often initiate failures that propagate inward. Current edge strengthening techniques provide inadequate protection against these failure modes, especially when devices experience drop impacts or localized pressure.

Environmental factors substantially impact UTG durability. Temperature fluctuations induce thermal expansion and contraction cycles that create additional stress, while humidity can facilitate stress corrosion cracking through ion exchange at crack tips. These environmental sensitivities are particularly problematic in consumer electronics designed for diverse usage conditions.

The adhesive interface between UTG and other display components introduces complex stress distributions. Current adhesive solutions often create uneven stress patterns during flexing operations, leading to delamination or localized stress concentration. The mechanical property mismatch between UTG and polymer layers further complicates this challenge.

Testing methodologies for UTG durability remain inconsistent across the industry. The lack of standardized testing protocols makes comparative analysis difficult and hampers the development of reliable predictive models for failure. Current accelerated aging tests frequently fail to accurately simulate real-world usage patterns, leading to unexpected field failures despite laboratory validation.

Surface defects represent a critical failure point in UTG applications. Microscopic flaws, including scratches, microcracks, and chemical imperfections introduced during manufacturing, handling, or chemical strengthening processes, serve as stress concentration points. These defects, often invisible to the naked eye, can propagate rapidly under minimal stress, leading to catastrophic failure.

Repeated folding and unfolding actions in flexible display applications create cyclic stress patterns that accelerate fatigue-induced microcrack formation. Current UTG implementations typically demonstrate durability ranging from 100,000 to 200,000 fold cycles before visible damage occurs—insufficient for long-term consumer device reliability where 5+ years of daily use is expected.

Edge finishing quality presents another significant challenge. The glass edges, particularly vulnerable to chipping and microcrack formation, often initiate failures that propagate inward. Current edge strengthening techniques provide inadequate protection against these failure modes, especially when devices experience drop impacts or localized pressure.

Environmental factors substantially impact UTG durability. Temperature fluctuations induce thermal expansion and contraction cycles that create additional stress, while humidity can facilitate stress corrosion cracking through ion exchange at crack tips. These environmental sensitivities are particularly problematic in consumer electronics designed for diverse usage conditions.

The adhesive interface between UTG and other display components introduces complex stress distributions. Current adhesive solutions often create uneven stress patterns during flexing operations, leading to delamination or localized stress concentration. The mechanical property mismatch between UTG and polymer layers further complicates this challenge.

Testing methodologies for UTG durability remain inconsistent across the industry. The lack of standardized testing protocols makes comparative analysis difficult and hampers the development of reliable predictive models for failure. Current accelerated aging tests frequently fail to accurately simulate real-world usage patterns, leading to unexpected field failures despite laboratory validation.

Current Failure Analysis Methodologies

01 Structural reinforcement techniques for UTG

Various structural reinforcement techniques can be applied to ultra-thin glass to prevent crack initiation. These include adding reinforcement layers, using protective films, implementing buffer structures, and designing special support frames. These techniques distribute stress more evenly across the glass surface, reducing the likelihood of crack formation at stress concentration points. Reinforcement materials may include polymer layers, metal frames, or composite structures that enhance the mechanical stability of the UTG.- Structural reinforcement techniques for UTG: Various structural reinforcement techniques can be applied to ultra-thin glass to prevent crack initiation. These include adding reinforcement layers, using protective films, implementing buffer structures, and designing special frame supports that distribute stress more evenly. These structural modifications help absorb impact energy and prevent stress concentration that leads to crack formation in the delicate UTG material.

- Surface treatment methods to enhance UTG durability: Surface treatment methods can significantly improve the resistance of ultra-thin glass to crack initiation. These include chemical strengthening processes, ion exchange treatments, surface polishing techniques, and application of specialized coatings. These treatments modify the surface properties of UTG to increase hardness, reduce surface flaws, and create compressive stress layers that inhibit crack formation and propagation.

