Environmental Stability Tests For Humidity And Temperature On Ultra-Thin Glass (UTG) In Flexible Displays

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UTG Technology Background and Objectives

Ultra-Thin Glass (UTG) technology represents a significant breakthrough in the evolution of flexible display technologies. Originating from traditional glass manufacturing processes, UTG has undergone substantial refinement over the past decade to achieve thicknesses below 100 micrometers while maintaining essential glass properties. This remarkable advancement has positioned UTG as a critical component in next-generation flexible and foldable display devices, offering superior optical clarity, scratch resistance, and touch sensitivity compared to polymer alternatives.

The development trajectory of UTG has been characterized by progressive improvements in manufacturing techniques, particularly in areas of chemical strengthening, precision thinning processes, and handling methodologies for extremely thin substrates. Early iterations faced significant challenges in achieving consistent production quality at scale, but recent technological breakthroughs have enabled commercial viability across multiple display applications.

Current market trends indicate an accelerating shift toward flexible display technologies in consumer electronics, automotive interfaces, and wearable devices. This transition is driving unprecedented demand for UTG solutions that can withstand the mechanical stresses of repeated folding while maintaining optical and structural integrity over extended product lifecycles.

The primary technical objective for UTG development centers on environmental stability—specifically, understanding and enhancing performance under varying humidity and temperature conditions. Unlike rigid display components, flexible UTG must maintain its properties while experiencing dimensional changes, thermal expansion, and potential moisture ingress at fold points and edges. These challenges are particularly acute in consumer applications where devices may be exposed to extreme environmental conditions.

Research objectives in this domain focus on establishing standardized testing protocols that accurately predict real-world performance, identifying failure mechanisms under combined humidity and temperature stress, and developing mitigation strategies through material composition adjustments or protective layer innovations. Additionally, there is significant interest in understanding the long-term aging effects of environmental exposure on UTG mechanical properties.

The technology aims to achieve reliable performance across operating temperatures from -40°C to 85°C and relative humidity levels from 10% to 95%, while maintaining optical transparency above 90% and bend radius capabilities below 3mm. Meeting these targets would represent a substantial advancement over current flexible display solutions and enable new form factors previously unattainable in consumer electronics.

As UTG technology continues to mature, interdisciplinary collaboration between materials science, mechanical engineering, and manufacturing process optimization will be essential to overcome remaining technical barriers and establish UTG as the dominant solution for next-generation flexible display applications.

The development trajectory of UTG has been characterized by progressive improvements in manufacturing techniques, particularly in areas of chemical strengthening, precision thinning processes, and handling methodologies for extremely thin substrates. Early iterations faced significant challenges in achieving consistent production quality at scale, but recent technological breakthroughs have enabled commercial viability across multiple display applications.

Current market trends indicate an accelerating shift toward flexible display technologies in consumer electronics, automotive interfaces, and wearable devices. This transition is driving unprecedented demand for UTG solutions that can withstand the mechanical stresses of repeated folding while maintaining optical and structural integrity over extended product lifecycles.

The primary technical objective for UTG development centers on environmental stability—specifically, understanding and enhancing performance under varying humidity and temperature conditions. Unlike rigid display components, flexible UTG must maintain its properties while experiencing dimensional changes, thermal expansion, and potential moisture ingress at fold points and edges. These challenges are particularly acute in consumer applications where devices may be exposed to extreme environmental conditions.

Research objectives in this domain focus on establishing standardized testing protocols that accurately predict real-world performance, identifying failure mechanisms under combined humidity and temperature stress, and developing mitigation strategies through material composition adjustments or protective layer innovations. Additionally, there is significant interest in understanding the long-term aging effects of environmental exposure on UTG mechanical properties.

The technology aims to achieve reliable performance across operating temperatures from -40°C to 85°C and relative humidity levels from 10% to 95%, while maintaining optical transparency above 90% and bend radius capabilities below 3mm. Meeting these targets would represent a substantial advancement over current flexible display solutions and enable new form factors previously unattainable in consumer electronics.

