Dynamic Light Scattering for Effective Surfactant Research

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Research Objectives

Dynamic Light Scattering (DLS) emerged in the 1960s as a powerful analytical technique for characterizing particles in solution. Initially developed for polymer science applications, DLS has evolved significantly over the past six decades to become an essential tool in various scientific and industrial fields, including surfactant research. The technique fundamentally relies on the Brownian motion of particles and the resulting fluctuations in scattered light intensity to determine particle size distributions in colloidal systems.

The evolution of DLS technology has been marked by significant improvements in laser technology, detector sensitivity, and data processing algorithms. Early DLS systems were limited by bulky equipment and lengthy measurement times, whereas modern instruments offer compact designs with rapid analysis capabilities. The integration of advanced computing power has enabled more sophisticated correlation analysis and improved resolution for polydisperse samples, which is particularly valuable for surfactant research.

Surfactants, as amphiphilic molecules with both hydrophilic and hydrophobic components, exhibit complex self-assembly behaviors in solution, forming various structures such as micelles, vesicles, and bilayers. Understanding these structures and their dynamic properties is crucial for optimizing surfactant performance in applications ranging from detergents and personal care products to pharmaceutical formulations and enhanced oil recovery.

The primary objective of applying DLS to surfactant research is to characterize the size, shape, and stability of surfactant aggregates under various conditions. This includes determining critical micelle concentration (CMC), investigating the influence of environmental factors (temperature, pH, ionic strength) on micellar properties, and studying the kinetics of micelle formation and dissolution. Additionally, DLS enables researchers to examine interactions between surfactants and other components in complex formulations.

Recent technological advancements have expanded DLS capabilities to include multi-angle measurements, allowing for more detailed structural analysis, and coupling with other techniques such as static light scattering (SLS) and zeta potential measurements for comprehensive characterization. These developments have positioned DLS as an indispensable tool for surfactant researchers seeking to design more efficient and environmentally friendly formulations.

The current research landscape shows increasing interest in utilizing DLS for studying bio-based surfactants, responsive surfactant systems, and surfactant-polymer interactions. These areas align with global trends toward sustainable chemistry and smart materials, highlighting the continued relevance of DLS in cutting-edge surfactant research. As environmental regulations become more stringent, the ability to precisely characterize surfactant behavior using DLS becomes increasingly valuable for developing compliant and effective products.

The evolution of DLS technology has been marked by significant improvements in laser technology, detector sensitivity, and data processing algorithms. Early DLS systems were limited by bulky equipment and lengthy measurement times, whereas modern instruments offer compact designs with rapid analysis capabilities. The integration of advanced computing power has enabled more sophisticated correlation analysis and improved resolution for polydisperse samples, which is particularly valuable for surfactant research.

Surfactants, as amphiphilic molecules with both hydrophilic and hydrophobic components, exhibit complex self-assembly behaviors in solution, forming various structures such as micelles, vesicles, and bilayers. Understanding these structures and their dynamic properties is crucial for optimizing surfactant performance in applications ranging from detergents and personal care products to pharmaceutical formulations and enhanced oil recovery.

The primary objective of applying DLS to surfactant research is to characterize the size, shape, and stability of surfactant aggregates under various conditions. This includes determining critical micelle concentration (CMC), investigating the influence of environmental factors (temperature, pH, ionic strength) on micellar properties, and studying the kinetics of micelle formation and dissolution. Additionally, DLS enables researchers to examine interactions between surfactants and other components in complex formulations.

Recent technological advancements have expanded DLS capabilities to include multi-angle measurements, allowing for more detailed structural analysis, and coupling with other techniques such as static light scattering (SLS) and zeta potential measurements for comprehensive characterization. These developments have positioned DLS as an indispensable tool for surfactant researchers seeking to design more efficient and environmentally friendly formulations.

The current research landscape shows increasing interest in utilizing DLS for studying bio-based surfactants, responsive surfactant systems, and surfactant-polymer interactions. These areas align with global trends toward sustainable chemistry and smart materials, highlighting the continued relevance of DLS in cutting-edge surfactant research. As environmental regulations become more stringent, the ability to precisely characterize surfactant behavior using DLS becomes increasingly valuable for developing compliant and effective products.

