Dynamic Light Scattering for Characterizing Hydrogels in R&D

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Research Objectives

Dynamic Light Scattering (DLS) has evolved significantly since its theoretical foundation was established in the early 20th century through Einstein's work on Brownian motion. The technique gained practical application in the 1960s with the advent of laser technology, which provided the coherent light source necessary for precise measurements. Over subsequent decades, DLS has transformed from a specialized academic tool into a standard analytical method across multiple industries, particularly in pharmaceutical development, materials science, and biotechnology.

The fundamental principle of DLS relies on measuring the time-dependent fluctuations in scattered light intensity caused by particles undergoing Brownian motion in solution. These fluctuations contain valuable information about particle size distribution, which is extracted through autocorrelation analysis. Recent technological advancements have significantly enhanced DLS capabilities, including improved detectors, more sophisticated data processing algorithms, and integration with complementary techniques.

In the specific context of hydrogel characterization, DLS offers unique insights into these three-dimensional networks of hydrophilic polymers. Hydrogels represent a critical class of biomaterials with applications ranging from drug delivery systems to tissue engineering scaffolds and wound dressings. Their performance is intimately tied to their structural properties, including mesh size, crosslinking density, and swelling behavior—parameters that DLS can help quantify.

The evolution of DLS for hydrogel analysis has been driven by increasing demands for more precise control over hydrogel properties in biomedical applications. Traditional characterization methods often provide only bulk properties or require destructive testing, whereas DLS offers non-invasive analysis of structural dynamics at the nanoscale. This capability is particularly valuable for understanding hydrogel behavior under physiologically relevant conditions.

Current trends in DLS technology development include miniaturization of instruments, automation of measurement protocols, and integration with artificial intelligence for data interpretation. These advancements aim to address the challenges of analyzing complex, heterogeneous systems like hydrogels, where multiple scattering effects and sample polydispersity can complicate analysis.

The primary objective of this technical research is to evaluate the current capabilities and limitations of DLS for comprehensive hydrogel characterization in R&D settings. Specifically, we aim to assess how DLS can provide insights into critical hydrogel parameters such as mesh size distribution, degradation kinetics, and response to environmental stimuli. Additionally, we seek to identify emerging DLS methodologies that may overcome current limitations and enable more precise control over hydrogel properties for advanced biomedical applications.

The fundamental principle of DLS relies on measuring the time-dependent fluctuations in scattered light intensity caused by particles undergoing Brownian motion in solution. These fluctuations contain valuable information about particle size distribution, which is extracted through autocorrelation analysis. Recent technological advancements have significantly enhanced DLS capabilities, including improved detectors, more sophisticated data processing algorithms, and integration with complementary techniques.

In the specific context of hydrogel characterization, DLS offers unique insights into these three-dimensional networks of hydrophilic polymers. Hydrogels represent a critical class of biomaterials with applications ranging from drug delivery systems to tissue engineering scaffolds and wound dressings. Their performance is intimately tied to their structural properties, including mesh size, crosslinking density, and swelling behavior—parameters that DLS can help quantify.

The evolution of DLS for hydrogel analysis has been driven by increasing demands for more precise control over hydrogel properties in biomedical applications. Traditional characterization methods often provide only bulk properties or require destructive testing, whereas DLS offers non-invasive analysis of structural dynamics at the nanoscale. This capability is particularly valuable for understanding hydrogel behavior under physiologically relevant conditions.

Current trends in DLS technology development include miniaturization of instruments, automation of measurement protocols, and integration with artificial intelligence for data interpretation. These advancements aim to address the challenges of analyzing complex, heterogeneous systems like hydrogels, where multiple scattering effects and sample polydispersity can complicate analysis.

The primary objective of this technical research is to evaluate the current capabilities and limitations of DLS for comprehensive hydrogel characterization in R&D settings. Specifically, we aim to assess how DLS can provide insights into critical hydrogel parameters such as mesh size distribution, degradation kinetics, and response to environmental stimuli. Additionally, we seek to identify emerging DLS methodologies that may overcome current limitations and enable more precise control over hydrogel properties for advanced biomedical applications.

