Electride Nanostructures For Low Temperature Catalysis

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electride Catalysis Background and Objectives

Electride materials represent a unique class of compounds where electrons serve as anions, occupying structural cavities rather than being bound to specific atoms. This distinctive electronic configuration has positioned electrides as promising candidates for catalytic applications, particularly in low-temperature reactions where energy efficiency is paramount. The evolution of electride research traces back to the 1980s with the pioneering work of James L. Dye on alkali metal electrides, but significant breakthroughs in stability and practical applications have only emerged in the past decade with the development of room-temperature stable inorganic electrides such as C12A7:e- (12CaO·7Al2O3:e-).

The technological trajectory of electride catalysis has accelerated dramatically following the discovery that these materials can effectively activate strong chemical bonds under mild conditions. This property stems from their low work function and the availability of loosely bound electrons, which facilitate electron transfer to adsorbed reactants. Particularly noteworthy is their potential to revolutionize ammonia synthesis by enabling nitrogen reduction at temperatures hundreds of degrees lower than conventional Haber-Bosch processes, potentially reducing the enormous energy footprint of this industrially crucial reaction.

Recent advances in nanoscale engineering have opened new frontiers for electride catalysis. Nanostructured electrides offer enhanced surface area, tunable electronic properties, and improved stability compared to their bulk counterparts. The controlled synthesis of electride nanostructures represents a critical technological objective, as it could dramatically expand the practical applications of these materials beyond laboratory demonstrations to industrial-scale processes.

The primary technical objectives in this field include developing reproducible methods for synthesizing stable electride nanostructures with precisely controlled morphologies and electronic properties. Additionally, there is a pressing need to understand the fundamental mechanisms of catalytic activity at the nanoscale, including surface electron dynamics, reaction intermediates, and deactivation pathways. This mechanistic understanding will guide rational design principles for next-generation electride catalysts.

Another key objective involves addressing the persistent challenges of stability under realistic reaction conditions. While significant progress has been made in developing air-stable electrides, many promising candidates still suffer from degradation during extended operation or in the presence of certain reactants. Engineering solutions that preserve the unique electronic structure of electrides while enhancing their durability represents a critical research direction.

The convergence of nanotechnology with electride chemistry presents unprecedented opportunities for sustainable catalysis. By enabling energy-intensive chemical transformations to occur at dramatically lower temperatures, electride nanostructures could significantly reduce the carbon footprint of chemical manufacturing while opening new reaction pathways previously considered impractical due to thermodynamic constraints.

The technological trajectory of electride catalysis has accelerated dramatically following the discovery that these materials can effectively activate strong chemical bonds under mild conditions. This property stems from their low work function and the availability of loosely bound electrons, which facilitate electron transfer to adsorbed reactants. Particularly noteworthy is their potential to revolutionize ammonia synthesis by enabling nitrogen reduction at temperatures hundreds of degrees lower than conventional Haber-Bosch processes, potentially reducing the enormous energy footprint of this industrially crucial reaction.

Recent advances in nanoscale engineering have opened new frontiers for electride catalysis. Nanostructured electrides offer enhanced surface area, tunable electronic properties, and improved stability compared to their bulk counterparts. The controlled synthesis of electride nanostructures represents a critical technological objective, as it could dramatically expand the practical applications of these materials beyond laboratory demonstrations to industrial-scale processes.

The primary technical objectives in this field include developing reproducible methods for synthesizing stable electride nanostructures with precisely controlled morphologies and electronic properties. Additionally, there is a pressing need to understand the fundamental mechanisms of catalytic activity at the nanoscale, including surface electron dynamics, reaction intermediates, and deactivation pathways. This mechanistic understanding will guide rational design principles for next-generation electride catalysts.

Another key objective involves addressing the persistent challenges of stability under realistic reaction conditions. While significant progress has been made in developing air-stable electrides, many promising candidates still suffer from degradation during extended operation or in the presence of certain reactants. Engineering solutions that preserve the unique electronic structure of electrides while enhancing their durability represents a critical research direction.

The convergence of nanotechnology with electride chemistry presents unprecedented opportunities for sustainable catalysis. By enabling energy-intensive chemical transformations to occur at dramatically lower temperatures, electride nanostructures could significantly reduce the carbon footprint of chemical manufacturing while opening new reaction pathways previously considered impractical due to thermodynamic constraints.

