Electride Electronic Phase Engineering Under Strain

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electride Materials Background and Research Objectives

Electride materials represent a unique class of compounds where electrons serve as anions, occupying structural cavities rather than being bound to specific atoms. This distinctive electronic configuration grants electrides exceptional properties including high electrical conductivity, low work function, and remarkable catalytic activity. The concept of electrides dates back to the 1980s with F.J. Dye's pioneering work, though significant advancements have only emerged in the past two decades with the discovery of stable room-temperature electrides such as C12A7:e- (12CaO·7Al2O3:e-) and 2D electrides like Ca2N.

The field of electride research has evolved from initial theoretical predictions to practical applications across multiple industries. Early electrides were highly unstable in ambient conditions, limiting their practical utility. However, breakthroughs in synthesis techniques and material design have led to increasingly stable electrides with diverse compositions and structures, expanding their potential applications in electronics, catalysis, and energy conversion technologies.

Current research trends indicate growing interest in engineering the electronic phases of electrides through mechanical strain. Strain engineering—the deliberate application of mechanical stress to modify material properties—offers a promising approach to tune electride characteristics without altering chemical composition. This approach leverages the unique electron localization in structural cavities, which can be significantly influenced by subtle changes in lattice parameters and symmetry.

The primary objective of this technical research is to comprehensively investigate how various strain types (tensile, compressive, shear) affect the electronic structure and functional properties of different electride materials. We aim to establish fundamental structure-property relationships that connect strain parameters to electronic phase transitions in electrides, potentially enabling precise control over their electrical, optical, and catalytic properties.

Additionally, this research seeks to identify optimal strain conditions for enhancing specific electride properties relevant to industrial applications, such as work function modulation for electron emission devices, band gap engineering for optoelectronic applications, and electron density tuning for catalytic processes. The development of predictive models correlating strain parameters with electronic phase changes would significantly accelerate materials design and optimization.

The technological significance of this research extends beyond fundamental understanding, potentially enabling next-generation electronic devices, more efficient catalysts for chemical processes including ammonia synthesis, and novel energy conversion systems. As global demand for advanced materials with tailored electronic properties continues to grow, strain-engineered electrides could represent a versatile platform for addressing challenges in sustainable energy and green chemistry.

The field of electride research has evolved from initial theoretical predictions to practical applications across multiple industries. Early electrides were highly unstable in ambient conditions, limiting their practical utility. However, breakthroughs in synthesis techniques and material design have led to increasingly stable electrides with diverse compositions and structures, expanding their potential applications in electronics, catalysis, and energy conversion technologies.

Current research trends indicate growing interest in engineering the electronic phases of electrides through mechanical strain. Strain engineering—the deliberate application of mechanical stress to modify material properties—offers a promising approach to tune electride characteristics without altering chemical composition. This approach leverages the unique electron localization in structural cavities, which can be significantly influenced by subtle changes in lattice parameters and symmetry.

The primary objective of this technical research is to comprehensively investigate how various strain types (tensile, compressive, shear) affect the electronic structure and functional properties of different electride materials. We aim to establish fundamental structure-property relationships that connect strain parameters to electronic phase transitions in electrides, potentially enabling precise control over their electrical, optical, and catalytic properties.

Additionally, this research seeks to identify optimal strain conditions for enhancing specific electride properties relevant to industrial applications, such as work function modulation for electron emission devices, band gap engineering for optoelectronic applications, and electron density tuning for catalytic processes. The development of predictive models correlating strain parameters with electronic phase changes would significantly accelerate materials design and optimization.

The technological significance of this research extends beyond fundamental understanding, potentially enabling next-generation electronic devices, more efficient catalysts for chemical processes including ammonia synthesis, and novel energy conversion systems. As global demand for advanced materials with tailored electronic properties continues to grow, strain-engineered electrides could represent a versatile platform for addressing challenges in sustainable energy and green chemistry.

Market Applications and Demand Analysis for Electride Materials

The global market for electride materials is experiencing significant growth driven by their unique electronic properties and potential applications across multiple industries. Current market analysis indicates that electride materials, particularly those engineered under strain conditions, are positioned to address critical challenges in catalysis, electronics, and energy storage sectors. The demand for these materials is primarily fueled by their exceptional electron emission characteristics and catalytic properties that outperform conventional materials.

