Passivation Techniques To Protect Electrides From Oxidation

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electride Passivation Background and Objectives

Electrides represent a unique class of materials where electrons serve as anions, occupying specific lattice sites typically filled by negative ions. Since their discovery in the 1980s, these materials have garnered significant attention due to their exceptional electronic properties, including high electron mobility, low work function, and catalytic activity. However, the inherent reactivity of these materials with atmospheric oxygen presents a substantial challenge to their practical application and commercialization.

The evolution of electride technology has progressed through several distinct phases. Initially, organic electrides dominated research, with crown ether complexes serving as the primary structures. These materials, while groundbreaking, suffered from extreme instability in ambient conditions, limiting their practical utility. The field experienced a paradigm shift with the discovery of inorganic electrides, particularly C12A7:e- (12CaO·7Al2O3:e-), which demonstrated significantly improved stability while retaining the unique electronic properties characteristic of electrides.

Recent technological advancements have expanded the electride family to include 2D materials such as Ca2N and Y2C, offering new possibilities for applications in electronics and catalysis. Despite these developments, the fundamental challenge of oxygen sensitivity remains a critical barrier to widespread implementation of electride-based technologies.

The primary objective of passivation research for electrides is to develop robust protection strategies that preserve their unique electronic properties while significantly enhancing their stability against oxidation. This involves creating effective barrier layers or surface treatments that prevent oxygen penetration while maintaining electrical conductivity and other functional properties. The ideal passivation technique would enable electrides to operate reliably in ambient conditions without specialized handling or encapsulation requirements.

Secondary objectives include understanding the fundamental mechanisms of oxidation in different electride systems, quantifying the relationship between passivation methods and performance retention, and developing standardized protocols for evaluating passivation effectiveness. Additionally, research aims to identify passivation approaches that are scalable and compatible with existing manufacturing processes to facilitate industrial adoption.

The technological trajectory suggests that successful passivation techniques could unlock numerous applications for electrides, including next-generation electronic devices, efficient catalysts for chemical processes, and novel energy storage systems. As global research efforts intensify, the development of effective passivation strategies represents a critical enabling technology that could transform electrides from laboratory curiosities into commercially viable materials with transformative potential across multiple industries.

The evolution of electride technology has progressed through several distinct phases. Initially, organic electrides dominated research, with crown ether complexes serving as the primary structures. These materials, while groundbreaking, suffered from extreme instability in ambient conditions, limiting their practical utility. The field experienced a paradigm shift with the discovery of inorganic electrides, particularly C12A7:e- (12CaO·7Al2O3:e-), which demonstrated significantly improved stability while retaining the unique electronic properties characteristic of electrides.

Recent technological advancements have expanded the electride family to include 2D materials such as Ca2N and Y2C, offering new possibilities for applications in electronics and catalysis. Despite these developments, the fundamental challenge of oxygen sensitivity remains a critical barrier to widespread implementation of electride-based technologies.

The primary objective of passivation research for electrides is to develop robust protection strategies that preserve their unique electronic properties while significantly enhancing their stability against oxidation. This involves creating effective barrier layers or surface treatments that prevent oxygen penetration while maintaining electrical conductivity and other functional properties. The ideal passivation technique would enable electrides to operate reliably in ambient conditions without specialized handling or encapsulation requirements.

Secondary objectives include understanding the fundamental mechanisms of oxidation in different electride systems, quantifying the relationship between passivation methods and performance retention, and developing standardized protocols for evaluating passivation effectiveness. Additionally, research aims to identify passivation approaches that are scalable and compatible with existing manufacturing processes to facilitate industrial adoption.

The technological trajectory suggests that successful passivation techniques could unlock numerous applications for electrides, including next-generation electronic devices, efficient catalysts for chemical processes, and novel energy storage systems. As global research efforts intensify, the development of effective passivation strategies represents a critical enabling technology that could transform electrides from laboratory curiosities into commercially viable materials with transformative potential across multiple industries.