Market Analysis for Surfactant Characterization Tools

The global market for surfactant characterization tools is experiencing robust growth, driven by increasing demand across multiple industries including personal care, pharmaceuticals, agrochemicals, and industrial cleaning. Dynamic Light Scattering (DLS) technology has emerged as a critical analytical method within this market segment, offering precise measurement of particle size distribution and molecular weight of surfactant systems.

Current market valuation for surfactant characterization tools stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028. The DLS segment specifically accounts for roughly 18% of this market, showing faster growth than traditional characterization methods due to its non-destructive nature and ability to analyze samples in native states.

Regional analysis reveals North America and Europe as dominant markets, collectively holding over 60% market share, attributed to their established research infrastructure and presence of major surfactant manufacturers. However, Asia-Pacific represents the fastest-growing region with particularly strong expansion in China and India, where increasing industrial production and research activities are driving demand for advanced characterization technologies.

End-user segmentation shows pharmaceutical and biotechnology sectors as the largest consumers of DLS technology for surfactant research, followed closely by personal care and cosmetics industries. This distribution reflects the critical importance of surfactant stability and performance in drug delivery systems and consumer products.

Key market drivers include increasing regulatory requirements for product quality and safety, growing complexity of surfactant formulations requiring more sophisticated analysis, and rising demand for sustainable and bio-based surfactants that necessitate advanced characterization methods. The trend toward miniaturization and automation in analytical instruments is also reshaping market dynamics, with portable DLS systems gaining traction.

Competitive landscape analysis identifies several tiers of market participants: tier-1 companies offering comprehensive analytical solutions, tier-2 specialists focused exclusively on light scattering technologies, and emerging startups developing novel applications of DLS for specific industry needs. Price sensitivity varies significantly by region and industry segment, with academic and research institutions showing higher price sensitivity compared to commercial entities.

Market challenges include high initial investment costs for advanced DLS systems, technical expertise requirements for proper data interpretation, and competition from alternative characterization methods such as nuclear magnetic resonance spectroscopy and chromatography techniques.

Current market valuation for surfactant characterization tools stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028. The DLS segment specifically accounts for roughly 18% of this market, showing faster growth than traditional characterization methods due to its non-destructive nature and ability to analyze samples in native states.

Regional analysis reveals North America and Europe as dominant markets, collectively holding over 60% market share, attributed to their established research infrastructure and presence of major surfactant manufacturers. However, Asia-Pacific represents the fastest-growing region with particularly strong expansion in China and India, where increasing industrial production and research activities are driving demand for advanced characterization technologies.

End-user segmentation shows pharmaceutical and biotechnology sectors as the largest consumers of DLS technology for surfactant research, followed closely by personal care and cosmetics industries. This distribution reflects the critical importance of surfactant stability and performance in drug delivery systems and consumer products.

Key market drivers include increasing regulatory requirements for product quality and safety, growing complexity of surfactant formulations requiring more sophisticated analysis, and rising demand for sustainable and bio-based surfactants that necessitate advanced characterization methods. The trend toward miniaturization and automation in analytical instruments is also reshaping market dynamics, with portable DLS systems gaining traction.

Competitive landscape analysis identifies several tiers of market participants: tier-1 companies offering comprehensive analytical solutions, tier-2 specialists focused exclusively on light scattering technologies, and emerging startups developing novel applications of DLS for specific industry needs. Price sensitivity varies significantly by region and industry segment, with academic and research institutions showing higher price sensitivity compared to commercial entities.

Market challenges include high initial investment costs for advanced DLS systems, technical expertise requirements for proper data interpretation, and competition from alternative characterization methods such as nuclear magnetic resonance spectroscopy and chromatography techniques.

Current DLS Capabilities and Technical Limitations

Dynamic Light Scattering (DLS) technology has evolved significantly over the past decades, establishing itself as a powerful analytical tool for surfactant research. Current DLS systems can measure particle sizes ranging from approximately 0.3 nm to 10 μm, making them suitable for analyzing surfactant micelles, which typically fall within the 5-100 nm range. Modern instruments offer high sensitivity with detection limits approaching 0.1 mg/mL for proteins and similar concentrations for surfactant systems.