Market Analysis for Hydrogel Characterization Tools

The global market for hydrogel characterization tools is experiencing robust growth, driven by expanding applications in biomedical research, pharmaceutical development, and tissue engineering. The current market size for advanced analytical instruments used in hydrogel characterization is estimated at $2.3 billion, with a compound annual growth rate projected at 7.8% through 2028. Dynamic Light Scattering (DLS) instruments specifically represent approximately $340 million of this market, showing particularly strong growth at 9.2% annually.

Key market drivers include the increasing adoption of hydrogels in drug delivery systems, wound healing applications, and regenerative medicine. The pharmaceutical sector accounts for the largest market share at 42%, followed by academic research institutions at 31%, and biotechnology companies at 18%. The remaining market share is distributed among government laboratories and contract research organizations.

Regional analysis reveals North America as the dominant market with 38% share, followed by Europe at 29% and Asia-Pacific at 24%. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 11.3% annually, attributed to increasing R&D investments and expanding biotechnology sectors.

Customer segmentation shows distinct needs across different user groups. Pharmaceutical companies prioritize high-throughput capabilities and regulatory compliance features in DLS instruments. Academic institutions favor versatility and cost-effectiveness, while biotechnology startups emphasize ease of use and minimal sample requirements.

The competitive landscape features established analytical instrument manufacturers like Malvern Panalytical, Brookhaven Instruments, and Wyatt Technology dominating the high-end market segment. Mid-tier offerings come from companies like Anton Paar and Microtrac, while newer entrants such as Spectradyne and NanoFCM are disrupting the market with innovative approaches to nanoparticle characterization in complex matrices like hydrogels.

Price sensitivity varies significantly by segment, with academic institutions demonstrating high price sensitivity compared to pharmaceutical companies. The average investment for a comprehensive DLS system ranges from $50,000 to $150,000, with additional costs for specialized sample handling accessories for hydrogel characterization.

Market trends indicate growing demand for integrated characterization platforms that combine DLS with complementary techniques such as rheology, microscopy, or spectroscopy. Additionally, there is increasing interest in portable or benchtop DLS instruments that offer comparable performance to traditional systems while requiring less laboratory space and technical expertise.

Key market drivers include the increasing adoption of hydrogels in drug delivery systems, wound healing applications, and regenerative medicine. The pharmaceutical sector accounts for the largest market share at 42%, followed by academic research institutions at 31%, and biotechnology companies at 18%. The remaining market share is distributed among government laboratories and contract research organizations.

Regional analysis reveals North America as the dominant market with 38% share, followed by Europe at 29% and Asia-Pacific at 24%. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 11.3% annually, attributed to increasing R&D investments and expanding biotechnology sectors.

Customer segmentation shows distinct needs across different user groups. Pharmaceutical companies prioritize high-throughput capabilities and regulatory compliance features in DLS instruments. Academic institutions favor versatility and cost-effectiveness, while biotechnology startups emphasize ease of use and minimal sample requirements.

The competitive landscape features established analytical instrument manufacturers like Malvern Panalytical, Brookhaven Instruments, and Wyatt Technology dominating the high-end market segment. Mid-tier offerings come from companies like Anton Paar and Microtrac, while newer entrants such as Spectradyne and NanoFCM are disrupting the market with innovative approaches to nanoparticle characterization in complex matrices like hydrogels.

Price sensitivity varies significantly by segment, with academic institutions demonstrating high price sensitivity compared to pharmaceutical companies. The average investment for a comprehensive DLS system ranges from $50,000 to $150,000, with additional costs for specialized sample handling accessories for hydrogel characterization.

Market trends indicate growing demand for integrated characterization platforms that combine DLS with complementary techniques such as rheology, microscopy, or spectroscopy. Additionally, there is increasing interest in portable or benchtop DLS instruments that offer comparable performance to traditional systems while requiring less laboratory space and technical expertise.

Current Challenges in Hydrogel Analysis via DLS

Despite the significant advancements in Dynamic Light Scattering (DLS) technology for characterizing colloidal systems, several substantial challenges persist when applying this technique to hydrogel analysis in research and development settings. These challenges primarily stem from the complex structural nature of hydrogels as compared to simple colloidal suspensions.