Market Analysis for Oxidation-Resistant Electrides

The global market for electrides is experiencing significant growth, driven by their unique electronic properties that make them valuable in various applications including catalysis, electronics, and energy storage. The market for oxidation-resistant electrides specifically is projected to reach substantial value by 2030, with a compound annual growth rate exceeding the broader advanced materials sector average.

Demand for oxidation-resistant electrides is primarily concentrated in three key sectors. The catalysis industry represents the largest market segment, where electrides serve as efficient electron donors for chemical transformations, particularly in ammonia synthesis and hydrogenation reactions. The electronics sector follows closely, utilizing electrides in semiconductor applications and emerging quantum computing technologies. The energy storage and conversion sector is rapidly expanding its adoption of electrides for next-generation batteries and fuel cells.

Regional analysis reveals that Asia-Pacific currently dominates the market, with Japan and China leading in both research and commercialization efforts. North America maintains strong positions in high-end applications, particularly in defense and aerospace sectors where performance requirements justify premium pricing. European markets show growing interest, especially in sustainable chemistry applications aligned with green technology initiatives.

Market penetration faces significant barriers related to production scalability and stability concerns. Current oxidation-resistant electrides command premium pricing due to complex synthesis requirements and specialized passivation techniques. This price sensitivity limits broader adoption in cost-conscious industries despite performance advantages.

Customer segmentation analysis indicates that research institutions and specialty chemical companies represent early adopters, while larger industrial players remain in evaluation phases. The technology adoption curve suggests we are still in the early majority phase, with significant growth potential as passivation techniques improve and production costs decrease.

Competitive analysis reveals that established materials science companies are increasingly investing in electride technology, while specialized startups focus on proprietary passivation methods. Strategic partnerships between academic institutions and industry players are accelerating commercialization efforts, particularly for oxidation-resistant variants.

Market forecasts suggest that improvements in passivation techniques could expand the addressable market by enabling electride use in previously unsuitable environments. As production scales and stability improves, price points are expected to decrease, potentially opening applications in consumer electronics and general industrial catalysis.

Customer feedback indicates that longevity and reliability under variable environmental conditions remain primary concerns, highlighting the critical importance of advanced passivation techniques for market expansion.

Demand for oxidation-resistant electrides is primarily concentrated in three key sectors. The catalysis industry represents the largest market segment, where electrides serve as efficient electron donors for chemical transformations, particularly in ammonia synthesis and hydrogenation reactions. The electronics sector follows closely, utilizing electrides in semiconductor applications and emerging quantum computing technologies. The energy storage and conversion sector is rapidly expanding its adoption of electrides for next-generation batteries and fuel cells.

Regional analysis reveals that Asia-Pacific currently dominates the market, with Japan and China leading in both research and commercialization efforts. North America maintains strong positions in high-end applications, particularly in defense and aerospace sectors where performance requirements justify premium pricing. European markets show growing interest, especially in sustainable chemistry applications aligned with green technology initiatives.

Market penetration faces significant barriers related to production scalability and stability concerns. Current oxidation-resistant electrides command premium pricing due to complex synthesis requirements and specialized passivation techniques. This price sensitivity limits broader adoption in cost-conscious industries despite performance advantages.

Customer segmentation analysis indicates that research institutions and specialty chemical companies represent early adopters, while larger industrial players remain in evaluation phases. The technology adoption curve suggests we are still in the early majority phase, with significant growth potential as passivation techniques improve and production costs decrease.

Competitive analysis reveals that established materials science companies are increasingly investing in electride technology, while specialized startups focus on proprietary passivation methods. Strategic partnerships between academic institutions and industry players are accelerating commercialization efforts, particularly for oxidation-resistant variants.

Market forecasts suggest that improvements in passivation techniques could expand the addressable market by enabling electride use in previously unsuitable environments. As production scales and stability improves, price points are expected to decrease, potentially opening applications in consumer electronics and general industrial catalysis.

Customer feedback indicates that longevity and reliability under variable environmental conditions remain primary concerns, highlighting the critical importance of advanced passivation techniques for market expansion.

