Mechanical Strengthening And Ion-Exchange Process Parameters For Ultra-Thin Glass (UTG) In Flexible Displays

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UTG Strengthening Background and Objectives

Ultra-thin glass (UTG) has emerged as a transformative material in the display industry, particularly for flexible and foldable devices. The evolution of UTG technology can be traced back to the early 2000s when glass manufacturers began exploring methods to produce increasingly thinner glass substrates while maintaining adequate mechanical properties. Traditional display glass with thicknesses of 0.4-0.7mm has gradually given way to ultra-thin variants measuring below 0.1mm, enabling unprecedented flexibility while preserving the superior optical properties and scratch resistance inherent to glass materials.

The technological trajectory of UTG has been driven by the growing consumer demand for more durable, flexible electronic devices with enhanced form factors. As smartphone and wearable technology markets expanded, manufacturers faced increasing pressure to develop displays that could bend, fold, and withstand daily mechanical stresses without compromising visual quality or device longevity. This market pull catalyzed significant research investment in glass strengthening technologies specifically tailored for ultra-thin substrates.

A critical milestone in UTG development occurred around 2018-2019 when commercial foldable smartphones first incorporated this technology, demonstrating its viability for mass-market applications. However, the inherent brittleness of glass at reduced thicknesses presented substantial engineering challenges that conventional strengthening methods could not adequately address. This necessitated the refinement of specialized strengthening techniques, particularly chemical ion-exchange processes optimized for the unique constraints of sub-100μm glass.

The primary technical objectives for UTG strengthening include achieving a delicate balance between flexibility and durability. Specifically, the industry aims to develop glass that can withstand repeated folding cycles (typically targeting 200,000+ folds) while maintaining a bend radius below 5mm without fracture. Additionally, the strengthened glass must resist micro-cracks and surface damage from everyday use while preserving optical clarity and touch sensitivity.

Current research focuses on optimizing ion-exchange parameters such as salt bath composition, immersion time, temperature profiles, and post-treatment processes specifically for UTG applications. The goal is to create a compressive stress layer that enhances mechanical durability without compromising the glass's inherent flexibility. Simultaneously, researchers are exploring complementary strengthening methods including surface coating technologies, lamination techniques, and composite structures to further enhance UTG performance.

The ultimate objective of UTG strengthening research is to enable the next generation of flexible display technologies, including rollable displays, enhanced foldable devices, and conformable electronics that can adapt to various form factors while maintaining the premium look, feel, and durability that consumers expect from glass-based displays.

The technological trajectory of UTG has been driven by the growing consumer demand for more durable, flexible electronic devices with enhanced form factors. As smartphone and wearable technology markets expanded, manufacturers faced increasing pressure to develop displays that could bend, fold, and withstand daily mechanical stresses without compromising visual quality or device longevity. This market pull catalyzed significant research investment in glass strengthening technologies specifically tailored for ultra-thin substrates.

A critical milestone in UTG development occurred around 2018-2019 when commercial foldable smartphones first incorporated this technology, demonstrating its viability for mass-market applications. However, the inherent brittleness of glass at reduced thicknesses presented substantial engineering challenges that conventional strengthening methods could not adequately address. This necessitated the refinement of specialized strengthening techniques, particularly chemical ion-exchange processes optimized for the unique constraints of sub-100μm glass.

The primary technical objectives for UTG strengthening include achieving a delicate balance between flexibility and durability. Specifically, the industry aims to develop glass that can withstand repeated folding cycles (typically targeting 200,000+ folds) while maintaining a bend radius below 5mm without fracture. Additionally, the strengthened glass must resist micro-cracks and surface damage from everyday use while preserving optical clarity and touch sensitivity.

Current research focuses on optimizing ion-exchange parameters such as salt bath composition, immersion time, temperature profiles, and post-treatment processes specifically for UTG applications. The goal is to create a compressive stress layer that enhances mechanical durability without compromising the glass's inherent flexibility. Simultaneously, researchers are exploring complementary strengthening methods including surface coating technologies, lamination techniques, and composite structures to further enhance UTG performance.

The ultimate objective of UTG strengthening research is to enable the next generation of flexible display technologies, including rollable displays, enhanced foldable devices, and conformable electronics that can adapt to various form factors while maintaining the premium look, feel, and durability that consumers expect from glass-based displays.

Market Analysis for UTG in Flexible Display Applications

The global market for Ultra-Thin Glass (UTG) in flexible displays has witnessed remarkable growth in recent years, primarily driven by the increasing demand for foldable smartphones, wearable devices, and other flexible electronic applications. As of 2023, the market size for UTG in flexible displays is valued at approximately $1.2 billion, with projections indicating a compound annual growth rate (CAGR) of 28% through 2028.

Consumer electronics represents the largest application segment for UTG, accounting for over 65% of the total market share. Within this segment, foldable smartphones have emerged as the primary growth driver, with major manufacturers like Samsung, Huawei, and Motorola incorporating UTG in their flagship foldable devices. The wearable technology sector follows closely, representing about 20% of the market, with smartwatches and fitness trackers increasingly adopting flexible display technologies.