As UTG technology continues to mature, interdisciplinary collaboration between materials science, mechanical engineering, and manufacturing process optimization will be essential to overcome remaining technical barriers and establish UTG as the dominant solution for next-generation flexible display applications.

Market Demand Analysis for Flexible Display Solutions

The flexible display market has witnessed exponential growth in recent years, driven primarily by consumer electronics applications. Market research indicates that the global flexible display market is projected to reach $42.85 billion by 2027, growing at a CAGR of 28.1% from 2020 to 2027. This remarkable growth trajectory underscores the increasing demand for flexible display solutions across various industries.

Smartphone manufacturers represent the largest consumer segment for flexible displays, with foldable phones emerging as a premium product category. Samsung's Galaxy Z Fold and Z Flip series, Motorola's Razr, and Huawei's Mate X have demonstrated strong consumer interest despite their premium pricing. Industry analysts report that shipments of foldable smartphones increased by 264% in 2021 compared to the previous year, with over 7.1 million units sold globally.

Beyond smartphones, wearable technology constitutes another significant market segment for flexible displays. Smartwatches, fitness trackers, and emerging form factors like smart clothing and accessories benefit from the conformable nature of flexible displays. The wearable technology market is expected to surpass $81.5 billion by 2025, with flexible displays playing a crucial role in this expansion.

Automotive applications represent an emerging high-value market for flexible displays. Premium vehicle manufacturers are increasingly incorporating curved and flexible displays in dashboards, center consoles, and entertainment systems. This segment is projected to grow at a CAGR of 24.3% through 2026, as automakers differentiate their offerings through advanced display technologies.

Consumer demand for flexible displays is driven by several key factors. Durability ranks as a primary concern, with 78% of potential buyers citing device longevity as a critical purchasing factor. This highlights the importance of environmental stability testing for UTG in flexible displays, particularly regarding humidity and temperature resistance.

Form factor innovation represents another significant demand driver, with 67% of consumers expressing interest in devices that can transform between different configurations. The ability of UTG to enable reliable folding mechanisms while maintaining display integrity directly addresses this market need.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display technologies, accounting for approximately 61% of global demand. North America follows at 22%, with Europe representing 14% of the market. Emerging economies in Southeast Asia and Latin America are expected to drive the next wave of growth as manufacturing costs decrease and technology adoption accelerates.

Smartphone manufacturers represent the largest consumer segment for flexible displays, with foldable phones emerging as a premium product category. Samsung's Galaxy Z Fold and Z Flip series, Motorola's Razr, and Huawei's Mate X have demonstrated strong consumer interest despite their premium pricing. Industry analysts report that shipments of foldable smartphones increased by 264% in 2021 compared to the previous year, with over 7.1 million units sold globally.

Beyond smartphones, wearable technology constitutes another significant market segment for flexible displays. Smartwatches, fitness trackers, and emerging form factors like smart clothing and accessories benefit from the conformable nature of flexible displays. The wearable technology market is expected to surpass $81.5 billion by 2025, with flexible displays playing a crucial role in this expansion.

Automotive applications represent an emerging high-value market for flexible displays. Premium vehicle manufacturers are increasingly incorporating curved and flexible displays in dashboards, center consoles, and entertainment systems. This segment is projected to grow at a CAGR of 24.3% through 2026, as automakers differentiate their offerings through advanced display technologies.

Consumer demand for flexible displays is driven by several key factors. Durability ranks as a primary concern, with 78% of potential buyers citing device longevity as a critical purchasing factor. This highlights the importance of environmental stability testing for UTG in flexible displays, particularly regarding humidity and temperature resistance.