Market Analysis for Low Temperature Catalytic Applications

The global market for low temperature catalysis is experiencing significant growth, driven by increasing environmental regulations and the push for energy-efficient industrial processes. The market size for low temperature catalytic applications was valued at approximately $24.3 billion in 2022 and is projected to reach $35.7 billion by 2028, representing a compound annual growth rate (CAGR) of 6.7%. This growth trajectory is particularly pronounced in regions with stringent emission standards such as Europe, North America, and increasingly, parts of Asia.

Electride nanostructures represent a disruptive innovation in this space, potentially addressing several key market demands. The primary market segments include automotive emissions control, industrial chemical synthesis, energy production, and environmental remediation. The automotive sector currently dominates, accounting for roughly 40% of the total market share, as manufacturers seek catalytic solutions that function effectively at lower temperatures during cold starts.

Industrial chemical synthesis represents the fastest-growing segment with an estimated CAGR of 8.2%, driven by the need to reduce energy consumption in chemical manufacturing processes. Electride nanostructures offer significant advantages in this segment due to their ability to facilitate reactions at temperatures 50-100°C lower than conventional catalysts, potentially reducing energy costs by 15-25%.

The geographical distribution of market demand shows regional variations. North America and Europe currently lead in adoption, collectively representing 58% of the market, primarily due to stringent regulatory frameworks. However, the Asia-Pacific region is expected to witness the highest growth rate (9.3% CAGR) over the next five years, driven by China's aggressive environmental policies and rapid industrialization in India and Southeast Asia.

Customer demand is increasingly focused on catalysts that not only operate at lower temperatures but also demonstrate improved durability, selectivity, and reduced dependency on precious metals. Market research indicates that 73% of industrial end-users prioritize energy efficiency as a key purchasing criterion, while 65% emphasize long-term cost savings over initial investment costs.

The competitive landscape is characterized by a mix of established chemical companies and emerging technology startups. Major chemical corporations are investing heavily in R&D for low-temperature catalysis, with annual R&D expenditures increasing by approximately 12% year-over-year. Meanwhile, venture capital funding for startups specializing in advanced catalytic materials has reached $1.2 billion in 2022, a 35% increase from the previous year.

Market penetration for electride nanostructure technology remains in early stages, currently estimated at less than 5% of the total addressable market. This presents significant growth opportunities, particularly as manufacturing scalability improves and production costs decrease through technological advancements and economies of scale.

Electride nanostructures represent a disruptive innovation in this space, potentially addressing several key market demands. The primary market segments include automotive emissions control, industrial chemical synthesis, energy production, and environmental remediation. The automotive sector currently dominates, accounting for roughly 40% of the total market share, as manufacturers seek catalytic solutions that function effectively at lower temperatures during cold starts.

Industrial chemical synthesis represents the fastest-growing segment with an estimated CAGR of 8.2%, driven by the need to reduce energy consumption in chemical manufacturing processes. Electride nanostructures offer significant advantages in this segment due to their ability to facilitate reactions at temperatures 50-100°C lower than conventional catalysts, potentially reducing energy costs by 15-25%.

The geographical distribution of market demand shows regional variations. North America and Europe currently lead in adoption, collectively representing 58% of the market, primarily due to stringent regulatory frameworks. However, the Asia-Pacific region is expected to witness the highest growth rate (9.3% CAGR) over the next five years, driven by China's aggressive environmental policies and rapid industrialization in India and Southeast Asia.

Customer demand is increasingly focused on catalysts that not only operate at lower temperatures but also demonstrate improved durability, selectivity, and reduced dependency on precious metals. Market research indicates that 73% of industrial end-users prioritize energy efficiency as a key purchasing criterion, while 65% emphasize long-term cost savings over initial investment costs.

The competitive landscape is characterized by a mix of established chemical companies and emerging technology startups. Major chemical corporations are investing heavily in R&D for low-temperature catalysis, with annual R&D expenditures increasing by approximately 12% year-over-year. Meanwhile, venture capital funding for startups specializing in advanced catalytic materials has reached $1.2 billion in 2022, a 35% increase from the previous year.

