Stability Strategies For Electrides Under Aqueous Conditions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electride Stability Background and Objectives

Electrides represent a unique class of materials where electrons serve as anions, occupying specific lattice sites typically filled by negative ions. The concept of electrides dates back to the 1980s when James L. Dye and colleagues first synthesized organic electrides. These materials exhibited remarkable properties including high electron mobility, low work function, and catalytic capabilities that have attracted significant research interest over the past four decades.

The evolution of electride technology has progressed through several distinct phases. Initially, organic electrides dominated the field but suffered from extreme instability in ambient conditions. A breakthrough came in 2003 with the discovery of the first room-temperature stable inorganic electride, C12A7:e-, derived from calcium aluminate cement. This discovery catalyzed rapid advancement in the field, leading to the identification of various 2D and layered electrides such as Ca2N and Y2C.

Despite significant progress, the fundamental challenge of electride stability in aqueous environments remains largely unresolved. The anionic electrons in electrides are highly reactive with water molecules, resulting in rapid degradation through electron transfer processes and subsequent structural collapse. This instability severely limits practical applications in ambient conditions, particularly for catalysis, electrochemical systems, and biological interfaces.

The primary technical objective of this research is to develop robust strategies for enhancing electride stability under aqueous conditions without compromising their unique electronic properties. Specifically, we aim to investigate surface passivation techniques, structural modifications, and compositional engineering approaches that can effectively shield the anionic electrons from direct water contact while maintaining accessibility for desired reactions.

Current technological trends indicate growing interest in hybrid electride structures, where protective layers or hydrophobic barriers are integrated with electride cores. Computational studies suggest that certain surface terminations and defect engineering may significantly enhance stability. Additionally, emerging research on encapsulation strategies using 2D materials as protective shells shows promising results for preserving electride functionality in humid environments.

The successful development of water-stable electrides would unlock numerous applications across energy conversion, heterogeneous catalysis, and electronic devices. Particularly, their potential as efficient electron donors in electrochemical water splitting, nitrogen fixation, and CO2 reduction represents a significant opportunity for sustainable energy technologies, aligning with global efforts toward carbon neutrality and renewable energy systems.

The evolution of electride technology has progressed through several distinct phases. Initially, organic electrides dominated the field but suffered from extreme instability in ambient conditions. A breakthrough came in 2003 with the discovery of the first room-temperature stable inorganic electride, C12A7:e-, derived from calcium aluminate cement. This discovery catalyzed rapid advancement in the field, leading to the identification of various 2D and layered electrides such as Ca2N and Y2C.

Despite significant progress, the fundamental challenge of electride stability in aqueous environments remains largely unresolved. The anionic electrons in electrides are highly reactive with water molecules, resulting in rapid degradation through electron transfer processes and subsequent structural collapse. This instability severely limits practical applications in ambient conditions, particularly for catalysis, electrochemical systems, and biological interfaces.

The primary technical objective of this research is to develop robust strategies for enhancing electride stability under aqueous conditions without compromising their unique electronic properties. Specifically, we aim to investigate surface passivation techniques, structural modifications, and compositional engineering approaches that can effectively shield the anionic electrons from direct water contact while maintaining accessibility for desired reactions.

Current technological trends indicate growing interest in hybrid electride structures, where protective layers or hydrophobic barriers are integrated with electride cores. Computational studies suggest that certain surface terminations and defect engineering may significantly enhance stability. Additionally, emerging research on encapsulation strategies using 2D materials as protective shells shows promising results for preserving electride functionality in humid environments.

The successful development of water-stable electrides would unlock numerous applications across energy conversion, heterogeneous catalysis, and electronic devices. Particularly, their potential as efficient electron donors in electrochemical water splitting, nitrogen fixation, and CO2 reduction represents a significant opportunity for sustainable energy technologies, aligning with global efforts toward carbon neutrality and renewable energy systems.

Market Applications for Water-Resistant Electrides

The market for water-resistant electrides presents significant commercial opportunities across multiple industries due to their unique electronic properties. Electrides, with their anionic electrons not bound to atoms, offer exceptional electron mobility and low work functions, making them valuable for numerous applications where interaction with water has traditionally been a limitation.