Current Passivation Technologies and Challenges

Electrides represent a unique class of materials where electrons serve as anions, occupying specific lattice sites. Their exceptional properties, including high electron mobility and low work function, make them promising for various applications. However, these materials are extremely sensitive to oxidation, which significantly limits their practical utility. Current passivation technologies aim to protect electrides from environmental degradation while preserving their unique electronic properties.

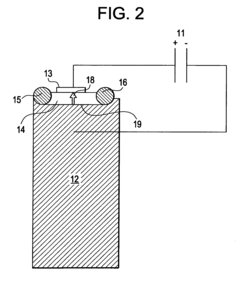

Physical encapsulation represents the most straightforward approach currently employed. This involves hermetically sealing electride materials using impermeable barriers such as glass, ceramics, or specialized polymers. While effective in laboratory settings, these methods often compromise the functionality of devices incorporating electrides due to their bulk and rigidity. Additionally, perfect seals are difficult to maintain over extended periods, eventually leading to oxidation.

Surface modification techniques have emerged as a more sophisticated alternative. These involve chemically altering the electride surface to create a protective layer that prevents oxygen penetration while maintaining electronic functionality. Approaches include fluorination, where surface atoms are replaced with fluorine to create a chemically stable barrier, and the application of self-assembled monolayers (SAMs) that form ordered protective films. Though promising, these methods often alter the surface electronic properties of electrides, potentially compromising their performance.

Atomic layer deposition (ALD) has gained significant attention for creating conformal, pinhole-free protective layers. This technique allows for precise thickness control at the nanometer scale, enabling the deposition of ultrathin oxide or nitride films that can effectively block oxygen diffusion while minimizing interference with electronic properties. However, the high temperatures often required for ALD processing can damage temperature-sensitive electride materials.

Composite protection strategies combine multiple approaches, such as initial surface modification followed by encapsulation. These hybrid methods aim to leverage the strengths of different techniques while mitigating their individual limitations. For instance, a thin ALD-deposited layer might be followed by a polymer encapsulant to provide both immediate surface protection and longer-term environmental isolation.

Despite these advances, significant challenges persist. The fundamental trade-off between protection efficacy and preservation of electronic properties remains unresolved. Most current passivation techniques either provide inadequate protection or significantly alter the unique properties that make electrides valuable. Additionally, long-term stability under realistic operating conditions remains largely unproven, with most studies limited to laboratory timeframes rather than the years or decades required for practical applications.

Another critical challenge is scalability. Many current protection methods are laboratory-scale techniques that are difficult to implement in mass production environments. The development of industrially viable passivation processes that can be integrated into existing manufacturing workflows represents a significant hurdle for commercial adoption of electride-based technologies.

Physical encapsulation represents the most straightforward approach currently employed. This involves hermetically sealing electride materials using impermeable barriers such as glass, ceramics, or specialized polymers. While effective in laboratory settings, these methods often compromise the functionality of devices incorporating electrides due to their bulk and rigidity. Additionally, perfect seals are difficult to maintain over extended periods, eventually leading to oxidation.

Surface modification techniques have emerged as a more sophisticated alternative. These involve chemically altering the electride surface to create a protective layer that prevents oxygen penetration while maintaining electronic functionality. Approaches include fluorination, where surface atoms are replaced with fluorine to create a chemically stable barrier, and the application of self-assembled monolayers (SAMs) that form ordered protective films. Though promising, these methods often alter the surface electronic properties of electrides, potentially compromising their performance.

Atomic layer deposition (ALD) has gained significant attention for creating conformal, pinhole-free protective layers. This technique allows for precise thickness control at the nanometer scale, enabling the deposition of ultrathin oxide or nitride films that can effectively block oxygen diffusion while minimizing interference with electronic properties. However, the high temperatures often required for ALD processing can damage temperature-sensitive electride materials.