Form factor innovation represents another significant demand driver, with 67% of consumers expressing interest in devices that can transform between different configurations. The ability of UTG to enable reliable folding mechanisms while maintaining display integrity directly addresses this market need.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display technologies, accounting for approximately 61% of global demand. North America follows at 22%, with Europe representing 14% of the market. Emerging economies in Southeast Asia and Latin America are expected to drive the next wave of growth as manufacturing costs decrease and technology adoption accelerates.

Current UTG Environmental Stability Challenges

Ultra-Thin Glass (UTG) in flexible displays faces significant environmental stability challenges that impact its performance and longevity. The primary concern is UTG's susceptibility to humidity-induced degradation, where moisture penetration can lead to delamination between glass layers and supporting films. This issue becomes particularly pronounced in high humidity environments (>70% RH), causing optical clarity reduction and potentially compromising the structural integrity of the display.

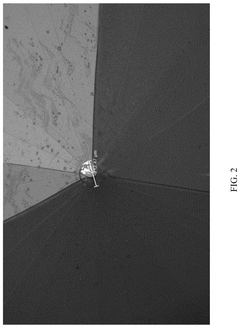

Temperature fluctuations present another critical challenge, as UTG exhibits different thermal expansion coefficients compared to other display components. Rapid temperature changes can induce mechanical stress at material interfaces, leading to microcracks that may not be immediately visible but propagate over time. Testing has shown that temperature cycling between -20°C and 60°C can accelerate these failure mechanisms, particularly at the folding areas of flexible displays.

The combined effects of humidity and temperature create particularly challenging conditions for UTG stability. Under simultaneous high humidity and temperature conditions (85% RH/85°C), accelerated aging tests reveal that UTG can experience significant degradation in optical properties within 500-1000 hours of exposure. The moisture-temperature interaction catalyzes chemical reactions at interface layers, potentially compromising the adhesion between UTG and functional films.

Current testing methodologies for UTG environmental stability face limitations in accurately predicting real-world performance. Standard ASTM and IEC test protocols designed for conventional display glass often fail to address the unique mechanical stresses present in flexible applications. The industry lacks standardized testing procedures specifically designed for folding and rolling scenarios under varying environmental conditions.

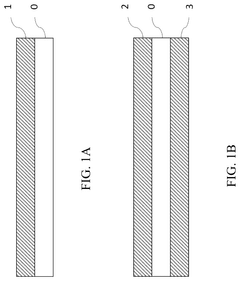

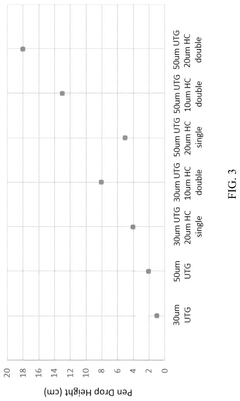

Thickness variations in UTG production (typically ranging from 30μm to 100μm) create inconsistent environmental response profiles, complicating quality control and reliability predictions. Thinner UTG variants show greater susceptibility to humidity penetration, while exhibiting different stress patterns under temperature fluctuations compared to thicker variants.

Surface treatment technologies intended to enhance UTG's environmental resistance present their own challenges. Hydrophobic coatings can reduce moisture ingress but may degrade under repeated mechanical stress at folding points. Meanwhile, strengthening treatments like ion exchange processes must be carefully calibrated to avoid introducing new stress points that could become failure initiation sites under environmental loading.

The integration of UTG with polarizer films and touch sensors introduces additional interface regions vulnerable to environmental degradation. These multi-material boundaries create potential pathways for moisture ingress and sites for delamination under thermal stress, requiring comprehensive testing approaches that evaluate the entire display stack rather than UTG in isolation.

Temperature fluctuations present another critical challenge, as UTG exhibits different thermal expansion coefficients compared to other display components. Rapid temperature changes can induce mechanical stress at material interfaces, leading to microcracks that may not be immediately visible but propagate over time. Testing has shown that temperature cycling between -20°C and 60°C can accelerate these failure mechanisms, particularly at the folding areas of flexible displays.