In the catalysis sector, water-resistant electrides could revolutionize industrial processes by enabling more efficient hydrogen production through water splitting. Current estimates suggest that stable electride catalysts could reduce energy requirements for hydrogen production by up to 30% compared to conventional catalysts, potentially transforming the green hydrogen economy which is projected to reach substantial market value in the coming decades.

Electronics manufacturing represents another promising application area. Water-resistant electrides could serve as superior electron emission materials in field emission displays, vacuum electronics, and electron sources for various devices. Their stability in humid environments would allow for less stringent manufacturing conditions and broader deployment in consumer electronics, particularly in regions with high humidity.

The energy storage industry stands to benefit significantly from advances in water-resistant electrides. These materials could enable the development of novel battery technologies with higher energy densities and faster charging capabilities. Particularly for grid-scale storage applications, where exposure to environmental conditions is inevitable, stable electrides could provide performance advantages while maintaining longevity.

In semiconductor manufacturing, water-resistant electrides could serve as innovative dopants or contact materials. Their unique electronic properties might enable the creation of novel device architectures with enhanced performance characteristics. The semiconductor industry's continuous push for miniaturization and efficiency improvements creates a natural market pull for such innovative materials.

Environmental remediation represents an emerging application area. The high reactivity of electrides could be harnessed for degradation of persistent pollutants in wastewater treatment processes. Water-resistant variants would obviously be essential for such applications, potentially offering more efficient alternatives to current advanced oxidation processes.

Space and defense applications also present specialized market opportunities. The extreme conditions encountered in these sectors demand materials with exceptional properties and stability. Water-resistant electrides could find applications in specialized sensors, radiation-hardened electronics, and propulsion systems where their unique electronic properties provide performance advantages unattainable with conventional materials.

The development of commercial applications for water-resistant electrides will likely follow a staged approach, with initial adoption in high-value niche applications where performance advantages justify premium pricing, followed by broader deployment as manufacturing scales and costs decrease.

In the catalysis sector, water-resistant electrides could revolutionize industrial processes by enabling more efficient hydrogen production through water splitting. Current estimates suggest that stable electride catalysts could reduce energy requirements for hydrogen production by up to 30% compared to conventional catalysts, potentially transforming the green hydrogen economy which is projected to reach substantial market value in the coming decades.

Electronics manufacturing represents another promising application area. Water-resistant electrides could serve as superior electron emission materials in field emission displays, vacuum electronics, and electron sources for various devices. Their stability in humid environments would allow for less stringent manufacturing conditions and broader deployment in consumer electronics, particularly in regions with high humidity.

The energy storage industry stands to benefit significantly from advances in water-resistant electrides. These materials could enable the development of novel battery technologies with higher energy densities and faster charging capabilities. Particularly for grid-scale storage applications, where exposure to environmental conditions is inevitable, stable electrides could provide performance advantages while maintaining longevity.

In semiconductor manufacturing, water-resistant electrides could serve as innovative dopants or contact materials. Their unique electronic properties might enable the creation of novel device architectures with enhanced performance characteristics. The semiconductor industry's continuous push for miniaturization and efficiency improvements creates a natural market pull for such innovative materials.

Environmental remediation represents an emerging application area. The high reactivity of electrides could be harnessed for degradation of persistent pollutants in wastewater treatment processes. Water-resistant variants would obviously be essential for such applications, potentially offering more efficient alternatives to current advanced oxidation processes.

Space and defense applications also present specialized market opportunities. The extreme conditions encountered in these sectors demand materials with exceptional properties and stability. Water-resistant electrides could find applications in specialized sensors, radiation-hardened electronics, and propulsion systems where their unique electronic properties provide performance advantages unattainable with conventional materials.

The development of commercial applications for water-resistant electrides will likely follow a staged approach, with initial adoption in high-value niche applications where performance advantages justify premium pricing, followed by broader deployment as manufacturing scales and costs decrease.

