Electride Based Thermoelectrics Prospects And Hurdles

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electride Thermoelectrics Background and Objectives

Thermoelectric materials, which convert heat directly into electricity, have been a subject of intensive research for decades due to their potential applications in waste heat recovery and solid-state cooling. Among various thermoelectric materials, electrides have emerged as promising candidates in recent years. Electrides are a unique class of ionic compounds where electrons serve as anions, occupying specific sites in the crystal lattice. This distinctive electronic structure gives rise to exceptional properties that are particularly advantageous for thermoelectric applications.

The concept of electrides dates back to the 1980s, but their practical realization and application in thermoelectrics have gained momentum only in the past decade. The evolution of electride research has progressed from alkali metal-based electrides, which were unstable in ambient conditions, to more stable inorganic electrides such as C12A7:e- (12CaO·7Al2O3:e-) and 2D electrides like Ca2N. These advancements have opened new avenues for exploring their thermoelectric properties.

The fundamental appeal of electrides for thermoelectric applications lies in their unique electronic structure. The loosely bound electrons in electrides can contribute to high electrical conductivity while the complex crystal structure can simultaneously lead to low thermal conductivity – a combination that is ideal for achieving high thermoelectric efficiency, quantified by the figure of merit ZT.

Current research objectives in electride-based thermoelectrics are multifaceted. Primarily, there is a focus on enhancing the thermoelectric figure of merit (ZT) of electride materials to values exceeding 2, which would make them commercially viable for widespread applications. This involves optimizing the power factor (a product of electrical conductivity and Seebeck coefficient squared) while minimizing thermal conductivity.

Another critical objective is to develop electride materials that are stable under operating conditions, particularly at elevated temperatures and in the presence of oxygen and moisture. The inherent reactivity of many electrides poses significant challenges for practical applications, necessitating innovative approaches to enhance their stability.

Furthermore, there is a growing emphasis on developing environmentally friendly and cost-effective electride materials. Many current high-performance thermoelectric materials contain toxic or rare elements, limiting their large-scale deployment. Electrides based on abundant elements offer a promising alternative, aligning with global sustainability goals.

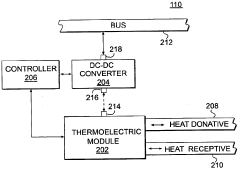

The integration of electride materials into practical thermoelectric devices represents another key objective. This includes addressing challenges related to contact resistance, thermal management, and device architecture to maximize energy conversion efficiency in real-world applications.

The concept of electrides dates back to the 1980s, but their practical realization and application in thermoelectrics have gained momentum only in the past decade. The evolution of electride research has progressed from alkali metal-based electrides, which were unstable in ambient conditions, to more stable inorganic electrides such as C12A7:e- (12CaO·7Al2O3:e-) and 2D electrides like Ca2N. These advancements have opened new avenues for exploring their thermoelectric properties.

The fundamental appeal of electrides for thermoelectric applications lies in their unique electronic structure. The loosely bound electrons in electrides can contribute to high electrical conductivity while the complex crystal structure can simultaneously lead to low thermal conductivity – a combination that is ideal for achieving high thermoelectric efficiency, quantified by the figure of merit ZT.

Current research objectives in electride-based thermoelectrics are multifaceted. Primarily, there is a focus on enhancing the thermoelectric figure of merit (ZT) of electride materials to values exceeding 2, which would make them commercially viable for widespread applications. This involves optimizing the power factor (a product of electrical conductivity and Seebeck coefficient squared) while minimizing thermal conductivity.

Another critical objective is to develop electride materials that are stable under operating conditions, particularly at elevated temperatures and in the presence of oxygen and moisture. The inherent reactivity of many electrides poses significant challenges for practical applications, necessitating innovative approaches to enhance their stability.

Furthermore, there is a growing emphasis on developing environmentally friendly and cost-effective electride materials. Many current high-performance thermoelectric materials contain toxic or rare elements, limiting their large-scale deployment. Electrides based on abundant elements offer a promising alternative, aligning with global sustainability goals.

The integration of electride materials into practical thermoelectric devices represents another key objective. This includes addressing challenges related to contact resistance, thermal management, and device architecture to maximize energy conversion efficiency in real-world applications.