The combined effects of humidity and temperature create particularly challenging conditions for UTG stability. Under simultaneous high humidity and temperature conditions (85% RH/85°C), accelerated aging tests reveal that UTG can experience significant degradation in optical properties within 500-1000 hours of exposure. The moisture-temperature interaction catalyzes chemical reactions at interface layers, potentially compromising the adhesion between UTG and functional films.

Current testing methodologies for UTG environmental stability face limitations in accurately predicting real-world performance. Standard ASTM and IEC test protocols designed for conventional display glass often fail to address the unique mechanical stresses present in flexible applications. The industry lacks standardized testing procedures specifically designed for folding and rolling scenarios under varying environmental conditions.

Thickness variations in UTG production (typically ranging from 30μm to 100μm) create inconsistent environmental response profiles, complicating quality control and reliability predictions. Thinner UTG variants show greater susceptibility to humidity penetration, while exhibiting different stress patterns under temperature fluctuations compared to thicker variants.

Surface treatment technologies intended to enhance UTG's environmental resistance present their own challenges. Hydrophobic coatings can reduce moisture ingress but may degrade under repeated mechanical stress at folding points. Meanwhile, strengthening treatments like ion exchange processes must be carefully calibrated to avoid introducing new stress points that could become failure initiation sites under environmental loading.

The integration of UTG with polarizer films and touch sensors introduces additional interface regions vulnerable to environmental degradation. These multi-material boundaries create potential pathways for moisture ingress and sites for delamination under thermal stress, requiring comprehensive testing approaches that evaluate the entire display stack rather than UTG in isolation.

Current Testing Methodologies for UTG Environmental Stability

01 Protective coating solutions for UTG

Various protective coatings can be applied to ultra-thin glass to enhance its environmental stability. These coatings include polymer layers, hard coatings, and multi-layer structures that protect the glass surface from scratches, impacts, and environmental factors such as moisture and temperature fluctuations. These protective layers significantly improve the durability of UTG while maintaining its flexibility and optical properties.- Protective coating technologies for UTG: Various protective coating technologies are employed to enhance the environmental stability of ultra-thin glass. These coatings serve as barriers against moisture, chemicals, and physical damage, thereby extending the lifespan of UTG in various applications. The protective layers can be made from materials such as metal oxides, polymers, or composite structures that adhere well to glass surfaces while maintaining optical transparency. These coatings significantly improve the resistance of UTG to environmental factors without compromising its flexibility or optical properties.

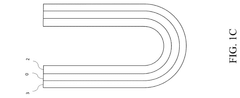

- Moisture resistance enhancement methods: Specific techniques are developed to improve the moisture resistance of ultra-thin glass, which is critical for its environmental stability. These methods include specialized edge sealing technologies, hydrophobic surface treatments, and multi-layer barrier structures that prevent water vapor penetration. By controlling the glass composition and incorporating moisture-repelling additives during manufacturing, the hygroscopic properties of UTG can be significantly reduced. These enhancements are particularly important for flexible display applications where moisture ingress can lead to delamination and optical degradation over time.

- Thermal stability and stress management: Managing thermal stability and mechanical stress is essential for maintaining the environmental durability of ultra-thin glass. Various approaches include specialized annealing processes, stress-relieving interlayers, and thermal expansion matching with adjacent materials. Advanced tempering techniques specifically adapted for ultra-thin glass help distribute thermal stresses more evenly across the material. Additionally, engineered buffer layers can absorb differential expansion between the glass and other components in multilayer structures, preventing warping or cracking when exposed to temperature fluctuations in various environments.

- Chemical resistance improvement techniques: Techniques to enhance the chemical resistance of ultra-thin glass focus on protecting it from acids, alkalis, and other corrosive substances. These include specialized surface treatments, ion exchange processes to strengthen the glass surface, and chemical-resistant barrier layers. Modified glass compositions with increased proportions of stabilizing oxides can significantly improve resistance to chemical attack. Additionally, nano-coatings can be applied to create chemically inert surfaces while maintaining the optical clarity and flexibility that make UTG valuable for advanced display and electronic applications.