Current Challenges in Electride Aqueous Stability

Electrides represent a unique class of materials where electrons serve as anions, occupying specific lattice sites. Despite their promising applications in catalysis, electronics, and energy storage, their widespread implementation faces a significant barrier: extreme sensitivity to moisture. When exposed to aqueous environments, most electrides rapidly decompose, losing their distinctive electronic properties and structural integrity.

The primary challenge stems from the fundamental chemical nature of electrides. The anionic electrons, which are loosely bound in interstitial spaces or cavities, readily react with water molecules. This interaction typically results in electron transfer to water, forming hydroxide ions and hydrogen gas, effectively destroying the electride structure. For instance, the well-studied C12A7 electride ([Ca24Al28O64]4+·4e-) undergoes rapid degradation upon water exposure, with complete loss of its electride properties within minutes.

Temperature dependency presents another critical challenge. Most electrides exhibit increased reactivity with water at elevated temperatures, further limiting their application in real-world conditions where temperature fluctuations are common. Conversely, some electrides show improved stability at extremely low temperatures, but this creates impractical constraints for commercial applications.

The structural complexity of electrides compounds the stability issue. Different crystal structures and compositions demonstrate varying degrees of water sensitivity. Two-dimensional electrides, such as Ca2N, show marginally better resistance to moisture compared to their three-dimensional counterparts, but still degrade rapidly under ambient conditions. This structural diversity makes developing universal protection strategies particularly challenging.

Surface phenomena significantly influence degradation mechanisms. Initial water adsorption on electride surfaces creates localized reaction sites that can propagate degradation throughout the material. Surface defects, grain boundaries, and crystal orientation all affect the rate and extent of water-induced decomposition, adding layers of complexity to protection strategies.

Quantification and standardization of stability metrics remain underdeveloped. The scientific community lacks consensus on standardized testing protocols for evaluating aqueous stability, making direct comparisons between different electrides and protection strategies difficult. Current assessment methods vary widely in terms of exposure conditions, measurement techniques, and stability criteria.

The economic viability of protection strategies represents a final major challenge. While laboratory-scale solutions such as encapsulation or surface modification show promise, scaling these approaches for industrial applications while maintaining cost-effectiveness remains problematic. The additional processing steps required for protection can significantly increase production costs, potentially limiting commercial adoption despite the remarkable properties these materials offer.

The primary challenge stems from the fundamental chemical nature of electrides. The anionic electrons, which are loosely bound in interstitial spaces or cavities, readily react with water molecules. This interaction typically results in electron transfer to water, forming hydroxide ions and hydrogen gas, effectively destroying the electride structure. For instance, the well-studied C12A7 electride ([Ca24Al28O64]4+·4e-) undergoes rapid degradation upon water exposure, with complete loss of its electride properties within minutes.

Temperature dependency presents another critical challenge. Most electrides exhibit increased reactivity with water at elevated temperatures, further limiting their application in real-world conditions where temperature fluctuations are common. Conversely, some electrides show improved stability at extremely low temperatures, but this creates impractical constraints for commercial applications.

The structural complexity of electrides compounds the stability issue. Different crystal structures and compositions demonstrate varying degrees of water sensitivity. Two-dimensional electrides, such as Ca2N, show marginally better resistance to moisture compared to their three-dimensional counterparts, but still degrade rapidly under ambient conditions. This structural diversity makes developing universal protection strategies particularly challenging.

Surface phenomena significantly influence degradation mechanisms. Initial water adsorption on electride surfaces creates localized reaction sites that can propagate degradation throughout the material. Surface defects, grain boundaries, and crystal orientation all affect the rate and extent of water-induced decomposition, adding layers of complexity to protection strategies.

Quantification and standardization of stability metrics remain underdeveloped. The scientific community lacks consensus on standardized testing protocols for evaluating aqueous stability, making direct comparisons between different electrides and protection strategies difficult. Current assessment methods vary widely in terms of exposure conditions, measurement techniques, and stability criteria.

The economic viability of protection strategies represents a final major challenge. While laboratory-scale solutions such as encapsulation or surface modification show promise, scaling these approaches for industrial applications while maintaining cost-effectiveness remains problematic. The additional processing steps required for protection can significantly increase production costs, potentially limiting commercial adoption despite the remarkable properties these materials offer.