Regional analysis reveals that Asia-Pacific dominates the UTG market, holding approximately 58% of the global share. This dominance is attributed to the strong presence of display manufacturers and electronic device producers in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow with market shares of 22% and 15% respectively, primarily driven by high consumer adoption rates of premium electronic devices.

The demand for mechanically strengthened UTG is particularly pronounced in the premium segment of the consumer electronics market, where durability and aesthetic appeal are paramount considerations. Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring enhanced durability through advanced glass strengthening technologies.

Key market trends include the increasing integration of UTG in automotive displays, growing demand for larger foldable displays in tablets and laptops, and rising interest in multi-fold display configurations. The automotive sector, in particular, is expected to emerge as a significant growth opportunity, with a projected CAGR of 35% for UTG applications in vehicle displays through 2028.

Market challenges include high production costs associated with specialized ion-exchange processes for UTG, supply chain constraints for high-quality thin glass substrates, and competition from alternative flexible display technologies such as colorless polyimide (CPI). The average production cost for UTG remains 30-40% higher than traditional display glass, presenting a significant barrier to wider adoption in mid-range electronic devices.

Consumer feedback data indicates that scratch resistance and fold durability are the most critical performance factors influencing purchasing decisions for foldable devices, highlighting the importance of continued innovation in mechanical strengthening processes for UTG.

Consumer electronics represents the largest application segment for UTG, accounting for over 65% of the total market share. Within this segment, foldable smartphones have emerged as the primary growth driver, with major manufacturers like Samsung, Huawei, and Motorola incorporating UTG in their flagship foldable devices. The wearable technology sector follows closely, representing about 20% of the market, with smartwatches and fitness trackers increasingly adopting flexible display technologies.

Regional analysis reveals that Asia-Pacific dominates the UTG market, holding approximately 58% of the global share. This dominance is attributed to the strong presence of display manufacturers and electronic device producers in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow with market shares of 22% and 15% respectively, primarily driven by high consumer adoption rates of premium electronic devices.

The demand for mechanically strengthened UTG is particularly pronounced in the premium segment of the consumer electronics market, where durability and aesthetic appeal are paramount considerations. Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring enhanced durability through advanced glass strengthening technologies.

Key market trends include the increasing integration of UTG in automotive displays, growing demand for larger foldable displays in tablets and laptops, and rising interest in multi-fold display configurations. The automotive sector, in particular, is expected to emerge as a significant growth opportunity, with a projected CAGR of 35% for UTG applications in vehicle displays through 2028.

Market challenges include high production costs associated with specialized ion-exchange processes for UTG, supply chain constraints for high-quality thin glass substrates, and competition from alternative flexible display technologies such as colorless polyimide (CPI). The average production cost for UTG remains 30-40% higher than traditional display glass, presenting a significant barrier to wider adoption in mid-range electronic devices.

Consumer feedback data indicates that scratch resistance and fold durability are the most critical performance factors influencing purchasing decisions for foldable devices, highlighting the importance of continued innovation in mechanical strengthening processes for UTG.

Current Challenges in UTG Mechanical Strengthening

Despite significant advancements in Ultra-Thin Glass (UTG) technology for flexible displays, mechanical strengthening remains one of the most critical challenges in the industry. The fundamental issue stems from the inverse relationship between glass thickness and flexibility - as glass becomes thinner to achieve greater flexibility, its inherent mechanical strength decreases exponentially. UTG with thickness below 100μm becomes extremely fragile and susceptible to fracture during both processing and end-use.