The temporal resolution of contemporary DLS equipment has improved dramatically, with data acquisition times reduced to seconds or minutes, enabling real-time monitoring of dynamic surfactant behaviors such as micelle formation and transformation. Advanced correlation algorithms have enhanced signal processing capabilities, allowing for more accurate size distribution analyses even in complex polydisperse surfactant systems.

Temperature control represents another significant advancement, with current systems capable of maintaining stable conditions from 0°C to 90°C with precision of ±0.1°C. This feature is crucial for studying temperature-dependent surfactant behaviors, including critical micelle concentration (CMC) shifts and phase transitions.

Despite these capabilities, DLS technology faces several notable limitations when applied to surfactant research. Multiple scattering effects remain problematic in highly concentrated surfactant solutions, typically limiting accurate measurements to concentrations below 10% w/v. This constraint hinders the study of surfactant behaviors in industrially relevant concentrated formulations.

Size resolution presents another significant challenge, with conventional DLS systems struggling to differentiate between particles whose sizes differ by less than 3:1 ratio. This limitation becomes particularly problematic when analyzing complex surfactant mixtures with closely sized micelles or during transitional phases of micelle formation.

Sample purity requirements pose additional constraints, as dust particles and large aggregates can disproportionately influence scattering intensity, potentially masking the signal from smaller surfactant structures. This necessitates meticulous sample preparation protocols that may alter the native state of surfactant systems.

The interpretation of DLS data for non-spherical particles remains problematic, as standard analysis algorithms assume spherical geometry. Many surfactant systems form non-spherical structures such as rods, discs, or wormlike micelles, leading to potential misinterpretation of size and distribution data when using conventional analysis methods.

Lastly, current DLS technology provides limited chemical specificity, offering size information without direct identification of chemical composition. This necessitates complementary analytical techniques when studying complex multi-component surfactant formulations, increasing analytical complexity and resource requirements.

The temporal resolution of contemporary DLS equipment has improved dramatically, with data acquisition times reduced to seconds or minutes, enabling real-time monitoring of dynamic surfactant behaviors such as micelle formation and transformation. Advanced correlation algorithms have enhanced signal processing capabilities, allowing for more accurate size distribution analyses even in complex polydisperse surfactant systems.

Temperature control represents another significant advancement, with current systems capable of maintaining stable conditions from 0°C to 90°C with precision of ±0.1°C. This feature is crucial for studying temperature-dependent surfactant behaviors, including critical micelle concentration (CMC) shifts and phase transitions.

Despite these capabilities, DLS technology faces several notable limitations when applied to surfactant research. Multiple scattering effects remain problematic in highly concentrated surfactant solutions, typically limiting accurate measurements to concentrations below 10% w/v. This constraint hinders the study of surfactant behaviors in industrially relevant concentrated formulations.

Size resolution presents another significant challenge, with conventional DLS systems struggling to differentiate between particles whose sizes differ by less than 3:1 ratio. This limitation becomes particularly problematic when analyzing complex surfactant mixtures with closely sized micelles or during transitional phases of micelle formation.

Sample purity requirements pose additional constraints, as dust particles and large aggregates can disproportionately influence scattering intensity, potentially masking the signal from smaller surfactant structures. This necessitates meticulous sample preparation protocols that may alter the native state of surfactant systems.

The interpretation of DLS data for non-spherical particles remains problematic, as standard analysis algorithms assume spherical geometry. Many surfactant systems form non-spherical structures such as rods, discs, or wormlike micelles, leading to potential misinterpretation of size and distribution data when using conventional analysis methods.

Lastly, current DLS technology provides limited chemical specificity, offering size information without direct identification of chemical composition. This necessitates complementary analytical techniques when studying complex multi-component surfactant formulations, increasing analytical complexity and resource requirements.