- Structural reinforcement for environmental durability: Structural reinforcement strategies are implemented to improve the overall environmental durability of ultra-thin glass. These include lamination with polymer interlayers, composite structures with supporting materials, and specialized edge strengthening techniques. Micro-structural modifications at the glass surface can create compressive stress layers that enhance resistance to environmental factors. Some approaches incorporate flexible supporting substrates that work synergistically with the glass to maintain structural integrity under environmental stresses while preserving the advantageous properties of UTG such as optical clarity and touch sensitivity.

02 Composition modifications for enhanced stability

The chemical composition of ultra-thin glass can be modified to improve its environmental stability. By incorporating specific elements or compounds such as alumina, boron oxide, or alkaline earth metals into the glass formulation, manufacturers can create UTG with superior resistance to chemical corrosion, thermal shock, and mechanical stress. These composition modifications help maintain the structural integrity of the glass under various environmental conditions.Expand Specific Solutions03 Lamination and encapsulation techniques

Lamination and encapsulation methods are employed to protect ultra-thin glass from environmental factors. By sandwiching UTG between protective polymer layers or encapsulating it within specialized materials, the glass is shielded from moisture, oxygen, and mechanical damage. These techniques often involve adhesives with specific properties that accommodate the flexibility of UTG while providing a hermetic seal against environmental contaminants.Expand Specific Solutions04 Surface treatment processes for UTG

Various surface treatment processes can be applied to ultra-thin glass to enhance its environmental stability. These include ion exchange strengthening, chemical etching, plasma treatment, and surface functionalization. Such treatments modify the surface properties of UTG to improve its resistance to scratches, fingerprints, and chemical attack, while also potentially enhancing its hydrophobic or oleophobic characteristics.Expand Specific Solutions05 Testing and evaluation methods for UTG stability

Specialized testing and evaluation methods have been developed to assess the environmental stability of ultra-thin glass. These include accelerated aging tests, thermal cycling, humidity exposure, chemical resistance testing, and mechanical stress evaluations. Such testing protocols help manufacturers understand how UTG will perform under various environmental conditions and over extended periods, enabling the development of more stable and reliable ultra-thin glass products.Expand Specific Solutions

Key Industry Players in Flexible Display Technology

The environmental stability testing market for Ultra-Thin Glass (UTG) in flexible displays is currently in a growth phase, driven by increasing adoption of foldable devices. The global market size for flexible display components is expanding rapidly, expected to reach significant volumes as major manufacturers integrate UTG solutions. Technologically, UTG testing capabilities vary across key players, with Samsung Display and Corning leading innovation through advanced humidity and temperature testing protocols. Companies like SCHOTT Glass, Dongxu Technology, and Triumph Science & Technology are developing competitive solutions, while Huawei and OPPO are actively implementing UTG in consumer products. The ecosystem shows a balance between established glass manufacturers and electronics companies collaborating to improve UTG durability against environmental stressors.

SCHOTT Glass Technologies (Suzhou) Co. Ltd.

Technical Solution: SCHOTT has developed an advanced environmental stability testing framework for their ultra-thin glass solutions used in flexible displays. Their approach centers on their proprietary "Xensation Flex" UTG technology, which undergoes rigorous environmental chamber testing across extreme temperature ranges (-40°C to 105°C) and humidity conditions (up to 98% RH). SCHOTT employs specialized ion-exchange strengthening processes optimized for ultra-thin substrates, creating a compressed surface layer that enhances both mechanical and environmental durability. Their testing methodology includes continuous monitoring of optical properties during environmental cycling, with automated systems measuring transmission, haze, and color shift at microsecond intervals. SCHOTT has developed specialized edge treatment technologies that significantly reduce moisture ingress at the glass boundaries - typically the most vulnerable areas for environmental degradation. Their data indicates their UTG maintains structural integrity after 500 hours of 85°C/85% RH exposure while maintaining flexibility for radii down to 2mm.