Market Analysis for Electride-Based Thermoelectric Applications

The global market for thermoelectric materials and devices is experiencing significant growth, driven by increasing demand for energy efficiency solutions and waste heat recovery systems. The thermoelectric market was valued at approximately $460 million in 2020 and is projected to reach $720 million by 2025, growing at a CAGR of 9.4%. Within this expanding market, electride-based thermoelectrics represent an emerging segment with substantial potential for disruption.

Electride-based thermoelectric materials address several key market demands that conventional thermoelectric materials struggle to fulfill. The primary market driver is the superior figure of merit (ZT) that electrides can potentially achieve, which directly translates to higher energy conversion efficiency. This efficiency improvement could unlock applications where traditional thermoelectrics have been economically unfeasible.

The automotive sector presents one of the most promising markets for electride thermoelectrics. With stringent emissions regulations worldwide, automotive manufacturers are seeking technologies to improve fuel efficiency. Waste heat recovery systems using high-performance thermoelectrics could recover up to 5% of engine waste heat, representing a potential market of $300 million annually if widely adopted.

Industrial waste heat recovery represents another substantial market opportunity. Manufacturing processes in steel, glass, cement, and chemical industries generate enormous amounts of waste heat. The global industrial waste heat recovery market is expected to reach $80 billion by 2025, with thermoelectric solutions competing for a significant share of this market.

Consumer electronics and IoT devices constitute a rapidly growing application area for thermoelectric materials. The need for self-powered sensors and devices is driving demand for miniaturized power generation solutions. Electride-based thermoelectrics, with their potentially higher power density, could capture a significant portion of this market, estimated to grow to $25 billion by 2026.

Space exploration and remote power generation represent niche but high-value markets where electride thermoelectrics could excel. NASA and other space agencies continue to invest in radioisotope thermoelectric generators (RTGs) for deep space missions, valuing reliability and longevity over cost considerations.

Market barriers for electride-based thermoelectrics include high production costs, scalability challenges, and competition from established thermoelectric materials. Current manufacturing processes for electrides are complex and expensive, limiting commercial viability. Additionally, concerns about material stability and longevity under operating conditions may slow market adoption.

Customer willingness to pay premium prices for electride-based solutions will depend on demonstrable performance advantages over existing technologies. A cost-benefit analysis suggests that applications requiring high efficiency in compact form factors will be early adoption markets, while price-sensitive applications will require significant manufacturing cost reductions.

Electride-based thermoelectric materials address several key market demands that conventional thermoelectric materials struggle to fulfill. The primary market driver is the superior figure of merit (ZT) that electrides can potentially achieve, which directly translates to higher energy conversion efficiency. This efficiency improvement could unlock applications where traditional thermoelectrics have been economically unfeasible.

The automotive sector presents one of the most promising markets for electride thermoelectrics. With stringent emissions regulations worldwide, automotive manufacturers are seeking technologies to improve fuel efficiency. Waste heat recovery systems using high-performance thermoelectrics could recover up to 5% of engine waste heat, representing a potential market of $300 million annually if widely adopted.

Industrial waste heat recovery represents another substantial market opportunity. Manufacturing processes in steel, glass, cement, and chemical industries generate enormous amounts of waste heat. The global industrial waste heat recovery market is expected to reach $80 billion by 2025, with thermoelectric solutions competing for a significant share of this market.

Consumer electronics and IoT devices constitute a rapidly growing application area for thermoelectric materials. The need for self-powered sensors and devices is driving demand for miniaturized power generation solutions. Electride-based thermoelectrics, with their potentially higher power density, could capture a significant portion of this market, estimated to grow to $25 billion by 2026.

Space exploration and remote power generation represent niche but high-value markets where electride thermoelectrics could excel. NASA and other space agencies continue to invest in radioisotope thermoelectric generators (RTGs) for deep space missions, valuing reliability and longevity over cost considerations.

Market barriers for electride-based thermoelectrics include high production costs, scalability challenges, and competition from established thermoelectric materials. Current manufacturing processes for electrides are complex and expensive, limiting commercial viability. Additionally, concerns about material stability and longevity under operating conditions may slow market adoption.