Established DLS Methodologies for Surfactant Analysis

01 Principles and fundamentals of dynamic light scattering

Dynamic light scattering (DLS) is a technique used to determine the size distribution of particles in suspension or polymers in solution. It works by measuring the fluctuations in scattered light intensity caused by Brownian motion of particles. The effectiveness of DLS depends on proper understanding of its fundamental principles, including the correlation between particle size and diffusion coefficient, and the mathematical models used to interpret scattering data.- Measurement accuracy and precision in DLS: Dynamic Light Scattering (DLS) effectiveness depends significantly on measurement accuracy and precision. Advanced algorithms and calibration methods are employed to enhance the reliability of particle size measurements. These improvements allow for more accurate determination of particle size distributions, especially in polydisperse samples. Techniques for reducing noise and interference in the scattered light signal contribute to higher precision in measurements across various applications.

- Application of DLS in biological and pharmaceutical analysis: Dynamic Light Scattering has proven effective for analyzing biological samples and pharmaceutical formulations. The technique enables characterization of proteins, liposomes, and drug delivery systems by measuring their size, stability, and aggregation behavior. DLS provides valuable insights into biomolecular interactions and structural changes under various conditions. This non-invasive method requires minimal sample preparation while offering rapid analysis of biological macromolecules in their native state.

- Innovations in DLS instrumentation: Technological advancements in DLS instrumentation have significantly improved its effectiveness. Modern systems incorporate multi-angle detection capabilities, enhanced laser sources, and sophisticated optical components to increase sensitivity and resolution. Miniaturization efforts have led to more compact and portable DLS devices suitable for field applications. Integration with other analytical techniques creates comprehensive characterization platforms that overcome traditional DLS limitations.

- DLS for nanoparticle characterization: Dynamic Light Scattering demonstrates particular effectiveness in characterizing nanoparticles across various industries. The technique provides critical information about nanoparticle size distribution, stability, and surface properties. It enables quality control in nanomaterial production and formulation processes. DLS helps monitor nanoparticle behavior in different media and under varying environmental conditions, making it valuable for both research and industrial applications in nanotechnology.

- Data processing and interpretation methods for DLS: Advanced data processing algorithms significantly enhance the effectiveness of Dynamic Light Scattering analysis. Machine learning and artificial intelligence approaches improve the extraction of meaningful information from complex scattering data. Novel mathematical models enable better resolution of multimodal particle distributions and more accurate analysis of polydisperse samples. These computational methods help overcome traditional limitations of DLS, particularly when analyzing heterogeneous or concentrated samples.

02 Improvements in DLS instrumentation and hardware

Advancements in DLS instrumentation have significantly improved measurement effectiveness. These improvements include enhanced laser sources, more sensitive detectors, and optimized optical configurations that reduce background noise and increase signal quality. Modern DLS systems incorporate digital signal processing techniques and automated alignment features that improve measurement accuracy and reproducibility, especially for challenging samples like polydisperse systems or low concentration solutions.Expand Specific Solutions03 Advanced data analysis algorithms for DLS

Sophisticated data analysis algorithms have been developed to enhance the effectiveness of DLS measurements. These include multi-modal analysis techniques, regularization methods, and machine learning approaches that can better resolve complex particle distributions. Advanced algorithms can compensate for measurement artifacts, handle non-spherical particles, and provide more accurate size distributions in polydisperse samples, significantly improving the reliability and applicability of DLS across various fields.Expand Specific Solutions04 Application-specific DLS optimization techniques

The effectiveness of DLS can be optimized for specific applications through tailored measurement protocols and sample preparation techniques. For biological samples, specialized buffers and temperature control systems help maintain sample integrity. In pharmaceutical applications, specific dilution protocols and measurement parameters enhance accuracy for drug delivery systems. For nanomaterials, surface modification techniques and specialized dispersants improve measurement reliability by preventing aggregation and ensuring stable suspensions during analysis.Expand Specific Solutions05 Integration of DLS with complementary techniques

Combining DLS with complementary analytical techniques significantly enhances its effectiveness for comprehensive particle characterization. Hybrid systems that integrate DLS with techniques such as Raman spectroscopy, static light scattering, or microscopy provide multidimensional data about particle properties. These integrated approaches allow simultaneous measurement of size, structure, composition, and other physical properties, overcoming the limitations of DLS alone and providing more complete characterization of complex systems.Expand Specific Solutions