Strengths: Decades of specialized glass manufacturing expertise; advanced materials science capabilities allowing for custom glass compositions optimized for flexibility and environmental resistance. Weaknesses: Less direct consumer device integration experience compared to display manufacturers; requires partnerships for full implementation in commercial products.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has pioneered a multi-layered environmental stability testing approach for their UTG implementation in flexible displays. Their system employs specialized environmental chambers capable of rapid thermal cycling (-20°C to 60°C) while maintaining precise humidity control (20-95% RH), allowing for accelerated testing of UTG durability. Samsung's methodology includes proprietary "stress-while-testing" protocols where the UTG undergoes continuous folding operations (up to 200,000 cycles) inside controlled environmental chambers to simulate real-world usage conditions. Their testing incorporates high-precision optical measurement tools that detect micro-fractures and haze development with resolution down to 0.1%. Samsung has developed composite UTG structures with specialized interlayers that significantly improve moisture resistance while maintaining flexibility, achieving a 40% improvement in humidity resistance compared to first-generation UTG implementations while reducing thickness to under 30 micrometers.

Strengths: Vertical integration allowing for comprehensive testing from glass development through final device implementation; extensive real-world data from commercial deployments informing test protocols. Weaknesses: Proprietary testing methodologies make cross-industry comparisons difficult; current solutions still require polymer protective layers that can degrade under extreme conditions.

Critical Patents and Research on UTG Environmental Resistance

Foldable ultrathin glass with transparent, impact-resistant hard coating

PatentActiveUS12116308B2

Innovation

- A single-layer hard coating composed of silsesquioxane with a silicon-oxygen core framework directly bonded to the ultrathin tempered glass substrate, providing a surface hardness of at least 7H, hydrophobic properties, and improved impact resistance without the need for an adhesive layer, achieved through chemical tempering and specific molecular weight ranges of the silsesquioxane.

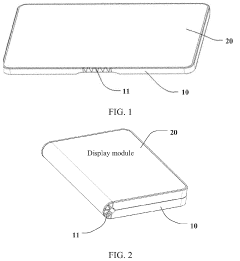

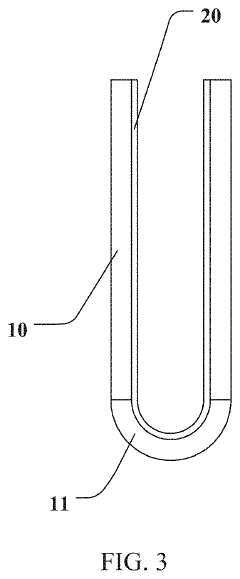

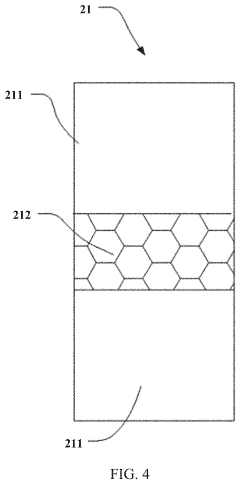

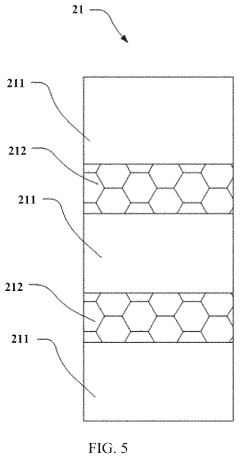

Flexible Display Cover, Flexible Display Module, And Flexible Display Apparatus

PatentActiveUS20220118744A1

Innovation

- A flexible display cover comprising a glass layer with a hardened layer and a flexible protective layer, where the glass layer is chemically strengthened and coated with a hardened material to enhance scratch and impact resistance, and an anti-shatter layer is optionally included to prevent glass fragmentation.