In the electronics industry, electride materials show promising applications in field emission displays, electron sources, and next-generation semiconductor devices. The increasing miniaturization of electronic components and the push for higher efficiency has created a substantial market opportunity for electride-based solutions. Companies developing advanced display technologies are particularly interested in the low work function properties of electrides that enable efficient electron emission at lower operating voltages.

The renewable energy sector represents another significant market for electride materials. Their application in water splitting for hydrogen production has demonstrated superior catalytic activity compared to traditional noble metal catalysts. With the global hydrogen economy projected to expand rapidly in the coming decades, the demand for cost-effective and efficient catalysts like electrides is expected to grow substantially. Additionally, their potential use in ammonia synthesis could revolutionize fertilizer production, addressing a market worth billions globally.

Aerospace and defense industries are exploring electride materials for specialized applications in propulsion systems and sensors. The unique electronic properties of electrides under strain engineering make them candidates for high-performance components in extreme environments. Though currently a niche application, this sector offers premium pricing opportunities for advanced materials with exceptional properties.

Regional market analysis shows that Asia-Pacific, particularly Japan, China, and South Korea, leads in electride research and commercial development, followed by North America and Europe. The concentration of electronics manufacturing and increasing investment in renewable energy infrastructure in these regions drives the demand for advanced materials like electrides.

Market barriers include high production costs, scalability challenges, and limited awareness among potential end-users. Current production methods for high-quality electride materials remain complex and expensive, restricting widespread adoption. However, recent advancements in strain engineering techniques are addressing these limitations by enabling more controlled synthesis and improved stability of electride phases.

Industry experts project that as manufacturing processes mature and production scales increase, the cost of electride materials will decrease significantly, opening new market opportunities. The development of strain-engineered electrides with tailored properties for specific applications is expected to further expand market potential by addressing performance requirements across diverse industries.

In the electronics industry, electride materials show promising applications in field emission displays, electron sources, and next-generation semiconductor devices. The increasing miniaturization of electronic components and the push for higher efficiency has created a substantial market opportunity for electride-based solutions. Companies developing advanced display technologies are particularly interested in the low work function properties of electrides that enable efficient electron emission at lower operating voltages.

The renewable energy sector represents another significant market for electride materials. Their application in water splitting for hydrogen production has demonstrated superior catalytic activity compared to traditional noble metal catalysts. With the global hydrogen economy projected to expand rapidly in the coming decades, the demand for cost-effective and efficient catalysts like electrides is expected to grow substantially. Additionally, their potential use in ammonia synthesis could revolutionize fertilizer production, addressing a market worth billions globally.

Aerospace and defense industries are exploring electride materials for specialized applications in propulsion systems and sensors. The unique electronic properties of electrides under strain engineering make them candidates for high-performance components in extreme environments. Though currently a niche application, this sector offers premium pricing opportunities for advanced materials with exceptional properties.

Regional market analysis shows that Asia-Pacific, particularly Japan, China, and South Korea, leads in electride research and commercial development, followed by North America and Europe. The concentration of electronics manufacturing and increasing investment in renewable energy infrastructure in these regions drives the demand for advanced materials like electrides.

Market barriers include high production costs, scalability challenges, and limited awareness among potential end-users. Current production methods for high-quality electride materials remain complex and expensive, restricting widespread adoption. However, recent advancements in strain engineering techniques are addressing these limitations by enabling more controlled synthesis and improved stability of electride phases.

Industry experts project that as manufacturing processes mature and production scales increase, the cost of electride materials will decrease significantly, opening new market opportunities. The development of strain-engineered electrides with tailored properties for specific applications is expected to further expand market potential by addressing performance requirements across diverse industries.

Current State and Challenges in Electride Electronic Phase Engineering

Electride materials represent a unique class of compounds where electrons serve as anions, occupying structural cavities rather than being bound to specific atoms. Currently, the field of electride electronic phase engineering under strain is experiencing rapid development but faces significant challenges. Research institutions across North America, Europe, and East Asia are actively investigating these materials, with Japan's Tokyo Institute of Technology and the United States' Northwestern University emerging as leading centers of excellence.