Composite protection strategies combine multiple approaches, such as initial surface modification followed by encapsulation. These hybrid methods aim to leverage the strengths of different techniques while mitigating their individual limitations. For instance, a thin ALD-deposited layer might be followed by a polymer encapsulant to provide both immediate surface protection and longer-term environmental isolation.

Despite these advances, significant challenges persist. The fundamental trade-off between protection efficacy and preservation of electronic properties remains unresolved. Most current passivation techniques either provide inadequate protection or significantly alter the unique properties that make electrides valuable. Additionally, long-term stability under realistic operating conditions remains largely unproven, with most studies limited to laboratory timeframes rather than the years or decades required for practical applications.

Another critical challenge is scalability. Many current protection methods are laboratory-scale techniques that are difficult to implement in mass production environments. The development of industrially viable passivation processes that can be integrated into existing manufacturing workflows represents a significant hurdle for commercial adoption of electride-based technologies.

State-of-the-Art Passivation Techniques for Electrides

01 Protective coatings for electride materials

Various coating materials can be applied to electride surfaces to prevent oxidation. These protective layers act as barriers against oxygen and moisture, significantly extending the stability of electrides in ambient conditions. Common coating materials include metal oxides, polymers, and specialized composite materials that maintain the unique electronic properties of electrides while providing oxidation resistance.- Protective coatings for electride materials: Various coating materials can be applied to electride surfaces to prevent oxidation. These protective layers act as barriers against oxygen and moisture, significantly extending the stability of electrides in ambient conditions. Common coating materials include metal oxides, polymers, and specialized composite materials that maintain the unique electronic properties of electrides while providing oxidation resistance.

- Encapsulation techniques for electride preservation: Encapsulation methods involve completely sealing electride materials within protective shells or matrices to prevent contact with oxidizing agents. These techniques include hermetic sealing, glass encapsulation, and polymer embedding processes. The encapsulation materials are selected for their impermeability to oxygen and moisture while maintaining compatibility with the electride's electronic properties and intended applications.

- Doping strategies to enhance oxidation resistance: Introducing specific dopants into electride structures can significantly improve their resistance to oxidation. These dopants modify the electronic structure or create protective oxide layers in-situ when minimal oxygen exposure occurs. Common dopants include alkaline earth metals, transition metals, and rare earth elements that can stabilize the electron localization centers while providing oxidation protection.

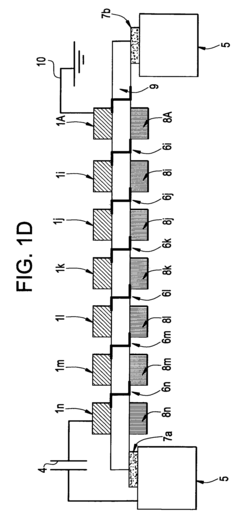

- Inert atmosphere processing and storage systems: Specialized processing and storage systems that maintain electrides in oxygen-free environments are crucial for preventing oxidation. These systems utilize inert gases like argon or nitrogen and may incorporate oxygen scavengers to remove trace oxygen. Advanced handling protocols and equipment designs minimize exposure to air during manufacturing, testing, and application of electride materials.

- Novel electride compositions with inherent stability: Development of new electride compositions with intrinsically higher resistance to oxidation represents a fundamental approach to the oxidation problem. These materials incorporate structural features or chemical elements that naturally resist electron transfer to oxygen molecules. Research focuses on complex crystal structures, layered materials, and compounds with specific electron localization patterns that maintain stability even when exposed to limited amounts of oxygen.

02 Encapsulation techniques for electride preservation

Encapsulation methods involve completely sealing electride materials within protective shells or matrices to prevent contact with oxidizing agents. These techniques include hermetic sealing, glass encapsulation, and polymer embedding processes. The encapsulation materials are selected for their impermeability to oxygen and moisture while maintaining compatibility with the electride's electronic properties and intended applications.Expand Specific Solutions03 Doping strategies to enhance oxidation resistance