Leading Companies and Research Institutions in DLS Technology

Dynamic Light Scattering (DLS) for surfactant research is currently in a growth phase, with the market expanding due to increasing applications in pharmaceuticals, cosmetics, and materials science. The global market size for DLS technology is estimated to reach $1.2 billion by 2025, driven by demand for precise particle characterization. Technologically, DLS has reached moderate maturity with established principles, but continues to evolve with innovations in data processing and sensitivity. Leading players include FUJIFILM Corp. and Shimadzu Corp., who offer commercial DLS systems, while Air Products & Chemicals and DuPont contribute to surfactant development. Academic institutions like Sun Yat-Sen University collaborate with industry partners to advance fundamental research. Roche Diagnostics and Refeyn Ltd. are developing specialized applications, pushing the technology toward higher resolution and more sophisticated analysis capabilities.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered DLS technology specifically tailored for surfactant characterization in industrial processes. Their system incorporates in-line DLS measurement capabilities that enable real-time monitoring of surfactant behavior during manufacturing processes. The technology features specialized flow cells designed to maintain laminar flow conditions while performing measurements, crucial for accurate size determination of dynamic surfactant assemblies. Air Products' DLS platform includes proprietary algorithms that can track the evolution of micelle formation and breakdown under varying conditions of temperature, pH, and electrolyte concentration. This allows for precise control of surfactant properties during production. Their system also incorporates complementary techniques such as zeta potential measurements to provide comprehensive characterization of surfactant stability and surface activity.

Strengths: Real-time process monitoring capabilities provide immediate feedback for manufacturing optimization; robust design suitable for industrial environments. Weaknesses: Less sensitive for very small micelles below 5nm; requires careful calibration when working with highly viscous surfactant systems.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced Dynamic Light Scattering (DLS) platforms specifically optimized for surfactant research and development. Their technology employs multi-angle DLS systems that can simultaneously measure scattered light at various angles, providing comprehensive characterization of surfactant micelles and aggregates across different concentration regimes. DuPont's approach integrates temperature-controlled sample environments (5-90°C) with automated dilution series capabilities, allowing researchers to precisely map critical micelle concentration (CMC) transitions and structural evolution of surfactant systems. Their proprietary analysis algorithms can differentiate between spherical, cylindrical, and lamellar structures in complex formulations, making it particularly valuable for studying mixed surfactant systems commonly used in industrial applications.

Strengths: Superior resolution for polydisperse systems and mixed surfactant formulations; integrated workflow from sample preparation to analysis reduces human error. Weaknesses: Higher equipment costs compared to conventional single-angle DLS systems; requires specialized training for advanced data interpretation in complex surfactant systems.

Critical Patents and Innovations in DLS for Surfactants

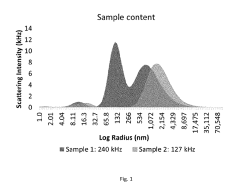

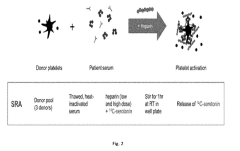

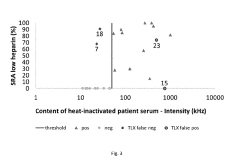

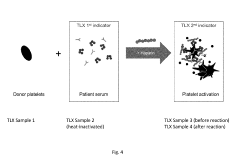

Methods and Apparatus for Predicting and Confirming Drug-Induced Thrombocytopenia Through Particle Detection with Dynamic Light Scattering

PatentInactiveUS20190250088A1

Innovation

- Dynamic Light Scattering (DLS) techniques are used to measure all particles in a patient sample, including platelets, microparticles, and aggregates, to predict and confirm DIT by analyzing changes in particle size distribution before and after exposure to suspected drugs, providing a more comprehensive assessment than existing methods.