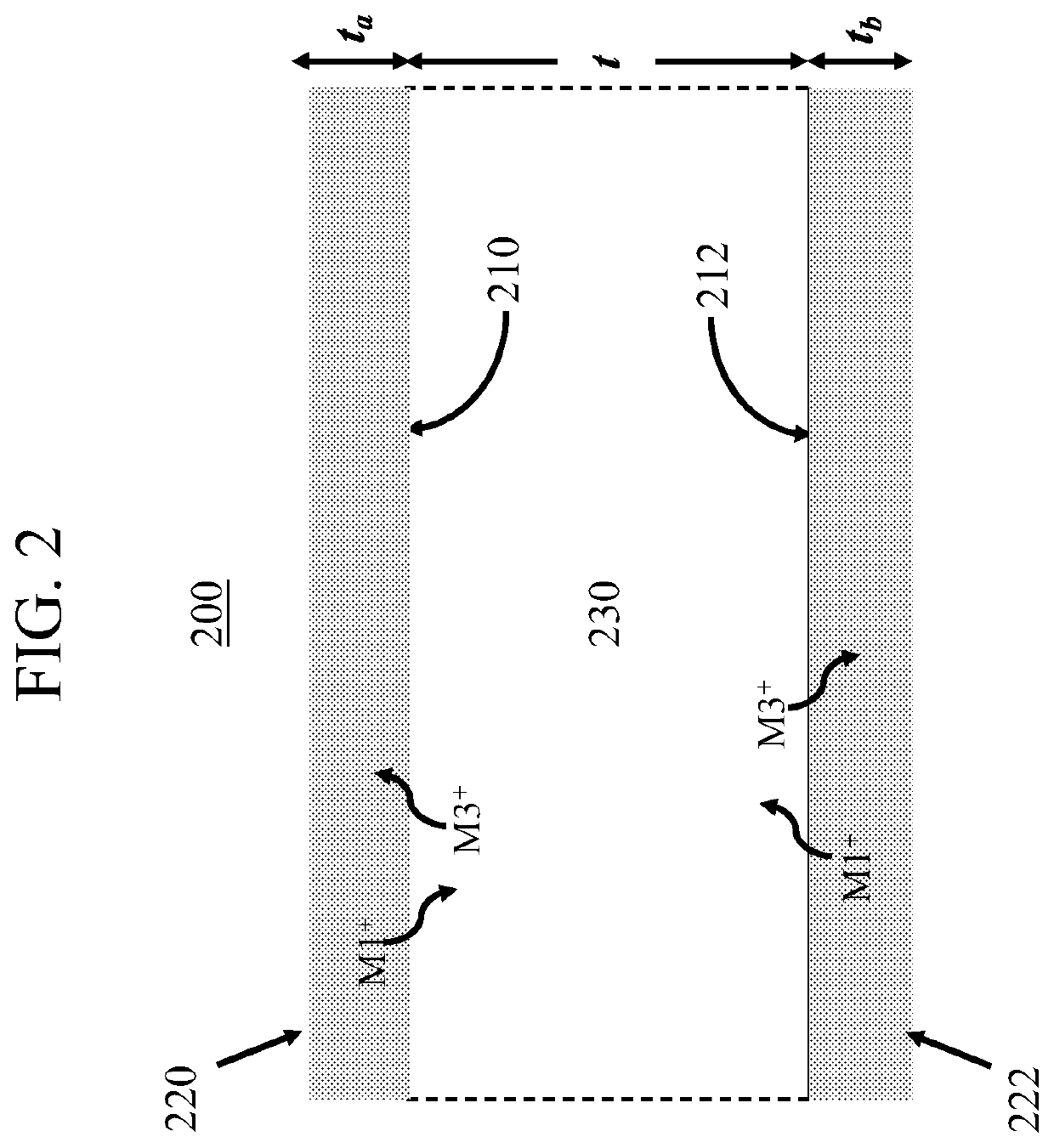

The ion-exchange strengthening process, while proven effective for conventional glass, presents unique challenges when applied to UTG. The diffusion dynamics of alkali ions (typically potassium replacing sodium) behave differently in ultra-thin substrates, often resulting in non-uniform stress profiles across the glass thickness. This non-uniformity creates unpredictable mechanical properties and potential failure points.

Temperature control during ion-exchange presents another significant challenge. UTG requires precise thermal management during strengthening, as even minor temperature fluctuations can induce warping or dimensional instability in such thin substrates. The industry currently struggles to develop equipment capable of maintaining temperature uniformity within ±1°C across large glass sheets measuring several square meters.

Process time optimization represents a delicate balance between achieving adequate strengthening and avoiding glass degradation. Extended immersion in molten salt baths can lead to surface defects, while insufficient treatment fails to provide necessary strength. Current processes lack real-time monitoring capabilities to determine optimal endpoint conditions for specific UTG compositions and thicknesses.

Edge strengthening poses particular difficulties for UTG. The edges of ultra-thin glass sheets remain vulnerable stress concentration points, with conventional edge finishing techniques proving inadequate. Laser cutting technologies, while promising, still introduce micro-cracks that can propagate under stress, compromising the entire display module.

Scalability of strengthening processes from laboratory to mass production environments presents substantial engineering challenges. Current batch processing methods introduce variations between treatment cycles, while continuous processing solutions struggle with maintaining consistent ion-exchange parameters across large substrate areas.

Quality control and inspection methodologies for strengthened UTG remain underdeveloped. Traditional stress measurement techniques like surface polarimetry provide insufficient data for ultra-thin substrates, while destructive testing methods are impractical for production environments. The industry lacks standardized non-destructive evaluation protocols specifically calibrated for UTG mechanical properties.

The ion-exchange strengthening process, while proven effective for conventional glass, presents unique challenges when applied to UTG. The diffusion dynamics of alkali ions (typically potassium replacing sodium) behave differently in ultra-thin substrates, often resulting in non-uniform stress profiles across the glass thickness. This non-uniformity creates unpredictable mechanical properties and potential failure points.

Temperature control during ion-exchange presents another significant challenge. UTG requires precise thermal management during strengthening, as even minor temperature fluctuations can induce warping or dimensional instability in such thin substrates. The industry currently struggles to develop equipment capable of maintaining temperature uniformity within ±1°C across large glass sheets measuring several square meters.

Process time optimization represents a delicate balance between achieving adequate strengthening and avoiding glass degradation. Extended immersion in molten salt baths can lead to surface defects, while insufficient treatment fails to provide necessary strength. Current processes lack real-time monitoring capabilities to determine optimal endpoint conditions for specific UTG compositions and thicknesses.