One of the most significant limitations is the inherent heterogeneity of hydrogel systems. Unlike uniform particle suspensions, hydrogels often contain regions of varying crosslinking density, creating a non-uniform scattering environment that complicates data interpretation. This heterogeneity leads to multi-modal size distributions that can be difficult to deconvolute using standard DLS algorithms, which typically assume spherical, non-interacting particles.

The dynamic nature of hydrogels presents another major challenge. During measurement, hydrogels continue to undergo swelling, degradation, or restructuring processes, causing temporal variations in scattering patterns. This dynamic behavior can lead to inconsistent results, particularly during long measurement times required for adequate signal averaging in DLS experiments.

Sample preparation issues further complicate hydrogel characterization. The concentration dependence of DLS measurements means that hydrogels must be appropriately diluted for analysis, yet dilution can fundamentally alter the network structure and properties being investigated. Additionally, the presence of dust or aggregates can disproportionately influence scattering intensity due to the R^6 dependence on particle size, potentially masking the signal from the hydrogel network itself.

Multiple scattering effects represent another technical hurdle. In concentrated hydrogel systems, photons may scatter multiple times before reaching the detector, violating the single-scattering assumption underlying conventional DLS theory. While techniques like cross-correlation DLS have been developed to address this issue, they require specialized equipment not universally available in research laboratories.

Temperature sensitivity adds another layer of complexity. Many hydrogels exhibit temperature-responsive behavior, with phase transitions occurring at specific temperatures. Maintaining precise temperature control during DLS measurements is essential but technically challenging, particularly for hydrogels with transition temperatures near ambient conditions.

Finally, data interpretation challenges persist due to the lack of standardized models specifically developed for hydrogel systems. Most commercial DLS software employs algorithms optimized for hard spheres or simple polymer solutions, which may not accurately represent the complex scattering behavior of crosslinked hydrogel networks with their characteristic mesh sizes and correlation lengths.

One of the most significant limitations is the inherent heterogeneity of hydrogel systems. Unlike uniform particle suspensions, hydrogels often contain regions of varying crosslinking density, creating a non-uniform scattering environment that complicates data interpretation. This heterogeneity leads to multi-modal size distributions that can be difficult to deconvolute using standard DLS algorithms, which typically assume spherical, non-interacting particles.

The dynamic nature of hydrogels presents another major challenge. During measurement, hydrogels continue to undergo swelling, degradation, or restructuring processes, causing temporal variations in scattering patterns. This dynamic behavior can lead to inconsistent results, particularly during long measurement times required for adequate signal averaging in DLS experiments.

Sample preparation issues further complicate hydrogel characterization. The concentration dependence of DLS measurements means that hydrogels must be appropriately diluted for analysis, yet dilution can fundamentally alter the network structure and properties being investigated. Additionally, the presence of dust or aggregates can disproportionately influence scattering intensity due to the R^6 dependence on particle size, potentially masking the signal from the hydrogel network itself.

Multiple scattering effects represent another technical hurdle. In concentrated hydrogel systems, photons may scatter multiple times before reaching the detector, violating the single-scattering assumption underlying conventional DLS theory. While techniques like cross-correlation DLS have been developed to address this issue, they require specialized equipment not universally available in research laboratories.

Temperature sensitivity adds another layer of complexity. Many hydrogels exhibit temperature-responsive behavior, with phase transitions occurring at specific temperatures. Maintaining precise temperature control during DLS measurements is essential but technically challenging, particularly for hydrogels with transition temperatures near ambient conditions.

Finally, data interpretation challenges persist due to the lack of standardized models specifically developed for hydrogel systems. Most commercial DLS software employs algorithms optimized for hard spheres or simple polymer solutions, which may not accurately represent the complex scattering behavior of crosslinked hydrogel networks with their characteristic mesh sizes and correlation lengths.

