Electrode Material Properties for Neuromorphic Computing Mechanisms

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Computing Electrode Materials Background and Objectives

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the human brain's neural networks to create more efficient and adaptable computing systems. The evolution of this field traces back to the 1980s when Carver Mead first introduced the concept, but significant advancements have only materialized in the last decade due to breakthroughs in material science and fabrication technologies.

The electrode materials used in neuromorphic devices serve as critical components that facilitate the transmission and modulation of electrical signals, mimicking the function of synapses and neurons in biological systems. Historically, conventional electrode materials like gold, platinum, and aluminum have dominated electronic devices. However, these materials present limitations in terms of biocompatibility, energy efficiency, and adaptability required for brain-inspired computing architectures.

Recent technological trends indicate a shift towards novel electrode materials including conductive polymers, carbon-based materials (graphene, carbon nanotubes), and transition metal oxides. These materials offer superior properties such as higher conductivity, better stability, and enhanced compatibility with biological systems. Additionally, the integration of these materials with emerging technologies like memristors and spintronics has opened new avenues for neuromorphic computing implementations.

The primary technical objectives in this domain include developing electrode materials that can accurately emulate synaptic plasticity, demonstrate low power consumption, maintain long-term stability, and support high-density integration. Researchers aim to create materials that can facilitate both short-term and long-term potentiation and depression, similar to biological neural networks, while operating at energy levels orders of magnitude lower than conventional computing systems.

Another critical goal is to bridge the gap between material properties and computational algorithms. This involves designing electrode materials that can inherently support learning algorithms such as spike-timing-dependent plasticity (STDP) without requiring complex external circuitry. Such integration would significantly reduce the complexity and energy requirements of neuromorphic systems.

Looking forward, the field is moving towards multi-functional electrode materials that can simultaneously process and store information, eliminating the traditional von Neumann bottleneck. These materials would ideally demonstrate adaptive properties, allowing neuromorphic systems to evolve and learn from their environment in real-time, much like biological neural networks.

The ultimate technological aspiration remains the development of electrode materials that can facilitate truly brain-like computing capabilities, including fault tolerance, parallel processing, and unsupervised learning, while maintaining energy efficiency and scalability for practical applications across various domains from edge computing to artificial intelligence systems.

The electrode materials used in neuromorphic devices serve as critical components that facilitate the transmission and modulation of electrical signals, mimicking the function of synapses and neurons in biological systems. Historically, conventional electrode materials like gold, platinum, and aluminum have dominated electronic devices. However, these materials present limitations in terms of biocompatibility, energy efficiency, and adaptability required for brain-inspired computing architectures.

Recent technological trends indicate a shift towards novel electrode materials including conductive polymers, carbon-based materials (graphene, carbon nanotubes), and transition metal oxides. These materials offer superior properties such as higher conductivity, better stability, and enhanced compatibility with biological systems. Additionally, the integration of these materials with emerging technologies like memristors and spintronics has opened new avenues for neuromorphic computing implementations.

The primary technical objectives in this domain include developing electrode materials that can accurately emulate synaptic plasticity, demonstrate low power consumption, maintain long-term stability, and support high-density integration. Researchers aim to create materials that can facilitate both short-term and long-term potentiation and depression, similar to biological neural networks, while operating at energy levels orders of magnitude lower than conventional computing systems.

Another critical goal is to bridge the gap between material properties and computational algorithms. This involves designing electrode materials that can inherently support learning algorithms such as spike-timing-dependent plasticity (STDP) without requiring complex external circuitry. Such integration would significantly reduce the complexity and energy requirements of neuromorphic systems.

Looking forward, the field is moving towards multi-functional electrode materials that can simultaneously process and store information, eliminating the traditional von Neumann bottleneck. These materials would ideally demonstrate adaptive properties, allowing neuromorphic systems to evolve and learn from their environment in real-time, much like biological neural networks.

The ultimate technological aspiration remains the development of electrode materials that can facilitate truly brain-like computing capabilities, including fault tolerance, parallel processing, and unsupervised learning, while maintaining energy efficiency and scalability for practical applications across various domains from edge computing to artificial intelligence systems.