Edge strengthening poses particular difficulties for UTG. The edges of ultra-thin glass sheets remain vulnerable stress concentration points, with conventional edge finishing techniques proving inadequate. Laser cutting technologies, while promising, still introduce micro-cracks that can propagate under stress, compromising the entire display module.

Scalability of strengthening processes from laboratory to mass production environments presents substantial engineering challenges. Current batch processing methods introduce variations between treatment cycles, while continuous processing solutions struggle with maintaining consistent ion-exchange parameters across large substrate areas.

Quality control and inspection methodologies for strengthened UTG remain underdeveloped. Traditional stress measurement techniques like surface polarimetry provide insufficient data for ultra-thin substrates, while destructive testing methods are impractical for production environments. The industry lacks standardized non-destructive evaluation protocols specifically calibrated for UTG mechanical properties.

Ion-Exchange Process Parameters and Implementation

01 Chemical strengthening processes for UTG

Chemical strengthening is a key method for enhancing the mechanical properties of ultra-thin glass. This process typically involves ion exchange, where smaller ions in the glass are replaced with larger ions, creating compressive stress on the surface. The process parameters such as temperature, duration, and chemical bath composition can be optimized to achieve desired strength levels while maintaining optical clarity. This technique is particularly effective for UTG used in flexible displays and foldable devices.- Chemical strengthening processes for UTG: Chemical strengthening is a key method for enhancing the mechanical properties of ultra-thin glass. This process typically involves ion exchange, where smaller ions in the glass are replaced with larger ions, creating compressive stress on the surface. The process parameters such as temperature, duration, and chemical bath composition can be optimized to achieve desired strength levels while maintaining optical clarity. This method is particularly effective for UTG used in flexible displays and foldable devices where both strength and flexibility are required.

- Physical strengthening techniques for UTG: Physical strengthening techniques involve mechanical or thermal processes to enhance the durability of ultra-thin glass. These include tempering, lamination with polymer films, and surface coating applications. The techniques create a balanced stress distribution throughout the glass structure, improving impact resistance and flexibility. Physical strengthening can be combined with other methods to achieve comprehensive protection for UTG in mobile devices and wearable technology applications.

- Composite structures for UTG reinforcement: Composite structures involve combining ultra-thin glass with other materials to create multi-layer systems with enhanced mechanical properties. These structures typically include polymer layers, functional adhesives, and protective films that work together to distribute stress and prevent crack propagation. The composite approach allows manufacturers to maintain the optical and touch-sensitive properties of glass while significantly improving its durability and flexibility for use in foldable displays and other advanced applications.

- Surface modification technologies for UTG: Surface modification technologies focus on altering the surface properties of ultra-thin glass to enhance its mechanical strength. These include nano-coating applications, surface etching, and deposition of strengthening materials at the molecular level. The modified surface layer provides improved scratch resistance, reduced friction, and better stress distribution. These technologies are particularly valuable for maintaining the pristine appearance and functionality of UTG in consumer electronics that are subject to daily handling and potential damage.

- Manufacturing processes for strengthened UTG: Specialized manufacturing processes have been developed specifically for producing strengthened ultra-thin glass. These include controlled cooling techniques, precision grinding and polishing methods, and advanced drawing processes that create inherently stronger glass structures. The manufacturing approach often incorporates in-line strengthening steps that integrate seamlessly with production, ensuring consistent quality and performance characteristics. These processes focus on minimizing defects and stress points that could lead to failure when the glass is subjected to bending or impact forces.

02 Physical strengthening techniques for UTG

Physical strengthening methods involve applying mechanical treatments to ultra-thin glass to enhance its durability. These techniques include thermal tempering, where controlled heating and rapid cooling create stress differentials, and mechanical polishing to remove surface flaws that could serve as fracture initiation points. Other approaches include applying protective coatings or films that can absorb impact energy and prevent crack propagation, significantly improving the glass's resistance to breakage while maintaining flexibility.Expand Specific Solutions03 Composite structures for UTG reinforcement

Composite structures combine ultra-thin glass with other materials to enhance mechanical properties. These typically involve laminating the UTG with polymer layers or other supporting materials to create a sandwich structure that distributes stress more effectively. Some designs incorporate functional interlayers that not only strengthen the glass but also provide additional features such as improved optical properties or self-healing capabilities. These composite approaches allow for thinner glass while maintaining or improving overall strength.Expand Specific Solutions04 Edge treatment and processing for UTG

Edge treatment is critical for strengthening ultra-thin glass, as edges are common failure points. Specialized techniques include edge grinding, polishing, and chamfering to remove microcracks and stress concentrations. Some methods involve laser edge treatment to create controlled micro-modifications that prevent crack propagation. Advanced edge sealing technologies can also be applied to protect the edges from environmental factors and mechanical stress, significantly improving the overall durability of UTG components.Expand Specific Solutions05 Manufacturing processes for strengthened UTG

Specialized manufacturing processes have been developed specifically for producing strengthened ultra-thin glass. These include modified float glass techniques that allow for thinner production while maintaining strength, and advanced drawing methods that create glass with fewer inherent defects. Process innovations include controlled cooling rates, specialized handling equipment to prevent damage during production, and in-line strengthening treatments. Some manufacturing approaches incorporate stress engineering during the glass formation process itself, resulting in inherently stronger UTG suitable for flexible display applications.Expand Specific Solutions