Established DLS Methodologies for Hydrogel Characterization

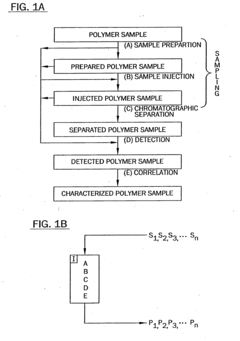

01 Basic principles and apparatus for dynamic light scattering

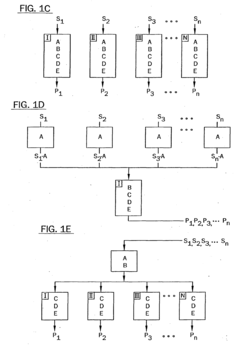

Dynamic light scattering (DLS) is a technique used to determine the size distribution of particles in a solution by measuring the fluctuations in scattered light intensity. The basic apparatus includes a light source (typically a laser), a sample holder, a detector, and signal processing equipment. The technique relies on analyzing the Brownian motion of particles, which causes fluctuations in the scattered light intensity. These fluctuations can be analyzed to determine the diffusion coefficient, which is related to the particle size through the Stokes-Einstein equation.- Principles and apparatus for dynamic light scattering measurements: Dynamic light scattering (DLS) is a technique used to determine the size distribution of particles in suspension by measuring the fluctuations in scattered light intensity. The apparatus typically includes a light source (usually a laser), a sample holder, a detector positioned at a specific angle, and signal processing equipment. The scattered light intensity fluctuations are analyzed to extract information about the diffusion coefficient of particles, which is related to their hydrodynamic radius through the Stokes-Einstein equation.

- Advanced DLS systems with improved detection capabilities: Advanced DLS systems incorporate technological improvements to enhance detection capabilities and measurement accuracy. These innovations include multi-angle detection systems, fiber optic components for improved signal transmission, and specialized optical arrangements to minimize background noise. Some systems employ cross-correlation techniques to suppress multiple scattering effects, allowing measurements in more concentrated samples. Other advancements include temperature control modules for studying temperature-dependent properties and automated sample handling for high-throughput applications.

- Applications of DLS in nanoparticle and biomolecule characterization: Dynamic light scattering is widely applied for characterizing nanoparticles and biomolecules in various fields. In pharmaceutical research, DLS helps determine the size distribution and stability of drug delivery systems. In biotechnology, it's used to analyze protein aggregation, conformational changes, and interactions. For nanomaterials, DLS provides critical information about particle size, polydispersity, and colloidal stability. The technique is particularly valuable for quality control in manufacturing processes where particle size consistency is crucial.

- Integration of DLS with complementary analytical techniques: Modern analytical approaches often integrate DLS with complementary techniques to provide more comprehensive characterization of complex systems. Combinations include DLS with static light scattering for molecular weight determination, with zeta potential measurements for stability assessment, or with size exclusion chromatography for fractionation before size analysis. Some systems incorporate spectroscopic methods like Raman or fluorescence to simultaneously gather compositional information alongside size data. These integrated approaches enable more thorough material characterization with reduced sample requirements.

- Data processing algorithms and software for DLS analysis: Advanced algorithms and software solutions have been developed to improve the analysis of DLS data. These include mathematical models for converting correlation functions to particle size distributions, methods for handling polydisperse samples, and approaches for deconvoluting complex mixtures. Machine learning techniques are increasingly applied to enhance data interpretation and extract meaningful information from noisy signals. Some systems incorporate real-time analysis capabilities, allowing for continuous monitoring of dynamic processes such as aggregation or dissolution phenomena.

02 Advanced DLS instrumentation and improvements

Advancements in DLS instrumentation have led to improved sensitivity, accuracy, and versatility. These improvements include multi-angle detection systems, fiber optic probes, enhanced signal processing algorithms, and integration with other analytical techniques. Modern DLS instruments can measure particles in a wider size range, at lower concentrations, and in more complex sample matrices. Some innovations focus on miniaturization, automation, and real-time monitoring capabilities, making DLS more accessible for various applications.Expand Specific Solutions03 Characterization of nanoparticles and colloidal systems

DLS is widely used for characterizing nanoparticles and colloidal systems in various fields. The technique provides information about particle size distribution, polydispersity, aggregation state, and stability of nanoparticle suspensions. It can be applied to characterize drug delivery systems, polymer nanoparticles, liposomes, protein aggregates, and inorganic nanoparticles. DLS measurements help in quality control, formulation development, and understanding the behavior of nanoparticles in different environments.Expand Specific Solutions04 Biological applications of DLS