Market Analysis for Brain-Inspired Computing Technologies

The neuromorphic computing market is experiencing significant growth, driven by increasing demand for AI applications that require efficient processing of complex neural networks. Current market projections indicate that the global neuromorphic computing market will reach approximately $8.9 billion by 2025, with a compound annual growth rate of 49.1% from 2020. This remarkable growth trajectory is fueled by advancements in electrode material properties that enable more efficient brain-inspired computing mechanisms.

The market for neuromorphic computing technologies can be segmented into several key application areas. Healthcare represents the largest segment, where brain-inspired computing is revolutionizing medical imaging, disease diagnosis, and drug discovery processes. The automotive industry follows closely, with neuromorphic systems being integrated into advanced driver-assistance systems and autonomous vehicles. Other significant market segments include robotics, consumer electronics, and military applications.

Geographically, North America currently dominates the neuromorphic computing market, accounting for approximately 42% of global market share. This dominance is attributed to substantial investments in research and development by major technology companies and academic institutions. The Asia-Pacific region is emerging as the fastest-growing market, with countries like China, Japan, and South Korea making significant investments in neuromorphic technology development.

From a materials perspective, the electrode materials market for neuromorphic computing is witnessing a shift from traditional silicon-based materials to novel alternatives. Phase-change materials, resistive random-access memory materials, and spintronic materials are gaining traction due to their superior performance characteristics. The market for these specialized electrode materials is projected to grow at a CAGR of 53.7% through 2025.

Key market drivers include the increasing need for energy-efficient computing solutions, growing adoption of AI and machine learning technologies, and rising demand for cognitive computing in various industries. The development of advanced electrode materials with properties that closely mimic biological neural systems is accelerating market growth by enabling more efficient and powerful neuromorphic computing systems.

Market challenges include high development costs, technical complexities in material fabrication, and integration issues with existing computing infrastructure. Additionally, the lack of standardization across neuromorphic computing platforms presents obstacles to widespread market adoption. However, these challenges are being addressed through collaborative research initiatives and strategic partnerships between material scientists, device manufacturers, and end-users.

The market for neuromorphic computing technologies can be segmented into several key application areas. Healthcare represents the largest segment, where brain-inspired computing is revolutionizing medical imaging, disease diagnosis, and drug discovery processes. The automotive industry follows closely, with neuromorphic systems being integrated into advanced driver-assistance systems and autonomous vehicles. Other significant market segments include robotics, consumer electronics, and military applications.

Geographically, North America currently dominates the neuromorphic computing market, accounting for approximately 42% of global market share. This dominance is attributed to substantial investments in research and development by major technology companies and academic institutions. The Asia-Pacific region is emerging as the fastest-growing market, with countries like China, Japan, and South Korea making significant investments in neuromorphic technology development.

From a materials perspective, the electrode materials market for neuromorphic computing is witnessing a shift from traditional silicon-based materials to novel alternatives. Phase-change materials, resistive random-access memory materials, and spintronic materials are gaining traction due to their superior performance characteristics. The market for these specialized electrode materials is projected to grow at a CAGR of 53.7% through 2025.

Key market drivers include the increasing need for energy-efficient computing solutions, growing adoption of AI and machine learning technologies, and rising demand for cognitive computing in various industries. The development of advanced electrode materials with properties that closely mimic biological neural systems is accelerating market growth by enabling more efficient and powerful neuromorphic computing systems.

Market challenges include high development costs, technical complexities in material fabrication, and integration issues with existing computing infrastructure. Additionally, the lack of standardization across neuromorphic computing platforms presents obstacles to widespread market adoption. However, these challenges are being addressed through collaborative research initiatives and strategic partnerships between material scientists, device manufacturers, and end-users.

Current Electrode Material Challenges in Neuromorphic Systems

Despite significant advancements in neuromorphic computing, electrode materials remain a critical bottleneck in system performance and scalability. Current electrode materials face substantial challenges in meeting the demanding requirements of next-generation neuromorphic architectures. Traditional metal electrodes such as platinum, gold, and tungsten exhibit limitations in biocompatibility, long-term stability, and signal-to-noise ratio when interfacing with biological neural systems or biomimetic devices.

Conductivity degradation represents a primary concern, as many electrode materials experience performance decline over operational cycles. This degradation manifests through oxidation, corrosion, or mechanical stress, particularly at the nanoscale dimensions required for high-density neural interfaces. The resulting impedance increases and signal attenuation significantly compromise system reliability and longevity.