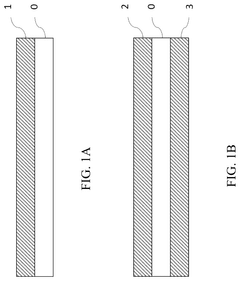

- Composite UTG structures with crack-resistant properties: Composite structures incorporating ultra-thin glass with other materials can effectively prevent crack initiation. These include UTG laminates with polymer interlayers, hybrid glass-polymer composites, and multi-layer structures with varying mechanical properties. The composite approach allows for the combination of the optical clarity of glass with the flexibility and crack resistance of polymers or other materials.

- Manufacturing processes to minimize UTG defects: Specialized manufacturing processes can reduce the likelihood of crack initiation in ultra-thin glass by minimizing defects. These include optimized drawing and thinning techniques, controlled cooling processes, defect detection systems, and edge processing methods. By reducing microscopic flaws during production, these processes create UTG with fewer stress concentration points that could lead to crack formation.

- Stress distribution and management in UTG applications: Effective stress distribution and management techniques can prevent crack initiation in ultra-thin glass used in electronic devices. These include specialized mounting structures, flexible adhesives, stress-absorbing components, and strategic placement of support points. These approaches help manage the mechanical stresses that occur during device assembly and use, reducing the likelihood of crack formation in the UTG.

02 Surface treatment methods to enhance UTG durability

Surface treatment methods can significantly improve the resistance of ultra-thin glass to crack initiation. These treatments include chemical strengthening processes, ion exchange techniques, surface coating applications, and micro-texture modifications. By altering the surface properties of the glass, these methods create compressive stress layers that inhibit crack formation and propagation. Surface treatments can also reduce friction and improve impact resistance, further protecting the UTG from damage during use.Expand Specific Solutions03 Stress management and distribution systems

Specialized stress management systems are designed to control and distribute mechanical stresses in ultra-thin glass applications. These systems include flexible mounting mechanisms, stress-absorbing adhesives, and dynamic support structures that can accommodate bending and folding operations. By effectively managing stress distribution, these systems prevent localized stress concentrations that typically lead to crack initiation. Advanced computational modeling is often used to optimize these stress management systems for specific UTG applications.Expand Specific Solutions04 Edge processing and protection techniques

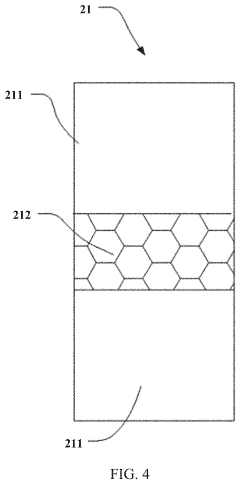

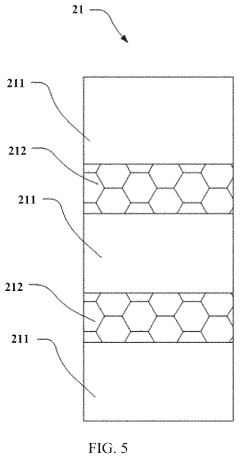

Edge processing and protection techniques focus on the vulnerable edges of ultra-thin glass where cracks often initiate. These techniques include precision edge grinding, laser edge treatment, edge sealing methods, and protective edge structures. Since glass edges typically contain microscopic flaws that can serve as crack initiation sites, proper edge processing is crucial for enhancing UTG durability. Edge protection may also involve special bezel designs or flexible edge covers that shield the glass edges from impact and stress.Expand Specific Solutions05 Composite and laminated UTG structures

Composite and laminated structures incorporate multiple layers of materials with ultra-thin glass to prevent crack initiation and propagation. These structures may include polymer interlayers, functional adhesives, secondary glass layers, or hybrid glass-polymer compositions. The additional layers not only provide mechanical support but also act as crack-stopping mechanisms. When a crack begins to form in the glass, the interlayers prevent it from propagating through the entire structure, thereby maintaining the integrity of the display or device even when the glass is damaged.Expand Specific Solutions