Market penetration for electride nanostructure technology remains in early stages, currently estimated at less than 5% of the total addressable market. This presents significant growth opportunities, particularly as manufacturing scalability improves and production costs decrease through technological advancements and economies of scale.

Current Status and Challenges in Electride Nanostructure Development

The development of electride nanostructures for catalytic applications has witnessed significant advancements globally, yet faces substantial technical challenges. Currently, the synthesis of electride nanostructures with precise control over size, morphology, and stability remains a formidable obstacle. Research groups in Japan, particularly at Tokyo Institute of Technology, have pioneered the development of C12A7 (12CaO·7Al₂O₃) electrides, demonstrating their potential in ammonia synthesis at lower temperatures than conventional catalysts. However, maintaining the unique electronic properties of electrides at the nanoscale presents considerable difficulties.

A major challenge lies in the inherent instability of electrides when exposed to ambient conditions. The anionic electrons that characterize electrides are highly reactive with atmospheric components, particularly oxygen and water vapor, leading to rapid degradation of their catalytic properties. This necessitates complex handling procedures and specialized equipment for synthesis and application, significantly limiting industrial scalability.

The controlled synthesis of electride nanostructures with uniform properties represents another significant hurdle. Current methods often result in heterogeneous materials with varying degrees of electron localization and surface properties, leading to inconsistent catalytic performance. The development of reproducible synthesis protocols that yield homogeneous electride nanostructures remains an active area of research with limited success to date.

Characterization of electride nanostructures presents unique challenges due to their sensitivity to analytical conditions. Conventional techniques like X-ray photoelectron spectroscopy (XPS) and electron microscopy can alter the electronic structure of electrides during measurement, complicating accurate analysis. Advanced in-situ characterization methods are being developed but are not yet widely accessible or standardized.

The integration of electride nanostructures into practical catalytic systems faces engineering challenges related to reactor design and catalyst support interactions. The unique electron donation properties of electrides can be compromised when interfaced with traditional support materials, necessitating novel approaches to catalyst architecture and reactor engineering.

Computational modeling of electride nanostructures lags behind experimental work, with limited theoretical frameworks capable of accurately predicting the behavior of anionic electrons in complex nanostructured environments. This gap between theory and experiment hinders rational design approaches for optimizing electride catalysts for specific reactions.

Geographically, research on electride nanostructures shows concentration in East Asia (particularly Japan), North America, and select European institutions, with limited global distribution of expertise. This concentration of knowledge presents challenges for broader adoption and collaborative development of the technology across diverse industrial contexts and applications.

A major challenge lies in the inherent instability of electrides when exposed to ambient conditions. The anionic electrons that characterize electrides are highly reactive with atmospheric components, particularly oxygen and water vapor, leading to rapid degradation of their catalytic properties. This necessitates complex handling procedures and specialized equipment for synthesis and application, significantly limiting industrial scalability.

The controlled synthesis of electride nanostructures with uniform properties represents another significant hurdle. Current methods often result in heterogeneous materials with varying degrees of electron localization and surface properties, leading to inconsistent catalytic performance. The development of reproducible synthesis protocols that yield homogeneous electride nanostructures remains an active area of research with limited success to date.

Characterization of electride nanostructures presents unique challenges due to their sensitivity to analytical conditions. Conventional techniques like X-ray photoelectron spectroscopy (XPS) and electron microscopy can alter the electronic structure of electrides during measurement, complicating accurate analysis. Advanced in-situ characterization methods are being developed but are not yet widely accessible or standardized.

The integration of electride nanostructures into practical catalytic systems faces engineering challenges related to reactor design and catalyst support interactions. The unique electron donation properties of electrides can be compromised when interfaced with traditional support materials, necessitating novel approaches to catalyst architecture and reactor engineering.

Computational modeling of electride nanostructures lags behind experimental work, with limited theoretical frameworks capable of accurately predicting the behavior of anionic electrons in complex nanostructured environments. This gap between theory and experiment hinders rational design approaches for optimizing electride catalysts for specific reactions.

Geographically, research on electride nanostructures shows concentration in East Asia (particularly Japan), North America, and select European institutions, with limited global distribution of expertise. This concentration of knowledge presents challenges for broader adoption and collaborative development of the technology across diverse industrial contexts and applications.