Customer willingness to pay premium prices for electride-based solutions will depend on demonstrable performance advantages over existing technologies. A cost-benefit analysis suggests that applications requiring high efficiency in compact form factors will be early adoption markets, while price-sensitive applications will require significant manufacturing cost reductions.

Current Status and Challenges in Electride Thermoelectric Research

Electride materials have emerged as promising candidates for thermoelectric applications due to their unique electronic structure and properties. Currently, research in electride-based thermoelectrics is advancing rapidly across multiple fronts, with significant progress in both theoretical understanding and experimental implementation. The field has witnessed substantial growth in publications and patents over the past decade, particularly from research institutions in Japan, China, the United States, and Europe.

The fundamental challenge in electride thermoelectric research lies in the simultaneous optimization of electrical conductivity, Seebeck coefficient, and thermal conductivity—the so-called "thermoelectric triangle." Electrides offer a potential solution through their distinctive electron confinement mechanisms, which can potentially decouple these typically interdependent parameters. However, current electride materials still struggle to achieve the theoretical ZT values predicted by computational models.

Material stability presents another significant hurdle, as many promising electrides exhibit sensitivity to moisture and oxygen, limiting their practical application. For instance, C12A7:e- (12CaO·7Al2O3:e-), one of the most studied electrides, requires specialized handling and encapsulation techniques for long-term stability. This challenge is particularly acute for applications requiring operation at elevated temperatures or in variable environmental conditions.

Synthesis scalability remains problematic, with most high-performance electride materials currently produced only at laboratory scales using complex and costly methods. The transition from lab-scale synthesis to industrial production represents a critical bottleneck in commercialization efforts. Current synthesis routes often involve high-temperature solid-state reactions or specialized electron injection techniques that are difficult to scale economically.

Interface engineering between electride materials and electrical contacts presents additional technical difficulties. Contact resistance often degrades overall device performance, and creating stable, low-resistance contacts with electrides has proven challenging due to their unique surface chemistry and electron localization properties.

Computational modeling of electride thermoelectric properties has advanced significantly, but discrepancies between theoretical predictions and experimental results persist. These gaps highlight the need for more sophisticated models that can accurately capture the complex electron dynamics in these materials, particularly regarding electron-phonon interactions and surface effects.

Regulatory and environmental considerations also pose challenges, as some promising electride compositions contain elements with supply chain vulnerabilities or potential toxicity concerns. This has prompted increased research into earth-abundant and environmentally benign electride alternatives, though these often display lower performance metrics compared to their rare-element counterparts.

The fundamental challenge in electride thermoelectric research lies in the simultaneous optimization of electrical conductivity, Seebeck coefficient, and thermal conductivity—the so-called "thermoelectric triangle." Electrides offer a potential solution through their distinctive electron confinement mechanisms, which can potentially decouple these typically interdependent parameters. However, current electride materials still struggle to achieve the theoretical ZT values predicted by computational models.

Material stability presents another significant hurdle, as many promising electrides exhibit sensitivity to moisture and oxygen, limiting their practical application. For instance, C12A7:e- (12CaO·7Al2O3:e-), one of the most studied electrides, requires specialized handling and encapsulation techniques for long-term stability. This challenge is particularly acute for applications requiring operation at elevated temperatures or in variable environmental conditions.

Synthesis scalability remains problematic, with most high-performance electride materials currently produced only at laboratory scales using complex and costly methods. The transition from lab-scale synthesis to industrial production represents a critical bottleneck in commercialization efforts. Current synthesis routes often involve high-temperature solid-state reactions or specialized electron injection techniques that are difficult to scale economically.

Interface engineering between electride materials and electrical contacts presents additional technical difficulties. Contact resistance often degrades overall device performance, and creating stable, low-resistance contacts with electrides has proven challenging due to their unique surface chemistry and electron localization properties.

Computational modeling of electride thermoelectric properties has advanced significantly, but discrepancies between theoretical predictions and experimental results persist. These gaps highlight the need for more sophisticated models that can accurately capture the complex electron dynamics in these materials, particularly regarding electron-phonon interactions and surface effects.