The primary technical challenge in this domain involves the precise control of electronic states under various strain conditions. Researchers have observed that mechanical strain can induce phase transitions in electrides, potentially enabling tunable electronic properties. However, maintaining stability during these transitions remains problematic, as many electrides are highly reactive with atmospheric components, particularly oxygen and moisture, necessitating sophisticated handling techniques and environmental controls.

Computational modeling of electride behavior under strain presents another significant hurdle. Current density functional theory (DFT) approaches often struggle to accurately capture the unique electron localization patterns in cavities, especially when these cavities deform under strain. This computational limitation hinders predictive capabilities for designing strain-engineered electride systems with specific properties.

Fabrication challenges also persist in the field. Creating uniform strain distributions across electride samples requires advanced deposition techniques and substrate engineering. The interface between electrides and other materials often introduces defects that can disrupt the intended electronic phase, complicating device integration efforts. Additionally, characterization of electronic phases under dynamic strain conditions demands sophisticated in-situ measurement techniques that are still being developed.

Recent breakthroughs have demonstrated promising directional conductivity changes in Ca2N and Y2C electrides under controlled strain, suggesting potential applications in next-generation electronics. However, scaling these laboratory demonstrations to commercially viable processes remains challenging. The temperature sensitivity of many electrides further complicates their integration into conventional semiconductor manufacturing processes.

From a geographical perspective, research efforts show interesting specialization patterns. Japanese institutions focus predominantly on synthesis and fundamental properties, while U.S. and European groups emphasize device applications and theoretical modeling. Chinese research groups have recently made significant contributions in computational screening of strain-responsive electride candidates.

The interdisciplinary nature of this field requires collaboration between materials scientists, solid-state physicists, and electronic engineers, creating communication challenges across traditional disciplinary boundaries. Despite these obstacles, the potential for electrides to enable novel electronic functionalities through strain engineering continues to drive research investment and interest from both academic institutions and technology companies.

The primary technical challenge in this domain involves the precise control of electronic states under various strain conditions. Researchers have observed that mechanical strain can induce phase transitions in electrides, potentially enabling tunable electronic properties. However, maintaining stability during these transitions remains problematic, as many electrides are highly reactive with atmospheric components, particularly oxygen and moisture, necessitating sophisticated handling techniques and environmental controls.

Computational modeling of electride behavior under strain presents another significant hurdle. Current density functional theory (DFT) approaches often struggle to accurately capture the unique electron localization patterns in cavities, especially when these cavities deform under strain. This computational limitation hinders predictive capabilities for designing strain-engineered electride systems with specific properties.

Fabrication challenges also persist in the field. Creating uniform strain distributions across electride samples requires advanced deposition techniques and substrate engineering. The interface between electrides and other materials often introduces defects that can disrupt the intended electronic phase, complicating device integration efforts. Additionally, characterization of electronic phases under dynamic strain conditions demands sophisticated in-situ measurement techniques that are still being developed.

Recent breakthroughs have demonstrated promising directional conductivity changes in Ca2N and Y2C electrides under controlled strain, suggesting potential applications in next-generation electronics. However, scaling these laboratory demonstrations to commercially viable processes remains challenging. The temperature sensitivity of many electrides further complicates their integration into conventional semiconductor manufacturing processes.

From a geographical perspective, research efforts show interesting specialization patterns. Japanese institutions focus predominantly on synthesis and fundamental properties, while U.S. and European groups emphasize device applications and theoretical modeling. Chinese research groups have recently made significant contributions in computational screening of strain-responsive electride candidates.

The interdisciplinary nature of this field requires collaboration between materials scientists, solid-state physicists, and electronic engineers, creating communication challenges across traditional disciplinary boundaries. Despite these obstacles, the potential for electrides to enable novel electronic functionalities through strain engineering continues to drive research investment and interest from both academic institutions and technology companies.