Key Industry Players in UTG Manufacturing

The ultra-thin glass (UTG) market for flexible displays is currently in a growth phase, with increasing adoption in foldable smartphones and wearable devices. The market size is expanding rapidly, projected to reach significant value as demand for flexible display technologies rises. Technologically, UTG remains challenging with crack initiation being a critical concern. Leading players like Samsung Display, BOE Technology, and Corning are at the forefront of innovation, with Samsung having the most mature commercial implementations. Chinese manufacturers including CSOT and Triumph Science & Technology are rapidly advancing their capabilities. Companies like Schott Glass and Dongxu Technology are focusing on specialized UTG solutions to address durability issues. The competitive landscape shows established display manufacturers collaborating with specialized glass producers to overcome technical barriers in crack prevention and manufacturing yield.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive UTG solution for flexible displays that addresses crack initiation through innovative material engineering and structural design. Their approach utilizes a specialized glass composition with optimized chemical strengthening parameters to create a more flexible yet durable UTG substrate. BOE's technology incorporates a gradient stress profile within the glass, with maximum compressive stress at the surfaces where cracks typically initiate. They've implemented a proprietary edge treatment process that eliminates microcracks and stress concentrations along cut edges - a primary failure point in UTG applications. Their manufacturing process includes precision thickness control systems that maintain uniformity within ±2μm across the entire display area, preventing stress concentration at thinner regions. BOE has developed a multi-layer composite structure where the UTG is supported by specially formulated polymer layers that absorb and redistribute mechanical stresses during folding operations. For root cause analysis, they employ advanced optical metrology combined with finite element analysis to identify potential failure points before they manifest as visible cracks. Their testing methodology includes accelerated life testing under various environmental conditions to identify failure modes that might emerge over extended use.

Strengths: Strong vertical integration capabilities allowing for customized UTG solutions optimized for specific device designs and use cases. Their approach effectively addresses edge-related failures through specialized processing techniques. Weaknesses: Less commercial deployment experience compared to some competitors, and their solutions may face challenges with extremely tight folding radii required for some next-generation device concepts.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an integrated approach to UTG failure prevention in their flexible displays. Their technology combines a specially formulated UTG with thickness optimization (typically 30μm) and a polymer-based protective layer system. Samsung's solution addresses crack initiation through a multi-faceted approach: they utilize a specialized heat treatment process that relieves internal stresses in the glass, reducing susceptibility to fracture. Their manufacturing process incorporates precision laser cutting techniques that minimize edge defects - a primary source of crack initiation. Samsung has implemented an advanced stress distribution system within their display stack, using carefully designed buffer layers that absorb and redistribute mechanical stresses during folding operations. Their UTG is integrated with a proprietary polymer coating that not only protects the glass surface but also enhances flexibility. For root cause analysis, Samsung employs in-situ mechanical testing combined with high-resolution optical monitoring to identify failure modes in real-time, allowing them to continuously refine their UTG implementation and folding mechanism designs to minimize stress concentrations at critical points.

Strengths: Comprehensive integration of UTG into commercial products with proven durability in real-world applications. Their solution balances flexibility and durability through careful material engineering and structural design. Weaknesses: Their approach still faces challenges with ultra-tight folding radii and may require thickness compromises that affect overall device dimensions.

Critical Stress Mechanisms in UTG

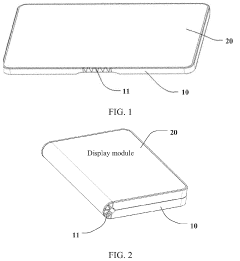

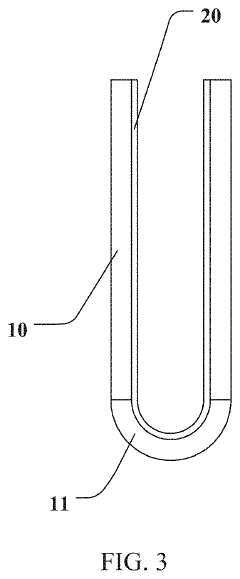

Flexible Display Cover, Flexible Display Module, And Flexible Display Apparatus

PatentActiveUS20220118744A1

Innovation

- A flexible display cover comprising a glass layer with a hardened layer and a flexible protective layer, where the glass layer is chemically strengthened and coated with a hardened material to enhance scratch and impact resistance, and an anti-shatter layer is optionally included to prevent glass fragmentation.