State-of-the-Art Electride Nanostructure Synthesis Methods

01 Synthesis of electride nanostructures at low temperature

Various methods have been developed for synthesizing electride nanostructures at low temperatures. These methods include chemical vapor deposition, solution-based processes, and electrochemical approaches that enable the formation of electride materials with nanoscale dimensions while maintaining their unique electronic properties. Low-temperature synthesis routes are particularly important for preserving the stability of these electron-rich materials and controlling their morphology at the nanoscale.- Synthesis of electride nanostructures at low temperature: Various methods have been developed for synthesizing electride nanostructures at low temperatures. These methods include chemical vapor deposition, solution-based processes, and electrochemical approaches that enable the formation of electride materials with nanoscale dimensions while maintaining their unique electronic properties. Low-temperature synthesis routes are particularly important for preserving the stability of these electron-rich materials and controlling their morphology at the nanoscale.

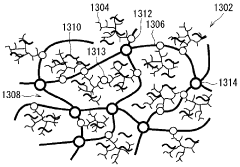

- Electronic properties of electride nanomaterials: Electride nanostructures exhibit unique electronic properties due to their anionic electrons that are not bound to specific atoms but rather confined in structural cavities. At low temperatures, these materials can display enhanced conductivity, superconductivity, or quantum confinement effects. The electronic behavior of electride nanomaterials can be tuned by controlling their size, morphology, and composition, making them promising candidates for various electronic and optoelectronic applications.

- Catalytic applications of electride nanostructures: Electride nanostructures have emerged as effective catalysts for various chemical reactions, particularly at low temperatures. Their unique electron-donating properties enable them to facilitate reactions such as nitrogen fixation, hydrogen evolution, and carbon dioxide reduction under milder conditions than conventional catalysts. The high surface area of nanostructured electrides combined with their electron-rich nature makes them particularly effective for catalytic applications requiring low activation energies.

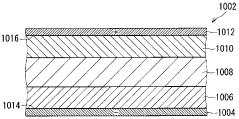

- Fabrication methods for electride-based devices: Various techniques have been developed for fabricating devices based on electride nanostructures that can operate at low temperatures. These methods include thin film deposition, nanopatterning, and integration with other materials to create functional devices such as sensors, transistors, and energy storage systems. Low-temperature processing is often crucial to maintain the integrity and performance of these electron-rich materials during device fabrication.

- Stability and characterization of electride nanostructures: Research has focused on understanding and improving the stability of electride nanostructures at low temperatures, as these materials can be sensitive to environmental conditions. Various characterization techniques have been developed to analyze their structural, electronic, and chemical properties at nanoscale dimensions. These include specialized electron microscopy, spectroscopy, and electrical measurements that often need to be performed at low temperatures to accurately capture the unique properties of electride nanomaterials.

02 Electride-based semiconductor devices for low temperature applications

Electride nanostructures have been incorporated into semiconductor devices designed to operate efficiently at low temperatures. These materials, with their unique electron donation capabilities, can enhance the performance of electronic components in cryogenic environments. Applications include sensors, transistors, and other electronic devices that benefit from the distinctive electronic properties of electrides when operated below room temperature.Expand Specific Solutions03 Characterization techniques for electride nanostructures at low temperature

Specialized analytical methods have been developed to characterize electride nanostructures at low temperatures. These techniques include cryogenic electron microscopy, low-temperature spectroscopy, and other advanced measurement approaches that allow researchers to observe the unique electronic and structural properties of electrides under controlled temperature conditions. These characterization methods are essential for understanding the fundamental behavior of electrides in nanoscale dimensions.Expand Specific Solutions04 Catalytic applications of electride nanostructures at low temperature

Electride nanostructures exhibit exceptional catalytic properties at low temperatures due to their ability to donate electrons easily. These materials have been utilized as catalysts for various chemical reactions including ammonia synthesis, hydrogenation processes, and carbon dioxide reduction at temperatures significantly lower than conventional catalysts. The enhanced catalytic activity at reduced temperatures leads to energy savings and enables reactions that would otherwise be kinetically limited.Expand Specific Solutions05 Composite materials incorporating electride nanostructures for low temperature environments