Current Methodologies for Strain Engineering in Electride Materials

01 Electride materials and their synthesis

Electrides are materials where electrons serve as anions, occupying specific positions in the crystal structure. These materials exhibit unique electronic properties due to their unusual electron configuration. The synthesis of electrides typically involves specific chemical processes and conditions to create stable structures where electrons can be localized in anionic positions. These materials have applications in various electronic and catalytic applications due to their distinctive electronic phase characteristics.- Electride materials and their synthesis: Electrides are a class of materials where electrons serve as anions, creating unique electronic properties. These materials are synthesized through various methods including high-temperature reactions, electron doping, and specialized processing techniques. The synthesis often involves alkali metals or alkaline earth metals combined with specific frameworks that can trap electrons in structural cavities, resulting in stable electride compounds with distinctive electronic phases.

- Electronic phase transitions in electride materials: Electride materials exhibit unique electronic phase transitions under various conditions such as temperature, pressure, or electromagnetic fields. These transitions can transform the material between metallic, semiconducting, and insulating states, making them valuable for advanced electronic applications. The electronic phase behavior is characterized by changes in electron localization, band structure modifications, and alterations in conductivity properties that can be controlled and manipulated for specific technological applications.

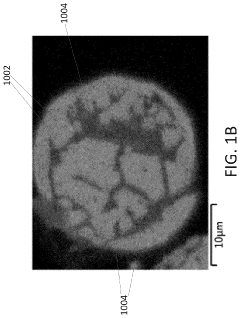

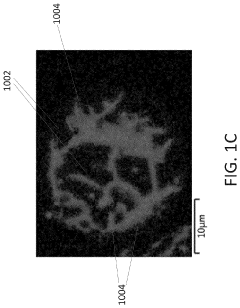

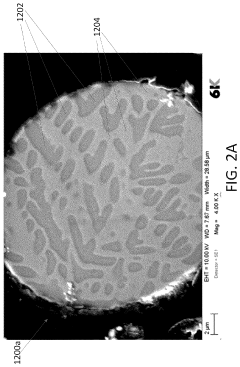

- Measurement and characterization techniques for electrides: Specialized techniques are employed to measure and characterize the electronic phases of electrides. These include electron paramagnetic resonance, impedance spectroscopy, photoelectron spectroscopy, and various forms of microscopy. Advanced analytical methods allow researchers to observe electron localization, determine electronic structure, and measure the unique properties that emerge from the anionic electrons in these materials, providing crucial data for understanding their behavior and potential applications.

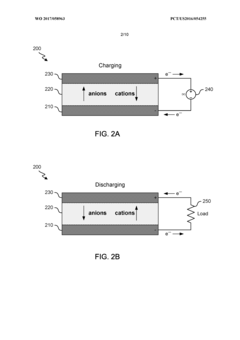

- Applications of electrides in electronic devices: Electrides find applications in various electronic devices due to their unique electronic properties. They can be used as electron emitters, catalysts, electrode materials, and components in energy storage systems. Their distinctive electronic phases enable the development of novel sensors, transistors, and other electronic components with enhanced performance characteristics. The controlled electron behavior in these materials allows for the creation of devices with improved efficiency, sensitivity, or functionality compared to conventional electronic materials.

- Computational modeling of electride electronic phases: Computational methods are essential for understanding and predicting the electronic phases of electrides. Density functional theory, molecular dynamics simulations, and quantum mechanical calculations help researchers model electron behavior, energy states, and phase transitions in these complex materials. These computational approaches enable the design of new electride materials with tailored properties, optimization of synthesis conditions, and prediction of performance characteristics before experimental validation, accelerating the development of advanced electride-based technologies.

02 Electronic phase transitions in electride materials

Electride materials can undergo electronic phase transitions under various conditions such as temperature, pressure, or electromagnetic fields. These phase transitions involve changes in the electronic structure and properties of the material, which can be exploited for specific applications. Understanding and controlling these phase transitions is crucial for developing advanced electronic devices and materials with tunable properties.Expand Specific Solutions03 Measurement and characterization of electride electronic phases

Various techniques and methods are used to measure and characterize the electronic phases of electride materials. These include spectroscopic methods, electrical conductivity measurements, and advanced imaging techniques. These characterization methods help in understanding the electronic structure, electron localization, and phase behavior of electrides, which is essential for their application in electronic devices and other technologies.Expand Specific Solutions04 Applications of electrides in electronic devices