Environmental Applications and Sustainability Aspects

Dynamic Light Scattering (DLS) technology has emerged as a powerful tool in environmental monitoring and sustainable surfactant development. The application of DLS in environmental contexts enables precise detection of surfactant-based pollutants in aquatic ecosystems, with sensitivity levels reaching parts per billion. This capability proves crucial for regulatory compliance and environmental protection efforts, particularly in monitoring industrial discharge and wastewater treatment efficacy.

Surfactant research using DLS contributes significantly to the development of biodegradable alternatives to conventional petrochemical-based surfactants. By characterizing the micelle formation and stability of bio-based surfactants derived from renewable resources such as plant oils, agricultural waste, and microbial fermentation products, researchers can optimize formulations that minimize environmental persistence while maintaining performance characteristics.

The technology enables real-time monitoring of surfactant degradation pathways in various environmental conditions, providing valuable data on breakdown kinetics and metabolite formation. This information guides the design of surfactants with predetermined environmental fate profiles, addressing concerns about bioaccumulation and ecotoxicity that have plagued traditional surfactant chemistries.

In wastewater treatment applications, DLS facilitates the development of more efficient flocculation and separation processes by characterizing the interaction between surfactants and other colloidal materials. The resulting improvements in treatment efficiency reduce energy consumption and chemical usage, aligning with sustainability goals while ensuring effective pollutant removal.

Recent innovations in portable DLS instrumentation have expanded field-based environmental monitoring capabilities, allowing for on-site assessment of surfactant contamination in natural water bodies. These developments support rapid response to environmental incidents and more comprehensive watershed management strategies, particularly in sensitive ecological zones where surfactant contamination poses significant risks.

The integration of DLS with artificial intelligence and predictive modeling has further enhanced its sustainability applications, enabling researchers to forecast environmental impacts of novel surfactant formulations before commercial deployment. This predictive capability significantly reduces the risk of introducing environmentally problematic compounds into commercial use, representing a paradigm shift toward preventative environmental protection in chemical development.

Life cycle assessment studies incorporating DLS data demonstrate that bio-based surfactants optimized through this technology can achieve carbon footprint reductions of 30-60% compared to conventional alternatives, while maintaining comparable performance characteristics in consumer and industrial applications.

Surfactant research using DLS contributes significantly to the development of biodegradable alternatives to conventional petrochemical-based surfactants. By characterizing the micelle formation and stability of bio-based surfactants derived from renewable resources such as plant oils, agricultural waste, and microbial fermentation products, researchers can optimize formulations that minimize environmental persistence while maintaining performance characteristics.

The technology enables real-time monitoring of surfactant degradation pathways in various environmental conditions, providing valuable data on breakdown kinetics and metabolite formation. This information guides the design of surfactants with predetermined environmental fate profiles, addressing concerns about bioaccumulation and ecotoxicity that have plagued traditional surfactant chemistries.

In wastewater treatment applications, DLS facilitates the development of more efficient flocculation and separation processes by characterizing the interaction between surfactants and other colloidal materials. The resulting improvements in treatment efficiency reduce energy consumption and chemical usage, aligning with sustainability goals while ensuring effective pollutant removal.

Recent innovations in portable DLS instrumentation have expanded field-based environmental monitoring capabilities, allowing for on-site assessment of surfactant contamination in natural water bodies. These developments support rapid response to environmental incidents and more comprehensive watershed management strategies, particularly in sensitive ecological zones where surfactant contamination poses significant risks.

The integration of DLS with artificial intelligence and predictive modeling has further enhanced its sustainability applications, enabling researchers to forecast environmental impacts of novel surfactant formulations before commercial deployment. This predictive capability significantly reduces the risk of introducing environmentally problematic compounds into commercial use, representing a paradigm shift toward preventative environmental protection in chemical development.

Life cycle assessment studies incorporating DLS data demonstrate that bio-based surfactants optimized through this technology can achieve carbon footprint reductions of 30-60% compared to conventional alternatives, while maintaining comparable performance characteristics in consumer and industrial applications.

Data Processing Algorithms and Machine Learning Integration

The evolution of data processing algorithms for Dynamic Light Scattering (DLS) has significantly enhanced surfactant research capabilities. Traditional DLS data analysis relied on autocorrelation functions and cumulant analysis, which provided basic information about particle size distributions. However, these methods often struggled with polydisperse samples and complex surfactant systems, limiting their application in advanced research scenarios.