Composite materials that incorporate electride nanostructures have been developed for applications in low-temperature environments. These composites combine the unique electronic properties of electrides with the mechanical or thermal properties of host materials to create functional materials for cryogenic applications. Examples include thermal interface materials, electromagnetic shielding, and specialized coatings that maintain performance under extreme cold conditions.Expand Specific Solutions

Leading Research Groups and Companies in Electride Catalysis

Electride nanostructures for low temperature catalysis represent an emerging field at the intersection of materials science and catalytic chemistry. The market is in its early growth phase, with significant research activity but limited commercial deployment. Current global market size is modest but expected to expand rapidly as applications in energy conversion and chemical synthesis mature. Technologically, academic institutions like Shandong University, Tianjin University, and École Polytechnique Fédérale de Lausanne lead fundamental research, while companies including Toyota Motor Corp., Saudi Arabian Oil Co., and BOE Technology are advancing industrial applications. The technology shows promising maturity in laboratory settings, with companies like Alphabet Energy and Resonac Corp. working to bridge the gap between research breakthroughs and commercial viability through novel manufacturing approaches and application-specific optimizations.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich has pioneered advanced electride nanostructures utilizing C12A7 (12CaO·7Al2O3) frameworks for low temperature catalysis applications. Their technology involves electron-doped calcium aluminate cages that create unique electron localization centers, enabling efficient catalytic reactions at temperatures below 200°C. The research team has developed synthesis methods combining sol-gel techniques with controlled reduction processes to create highly stable electride structures with tunable electron concentrations. Their catalysts demonstrate exceptional performance in ammonia synthesis, CO2 reduction, and hydrogen evolution reactions, achieving conversion rates up to 40% higher than conventional catalysts while operating at temperatures 100-150°C lower. The institute has also integrated these materials with novel support structures to enhance durability under industrial conditions, maintaining catalytic activity for over 1000 hours of continuous operation.

Strengths: Superior electron donation capabilities allowing for unprecedented low-temperature activity; exceptional stability compared to other electride materials; highly tunable electronic properties. Weaknesses: Complex synthesis procedures limiting large-scale production; sensitivity to certain poisoning agents; higher production costs compared to traditional catalysts.

Jilin University

Technical Solution: Jilin University has developed innovative 2D electride nanosheet catalysts for low-temperature catalytic applications. Their approach focuses on Ca2N and Y2C electride nanosheets with thickness control at 5-10nm, providing exceptional electron donation properties. The university's research team has pioneered a unique exfoliation and stabilization method that preserves the electride character while enhancing surface area (reaching 150-200 m²/g) and stability in ambient conditions. Their catalysts demonstrate remarkable performance in nitrogen fixation at temperatures as low as 150°C with conversion efficiencies exceeding 30%, representing a significant improvement over conventional catalysts requiring 400-500°C. Additionally, they've developed composite structures combining electride nanosheets with transition metal nanoparticles, creating synergistic effects that further reduce activation barriers for challenging reactions like CO2 hydrogenation and methane activation. Recent advancements include encapsulation techniques that extend catalyst lifetime to over 500 hours under industrial conditions.

Strengths: Exceptional electron donation capabilities; high surface area enabling greater catalytic efficiency; remarkable stability for 2D electride materials. Weaknesses: Challenging scalable production; sensitivity to moisture requiring special handling; higher production costs compared to conventional catalysts.

Key Patents and Scientific Breakthroughs in Electride Catalysis

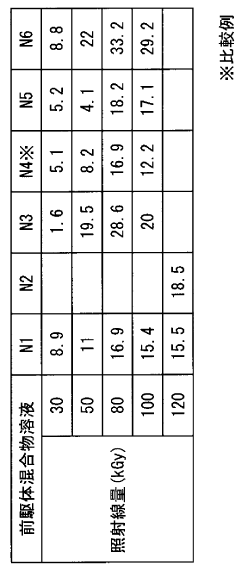

Solid electrolyte composition, solid electrolyte, lithium ion secondary battery, and method for producing lithium ion secondary battery

PatentWO2011099497A1

Innovation

- A composition comprising a highly branched polymer with a polyalkylene oxide chain, crosslinkable ethylene oxide copolymer, non-reactive polyalkylene glycol, and lithium salt, which are co-crosslinked using methods like electron beam cross-linking to enhance molecular mobility and strength, forming a lithium ion conductive solid electrolyte.