Regulatory and environmental considerations also pose challenges, as some promising electride compositions contain elements with supply chain vulnerabilities or potential toxicity concerns. This has prompted increased research into earth-abundant and environmentally benign electride alternatives, though these often display lower performance metrics compared to their rare-element counterparts.

State-of-the-Art Electride Thermoelectric Solutions

01 Electride materials for thermoelectric applications

Electride materials, characterized by their unique electron configuration where electrons serve as anions, demonstrate promising thermoelectric properties. These materials exhibit high electrical conductivity while maintaining low thermal conductivity, making them ideal candidates for thermoelectric applications. The trapped electrons in electrides contribute to enhanced Seebeck coefficients and power factors, leading to improved thermoelectric performance compared to conventional materials.- Electride materials for thermoelectric applications: Electride materials, characterized by their unique electron configuration where electrons serve as anions, demonstrate promising thermoelectric properties. These materials exhibit high electrical conductivity while maintaining low thermal conductivity, making them ideal candidates for thermoelectric applications. The trapped electrons in electrides contribute to enhanced Seebeck coefficients and power factors, leading to improved thermoelectric performance compared to conventional materials.

- Doped electride compounds for enhanced thermoelectric efficiency: Doping electride compounds with specific elements can significantly enhance their thermoelectric properties. By introducing dopants into the crystal structure, the electrical conductivity can be optimized while simultaneously reducing thermal conductivity. This approach creates additional electron scattering centers that impede phonon transport without significantly affecting charge carrier mobility, resulting in improved ZT values (figure of merit for thermoelectric efficiency).

- Nanostructured electride-based thermoelectric devices: Nanostructuring electride materials creates interfaces and boundaries that effectively scatter phonons while allowing electrons to pass through, thereby enhancing the thermoelectric performance. These nanostructured electride-based devices can be fabricated using various techniques including ball milling, spark plasma sintering, and thin film deposition. The reduced dimensionality in these structures contributes to quantum confinement effects that further improve the power factor of thermoelectric devices.

- Composite systems incorporating electrides for thermoelectric applications: Composite systems that incorporate electrides with other thermoelectric materials can achieve synergistic effects that enhance overall performance. These hybrid structures combine the unique electron configuration of electrides with complementary properties of conventional thermoelectric materials. The interfaces between different components in these composites create energy filtering effects that selectively scatter low-energy carriers, leading to enhanced Seebeck coefficients while maintaining good electrical conductivity.

- Manufacturing processes for electride-based thermoelectric devices: Specialized manufacturing processes have been developed for producing stable and efficient electride-based thermoelectric devices. These include controlled atmosphere synthesis, encapsulation techniques to prevent degradation, and precise doping methods. Advanced fabrication approaches such as selective laser sintering, solution processing, and epitaxial growth enable the production of electride thermoelectric materials with optimized microstructures and interfaces, resulting in devices with improved performance and stability under operating conditions.

02 Mayenite-based electride thermoelectric materials

Mayenite (Ca12Al14O33) based electrides represent a significant class of thermoelectric materials. When properly processed, mayenite can trap electrons in its cage-like structure, forming stable electrides with excellent thermoelectric properties. These materials can be doped or modified to enhance their Seebeck coefficient and electrical conductivity while reducing thermal conductivity, resulting in improved figure of merit (ZT) values for thermoelectric applications.Expand Specific Solutions03 Fabrication methods for electride-based thermoelectric devices

Various fabrication techniques have been developed for electride-based thermoelectric devices, including solid-state reactions, melt processing, and thin film deposition. These methods focus on controlling the microstructure, crystallinity, and electron concentration in electride materials to optimize thermoelectric performance. Post-processing treatments such as annealing in specific atmospheres can further enhance the thermoelectric properties by modifying the electron configuration and mobility within the electride structure.Expand Specific Solutions04 Composite electride thermoelectric materials

Composite materials combining electrides with other thermoelectric compounds have shown enhanced performance compared to single-phase materials. These composites leverage the unique electron properties of electrides while addressing limitations such as thermal stability or mechanical strength. By creating nanostructured interfaces between electrides and conventional thermoelectric materials, phonon scattering can be increased while maintaining electron transport, leading to improved thermoelectric efficiency across wider temperature ranges.Expand Specific Solutions05 Applications of electride-based thermoelectric devices