Material Science Advancements for Enhanced UTG Durability

Recent advancements in material science have significantly contributed to enhancing the durability of Ultra-Thin Glass (UTG) in flexible displays. The evolution of UTG composition has been marked by the incorporation of strengthening elements such as alumina and zirconia, which increase fracture toughness while maintaining optical clarity. These modified glass formulations demonstrate superior resistance to environmental stressors, particularly humidity and temperature fluctuations.

Chemical strengthening processes have evolved beyond traditional ion exchange methods to include dual-ion exchange techniques that create deeper compression layers. This innovation has resulted in UTG that can withstand repeated folding while maintaining structural integrity under varying environmental conditions. The compression layer depth has increased from approximately 10μm to over 30μm in the latest generations, providing enhanced protection against moisture-induced stress corrosion.

Surface treatment technologies have also progressed substantially, with hydrophobic coatings now incorporating fluoropolymer compounds that repel moisture while maintaining transparency. These coatings demonstrate stability at temperatures ranging from -40°C to 85°C, significantly exceeding the operational requirements of most consumer electronics. Additionally, anti-fingerprint coatings with oleophobic properties have been integrated to prevent degradation from skin oils and environmental contaminants.

Composite structures represent another frontier in UTG durability enhancement. Researchers have developed hybrid materials combining UTG with specialized polymer interlayers that absorb mechanical stress and provide additional moisture barriers. These composites demonstrate up to 60% improvement in humidity resistance compared to standard UTG implementations, while maintaining the essential flexibility required for foldable displays.

Nano-lamination techniques have emerged as a promising approach, with alternating layers of glass and transparent ceramic materials creating a structure that inhibits crack propagation. These multi-layered systems show remarkable stability during thermal cycling tests, maintaining structural integrity through thousands of cycles between -20°C and 60°C with relative humidity variations from 20% to 90%.

Edge sealing technologies have advanced to address one of the most vulnerable aspects of UTG implementation. New edge treatment methods using laser-fused silica compounds create hermetic seals that significantly reduce moisture ingress at the display edges. These treatments have extended the mean time to failure in high-humidity environments by approximately 300%, addressing a critical failure point in previous UTG implementations.

Chemical strengthening processes have evolved beyond traditional ion exchange methods to include dual-ion exchange techniques that create deeper compression layers. This innovation has resulted in UTG that can withstand repeated folding while maintaining structural integrity under varying environmental conditions. The compression layer depth has increased from approximately 10μm to over 30μm in the latest generations, providing enhanced protection against moisture-induced stress corrosion.

Surface treatment technologies have also progressed substantially, with hydrophobic coatings now incorporating fluoropolymer compounds that repel moisture while maintaining transparency. These coatings demonstrate stability at temperatures ranging from -40°C to 85°C, significantly exceeding the operational requirements of most consumer electronics. Additionally, anti-fingerprint coatings with oleophobic properties have been integrated to prevent degradation from skin oils and environmental contaminants.

Composite structures represent another frontier in UTG durability enhancement. Researchers have developed hybrid materials combining UTG with specialized polymer interlayers that absorb mechanical stress and provide additional moisture barriers. These composites demonstrate up to 60% improvement in humidity resistance compared to standard UTG implementations, while maintaining the essential flexibility required for foldable displays.

Nano-lamination techniques have emerged as a promising approach, with alternating layers of glass and transparent ceramic materials creating a structure that inhibits crack propagation. These multi-layered systems show remarkable stability during thermal cycling tests, maintaining structural integrity through thousands of cycles between -20°C and 60°C with relative humidity variations from 20% to 90%.

Edge sealing technologies have advanced to address one of the most vulnerable aspects of UTG implementation. New edge treatment methods using laser-fused silica compounds create hermetic seals that significantly reduce moisture ingress at the display edges. These treatments have extended the mean time to failure in high-humidity environments by approximately 300%, addressing a critical failure point in previous UTG implementations.