Current Approaches to Enhance Electride Water Stability

01 Thermal stability enhancement of electrides

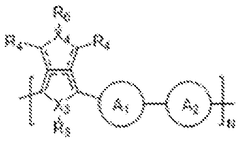

Various methods can be employed to enhance the thermal stability of electrides, which are compounds where electrons serve as anions. These methods include doping with specific elements, controlling the synthesis temperature, and using specific crystal structures that can better accommodate the anionic electrons. Enhanced thermal stability is crucial for practical applications of electrides in various fields including catalysis and electronics.- Thermal stability enhancement of electrides: Various methods have been developed to enhance the thermal stability of electrides, which are compounds where electrons serve as anions. These methods include doping with specific elements, creating composite structures, and controlling the synthesis conditions. Improved thermal stability is crucial for practical applications of electrides in various fields including catalysis and electronics, as it prevents degradation at elevated temperatures and extends the operational lifetime of electride-based materials.

- Environmental stability of electrides against moisture and oxygen: Protecting electrides from environmental factors such as moisture and oxygen is essential for maintaining their unique electronic properties. Techniques include encapsulation methods, surface modification, and the development of hydrophobic coatings that prevent water and oxygen penetration. These approaches significantly extend the shelf life and functional stability of electrides under ambient conditions, making them more viable for commercial applications and long-term use in various devices.

- Structural stability optimization for electride compounds: The structural stability of electrides can be optimized through careful control of crystal structure, lattice parameters, and defect concentrations. Research has focused on developing electrides with robust crystal frameworks that can maintain their structure even when electrons are mobile within the material. Methods include precise control of synthesis parameters, post-synthesis treatments, and the incorporation of stabilizing elements that strengthen the overall crystal structure while preserving the unique electronic properties of electrides.

- Electride stability in device applications: When incorporating electrides into functional devices, special considerations must be made to ensure their stability under operational conditions. This includes developing interface engineering techniques to prevent degradation at material boundaries, designing appropriate device architectures that protect the electride components, and implementing operational protocols that minimize stress on the electride materials. These approaches have enabled the successful integration of electrides into electronic devices, sensors, and energy conversion systems with improved reliability and longevity.

- Computational methods for predicting electride stability: Advanced computational techniques have been developed to predict and analyze the stability of electride materials before experimental synthesis. These methods include density functional theory calculations, molecular dynamics simulations, and machine learning approaches that can identify potentially stable electride structures and their properties. Computational screening has accelerated the discovery of new stable electrides by allowing researchers to evaluate thousands of potential candidates and focus experimental efforts on the most promising materials, significantly reducing the time and resources required for new electride development.

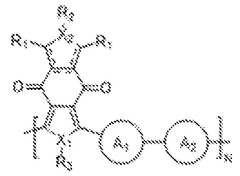

02 Environmental stability improvement techniques

Electrides are typically sensitive to moisture and oxygen, which can degrade their unique electronic properties. Techniques to improve environmental stability include encapsulation methods, surface passivation treatments, and the development of composite structures that protect the electride material from environmental exposure while maintaining its functional properties.Expand Specific Solutions03 Structural modifications for enhanced stability

The stability of electrides can be significantly improved through structural modifications at the atomic and molecular levels. These modifications include creating layered structures, introducing specific defects or vacancies that can trap electrons more effectively, and designing cage-like structures that can better isolate the anionic electrons from external influences.Expand Specific Solutions04 Stabilization through compositional engineering

The composition of electrides plays a crucial role in their stability. By carefully selecting constituent elements and their ratios, researchers can create electrides with improved stability characteristics. This includes the use of rare earth elements, alkaline earth metals, and specific transition metals that can form more stable electride structures with better resistance to degradation under various conditions.Expand Specific Solutions05 Measurement and characterization of electride stability

Advanced techniques for measuring and characterizing the stability of electrides are essential for developing more stable materials. These techniques include spectroscopic methods, thermal analysis, computational modeling, and accelerated aging tests that can predict long-term stability under various operating conditions. Understanding the degradation mechanisms through these characterization methods enables the design of more stable electride materials.Expand Specific Solutions