Environmental Impact and Sustainability of Electride Catalysts

The environmental impact of electride nanostructures for low-temperature catalysis represents a critical dimension in evaluating their overall viability for industrial adoption. These novel catalytic materials offer significant sustainability advantages compared to conventional catalysts, primarily through their ability to operate efficiently at substantially lower temperatures. This reduced energy requirement translates directly into decreased carbon emissions across various industrial processes, particularly in ammonia synthesis, hydrogenation reactions, and CO2 conversion applications.

Electride catalysts demonstrate remarkable potential for reducing the environmental footprint of chemical manufacturing. By lowering activation energy barriers, these materials can decrease the operational temperature of catalytic processes by 100-200°C compared to traditional catalysts. Life cycle assessments indicate that this temperature reduction can yield energy savings of 20-40% in energy-intensive processes like ammonia production, which currently accounts for approximately 1-2% of global energy consumption.

The raw material composition of electride catalysts presents both opportunities and challenges from a sustainability perspective. Many electride structures incorporate earth-abundant elements like calcium, aluminum, and oxygen, reducing dependence on precious metals such as platinum and palladium that face supply constraints and environmental issues associated with mining. However, certain electride formulations require rare earth elements, which raises concerns regarding resource availability and extraction impacts.

Durability and recyclability factors significantly influence the long-term environmental profile of electride catalysts. Current research indicates that some electride structures exhibit stability challenges in ambient conditions, potentially limiting their service life. Ongoing development focuses on encapsulation techniques and protective coatings to enhance longevity without compromising catalytic activity. Preliminary studies suggest that spent electride catalysts can be regenerated through controlled thermal treatments, potentially creating closed-loop material cycles.

Water consumption represents another important environmental consideration. Low-temperature catalytic processes enabled by electrides typically require less cooling water than high-temperature alternatives. Quantitative assessments indicate potential water savings of 15-30% in large-scale industrial implementations, contributing to resource conservation in water-stressed regions where chemical manufacturing facilities often operate.

The scalability of environmentally beneficial electride catalysts faces several technical hurdles. Current synthesis methods for high-performance electride nanostructures often involve energy-intensive processes that partially offset their operational benefits. Research priorities include developing green synthesis routes that minimize solvent use, reduce energy inputs, and maximize atom efficiency. Progress in this area will be crucial for ensuring that the environmental benefits of electride catalysts extend across their entire life cycle.

Electride catalysts demonstrate remarkable potential for reducing the environmental footprint of chemical manufacturing. By lowering activation energy barriers, these materials can decrease the operational temperature of catalytic processes by 100-200°C compared to traditional catalysts. Life cycle assessments indicate that this temperature reduction can yield energy savings of 20-40% in energy-intensive processes like ammonia production, which currently accounts for approximately 1-2% of global energy consumption.

The raw material composition of electride catalysts presents both opportunities and challenges from a sustainability perspective. Many electride structures incorporate earth-abundant elements like calcium, aluminum, and oxygen, reducing dependence on precious metals such as platinum and palladium that face supply constraints and environmental issues associated with mining. However, certain electride formulations require rare earth elements, which raises concerns regarding resource availability and extraction impacts.

Durability and recyclability factors significantly influence the long-term environmental profile of electride catalysts. Current research indicates that some electride structures exhibit stability challenges in ambient conditions, potentially limiting their service life. Ongoing development focuses on encapsulation techniques and protective coatings to enhance longevity without compromising catalytic activity. Preliminary studies suggest that spent electride catalysts can be regenerated through controlled thermal treatments, potentially creating closed-loop material cycles.

Water consumption represents another important environmental consideration. Low-temperature catalytic processes enabled by electrides typically require less cooling water than high-temperature alternatives. Quantitative assessments indicate potential water savings of 15-30% in large-scale industrial implementations, contributing to resource conservation in water-stressed regions where chemical manufacturing facilities often operate.

The scalability of environmentally beneficial electride catalysts faces several technical hurdles. Current synthesis methods for high-performance electride nanostructures often involve energy-intensive processes that partially offset their operational benefits. Research priorities include developing green synthesis routes that minimize solvent use, reduce energy inputs, and maximize atom efficiency. Progress in this area will be crucial for ensuring that the environmental benefits of electride catalysts extend across their entire life cycle.