Foldable ultrathin glass with transparent, impact-resistant hard coating

PatentActiveUS12116308B2

Innovation

- A single-layer hard coating composed of silsesquioxane with a silicon-oxygen core framework directly bonded to the ultrathin tempered glass substrate, providing a surface hardness of at least 7H, hydrophobic properties, and improved impact resistance without the need for an adhesive layer, achieved through chemical tempering and specific molecular weight ranges of the silsesquioxane.

Material Science Advancements for UTG

Recent advancements in material science have significantly propelled the development of Ultra-Thin Glass (UTG) for flexible display applications. The evolution of UTG has been marked by breakthroughs in glass composition, with manufacturers developing specialized formulations that enhance flexibility while maintaining structural integrity. These compositions typically incorporate modified aluminosilicate structures with optimized ion exchange properties, allowing for improved stress distribution during bending cycles.

Surface treatment technologies have emerged as a critical area of advancement, with innovations in chemical strengthening processes that create compressive stress layers without compromising flexibility. The development of nano-scale surface coatings has provided additional protection against micro-fractures while maintaining optical clarity, addressing one of the primary failure modes in UTG applications.

Manufacturing processes have undergone substantial refinement, with precision drawing techniques now capable of producing glass sheets with thicknesses below 30 micrometers while maintaining uniform properties. Advanced annealing protocols have been implemented to minimize residual stresses that could serve as crack initiation points under mechanical strain. These processes represent significant improvements over earlier generations of UTG production methods.

Hybrid material systems combining UTG with polymer layers have shown promising results in crack mitigation. These composite structures distribute mechanical stresses more effectively across the material interface, preventing localized stress concentrations that typically lead to crack initiation. Research indicates that carefully engineered adhesive layers between glass and polymer components can absorb impact energy and reduce crack propagation rates.

Characterization techniques have evolved to enable more precise analysis of UTG properties and failure mechanisms. Advanced imaging methods such as atomic force microscopy and high-resolution transmission electron microscopy now allow researchers to visualize nanoscale defects that serve as crack initiation sites. In-situ mechanical testing under controlled environmental conditions has provided valuable insights into the relationship between material composition and failure thresholds.

Computational modeling approaches have become increasingly sophisticated, enabling accurate prediction of crack initiation conditions based on material properties and stress distributions. Finite element analysis incorporating multi-scale modeling techniques has proven particularly valuable for optimizing UTG designs before physical prototyping, reducing development cycles and improving reliability outcomes in final products.

Surface treatment technologies have emerged as a critical area of advancement, with innovations in chemical strengthening processes that create compressive stress layers without compromising flexibility. The development of nano-scale surface coatings has provided additional protection against micro-fractures while maintaining optical clarity, addressing one of the primary failure modes in UTG applications.

Manufacturing processes have undergone substantial refinement, with precision drawing techniques now capable of producing glass sheets with thicknesses below 30 micrometers while maintaining uniform properties. Advanced annealing protocols have been implemented to minimize residual stresses that could serve as crack initiation points under mechanical strain. These processes represent significant improvements over earlier generations of UTG production methods.

Hybrid material systems combining UTG with polymer layers have shown promising results in crack mitigation. These composite structures distribute mechanical stresses more effectively across the material interface, preventing localized stress concentrations that typically lead to crack initiation. Research indicates that carefully engineered adhesive layers between glass and polymer components can absorb impact energy and reduce crack propagation rates.

Characterization techniques have evolved to enable more precise analysis of UTG properties and failure mechanisms. Advanced imaging methods such as atomic force microscopy and high-resolution transmission electron microscopy now allow researchers to visualize nanoscale defects that serve as crack initiation sites. In-situ mechanical testing under controlled environmental conditions has provided valuable insights into the relationship between material composition and failure thresholds.

Computational modeling approaches have become increasingly sophisticated, enabling accurate prediction of crack initiation conditions based on material properties and stress distributions. Finite element analysis incorporating multi-scale modeling techniques has proven particularly valuable for optimizing UTG designs before physical prototyping, reducing development cycles and improving reliability outcomes in final products.