Recent algorithmic developments have introduced more sophisticated approaches, including CONTIN, non-negative least squares (NNLS), and maximum entropy methods. These algorithms offer superior resolution for multimodal distributions commonly encountered in surfactant systems, particularly during micelle formation and phase transitions. The CONTIN algorithm, specifically optimized for DLS applications, has become instrumental in deconvoluting overlapping particle populations in mixed surfactant systems.

Real-time data processing capabilities have emerged as a critical advancement, enabling researchers to monitor dynamic surfactant behaviors during experiments. This has proven particularly valuable for studying time-dependent phenomena such as critical micelle concentration determination and surfactant-polymer interactions. Adaptive filtering algorithms have further improved signal quality by effectively removing dust contributions and other artifacts that previously compromised measurement accuracy.

Machine learning integration represents the frontier of DLS data analysis for surfactant research. Supervised learning models trained on extensive surfactant datasets can now predict micelle characteristics from scattering patterns with remarkable accuracy. Convolutional neural networks (CNNs) have demonstrated particular promise in extracting meaningful features from raw correlation data, often outperforming traditional analytical methods in complex systems.

Unsupervised learning approaches, including clustering algorithms and principal component analysis, have enabled researchers to identify previously unrecognized patterns in surfactant behavior across different environmental conditions. These techniques have proven especially valuable for formulation optimization in industrial applications, where subtle interactions between multiple surfactants must be understood.

Deep learning models are increasingly being deployed to handle the inverse problem in DLS—reconstructing particle size distributions from scattering data without assuming specific distribution shapes. This represents a significant departure from traditional methods and has revealed nuanced structural details in surfactant assemblies that were previously undetectable.

Cloud-based platforms integrating these advanced algorithms are democratizing access to sophisticated DLS analysis tools, enabling collaborative research and standardized methodologies across the surfactant research community. As computational capabilities continue to expand, real-time predictive modeling of surfactant behavior based on DLS measurements is becoming increasingly feasible, promising to accelerate innovation in this critical field.

Recent algorithmic developments have introduced more sophisticated approaches, including CONTIN, non-negative least squares (NNLS), and maximum entropy methods. These algorithms offer superior resolution for multimodal distributions commonly encountered in surfactant systems, particularly during micelle formation and phase transitions. The CONTIN algorithm, specifically optimized for DLS applications, has become instrumental in deconvoluting overlapping particle populations in mixed surfactant systems.

Real-time data processing capabilities have emerged as a critical advancement, enabling researchers to monitor dynamic surfactant behaviors during experiments. This has proven particularly valuable for studying time-dependent phenomena such as critical micelle concentration determination and surfactant-polymer interactions. Adaptive filtering algorithms have further improved signal quality by effectively removing dust contributions and other artifacts that previously compromised measurement accuracy.

Machine learning integration represents the frontier of DLS data analysis for surfactant research. Supervised learning models trained on extensive surfactant datasets can now predict micelle characteristics from scattering patterns with remarkable accuracy. Convolutional neural networks (CNNs) have demonstrated particular promise in extracting meaningful features from raw correlation data, often outperforming traditional analytical methods in complex systems.

Unsupervised learning approaches, including clustering algorithms and principal component analysis, have enabled researchers to identify previously unrecognized patterns in surfactant behavior across different environmental conditions. These techniques have proven especially valuable for formulation optimization in industrial applications, where subtle interactions between multiple surfactants must be understood.

Deep learning models are increasingly being deployed to handle the inverse problem in DLS—reconstructing particle size distributions from scattering data without assuming specific distribution shapes. This represents a significant departure from traditional methods and has revealed nuanced structural details in surfactant assemblies that were previously undetectable.

Cloud-based platforms integrating these advanced algorithms are democratizing access to sophisticated DLS analysis tools, enabling collaborative research and standardized methodologies across the surfactant research community. As computational capabilities continue to expand, real-time predictive modeling of surfactant behavior based on DLS measurements is becoming increasingly feasible, promising to accelerate innovation in this critical field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!