Introducing specific dopants into electride structures can significantly improve their resistance to oxidation. These dopants modify the electronic structure of electrides to make them less susceptible to oxidative degradation. Common dopants include transition metals, rare earth elements, and certain non-metals that can stabilize the electron localization centers without compromising the essential electride properties.Expand Specific Solutions04 Inert atmosphere processing and storage systems

Specialized processing and storage systems that maintain electrides in inert atmospheres are crucial for preventing oxidation. These systems typically use noble gases like argon or helium to create oxygen-free environments. Advanced designs incorporate continuous gas purification, pressure control mechanisms, and specialized transfer chambers that allow handling of electrides without exposure to air, extending their usable lifetime significantly.Expand Specific Solutions05 Surface modification techniques for oxidation protection

Various surface modification approaches can enhance the oxidation resistance of electrides without fully encapsulating them. These include chemical passivation, plasma treatment, and the creation of sacrificial protective layers. Such modifications alter the surface chemistry of electrides to make them less reactive with oxygen while preserving their bulk electronic properties and functionality in electronic or catalytic applications.Expand Specific Solutions

Leading Research Groups and Companies in Electride Passivation

The electride passivation technology market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size remains relatively modest but is expanding as industries recognize the potential of electrides in electronics, catalysis, and energy storage. Technologically, the field is still developing, with varying degrees of maturity across different passivation approaches. Leading players include established chemical companies like BASF and Saint-Gobain, automotive innovators such as Tesla and Nissan, and technology firms like Applied Materials and Infineon Technologies. Research institutions like Johns Hopkins University and industrial giants such as China Petroleum & Chemical Corp are advancing fundamental understanding, while specialized companies like SUPERALD are developing practical implementation solutions. The competitive landscape reflects a mix of academic research, corporate R&D, and emerging specialized service providers.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced atomic layer deposition (ALD) techniques specifically designed for electride passivation. Their approach utilizes ultra-thin conformal barrier layers of aluminum oxide and hafnium oxide to create hermetic seals that prevent oxygen penetration while maintaining the unique electronic properties of electrides. The company's process employs precise plasma-enhanced ALD at low temperatures (below 150°C) to deposit these barrier films with thickness control at the angstrom level. This enables effective passivation without thermal degradation of the sensitive electride structures. Applied Materials has also pioneered the integration of in-situ surface preparation steps that remove native oxides prior to passivation layer deposition, creating an oxygen-free interface that significantly enhances long-term stability.

Strengths: Industry-leading precision in thin film deposition with angstrom-level control; comprehensive integration with semiconductor manufacturing processes; extensive materials expertise. Weaknesses: Higher implementation costs compared to conventional passivation methods; requires specialized equipment that may limit accessibility for some research applications.

BASF Corp.

Technical Solution: BASF has developed advanced polymer-based passivation systems specifically engineered for electride protection. Their approach utilizes fluorinated polymers and specialized barrier additives to create multi-functional coatings that simultaneously prevent oxygen diffusion while maintaining electrical conductivity where required. BASF's innovation includes the development of solution-processable fluoropolymers that can be applied via conventional coating methods, eliminating the need for specialized vacuum deposition equipment. These materials form dense, hydrophobic barriers with extremely low oxygen transmission rates (<0.01 cc/m²/day). Additionally, BASF has pioneered the incorporation of oxygen-scavenging compounds within the polymer matrix that actively neutralize any oxygen molecules that penetrate the initial barrier, providing a secondary defense mechanism. Their systems also feature UV-curable formulations that enable rapid processing and integration with existing manufacturing workflows.

Strengths: Extensive polymer chemistry expertise; scalable solution-based processes compatible with large-area applications; multi-functional materials addressing multiple protection mechanisms simultaneously. Weaknesses: May not achieve the same level of hermeticity as inorganic barrier films in extreme environments; potential for polymer degradation under certain operating conditions.

Critical Patents and Research on Oxidation Protection

Method for protecting electrode material from moisture

PatentInactiveJP2020205288A

Innovation

- A method of grafting hydrophobic groups onto the carbon surface of carbon-coated composite oxide particles using diazonium chemistry, forming carbon-carbon covalent bonds to enhance hydrophobicity and protect the material from moisture.