Standardization and Quality Control Frameworks for UTG Testing

The standardization of Ultra-Thin Glass (UTG) testing methodologies represents a critical foundation for quality assurance in flexible display manufacturing. Currently, several international organizations are actively developing comprehensive frameworks specifically addressing environmental stability testing for UTG components. The International Electrotechnical Commission (IEC) has established the TC110 committee focused on electronic display devices, which has begun drafting standards for flexible display components including UTG environmental testing parameters.

ASTM International and the Society for Information Display (SID) have collaborated to develop testing protocols that specifically address humidity and temperature cycling for UTG materials. These protocols typically require testing across temperature ranges from -40°C to 85°C and relative humidity conditions from 5% to 95%, with standardized exposure durations and transition rates between environmental conditions.

The JEDEC JESD22-A104 environmental test method has been adapted specifically for UTG applications, providing standardized temperature cycling procedures that manufacturers can reference to ensure consistency across the industry. Similarly, IEC 60068-2-30 offers standardized damp heat cycling test procedures that have been modified to address the unique characteristics of ultra-thin glass substrates.

Quality control frameworks for UTG testing typically implement a three-tier verification system. The first tier involves in-line production testing using automated optical inspection systems that can detect micro-fractures and delamination issues resulting from environmental stress. The second tier encompasses batch sampling for comprehensive environmental chamber testing, where statistical process control methods determine appropriate sampling rates based on production volumes and historical defect rates.

The third tier consists of accelerated life testing protocols designed to simulate years of environmental exposure within compressed timeframes. These protocols typically employ Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) methodologies adapted specifically for UTG components in flexible displays.

Several major display manufacturers have established internal certification programs that exceed industry standards, creating proprietary testing frameworks that have become de facto benchmarks within the industry. These frameworks often incorporate more stringent pass/fail criteria than published standards, particularly regarding optical performance degradation after environmental exposure.

The emergence of digital twin modeling for UTG environmental testing represents a significant advancement in quality control frameworks. These computational models simulate environmental stress impacts on specific UTG formulations, allowing manufacturers to predict performance degradation patterns before physical testing begins, thereby optimizing test protocols and reducing development cycles.

ASTM International and the Society for Information Display (SID) have collaborated to develop testing protocols that specifically address humidity and temperature cycling for UTG materials. These protocols typically require testing across temperature ranges from -40°C to 85°C and relative humidity conditions from 5% to 95%, with standardized exposure durations and transition rates between environmental conditions.

The JEDEC JESD22-A104 environmental test method has been adapted specifically for UTG applications, providing standardized temperature cycling procedures that manufacturers can reference to ensure consistency across the industry. Similarly, IEC 60068-2-30 offers standardized damp heat cycling test procedures that have been modified to address the unique characteristics of ultra-thin glass substrates.

Quality control frameworks for UTG testing typically implement a three-tier verification system. The first tier involves in-line production testing using automated optical inspection systems that can detect micro-fractures and delamination issues resulting from environmental stress. The second tier encompasses batch sampling for comprehensive environmental chamber testing, where statistical process control methods determine appropriate sampling rates based on production volumes and historical defect rates.

The third tier consists of accelerated life testing protocols designed to simulate years of environmental exposure within compressed timeframes. These protocols typically employ Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) methodologies adapted specifically for UTG components in flexible displays.

Several major display manufacturers have established internal certification programs that exceed industry standards, creating proprietary testing frameworks that have become de facto benchmarks within the industry. These frameworks often incorporate more stringent pass/fail criteria than published standards, particularly regarding optical performance degradation after environmental exposure.

The emergence of digital twin modeling for UTG environmental testing represents a significant advancement in quality control frameworks. These computational models simulate environmental stress impacts on specific UTG formulations, allowing manufacturers to predict performance degradation patterns before physical testing begins, thereby optimizing test protocols and reducing development cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!