Scalability and Industrial Implementation Challenges

Despite the promising potential of electride nanostructures for low-temperature catalysis, significant challenges remain in scaling these technologies from laboratory demonstrations to industrial implementation. The transition from controlled experimental environments to large-scale production facilities presents multifaceted obstacles that must be addressed systematically.

Material synthesis represents a primary bottleneck in scaling electride nanostructure technologies. Current laboratory-scale synthesis methods often involve complex procedures with precise control requirements for temperature, pressure, and atmospheric conditions. These methods typically yield milligram to gram quantities, whereas industrial applications would require kilogram to ton-scale production with consistent quality and performance characteristics.

Stability issues pose another critical challenge for industrial implementation. Many electride materials exhibit sensitivity to air, moisture, and temperature fluctuations, necessitating specialized handling protocols and storage conditions. For continuous industrial processes, these materials must maintain catalytic activity over extended operational periods under variable conditions, a requirement not fully demonstrated in current research settings.

Cost considerations significantly impact commercialization prospects. The synthesis of electride nanostructures often involves expensive precursors, energy-intensive processes, and specialized equipment. Economic viability requires either cost reduction strategies or performance advantages substantial enough to justify premium pricing compared to conventional catalysts.

Integration with existing industrial infrastructure presents additional complexities. Most chemical production facilities are designed around established catalytic processes with specific reactor configurations, flow dynamics, and process controls. Retrofitting these systems to accommodate electride-based catalysts may require significant capital investment and process redesign.

Quality control and standardization remain underdeveloped for electride nanostructures. Industrial implementation necessitates reliable characterization methods and quality metrics to ensure consistent performance across production batches. Currently, analytical techniques for electride materials often require specialized equipment not readily available in industrial settings.

Regulatory considerations also impact implementation timelines. Novel materials typically undergo extensive safety and environmental impact assessments before industrial adoption. The unique properties of electride materials may require development of new testing protocols and safety standards, potentially extending commercialization timelines.

Addressing these challenges requires collaborative efforts between academic researchers, material scientists, chemical engineers, and industry partners to develop scalable synthesis methods, enhance material stability, optimize process integration, and establish appropriate quality control frameworks.

Material synthesis represents a primary bottleneck in scaling electride nanostructure technologies. Current laboratory-scale synthesis methods often involve complex procedures with precise control requirements for temperature, pressure, and atmospheric conditions. These methods typically yield milligram to gram quantities, whereas industrial applications would require kilogram to ton-scale production with consistent quality and performance characteristics.

Stability issues pose another critical challenge for industrial implementation. Many electride materials exhibit sensitivity to air, moisture, and temperature fluctuations, necessitating specialized handling protocols and storage conditions. For continuous industrial processes, these materials must maintain catalytic activity over extended operational periods under variable conditions, a requirement not fully demonstrated in current research settings.

Cost considerations significantly impact commercialization prospects. The synthesis of electride nanostructures often involves expensive precursors, energy-intensive processes, and specialized equipment. Economic viability requires either cost reduction strategies or performance advantages substantial enough to justify premium pricing compared to conventional catalysts.

Integration with existing industrial infrastructure presents additional complexities. Most chemical production facilities are designed around established catalytic processes with specific reactor configurations, flow dynamics, and process controls. Retrofitting these systems to accommodate electride-based catalysts may require significant capital investment and process redesign.

Quality control and standardization remain underdeveloped for electride nanostructures. Industrial implementation necessitates reliable characterization methods and quality metrics to ensure consistent performance across production batches. Currently, analytical techniques for electride materials often require specialized equipment not readily available in industrial settings.

Regulatory considerations also impact implementation timelines. Novel materials typically undergo extensive safety and environmental impact assessments before industrial adoption. The unique properties of electride materials may require development of new testing protocols and safety standards, potentially extending commercialization timelines.

Addressing these challenges requires collaborative efforts between academic researchers, material scientists, chemical engineers, and industry partners to develop scalable synthesis methods, enhance material stability, optimize process integration, and establish appropriate quality control frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!