Methods for diminishing or preventing the deposition of a metal oxide on an electrode surface

PatentInactiveUS20090301898A1

Innovation

- Applying a negative protection potential to metallic components to reduce the formation and deposition of metal oxides, using an auxiliary oxygen pump cell to continuously remove oxygen, and applying a positive protection potential to components in the fuel chamber to prevent the formation of volatile partially reduced metal oxides, thereby preventing electrode poisoning.

Environmental Impact of Passivation Materials

The environmental implications of passivation materials used to protect electrides from oxidation represent a critical consideration in the sustainable development of these advanced materials. Traditional passivation techniques often employ fluorinated compounds, heavy metals, and various synthetic polymers that pose significant environmental concerns throughout their lifecycle. The production processes for these materials frequently involve energy-intensive manufacturing methods and the use of toxic precursors, contributing to increased carbon footprints and potential environmental contamination during manufacturing.

When examining the operational phase, many passivation materials gradually degrade over time, potentially releasing harmful substances into the environment. Fluorinated compounds, commonly used for their excellent barrier properties, are particularly problematic due to their persistence in ecosystems and potential bioaccumulation characteristics. Studies have documented that perfluorinated compounds can remain in the environment for decades, with some detected in remote Arctic regions and marine organisms, indicating their extensive environmental mobility.

Disposal and end-of-life management of passivated electride materials present additional environmental challenges. The complex composite nature of these materials often complicates recycling efforts, leading to increased landfill waste. When incinerated, certain passivation compounds may release toxic gases or form hazardous byproducts, necessitating specialized waste treatment facilities that are not universally available.

Recent regulatory frameworks have begun addressing these concerns, with the European Union's REACH regulations and similar initiatives in other regions imposing stricter controls on environmentally persistent chemicals used in passivation. This regulatory landscape is driving research toward more environmentally benign alternatives, including bio-based polymers, water-based formulations, and naturally derived barrier materials that maintain protective efficacy while reducing environmental impact.

Life cycle assessment (LCA) studies comparing traditional and emerging passivation materials reveal significant variations in environmental footprints. For instance, silicon-based passivation techniques typically demonstrate lower aquatic toxicity profiles compared to fluorinated alternatives, though they may require more energy-intensive application processes. These trade-offs highlight the importance of comprehensive environmental assessment methodologies when developing new passivation strategies.

The growing emphasis on green chemistry principles has spurred innovation in environmentally responsible passivation technologies. Recent developments include self-healing barrier materials derived from renewable resources, biodegradable protective coatings, and atom-efficient synthesis routes that minimize waste generation. These advancements represent promising directions for reconciling the technical requirements of electride protection with environmental sustainability objectives.

When examining the operational phase, many passivation materials gradually degrade over time, potentially releasing harmful substances into the environment. Fluorinated compounds, commonly used for their excellent barrier properties, are particularly problematic due to their persistence in ecosystems and potential bioaccumulation characteristics. Studies have documented that perfluorinated compounds can remain in the environment for decades, with some detected in remote Arctic regions and marine organisms, indicating their extensive environmental mobility.

Disposal and end-of-life management of passivated electride materials present additional environmental challenges. The complex composite nature of these materials often complicates recycling efforts, leading to increased landfill waste. When incinerated, certain passivation compounds may release toxic gases or form hazardous byproducts, necessitating specialized waste treatment facilities that are not universally available.

Recent regulatory frameworks have begun addressing these concerns, with the European Union's REACH regulations and similar initiatives in other regions imposing stricter controls on environmentally persistent chemicals used in passivation. This regulatory landscape is driving research toward more environmentally benign alternatives, including bio-based polymers, water-based formulations, and naturally derived barrier materials that maintain protective efficacy while reducing environmental impact.

Life cycle assessment (LCA) studies comparing traditional and emerging passivation materials reveal significant variations in environmental footprints. For instance, silicon-based passivation techniques typically demonstrate lower aquatic toxicity profiles compared to fluorinated alternatives, though they may require more energy-intensive application processes. These trade-offs highlight the importance of comprehensive environmental assessment methodologies when developing new passivation strategies.