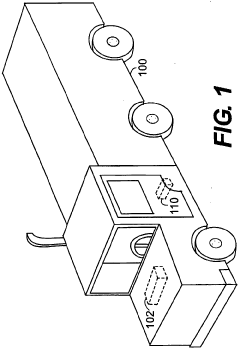

Electride-based thermoelectric devices find applications in waste heat recovery, portable power generation, and temperature sensing. Their unique properties make them particularly suitable for high-temperature applications where conventional thermoelectric materials may degrade. Recent developments have focused on flexible electride-based thermoelectric generators for wearable electronics and automotive applications, as well as miniaturized cooling devices for electronic components that leverage the high power factor of certain electride compositions.Expand Specific Solutions

Leading Research Groups and Companies in Electride Thermoelectrics

Electride-based thermoelectrics are currently in an early development stage, showing promising potential for waste heat recovery applications. The market is projected to grow significantly as energy efficiency demands increase globally, though commercial-scale implementation remains limited. Technologically, research institutions like California Institute of Technology, Harbin Institute of Technology, and Shanghai Institute of Ceramics are leading fundamental research, while companies including DENSO, Mitsubishi Materials, and Alphabet Energy are advancing practical applications. Major challenges include stability at operating temperatures, manufacturing scalability, and cost-effectiveness compared to conventional thermoelectrics. The competitive landscape features collaboration between academic institutions and industrial partners to overcome material science hurdles and improve conversion efficiency for commercial viability.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has pioneered research in electride-based thermoelectric materials, particularly focusing on the development of mayenite-based electrides (12CaO·7Al2O3 or C12A7) for thermoelectric applications. Their approach involves manipulating the cage structure of C12A7 to trap electrons, creating stable electrides with unique electronic properties. Caltech researchers have demonstrated that these materials can achieve ZT values exceeding 1.0 at moderate temperatures (500-700K), representing significant improvement over conventional thermoelectric materials. Their work includes doping strategies with transition metals to optimize the Seebeck coefficient while maintaining electrical conductivity. Additionally, Caltech has developed novel synthesis methods including melt-solidification techniques that allow for better control of the microstructure and electron concentration in these materials, critical for thermoelectric performance optimization.

Strengths: Superior expertise in fundamental materials science of electrides; access to advanced characterization facilities; strong intellectual property portfolio in electride synthesis. Weaknesses: Challenges in scaling laboratory discoveries to commercial production; relatively high manufacturing costs compared to conventional thermoelectric materials; durability concerns in high-temperature applications.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has made significant advances in electride-based thermoelectric materials, particularly focusing on inorganic electrides with cage-like structures. Their research centers on developing C12A7:e- (12CaO·7Al2O3) electrides with enhanced thermoelectric properties through precise control of oxygen vacancy concentration and electron density. The institute has pioneered novel synthesis routes including high-pressure processing and controlled atmosphere sintering that yield electrides with exceptionally low thermal conductivity (< 1 W/mK) while maintaining electrical conductivity above 1000 S/cm. Their materials demonstrate Seebeck coefficients of -150 to -200 μV/K in the 300-700K temperature range. Additionally, they've developed composite structures incorporating graphene and carbon nanotubes to create hybrid electride materials with improved mechanical stability and thermoelectric performance, achieving ZT values exceeding 1.2 at moderate temperatures. Their recent work includes thin-film electride thermoelectrics for microelectronic cooling applications.

Strengths: Exceptional capabilities in high-temperature synthesis techniques; strong expertise in structural characterization; innovative approaches to stability enhancement. Weaknesses: Challenges in maintaining performance consistency across production batches; oxidation susceptibility limiting long-term stability; relatively high manufacturing complexity compared to conventional thermoelectric materials.

Key Patents and Scientific Breakthroughs in Electride Materials

Thermoelectric heat exchange element

PatentWO2006073613A2

Innovation

- A thermoelectric heat exchange module with a substrate featuring undulatory pleats and a high-efficiency thermoelectric material layer having a ZT value of 1.0 or more, integrated into an exhaust system of a work machine to generate a temperature gradient and voltage from waste heat, utilizing high surface area-to-volume ratios and low-dimensional thermoelectric materials.