Leading Manufacturers and Suppliers in UTG Industry

The ultra-thin glass (UTG) market for flexible displays is currently in a growth phase, with increasing demand driven by the proliferation of foldable smartphones and wearable devices. The global market size is projected to expand significantly, reaching several billion dollars by 2025. Technologically, mechanical strengthening and ion-exchange processes for UTG are advancing toward maturity, with industry leaders like Corning, Schott, and Samsung Display pioneering innovations. Corning dominates with its proprietary ion-exchange technology, while Chinese players including BOE Technology and Dongxu Technology are rapidly closing the gap. Companies like Triumph Science & Technology and CNBM are investing heavily in UTG manufacturing capabilities. The competitive landscape is characterized by strategic partnerships between glass manufacturers and display makers, with increasing focus on achieving thinner, more durable glass solutions for next-generation flexible devices.

Corning, Inc.

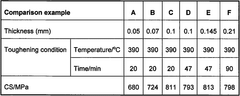

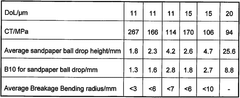

Technical Solution: Corning has developed a proprietary ion-exchange process for UTG called "Fusion Draw Process" combined with their chemical strengthening technology. Their approach involves immersing ultra-thin glass (typically 30-100μm thickness) in a molten potassium salt bath at temperatures between 380-450°C, creating a compressive stress layer of 15-20μm depth. The process parameters are precisely controlled with ion-exchange times ranging from 4-8 hours depending on desired strength profiles. Corning's UTG undergoes a two-step strengthening process: first, the glass is formed using their proprietary down-draw method ensuring pristine surface quality; second, the ion-exchange process replaces smaller sodium ions with larger potassium ions, creating compressive stress exceeding 700MPa at the surface while maintaining flexibility for bend radii down to 3-5mm.

Strengths: Industry-leading expertise in specialized glass formulations; vertically integrated manufacturing capabilities; decades of research in ion-exchange technology; established supply chain relationships with major display manufacturers. Weaknesses: Higher production costs compared to competitors; limited production capacity for rapidly growing demand; process requires precise temperature control that increases manufacturing complexity.

SCHOTT Glass Technologies (Suzhou) Co. Ltd.

Technical Solution: SCHOTT has engineered a specialized ion-exchange strengthening process for UTG called "AS Ultra Thin" technology. Their method utilizes a controlled immersion of aluminosilicate glass sheets (30-70μm thickness) in potassium nitrate baths at temperatures between 400-470°C. The process features proprietary temperature ramping profiles that optimize ion penetration while preventing warping. SCHOTT's innovation lies in their multi-stage ion-exchange approach where glass undergoes sequential treatments with varying salt bath compositions and temperatures, creating a graduated compressive stress profile reaching depths of 12-18μm. This results in surface compression strengths of 650-800MPa while maintaining optical clarity above 99.5% transmittance. Their process incorporates real-time monitoring systems that adjust parameters based on glass composition variations, ensuring consistent mechanical properties across production batches.

Strengths: Advanced process control systems allowing for consistent quality; specialized in high-precision thin glass manufacturing; strong R&D capabilities with over 130 years of glass expertise; flexible production capabilities for customized solutions. Weaknesses: Higher production costs than Asian competitors; limited production scale compared to larger manufacturers; technology requires significant capital investment for new production lines.