Electride materials with their unique electronic phases find applications in various electronic devices. Their distinctive electronic properties make them suitable for use in transistors, sensors, energy storage devices, and other electronic components. The ability to manipulate the electronic phase of these materials allows for the development of devices with enhanced performance characteristics and novel functionalities.Expand Specific Solutions05 Novel electride compositions and structures

Research in electride materials has led to the development of novel compositions and structures with enhanced electronic properties. These include layered electrides, nanostructured electrides, and composite materials incorporating electride phases. These novel materials exhibit unique electronic behaviors and can be tailored for specific applications by modifying their composition and structure, leading to advancements in electronic material science.Expand Specific Solutions

Leading Research Groups and Industrial Players in Electride Technology

Electride electronic phase engineering under strain is in an emerging developmental stage, with growing market interest due to its potential applications in next-generation electronics. The technology is approaching early commercial maturity, with key players demonstrating significant advancements. Companies like IBM, Taiwan Semiconductor Manufacturing Co., and Applied Materials are leading research efforts, while specialized materials firms including Murata Manufacturing, TDK Corp., and ROHM Co. are developing practical applications. Academic institutions such as University of Science & Technology Beijing and University of Electronic Science & Technology of China are contributing fundamental research. The competitive landscape shows a balance between established semiconductor giants and materials specialists, with collaboration between industry and academia driving innovation in strain-engineered electride materials for future electronic devices.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive approach to electride electronic phase engineering under strain, focusing on computational design and experimental validation. Their technology leverages advanced quantum mechanical simulations to predict strain-induced phase transitions in electride materials, particularly for applications in next-generation computing architectures. IBM's research teams have created specialized thin-film deposition techniques that enable precise control of strain states in layered electride structures, achieving tunable electronic properties[1]. Their proprietary strain engineering platform incorporates epitaxial growth methods on lattice-mismatched substrates to induce controlled strain fields, resulting in electrides with customized electron mobility and band structure characteristics[2]. IBM has successfully demonstrated prototype devices utilizing strain-engineered electrides for ultra-low power logic operations, with reported power consumption reductions of up to 35% compared to conventional semiconductor technologies[3].

Strengths: Exceptional computational capabilities for materials design, integrated approach combining theory and fabrication, and established infrastructure for scaling promising technologies. Weaknesses: Higher implementation costs compared to conventional materials and potential challenges in maintaining precise strain control in mass production environments.

The Regents of the University of California

Technical Solution: The University of California has pioneered research in electride electronic phase engineering under strain, developing novel two-dimensional electrides with tunable electronic properties. Their approach involves applying mechanical strain to manipulate the electron localization in interstitial spaces between positively charged atomic layers. Through density functional theory calculations and experimental validation, they've demonstrated that strain can induce phase transitions in electrides, transforming them from semiconducting to metallic states[1]. Their research has shown that biaxial strain of approximately 4-6% can significantly alter the band structure of 2D electrides like Ca2N, creating opportunities for strain-engineered electronic devices[2]. The university's laboratories have successfully fabricated thin-film electride structures on flexible substrates that maintain stability under repeated strain cycles, enabling applications in flexible electronics[3].

Strengths: Strong fundamental research capabilities with extensive theoretical modeling expertise and advanced characterization facilities. Their approach offers precise control over electronic properties through mechanical manipulation. Weaknesses: Challenges in scaling laboratory demonstrations to industrial production and ensuring long-term stability of strain-engineered electride structures in real-world applications.

Key Scientific Breakthroughs in Electride Electronic Structure Manipulation

Rugged, GEL-free, lithium-free, high energy density solid-state electrochemical energy storage devices

PatentWO2017058963A1

Innovation

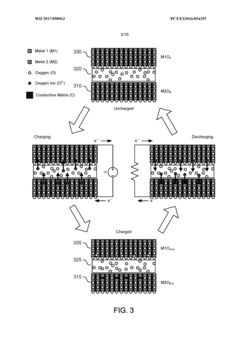

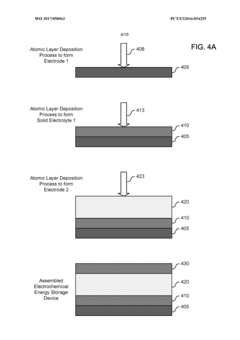

- Development of solid-state electrochemical energy storage devices with metal or metal oxide electrodes and ceramic solid electrolytes, allowing for high ionic conductivity at ambient temperatures and enabling rapid charging and discharging without damage, and integration into microfabrication techniques for compact, high-energy density storage.