DLS is increasingly used in biological research for characterizing biomolecules and their interactions. Applications include protein characterization, detection of protein aggregation, analysis of protein-protein interactions, and monitoring of conformational changes. The technique can provide insights into the size, shape, and stability of proteins, nucleic acids, viruses, and other biological entities. DLS is particularly valuable in biopharmaceutical development, where it helps assess the quality and stability of protein-based drugs.Expand Specific Solutions05 Combined and specialized DLS techniques

Various specialized and combined DLS techniques have been developed to enhance the capabilities and applications of traditional DLS. These include multi-angle DLS, depolarized DLS, cross-correlation DLS, and DLS combined with other analytical methods such as Raman spectroscopy, microscopy, or chromatography. These advanced techniques provide more detailed information about particle properties, overcome limitations of conventional DLS, and enable characterization of complex, concentrated, or polydisperse samples that would be challenging with standard DLS approaches.Expand Specific Solutions

Leading Companies and Research Institutions in DLS Technology

Dynamic Light Scattering (DLS) for hydrogel characterization is in a growth phase, with the global market expanding as biomedical and materials science applications increase. The technology has reached moderate maturity, with established players like Malvern Panalytical and Wyatt Technology dominating with comprehensive DLS solutions. Shimadzu and Agilent offer integrated analytical platforms incorporating DLS capabilities, while academic institutions such as University of Florida and NJIT contribute significant research advancements. BioNTech and Slingshot Biosciences represent the pharmaceutical and biotech sectors leveraging DLS for hydrogel-based drug delivery systems. The competitive landscape is diversifying with specialized applications emerging from smaller players and research institutions, particularly in biomedical and advanced materials sectors.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed advanced Dynamic Light Scattering (DLS) systems specifically optimized for hydrogel characterization. Their Zetasizer series incorporates proprietary Non-Invasive Back Scatter (NIBS) technology that enables accurate measurements of hydrogels across wide concentration ranges without sample dilution that might disrupt gel structure. The company's latest instruments feature adaptive correlation algorithms that can distinguish between the diffusive motion of hydrogel networks and embedded nanoparticles or proteins. Their Multi-Angle DLS capability allows for comprehensive structural analysis by measuring scattering at multiple angles simultaneously, providing insights into both mesh size distribution and network heterogeneity. Malvern's systems also integrate temperature control modules (15-90°C) with precision of ±0.1°C to study thermosensitive hydrogels and their gelation kinetics in real-time.

Strengths: Industry-leading resolution for polydisperse systems; proprietary NIBS technology minimizes multiple scattering effects common in dense hydrogels; comprehensive software suite specifically designed for hydrogel analysis. Weaknesses: Higher price point compared to competitors; complex systems require significant user training; some measurements may still require sample dilution for highly opaque hydrogels.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has pioneered multi-angle light scattering (MALS) technology that complements traditional DLS for comprehensive hydrogel characterization. Their DynaPro® NanoStar® instrument combines DLS with static light scattering capabilities to simultaneously determine both hydrodynamic radius and molecular weight of hydrogel components. Wyatt's proprietary DYNAMICS® software incorporates regularization algorithms specifically optimized for the complex scattering patterns of heterogeneous hydrogel networks. Their technology enables non-destructive in-situ monitoring of gelation processes with temporal resolution down to milliseconds, allowing researchers to capture critical transition points in hydrogel formation. The company has recently developed temperature-controlled microfluidic DLS modules that require minimal sample volumes (as little as 1.25 μL), making them ideal for precious hydrogel formulations in pharmaceutical R&D. Their systems can detect particle sizes ranging from 0.5 nm to 1000 nm, covering the typical mesh size range of most hydrogels.

Strengths: Exceptional sensitivity for low concentration samples; ability to combine DLS with other light scattering techniques for more comprehensive analysis; industry-leading temporal resolution for kinetic studies of gelation. Weaknesses: Systems optimized more for dilute solutions than for dense hydrogel networks; higher complexity in data interpretation compared to competitors; limited penetration depth in highly scattering hydrogel samples.