Critical Patents in UTG Strengthening Methodologies

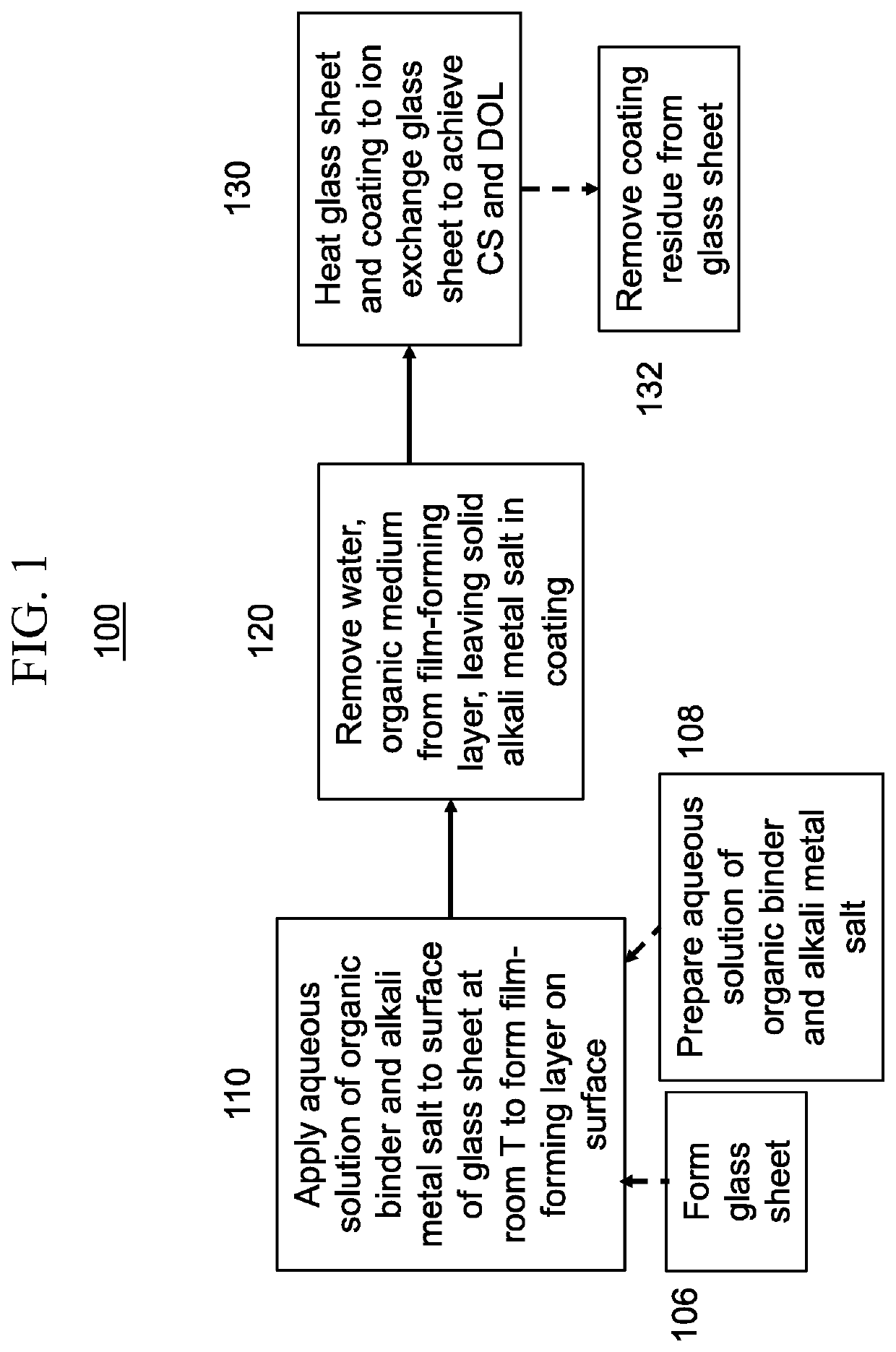

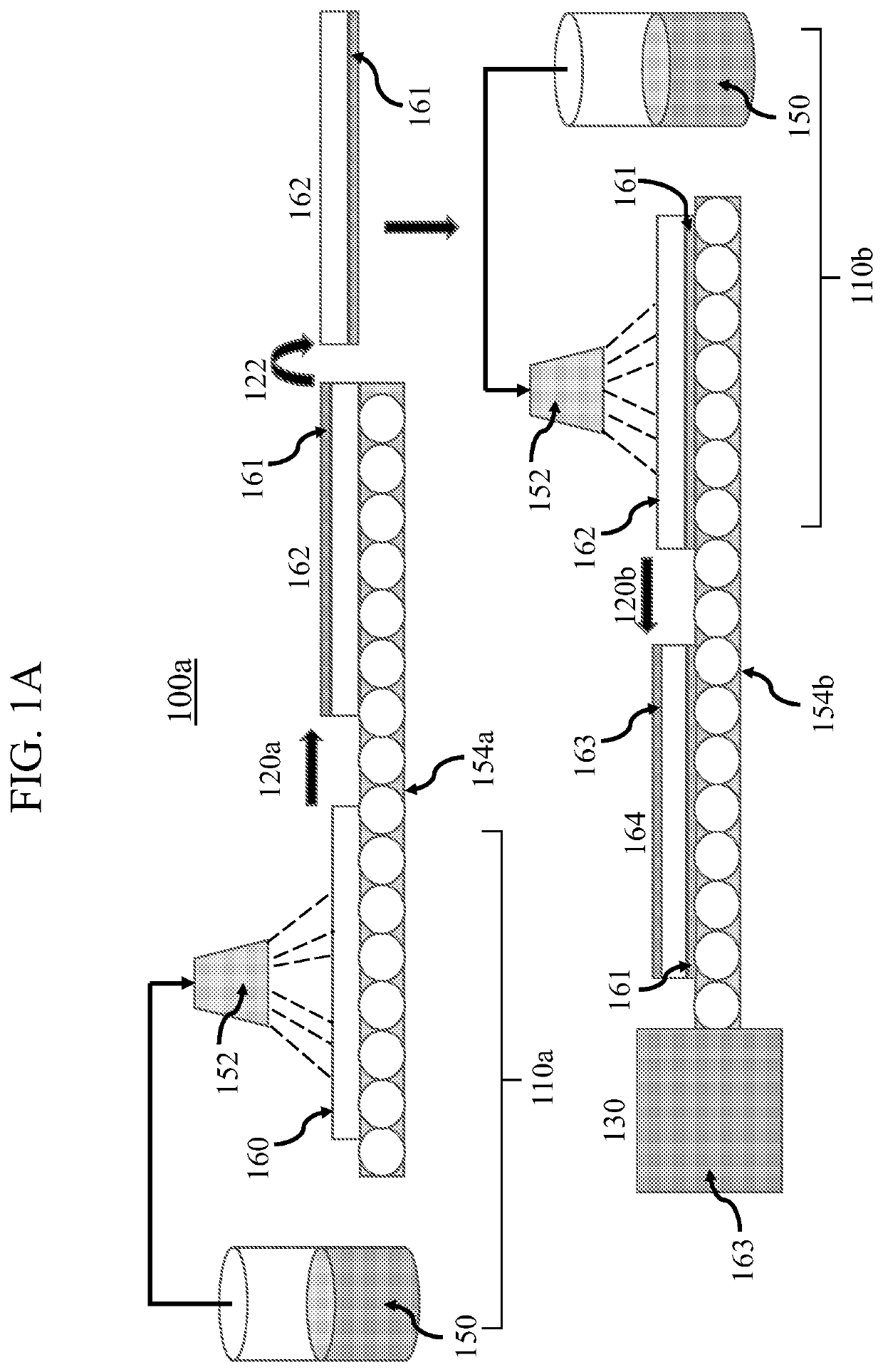

Ion exchange process for ultra-thin glass

PatentPendingUS20220289623A1

Innovation

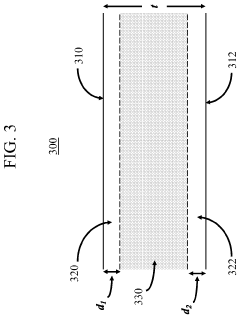

- A method involving an aqueous precursor solution with an organic binder and alkali metal salts is applied to the glass surface, followed by heating to form a film-forming coating, where the first alkali metal salt melts and replaces third alkali metal cations, creating a compressive stress layer extending from the surface to a controlled depth of 5 μm to 60 μm, achieving peak compressive stresses from 300 MPa to 2000 MPa.

Flexible ultrathin glass with high contact resistance

PatentWO2018218691A1

Innovation

- Development of UTG with optimized DoL (Depth of Layer) that is less than 30μm, avoiding fragility and self-breakage issues while maintaining high mechanical resistance.

- Creation of a toughening process specifically designed for ultrathin glass that enhances sharp impact resistance against hard objects and edges, addressing a key weakness in existing UTG solutions.

- Challenging the conventional assumption that DoL should be 0.1-0.2 times the glass thickness by developing a more nuanced approach to chemical strengthening parameters for UTG.

Material Science Advancements for UTG Durability

Recent advancements in materials science have significantly contributed to enhancing the durability of Ultra-Thin Glass (UTG) for flexible display applications. The evolution of UTG materials has been driven by the need for displays that can withstand repeated folding while maintaining optical clarity and structural integrity. Traditional glass compositions have been modified to incorporate higher concentrations of alkali ions, particularly potassium, which facilitates more efficient ion-exchange processes.

The development of aluminosilicate glass formulations specifically engineered for UTG applications represents a major breakthrough. These compositions feature optimized ratios of silicon dioxide, aluminum oxide, and alkali metal oxides that provide enhanced mechanical properties while maintaining the flexibility required for bendable displays. Research indicates that increasing the aluminum content by 2-3% can improve the ion-exchange efficiency by up to 30%, resulting in significantly higher surface compression strength.