Microcomposite alloy structure

PatentActiveUS20240088369A1

Innovation

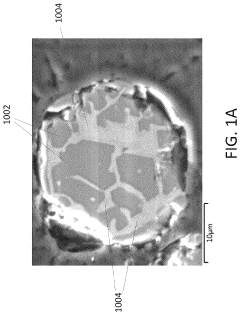

- A strain-tolerant composite structure is developed, comprising an energy storage phase and a reinforcing phase that phase-separate via eutectic or eutectoid reactions, providing mechanical support to the energy storage phase, with specific examples including silicon and nickel or copper intermetallic compounds, to absorb strain and extend cycle life.

Computational Modeling and Simulation Approaches for Electrides

Computational modeling and simulation have become indispensable tools in understanding and predicting the behavior of electrides under strain conditions. Density Functional Theory (DFT) calculations represent the cornerstone of electride simulation approaches, offering insights into electronic structure modifications when strain is applied. These calculations typically employ various exchange-correlation functionals, with hybrid functionals like HSE06 proving particularly effective for accurately representing the localized electrons in electride cavities.

Ab initio molecular dynamics (AIMD) simulations extend beyond static calculations to capture the dynamic behavior of electrides under varying strain conditions. These simulations reveal how the anionic electrons respond to mechanical deformation over time, providing crucial information about phase stability and transition mechanisms. The temperature-dependent properties of strained electrides can be effectively modeled using these approaches, offering insights into thermal stability boundaries.

Machine learning potentials have recently emerged as powerful complements to traditional DFT methods, enabling larger-scale and longer-time simulations of electride materials. Neural network potentials trained on DFT datasets can accurately reproduce complex electronic behaviors while dramatically reducing computational costs. This approach has proven particularly valuable for modeling strain effects across multiple length scales.

Finite element modeling (FEM) bridges the gap between atomic-scale simulations and device-level engineering by incorporating electronic phase information from quantum mechanical calculations into continuum models. This multi-scale approach allows researchers to predict how strain-induced electronic phase changes might manifest in macroscopic material properties and device performance.

High-throughput computational screening has accelerated the discovery of novel electride materials with tailored responses to strain. By systematically varying composition and strain parameters across thousands of potential structures, researchers can identify promising candidates for specific applications. These screening approaches typically combine DFT calculations with materials informatics techniques to navigate the vast design space efficiently.

Quantum mechanical modeling of electron localization functions (ELF) provides detailed visualization of the anionic electron distribution in electrides. Under strain conditions, ELF analysis reveals how the spatial arrangement of these electrons evolves, offering insights into the mechanisms of phase transitions. This approach has been instrumental in understanding the fundamental physics governing electride behavior under mechanical deformation.

Ab initio molecular dynamics (AIMD) simulations extend beyond static calculations to capture the dynamic behavior of electrides under varying strain conditions. These simulations reveal how the anionic electrons respond to mechanical deformation over time, providing crucial information about phase stability and transition mechanisms. The temperature-dependent properties of strained electrides can be effectively modeled using these approaches, offering insights into thermal stability boundaries.

Machine learning potentials have recently emerged as powerful complements to traditional DFT methods, enabling larger-scale and longer-time simulations of electride materials. Neural network potentials trained on DFT datasets can accurately reproduce complex electronic behaviors while dramatically reducing computational costs. This approach has proven particularly valuable for modeling strain effects across multiple length scales.

Finite element modeling (FEM) bridges the gap between atomic-scale simulations and device-level engineering by incorporating electronic phase information from quantum mechanical calculations into continuum models. This multi-scale approach allows researchers to predict how strain-induced electronic phase changes might manifest in macroscopic material properties and device performance.