Key Patents and Scientific Literature on DLS for Hydrogels

Fiber optic apparatus and use thereof in combinatorial material science

PatentInactiveEP1837642A2

Innovation

- The development of systems and protocols for rapid characterization of liquid samples using light-scattering methods, including dynamic and static light scattering, with fiber optic probes that allow for parallel and serial analysis of multiple samples without immersion, enabling near-real-time characterization of particle size, distribution, and other properties.

Standardization and Validation Protocols for DLS in Hydrogel R&D

The standardization and validation of Dynamic Light Scattering (DLS) methodologies for hydrogel characterization represents a critical challenge in the field. Current protocols exhibit significant variability across research institutions and commercial laboratories, leading to inconsistent results and hindering cross-study comparisons. Establishing robust standardization frameworks is essential for advancing hydrogel research and development.

A comprehensive validation protocol should begin with sample preparation guidelines that address concentration dependencies, filtration requirements, and temperature equilibration periods. These factors significantly influence DLS measurements of hydrogels, with inadequate preparation leading to artifacts such as dust contamination or temperature-induced structural changes that compromise data reliability.

Instrument calibration represents another crucial aspect of standardization. Regular verification using certified reference materials with known size distributions (such as polystyrene latex beads) should be mandatory before hydrogel analysis. Calibration should include not only size standards but also zeta potential references when applicable, ensuring measurement accuracy across different instrument models and laboratories.

Data acquisition parameters require strict standardization, including measurement angle optimization (typically 90° or 173° backscatter for hydrogels), count rate thresholds, and appropriate run durations. Multiple measurements (minimum n=5) should be performed on each sample to ensure statistical significance, with automatic outlier detection algorithms implemented to identify and exclude anomalous results.

Data analysis standardization presents particular challenges due to the complex nature of hydrogel systems. Protocols must specify appropriate mathematical models for size distribution analysis, with cumulants analysis for monomodal distributions and CONTIN algorithms for polydisperse systems. Threshold criteria for polydispersity index (PDI) values should be established, with PDI>0.3 triggering additional characterization requirements.

Interlaboratory validation studies represent the gold standard for protocol verification. Round-robin testing involving multiple facilities analyzing identical hydrogel samples should be conducted periodically, with statistical analysis of variance components to identify and address systematic errors. Results from these collaborative studies should inform continuous refinement of standardization protocols.

Documentation requirements constitute the final critical component of validation protocols. Comprehensive reporting templates should include not only measurement results but also detailed experimental conditions, sample history, and raw correlation data to enable meaningful comparison and reproduction of results across different research environments.

A comprehensive validation protocol should begin with sample preparation guidelines that address concentration dependencies, filtration requirements, and temperature equilibration periods. These factors significantly influence DLS measurements of hydrogels, with inadequate preparation leading to artifacts such as dust contamination or temperature-induced structural changes that compromise data reliability.

Instrument calibration represents another crucial aspect of standardization. Regular verification using certified reference materials with known size distributions (such as polystyrene latex beads) should be mandatory before hydrogel analysis. Calibration should include not only size standards but also zeta potential references when applicable, ensuring measurement accuracy across different instrument models and laboratories.

Data acquisition parameters require strict standardization, including measurement angle optimization (typically 90° or 173° backscatter for hydrogels), count rate thresholds, and appropriate run durations. Multiple measurements (minimum n=5) should be performed on each sample to ensure statistical significance, with automatic outlier detection algorithms implemented to identify and exclude anomalous results.

Data analysis standardization presents particular challenges due to the complex nature of hydrogel systems. Protocols must specify appropriate mathematical models for size distribution analysis, with cumulants analysis for monomodal distributions and CONTIN algorithms for polydisperse systems. Threshold criteria for polydispersity index (PDI) values should be established, with PDI>0.3 triggering additional characterization requirements.

Interlaboratory validation studies represent the gold standard for protocol verification. Round-robin testing involving multiple facilities analyzing identical hydrogel samples should be conducted periodically, with statistical analysis of variance components to identify and address systematic errors. Results from these collaborative studies should inform continuous refinement of standardization protocols.