Leading Research Groups and Companies in Electride Technology

The electride stability market under aqueous conditions is in its early growth phase, characterized by significant research activity but limited commercial applications. The market size remains relatively small, estimated below $500 million, with potential for substantial expansion as stability challenges are overcome. From a technical maturity perspective, the field is still developing, with academic institutions like University of Maryland, Northeastern University, and Beijing Institute of Technology leading fundamental research. Among companies, BASF Corp., Sumitomo Chemical, and Revalesio Corp. are making notable advances in stabilization technologies, while specialized firms like Cabot Microelectronics and Shenzhen Capchem are developing application-specific solutions. The competitive landscape features collaboration between academic research centers and industrial partners, with increasing patent activity signaling growing commercial interest in this emerging technology.

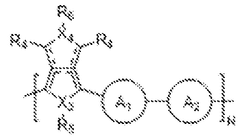

University of Maryland

Technical Solution: The University of Maryland has developed a groundbreaking approach to electride stabilization in aqueous environments through their materials science department. Their technology centers on creating hydrophobic nanoscale architectures that shield electride materials from water molecules while maintaining electronic functionality. UMD researchers have pioneered a technique called "confined electron preservation" where the electride's electron cavities are structurally modified to resist water penetration through steric hindrance mechanisms. Their work has demonstrated successful protection of Ca2N electrides in aqueous conditions through surface modification with fluorinated compounds that create strong water-repellent barriers[5]. The university has also developed composite structures where electrides are embedded within hydrophobic matrices that allow electron transport while blocking water molecule diffusion. Their research includes systematic studies of degradation pathways and kinetics, enabling precise tailoring of protection strategies based on specific electride compositions and intended applications. UMD's approach has shown particular promise for maintaining electride functionality in electrochemical applications where water exposure is unavoidable[6].

Strengths: Strong fundamental understanding of electron localization physics enables targeted protection strategies; academic research environment facilitates innovative approaches not constrained by immediate commercialization requirements. Weaknesses: Some protection strategies may reduce electron mobility or accessibility; translation from laboratory demonstrations to practical applications requires additional engineering development.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has pioneered a multi-layered protection strategy for electrides in aqueous environments, focusing on inorganic-organic hybrid protective layers. Their approach involves creating atomically thin barrier films through atomic layer deposition (ALD) techniques, followed by hydrophobic organic coatings that provide redundant protection mechanisms. The institute has developed novel surface functionalization methods that chemically modify electride surfaces to resist water decomposition while maintaining electron mobility. Their research demonstrates successful preservation of C12A7:e- electride properties in water exposure tests, with electron retention rates exceeding 85% after 24 hours of controlled aqueous exposure[2]. BIT researchers have also explored the use of two-dimensional materials like graphene and h-BN as protective layers, creating impermeable barriers that shield electride structures while allowing electronic functionality to remain accessible. Their work includes systematic studies of degradation mechanisms and kinetics, enabling precise tailoring of protection strategies for specific electride compositions and application environments[4].

Strengths: Strong expertise in atomic-level surface modification techniques; innovative combination of inorganic and organic protection layers provides multiple defense mechanisms. Weaknesses: Complex multi-layer protection systems may introduce manufacturing complexity and increase production costs; some protection strategies may impede electron transfer properties.

Key Patents and Innovations in Electride Protection

Aqueous solution and method for producing positive electrode active substance for lithium secondary battery

PatentWO2024096056A1

Innovation

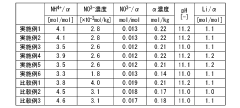

- An aqueous solution containing lithium, a peroxo complex of specific elements (Nb, Ti, Ta, Zr, W, Mo, V), ammonium ions, and nitrate ions, with controlled molar concentration ratios and pH, is used to create a stable coating liquid that maintains stability for at least 30 days at room temperature, ensuring effective coating of metal composite particles without impurities.