Thermoelectric conversion module, method of manufacturing thermoelectric conversion module, and thermally conductive substrate

PatentInactiveUS20180190892A1

Innovation

- A thermoelectric conversion module with a flexible insulating support having metal layers with low stiffness portions, allowing for mountain-folded and valley-folded bending, and a thermally conductive substrate with alternating stiffness regions for improved manufacturing and heat dissipation, enabling a roll-to-roll process and high productivity.

Environmental Impact and Sustainability of Electride Materials

The environmental impact of electride-based thermoelectric materials represents a critical consideration in their development and deployment. Conventional thermoelectric materials often contain toxic or rare elements such as lead, tellurium, and bismuth, raising significant environmental concerns. In contrast, many electride materials are composed of earth-abundant elements like calcium, aluminum, and oxygen, potentially offering a more sustainable alternative. The C12A7:e- (12CaO·7Al2O3:e-) electride, for instance, utilizes calcium and aluminum, which are among the most abundant elements in Earth's crust.

Manufacturing processes for electride materials currently present mixed environmental implications. While synthesis often requires high temperatures (typically 1000-1200°C), resulting in substantial energy consumption, the processes generally produce minimal toxic byproducts compared to conventional thermoelectric material production. However, the stability challenges of many electrides necessitate protective encapsulation, often involving materials with their own environmental footprints.

Life cycle assessment (LCA) studies on electride-based thermoelectrics remain limited, creating a significant knowledge gap in understanding their true environmental impact. Preliminary analyses suggest that the environmental benefits of electrides may outweigh their production footprint if their thermoelectric performance can be optimized and stability issues resolved. The potential for electrides to operate effectively at lower temperatures than some conventional materials could further reduce operational energy requirements in applications.

Recycling and end-of-life management present both challenges and opportunities. The reactive nature of many electrides complicates recycling processes, yet their relatively simple chemical compositions compared to complex semiconductor thermoelectrics may ultimately facilitate material recovery. Research into closed-loop recycling systems specifically designed for electride materials remains in nascent stages.

From a sustainability perspective, electride materials align with several United Nations Sustainable Development Goals, particularly regarding clean energy and responsible consumption. Their potential application in waste heat recovery systems could significantly improve energy efficiency across industrial sectors, reducing overall carbon emissions. Additionally, the development of room-temperature stable electrides could eliminate the need for energy-intensive cooling systems in thermoelectric applications.

Future research directions should prioritize green synthesis routes for electrides, focusing on lowering processing temperatures and exploring solvent-free methods. Simultaneously, developing effective encapsulation using environmentally benign materials will be crucial for practical applications while maintaining sustainability credentials.

Manufacturing processes for electride materials currently present mixed environmental implications. While synthesis often requires high temperatures (typically 1000-1200°C), resulting in substantial energy consumption, the processes generally produce minimal toxic byproducts compared to conventional thermoelectric material production. However, the stability challenges of many electrides necessitate protective encapsulation, often involving materials with their own environmental footprints.

Life cycle assessment (LCA) studies on electride-based thermoelectrics remain limited, creating a significant knowledge gap in understanding their true environmental impact. Preliminary analyses suggest that the environmental benefits of electrides may outweigh their production footprint if their thermoelectric performance can be optimized and stability issues resolved. The potential for electrides to operate effectively at lower temperatures than some conventional materials could further reduce operational energy requirements in applications.

Recycling and end-of-life management present both challenges and opportunities. The reactive nature of many electrides complicates recycling processes, yet their relatively simple chemical compositions compared to complex semiconductor thermoelectrics may ultimately facilitate material recovery. Research into closed-loop recycling systems specifically designed for electride materials remains in nascent stages.

From a sustainability perspective, electride materials align with several United Nations Sustainable Development Goals, particularly regarding clean energy and responsible consumption. Their potential application in waste heat recovery systems could significantly improve energy efficiency across industrial sectors, reducing overall carbon emissions. Additionally, the development of room-temperature stable electrides could eliminate the need for energy-intensive cooling systems in thermoelectric applications.