Surface treatment technologies have evolved beyond conventional chemical strengthening methods. Hybrid approaches combining ion-exchange with thin-film deposition techniques have emerged as promising solutions for UTG durability enhancement. These multi-layer systems create a gradient of mechanical properties from the surface to the core, effectively distributing stress during bending operations and preventing crack propagation.

Nano-composite glass structures represent another frontier in UTG material science. By incorporating nano-scale particles of materials such as zirconia or alumina into the glass matrix during formation, researchers have demonstrated improvements in fracture toughness by up to 40% compared to conventional UTG. These particles act as crack deflectors, significantly enhancing the overall mechanical resilience of the glass structure.

Advanced characterization techniques have enabled more precise understanding of glass microstructure and its relationship to mechanical properties. High-resolution transmission electron microscopy and atomic force microscopy have revealed critical insights into the ion diffusion mechanisms during strengthening processes, allowing for more targeted material design approaches. This has led to the development of UTG with compressive stress layers optimized specifically for the bending radii required in modern foldable devices.

Computational materials science has accelerated UTG development through predictive modeling of glass compositions and their mechanical behaviors. Molecular dynamics simulations now enable researchers to predict how various glass formulations will respond to ion-exchange processes before physical prototyping, significantly reducing development cycles and allowing for rapid iteration of material compositions tailored to specific mechanical requirements.

The development of aluminosilicate glass formulations specifically engineered for UTG applications represents a major breakthrough. These compositions feature optimized ratios of silicon dioxide, aluminum oxide, and alkali metal oxides that provide enhanced mechanical properties while maintaining the flexibility required for bendable displays. Research indicates that increasing the aluminum content by 2-3% can improve the ion-exchange efficiency by up to 30%, resulting in significantly higher surface compression strength.