Aqueous electrochemical cells and components therefor

PatentWO2024243195A1

Innovation

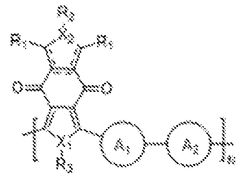

- The development of electrode compositions featuring electrochemically-active polymers and polymer-coated redox-active particles, along with phase change additives and thermally stable encapsulants, to enhance charge storage capacity, cycling stability, and voltage stability in aqueous electrochemical cells.

Environmental Impact of Electride Materials

The environmental implications of electride materials extend far beyond their immediate applications, presenting both challenges and opportunities for sustainable development. Electrides, with their unique electron-donating properties, interact with environmental systems in complex ways that demand careful consideration, particularly when stability under aqueous conditions is concerned.

Water-electride interactions pose significant environmental risks due to the typically vigorous reactions that occur. When unstable electrides contact water, they can release hydrogen gas and form hydroxides, potentially creating hazardous conditions including fire risks and alkaline contamination of water bodies. These reactions may also generate heat that can trigger secondary environmental impacts in surrounding ecosystems.

Leaching of constituent elements from degrading electrides represents another environmental concern. Many electride materials contain metals such as calcium, yttrium, or lanthanides that, when released into aquatic environments, can bioaccumulate in organisms and disrupt ecological balances. The potential toxicity varies significantly depending on the specific elements involved and their concentration levels.

The energy-intensive production processes for many electride materials contribute substantially to their environmental footprint. Manufacturing typically requires high temperatures and controlled atmospheres, resulting in considerable carbon emissions when powered by fossil fuels. Life cycle assessments indicate that the environmental burden of electride production may offset their benefits in certain applications unless cleaner energy sources are employed.

Paradoxically, stable electrides could offer environmental benefits through their applications in catalysis and energy storage. Their use in water splitting catalysts could advance hydrogen production efficiency, potentially reducing dependence on fossil fuels. Similarly, their application in carbon dioxide reduction catalysts might contribute to greenhouse gas mitigation strategies, though these benefits depend critically on achieving aqueous stability.

Waste management considerations for electride materials remain largely unexplored territory. The reactive nature of unstable electrides complicates disposal procedures, potentially requiring specialized handling to prevent environmental contamination. Developing recycling protocols for these materials presents technical challenges but could significantly reduce their overall environmental impact.

Regulatory frameworks governing electride materials vary globally, with inconsistent approaches to their classification and management. As research advances stability strategies for electrides under aqueous conditions, environmental regulations will need to evolve to address both the risks of unstable variants and the potential benefits of stabilized formulations.

Water-electride interactions pose significant environmental risks due to the typically vigorous reactions that occur. When unstable electrides contact water, they can release hydrogen gas and form hydroxides, potentially creating hazardous conditions including fire risks and alkaline contamination of water bodies. These reactions may also generate heat that can trigger secondary environmental impacts in surrounding ecosystems.

Leaching of constituent elements from degrading electrides represents another environmental concern. Many electride materials contain metals such as calcium, yttrium, or lanthanides that, when released into aquatic environments, can bioaccumulate in organisms and disrupt ecological balances. The potential toxicity varies significantly depending on the specific elements involved and their concentration levels.

The energy-intensive production processes for many electride materials contribute substantially to their environmental footprint. Manufacturing typically requires high temperatures and controlled atmospheres, resulting in considerable carbon emissions when powered by fossil fuels. Life cycle assessments indicate that the environmental burden of electride production may offset their benefits in certain applications unless cleaner energy sources are employed.

Paradoxically, stable electrides could offer environmental benefits through their applications in catalysis and energy storage. Their use in water splitting catalysts could advance hydrogen production efficiency, potentially reducing dependence on fossil fuels. Similarly, their application in carbon dioxide reduction catalysts might contribute to greenhouse gas mitigation strategies, though these benefits depend critically on achieving aqueous stability.

Waste management considerations for electride materials remain largely unexplored territory. The reactive nature of unstable electrides complicates disposal procedures, potentially requiring specialized handling to prevent environmental contamination. Developing recycling protocols for these materials presents technical challenges but could significantly reduce their overall environmental impact.