Documentation requirements constitute the final critical component of validation protocols. Comprehensive reporting templates should include not only measurement results but also detailed experimental conditions, sample history, and raw correlation data to enable meaningful comparison and reproduction of results across different research environments.

Integration with Complementary Analytical Techniques

Dynamic Light Scattering (DLS) analysis of hydrogels yields more comprehensive insights when integrated with complementary analytical techniques. This integration creates a multi-dimensional characterization framework that addresses the inherent limitations of DLS when used in isolation for complex hydrogel systems.

Rheological measurements provide critical mechanical property data that complements DLS particle size analysis. While DLS reveals information about the nanoscale structure and dynamics of hydrogel networks, rheology characterizes viscoelastic properties, yielding insights into gel strength, crosslinking density, and mechanical stability under various conditions. The correlation between DLS-derived mesh size and rheologically determined storage modulus offers a powerful approach to understanding structure-property relationships in hydrogels.

Microscopy techniques, particularly confocal and electron microscopy, offer direct visualization capabilities that enhance DLS data interpretation. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide high-resolution images of hydrogel morphology, while confocal microscopy enables non-destructive 3D visualization of hydrogel networks in their hydrated state. These visual confirmations of network architecture validate and contextualize the statistical data generated through DLS measurements.

Spectroscopic methods such as FTIR and Raman spectroscopy complement DLS by providing chemical composition information. These techniques identify specific functional groups and chemical bonds within the hydrogel network, offering insights into crosslinking mechanisms and polymer-water interactions that influence the hydrogel's dynamic behavior as measured by DLS.

Small-angle X-ray scattering (SAXS) and small-angle neutron scattering (SANS) techniques operate on similar principles to DLS but utilize different radiation sources. When combined with DLS, these techniques provide multi-scale structural information, with DLS typically covering larger length scales (1-1000 nm) while SAXS and SANS can probe smaller structural features (0.1-100 nm) with greater precision.

Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) offer thermodynamic insights that complement DLS measurements. These thermal techniques reveal phase transitions, water binding characteristics, and thermal stability parameters that directly influence the temperature-dependent behavior observed in DLS experiments.

Advanced data fusion algorithms and machine learning approaches are increasingly being employed to integrate multi-technique datasets. These computational methods identify correlations between parameters measured by different techniques, creating predictive models that enhance the value of DLS data when combined with complementary analytical results.

Rheological measurements provide critical mechanical property data that complements DLS particle size analysis. While DLS reveals information about the nanoscale structure and dynamics of hydrogel networks, rheology characterizes viscoelastic properties, yielding insights into gel strength, crosslinking density, and mechanical stability under various conditions. The correlation between DLS-derived mesh size and rheologically determined storage modulus offers a powerful approach to understanding structure-property relationships in hydrogels.

Microscopy techniques, particularly confocal and electron microscopy, offer direct visualization capabilities that enhance DLS data interpretation. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide high-resolution images of hydrogel morphology, while confocal microscopy enables non-destructive 3D visualization of hydrogel networks in their hydrated state. These visual confirmations of network architecture validate and contextualize the statistical data generated through DLS measurements.

Spectroscopic methods such as FTIR and Raman spectroscopy complement DLS by providing chemical composition information. These techniques identify specific functional groups and chemical bonds within the hydrogel network, offering insights into crosslinking mechanisms and polymer-water interactions that influence the hydrogel's dynamic behavior as measured by DLS.

Small-angle X-ray scattering (SAXS) and small-angle neutron scattering (SANS) techniques operate on similar principles to DLS but utilize different radiation sources. When combined with DLS, these techniques provide multi-scale structural information, with DLS typically covering larger length scales (1-1000 nm) while SAXS and SANS can probe smaller structural features (0.1-100 nm) with greater precision.

Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) offer thermodynamic insights that complement DLS measurements. These thermal techniques reveal phase transitions, water binding characteristics, and thermal stability parameters that directly influence the temperature-dependent behavior observed in DLS experiments.

Advanced data fusion algorithms and machine learning approaches are increasingly being employed to integrate multi-technique datasets. These computational methods identify correlations between parameters measured by different techniques, creating predictive models that enhance the value of DLS data when combined with complementary analytical results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!