The growing emphasis on green chemistry principles has spurred innovation in environmentally responsible passivation technologies. Recent developments include self-healing barrier materials derived from renewable resources, biodegradable protective coatings, and atom-efficient synthesis routes that minimize waste generation. These advancements represent promising directions for reconciling the technical requirements of electride protection with environmental sustainability objectives.

Scalability and Manufacturing Considerations

The scalability of electride passivation techniques represents a critical challenge for transitioning these materials from laboratory curiosities to commercially viable products. Current laboratory-scale passivation methods often involve highly controlled environments with specialized equipment, making them difficult to implement in mass production scenarios. Vacuum-based techniques, while effective for research purposes, face significant hurdles when scaled to industrial levels due to the substantial capital investment required for large vacuum chambers and associated infrastructure.

Manufacturing considerations must address the cost-effectiveness of passivation processes. Atomic layer deposition (ALD) techniques show promise for uniform protective coatings but typically operate at slow deposition rates that may impede high-volume production. Alternative approaches using solution-based passivation methods offer better throughput potential but may sacrifice some degree of protection quality. A comprehensive cost-benefit analysis reveals that hybrid approaches combining rapid initial passivation followed by more specialized protective treatments may offer the optimal balance between production speed and material stability.

Integration with existing semiconductor or electronic component manufacturing lines presents another significant consideration. Compatibility with standard clean room protocols and equipment is essential for widespread adoption. Current passivation techniques often require specialized handling that disrupts conventional manufacturing workflows. Development of passivation processes that can be implemented as modular additions to existing production lines would substantially improve adoption prospects.

Quality control and consistency represent additional manufacturing challenges. The effectiveness of passivation layers must be verified through standardized testing protocols that can be implemented in production environments. Current analytical techniques for assessing passivation quality, such as X-ray photoelectron spectroscopy, are primarily laboratory-based and not suited for in-line quality control. Development of rapid, non-destructive testing methods would significantly enhance manufacturing viability.

Environmental and safety considerations also impact scalability. Many current passivation techniques utilize hazardous chemicals or generate potentially harmful byproducts. Transitioning to greener passivation chemistries that maintain effectiveness while reducing environmental impact will be crucial for large-scale implementation. Recent advances in environmentally benign coating technologies from adjacent fields may offer transferable solutions for electride passivation.

Manufacturing considerations must address the cost-effectiveness of passivation processes. Atomic layer deposition (ALD) techniques show promise for uniform protective coatings but typically operate at slow deposition rates that may impede high-volume production. Alternative approaches using solution-based passivation methods offer better throughput potential but may sacrifice some degree of protection quality. A comprehensive cost-benefit analysis reveals that hybrid approaches combining rapid initial passivation followed by more specialized protective treatments may offer the optimal balance between production speed and material stability.

Integration with existing semiconductor or electronic component manufacturing lines presents another significant consideration. Compatibility with standard clean room protocols and equipment is essential for widespread adoption. Current passivation techniques often require specialized handling that disrupts conventional manufacturing workflows. Development of passivation processes that can be implemented as modular additions to existing production lines would substantially improve adoption prospects.

Quality control and consistency represent additional manufacturing challenges. The effectiveness of passivation layers must be verified through standardized testing protocols that can be implemented in production environments. Current analytical techniques for assessing passivation quality, such as X-ray photoelectron spectroscopy, are primarily laboratory-based and not suited for in-line quality control. Development of rapid, non-destructive testing methods would significantly enhance manufacturing viability.

Environmental and safety considerations also impact scalability. Many current passivation techniques utilize hazardous chemicals or generate potentially harmful byproducts. Transitioning to greener passivation chemistries that maintain effectiveness while reducing environmental impact will be crucial for large-scale implementation. Recent advances in environmentally benign coating technologies from adjacent fields may offer transferable solutions for electride passivation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!