Surface treatment technologies have evolved beyond conventional chemical strengthening methods. Hybrid approaches combining ion-exchange with thin-film deposition techniques have emerged as promising solutions for UTG durability enhancement. These multi-layer systems create a gradient of mechanical properties from the surface to the core, effectively distributing stress during bending operations and preventing crack propagation.

Nano-composite glass structures represent another frontier in UTG material science. By incorporating nano-scale particles of materials such as zirconia or alumina into the glass matrix during formation, researchers have demonstrated improvements in fracture toughness by up to 40% compared to conventional UTG. These particles act as crack deflectors, significantly enhancing the overall mechanical resilience of the glass structure.

Advanced characterization techniques have enabled more precise understanding of glass microstructure and its relationship to mechanical properties. High-resolution transmission electron microscopy and atomic force microscopy have revealed critical insights into the ion diffusion mechanisms during strengthening processes, allowing for more targeted material design approaches. This has led to the development of UTG with compressive stress layers optimized specifically for the bending radii required in modern foldable devices.

Computational materials science has accelerated UTG development through predictive modeling of glass compositions and their mechanical behaviors. Molecular dynamics simulations now enable researchers to predict how various glass formulations will respond to ion-exchange processes before physical prototyping, significantly reducing development cycles and allowing for rapid iteration of material compositions tailored to specific mechanical requirements.

Environmental Impact of UTG Manufacturing Processes

The manufacturing processes of Ultra-Thin Glass (UTG) for flexible displays involve several energy-intensive and chemically complex procedures that have significant environmental implications. The ion-exchange strengthening process, in particular, requires substantial energy consumption for maintaining high temperatures (typically 350-450°C) over extended periods, contributing to considerable carbon emissions. This thermal processing represents one of the most environmentally impactful aspects of UTG production, especially when powered by non-renewable energy sources.

Chemical usage in UTG manufacturing presents another environmental concern. The ion-exchange baths utilize alkali salts (primarily potassium nitrate) that require proper disposal after their effective lifespan is reached. These chemical wastes contain high concentrations of sodium and potassium ions that can potentially contaminate water systems if not properly managed. Additionally, the acid etching processes used for thinning glass employ hydrofluoric acid and sulfuric acid mixtures, which are extremely hazardous and require specialized containment and neutralization protocols.

Water consumption represents a significant environmental footprint in UTG production. The multiple cleaning cycles between processing steps demand ultra-pure water in large quantities. The wastewater generated contains trace metals, chemical compounds, and particulates that require advanced treatment before release. Some manufacturers have implemented closed-loop water recycling systems, reducing fresh water requirements by up to 60%, though implementation costs remain prohibitive for smaller facilities.

Resource efficiency in UTG production presents both challenges and opportunities. The mechanical thinning process typically results in material loss of 30-40%, creating substantial glass waste. While some of this waste can be recycled into new glass production, the specialized composition of display glass limits complete recyclability. Recent innovations in precision grinding technologies have shown promise in reducing material waste to below 25%, representing a significant improvement in resource utilization.

Emissions from UTG manufacturing facilities include volatile organic compounds (VOCs) from cleaning solvents, acid fumes from etching processes, and particulate matter from grinding operations. Advanced air filtration systems and scrubbers are essential for minimizing these airborne pollutants, though their implementation and maintenance add to the overall environmental cost of UTG production. Regulatory compliance varies significantly across manufacturing regions, with stricter standards in Europe and North America compared to some Asian manufacturing hubs.

Chemical usage in UTG manufacturing presents another environmental concern. The ion-exchange baths utilize alkali salts (primarily potassium nitrate) that require proper disposal after their effective lifespan is reached. These chemical wastes contain high concentrations of sodium and potassium ions that can potentially contaminate water systems if not properly managed. Additionally, the acid etching processes used for thinning glass employ hydrofluoric acid and sulfuric acid mixtures, which are extremely hazardous and require specialized containment and neutralization protocols.

Water consumption represents a significant environmental footprint in UTG production. The multiple cleaning cycles between processing steps demand ultra-pure water in large quantities. The wastewater generated contains trace metals, chemical compounds, and particulates that require advanced treatment before release. Some manufacturers have implemented closed-loop water recycling systems, reducing fresh water requirements by up to 60%, though implementation costs remain prohibitive for smaller facilities.

Resource efficiency in UTG production presents both challenges and opportunities. The mechanical thinning process typically results in material loss of 30-40%, creating substantial glass waste. While some of this waste can be recycled into new glass production, the specialized composition of display glass limits complete recyclability. Recent innovations in precision grinding technologies have shown promise in reducing material waste to below 25%, representing a significant improvement in resource utilization.

Emissions from UTG manufacturing facilities include volatile organic compounds (VOCs) from cleaning solvents, acid fumes from etching processes, and particulate matter from grinding operations. Advanced air filtration systems and scrubbers are essential for minimizing these airborne pollutants, though their implementation and maintenance add to the overall environmental cost of UTG production. Regulatory compliance varies significantly across manufacturing regions, with stricter standards in Europe and North America compared to some Asian manufacturing hubs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!