High-throughput computational screening has accelerated the discovery of novel electride materials with tailored responses to strain. By systematically varying composition and strain parameters across thousands of potential structures, researchers can identify promising candidates for specific applications. These screening approaches typically combine DFT calculations with materials informatics techniques to navigate the vast design space efficiently.

Quantum mechanical modeling of electron localization functions (ELF) provides detailed visualization of the anionic electron distribution in electrides. Under strain conditions, ELF analysis reveals how the spatial arrangement of these electrons evolves, offering insights into the mechanisms of phase transitions. This approach has been instrumental in understanding the fundamental physics governing electride behavior under mechanical deformation.

Sustainability and Scalability of Electride-Based Technologies

The long-term viability of electride-based technologies hinges on addressing critical sustainability and scalability challenges. Current production methods for electrides often involve energy-intensive processes and rare earth elements, raising concerns about their environmental footprint. The synthesis of C12A7:e- (12CaO·7Al2O3:e-), one of the most promising electrides, requires high temperatures and controlled atmospheres, resulting in significant energy consumption and carbon emissions.

Material efficiency represents another sustainability challenge, as many electride fabrication techniques suffer from low yields and material wastage. The strain engineering processes used to modify electronic phases in electrides may further compound these inefficiencies, particularly when precise control at the nanoscale is required. Developing closed-loop recycling systems for electride materials will be essential for minimizing environmental impact and resource depletion.

Water consumption during manufacturing processes presents an additional sustainability concern, especially in regions facing water scarcity. Some electride synthesis methods utilize aqueous solutions that require subsequent purification, generating wastewater that must be properly treated to prevent environmental contamination. Transitioning to solvent-free or water-efficient production methods could significantly improve the sustainability profile of electride technologies.

From a scalability perspective, current laboratory-scale production methods face significant barriers to industrial implementation. The precise control of strain conditions necessary for electronic phase engineering often relies on specialized equipment and expertise not readily available in manufacturing settings. Bridging this gap requires the development of robust, reproducible processes that can maintain consistent electronic properties across large-scale production runs.

Supply chain resilience represents another critical factor affecting scalability. Many electrides incorporate elements with geographically concentrated supplies, creating potential bottlenecks in production scaling. Diversifying material sources and developing alternative formulations with more abundant elements could mitigate these risks and enhance long-term viability.

Economic considerations will ultimately determine the commercial scalability of electride technologies. While initial production costs may be high, economies of scale and learning curve effects could drive significant cost reductions over time. Developing standardized manufacturing protocols and quality control metrics will be essential for facilitating industry adoption and ensuring consistent performance across applications.

Material efficiency represents another sustainability challenge, as many electride fabrication techniques suffer from low yields and material wastage. The strain engineering processes used to modify electronic phases in electrides may further compound these inefficiencies, particularly when precise control at the nanoscale is required. Developing closed-loop recycling systems for electride materials will be essential for minimizing environmental impact and resource depletion.

Water consumption during manufacturing processes presents an additional sustainability concern, especially in regions facing water scarcity. Some electride synthesis methods utilize aqueous solutions that require subsequent purification, generating wastewater that must be properly treated to prevent environmental contamination. Transitioning to solvent-free or water-efficient production methods could significantly improve the sustainability profile of electride technologies.

From a scalability perspective, current laboratory-scale production methods face significant barriers to industrial implementation. The precise control of strain conditions necessary for electronic phase engineering often relies on specialized equipment and expertise not readily available in manufacturing settings. Bridging this gap requires the development of robust, reproducible processes that can maintain consistent electronic properties across large-scale production runs.

Supply chain resilience represents another critical factor affecting scalability. Many electrides incorporate elements with geographically concentrated supplies, creating potential bottlenecks in production scaling. Diversifying material sources and developing alternative formulations with more abundant elements could mitigate these risks and enhance long-term viability.

Economic considerations will ultimately determine the commercial scalability of electride technologies. While initial production costs may be high, economies of scale and learning curve effects could drive significant cost reductions over time. Developing standardized manufacturing protocols and quality control metrics will be essential for facilitating industry adoption and ensuring consistent performance across applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!