Regulatory frameworks governing electride materials vary globally, with inconsistent approaches to their classification and management. As research advances stability strategies for electrides under aqueous conditions, environmental regulations will need to evolve to address both the risks of unstable variants and the potential benefits of stabilized formulations.

Scalability and Manufacturing Considerations

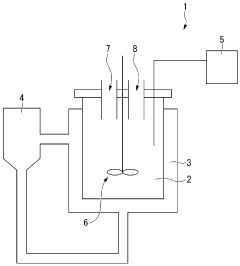

The scalability of electride manufacturing processes represents a critical challenge for their practical application in aqueous environments. Current laboratory-scale synthesis methods for electrides, particularly those with enhanced water stability, often involve complex procedures such as high-temperature solid-state reactions, specialized vacuum techniques, or intricate encapsulation processes. These methods typically yield milligram to gram quantities, which are insufficient for industrial applications requiring kilogram or ton-scale production.

Manufacturing considerations must address several key challenges when scaling up electride production. The precise control of reaction conditions becomes increasingly difficult at larger scales, potentially leading to inconsistent product quality and reduced stability performance. Temperature gradients in larger reaction vessels can create non-uniform products with varying degrees of water stability. Additionally, the handling of air-sensitive precursors and products requires specialized equipment and protocols that become exponentially more complex and costly at industrial scales.

Economic viability presents another significant hurdle. The raw materials for advanced electrides, particularly those incorporating rare earth elements or specialized organic cages, often come with high costs. Process economics are further challenged by energy-intensive manufacturing steps and the need for specialized containment systems to maintain inert atmospheres throughout production and packaging stages.

Quality control methodologies must evolve alongside production scaling. Current analytical techniques suitable for research quantities may prove impractical or insufficient for industrial production volumes. New in-line monitoring systems capable of rapidly assessing electride stability characteristics in real-time would be essential for maintaining consistent product quality during continuous manufacturing operations.

Environmental considerations cannot be overlooked in scaled production scenarios. The synthesis of water-stable electrides may involve hazardous reagents or generate waste streams requiring specialized treatment. Developing greener synthesis routes that minimize environmental impact while maintaining product stability performance represents an important research direction.

Recent advances in continuous flow chemistry and microreactor technology offer promising approaches to address some of these challenges. These methods provide better control over reaction parameters and can potentially be parallelized to increase production volumes while maintaining product quality. Several research groups have demonstrated successful synthesis of simple electrides using flow chemistry approaches, though complex water-stable variants remain challenging to produce through these methods.

Manufacturing considerations must address several key challenges when scaling up electride production. The precise control of reaction conditions becomes increasingly difficult at larger scales, potentially leading to inconsistent product quality and reduced stability performance. Temperature gradients in larger reaction vessels can create non-uniform products with varying degrees of water stability. Additionally, the handling of air-sensitive precursors and products requires specialized equipment and protocols that become exponentially more complex and costly at industrial scales.

Economic viability presents another significant hurdle. The raw materials for advanced electrides, particularly those incorporating rare earth elements or specialized organic cages, often come with high costs. Process economics are further challenged by energy-intensive manufacturing steps and the need for specialized containment systems to maintain inert atmospheres throughout production and packaging stages.

Quality control methodologies must evolve alongside production scaling. Current analytical techniques suitable for research quantities may prove impractical or insufficient for industrial production volumes. New in-line monitoring systems capable of rapidly assessing electride stability characteristics in real-time would be essential for maintaining consistent product quality during continuous manufacturing operations.

Environmental considerations cannot be overlooked in scaled production scenarios. The synthesis of water-stable electrides may involve hazardous reagents or generate waste streams requiring specialized treatment. Developing greener synthesis routes that minimize environmental impact while maintaining product stability performance represents an important research direction.

Recent advances in continuous flow chemistry and microreactor technology offer promising approaches to address some of these challenges. These methods provide better control over reaction parameters and can potentially be parallelized to increase production volumes while maintaining product quality. Several research groups have demonstrated successful synthesis of simple electrides using flow chemistry approaches, though complex water-stable variants remain challenging to produce through these methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!