Quality Control Standards for Flexible Displays

Quality control standards for flexible displays utilizing Ultra-Thin Glass (UTG) require comprehensive frameworks that address the unique challenges of this emerging technology. The inherent fragility of UTG, typically measuring less than 100 micrometers in thickness, necessitates stringent quality control protocols throughout the manufacturing process to prevent crack initiation and propagation.

Industry standards such as IEC 62715-6-1 and ASTM F3212 have established baseline requirements for flexible display durability, but UTG-specific standards are still evolving. These standards must address mechanical stress tolerance, bend radius limitations, and impact resistance parameters that differ significantly from traditional rigid display technologies.

Manufacturing quality control for UTG begins with raw material inspection, where glass composition homogeneity and surface defect detection are critical. Advanced optical inspection systems utilizing high-resolution cameras and laser scanning technology can detect microscopic flaws as small as 1-3 micrometers that could serve as crack initiation points under stress.

In-process quality control measures include real-time monitoring of temperature gradients during glass formation, as thermal stress is a primary contributor to microcrack development. Statistical Process Control (SPC) methodologies have been adapted specifically for UTG production, with control limits set significantly tighter than those for conventional glass manufacturing.

Post-production testing protocols for UTG-based flexible displays include cyclic bend testing (typically 100,000-200,000 cycles), micro-indentation hardness testing, and environmental stress screening. These tests must simulate real-world usage conditions while providing quantifiable data on structural integrity and failure thresholds.

Non-destructive testing methods have gained prominence in UTG quality assurance, with techniques such as digital holography, ultrasonic microscopy, and terahertz imaging enabling subsurface defect detection without compromising the glass structure. These methods can identify internal stress concentrations that traditional visual inspection might miss.

Traceability systems for UTG components have become essential quality control tools, allowing manufacturers to correlate field failures with specific production batches and process parameters. This data-driven approach facilitates continuous improvement in manufacturing processes and early identification of systematic failure modes.

Certification requirements for UTG-based flexible displays now include specialized drop testing protocols, temperature cycling tests, and humidity resistance verification that exceed traditional display standards. These enhanced requirements reflect the unique environmental sensitivities of ultra-thin glass structures in dynamic applications.

Industry standards such as IEC 62715-6-1 and ASTM F3212 have established baseline requirements for flexible display durability, but UTG-specific standards are still evolving. These standards must address mechanical stress tolerance, bend radius limitations, and impact resistance parameters that differ significantly from traditional rigid display technologies.

Manufacturing quality control for UTG begins with raw material inspection, where glass composition homogeneity and surface defect detection are critical. Advanced optical inspection systems utilizing high-resolution cameras and laser scanning technology can detect microscopic flaws as small as 1-3 micrometers that could serve as crack initiation points under stress.

In-process quality control measures include real-time monitoring of temperature gradients during glass formation, as thermal stress is a primary contributor to microcrack development. Statistical Process Control (SPC) methodologies have been adapted specifically for UTG production, with control limits set significantly tighter than those for conventional glass manufacturing.

Post-production testing protocols for UTG-based flexible displays include cyclic bend testing (typically 100,000-200,000 cycles), micro-indentation hardness testing, and environmental stress screening. These tests must simulate real-world usage conditions while providing quantifiable data on structural integrity and failure thresholds.

Non-destructive testing methods have gained prominence in UTG quality assurance, with techniques such as digital holography, ultrasonic microscopy, and terahertz imaging enabling subsurface defect detection without compromising the glass structure. These methods can identify internal stress concentrations that traditional visual inspection might miss.

Traceability systems for UTG components have become essential quality control tools, allowing manufacturers to correlate field failures with specific production batches and process parameters. This data-driven approach facilitates continuous improvement in manufacturing processes and early identification of systematic failure modes.

Certification requirements for UTG-based flexible displays now include specialized drop testing protocols, temperature cycling tests, and humidity resistance verification that exceed traditional display standards. These enhanced requirements reflect the unique environmental sensitivities of ultra-thin glass structures in dynamic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!