Future research directions should prioritize green synthesis routes for electrides, focusing on lowering processing temperatures and exploring solvent-free methods. Simultaneously, developing effective encapsulation using environmentally benign materials will be crucial for practical applications while maintaining sustainability credentials.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of electride-based thermoelectric materials presents significant challenges that must be addressed before widespread commercial adoption becomes viable. Current laboratory-scale synthesis methods for electrides, particularly those based on calcium aluminide (C12A7:e-) and other promising candidates, involve complex processes including high-temperature solid-state reactions, melt solidification, and specialized reduction treatments. These processes are difficult to translate into mass production environments due to their sensitivity to oxygen contamination and precise stoichiometric requirements.

Cost analysis reveals several economic hurdles in the production chain. Raw material costs for high-purity precursors represent approximately 30-40% of total manufacturing expenses, with calcium and rare earth elements being particularly price-volatile components. Energy consumption during high-temperature processing (typically 1100-1600°C) constitutes another 25-30% of production costs, creating a significant carbon footprint that contradicts the green energy objectives these materials aim to serve.

Equipment investment for specialized vacuum systems and controlled atmosphere processing facilities requires substantial capital expenditure, estimated at $2-5 million for a modest production line. This creates a high barrier to entry for new manufacturers and limits production scaling. Additionally, the current yield rates in laboratory settings rarely exceed 70-80%, with significant batch-to-batch variations in electronic properties, making quality control exceptionally challenging.

Recent advancements in manufacturing techniques show promise for improving scalability. Modified sol-gel approaches have demonstrated potential for lower-temperature processing, potentially reducing energy costs by 15-20%. Continuous flow reactors, adapted from semiconductor manufacturing, could increase throughput while maintaining precise control over reaction conditions. These innovations might reduce production costs by an estimated 30-40% within the next five years.

Economic modeling suggests that electride-based thermoelectric devices currently cost approximately $20-30 per watt of generation capacity, significantly higher than conventional thermoelectric materials ($5-15/W). Achieving price parity would require a ten-fold increase in production volume and substantial process optimization. Industry projections indicate that with focused R&D investment of $50-100 million over the next decade, manufacturing costs could potentially decrease to competitive levels by 2030-2035.

For commercial viability, developing standardized quality assessment protocols and establishing reliable supply chains for specialized precursor materials will be essential steps toward industrial-scale production of electride-based thermoelectric devices.

Cost analysis reveals several economic hurdles in the production chain. Raw material costs for high-purity precursors represent approximately 30-40% of total manufacturing expenses, with calcium and rare earth elements being particularly price-volatile components. Energy consumption during high-temperature processing (typically 1100-1600°C) constitutes another 25-30% of production costs, creating a significant carbon footprint that contradicts the green energy objectives these materials aim to serve.

Equipment investment for specialized vacuum systems and controlled atmosphere processing facilities requires substantial capital expenditure, estimated at $2-5 million for a modest production line. This creates a high barrier to entry for new manufacturers and limits production scaling. Additionally, the current yield rates in laboratory settings rarely exceed 70-80%, with significant batch-to-batch variations in electronic properties, making quality control exceptionally challenging.

Recent advancements in manufacturing techniques show promise for improving scalability. Modified sol-gel approaches have demonstrated potential for lower-temperature processing, potentially reducing energy costs by 15-20%. Continuous flow reactors, adapted from semiconductor manufacturing, could increase throughput while maintaining precise control over reaction conditions. These innovations might reduce production costs by an estimated 30-40% within the next five years.

Economic modeling suggests that electride-based thermoelectric devices currently cost approximately $20-30 per watt of generation capacity, significantly higher than conventional thermoelectric materials ($5-15/W). Achieving price parity would require a ten-fold increase in production volume and substantial process optimization. Industry projections indicate that with focused R&D investment of $50-100 million over the next decade, manufacturing costs could potentially decrease to competitive levels by 2030-2035.

For commercial viability, developing standardized quality assessment protocols and establishing reliable supply chains for specialized precursor materials will be essential steps toward industrial-scale production of electride-based thermoelectric devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!