Dimensional constraints pose another significant challenge. As neuromorphic systems strive for greater miniaturization and integration density, electrode materials must maintain their electrical properties at increasingly smaller scales. Current materials often exhibit dramatically different behaviors at nanoscale dimensions compared to their bulk properties, creating unpredictable performance characteristics.

Biocompatibility issues persist for implantable neuromorphic systems. Many high-performance electrode materials trigger inflammatory responses or encapsulation by glial cells when implanted, leading to signal degradation over time. The ideal electrode material must balance excellent electrical properties with minimal biological reactivity—a combination rarely found in conventional materials.

Energy efficiency represents another critical challenge. Current electrode materials often require substantial power for signal transmission, limiting the deployment of neuromorphic systems in energy-constrained applications like wearable devices or autonomous sensors. The high energy consumption stems from resistive losses and capacitive effects inherent to many conventional electrode materials.

Manufacturing scalability presents significant obstacles to widespread adoption. Many promising electrode materials demonstrate excellent properties in laboratory settings but prove difficult to fabricate at scale using industry-standard processes. This manufacturing gap delays the transition from research prototypes to commercial neuromorphic systems.

Interface stability between electrodes and active neuromorphic components (such as memristors or artificial synapses) remains problematic. Current materials often form unstable interfaces that degrade over time, leading to increased contact resistance and signal distortion. This instability is particularly pronounced in systems operating under variable environmental conditions or temperature fluctuations.

Conductivity degradation represents a primary concern, as many electrode materials experience performance decline over operational cycles. This degradation manifests through oxidation, corrosion, or mechanical stress, particularly at the nanoscale dimensions required for high-density neural interfaces. The resulting impedance increases and signal attenuation significantly compromise system reliability and longevity.

Dimensional constraints pose another significant challenge. As neuromorphic systems strive for greater miniaturization and integration density, electrode materials must maintain their electrical properties at increasingly smaller scales. Current materials often exhibit dramatically different behaviors at nanoscale dimensions compared to their bulk properties, creating unpredictable performance characteristics.

Biocompatibility issues persist for implantable neuromorphic systems. Many high-performance electrode materials trigger inflammatory responses or encapsulation by glial cells when implanted, leading to signal degradation over time. The ideal electrode material must balance excellent electrical properties with minimal biological reactivity—a combination rarely found in conventional materials.

Energy efficiency represents another critical challenge. Current electrode materials often require substantial power for signal transmission, limiting the deployment of neuromorphic systems in energy-constrained applications like wearable devices or autonomous sensors. The high energy consumption stems from resistive losses and capacitive effects inherent to many conventional electrode materials.

Manufacturing scalability presents significant obstacles to widespread adoption. Many promising electrode materials demonstrate excellent properties in laboratory settings but prove difficult to fabricate at scale using industry-standard processes. This manufacturing gap delays the transition from research prototypes to commercial neuromorphic systems.

Interface stability between electrodes and active neuromorphic components (such as memristors or artificial synapses) remains problematic. Current materials often form unstable interfaces that degrade over time, leading to increased contact resistance and signal distortion. This instability is particularly pronounced in systems operating under variable environmental conditions or temperature fluctuations.

Contemporary Electrode Material Solutions and Implementations

01 Carbon-based electrode materials

Carbon-based materials are widely used in electrode applications due to their excellent electrical conductivity, chemical stability, and versatility. These materials include graphene, carbon nanotubes, and activated carbon, which offer high surface area and good mechanical properties. The unique structure of carbon-based materials allows for efficient electron transfer and enhanced electrochemical performance, making them suitable for various applications including batteries, supercapacitors, and fuel cells.- Carbon-based electrode materials: Carbon-based materials are widely used in electrode applications due to their excellent electrical conductivity, chemical stability, and versatility. These materials include graphene, carbon nanotubes, and activated carbon, which offer high surface area and good electron transfer properties. The unique structure of carbon-based materials allows for efficient energy storage and conversion, making them suitable for batteries, supercapacitors, and fuel cells.

- Metal oxide electrode materials: Metal oxide materials serve as important electrode components due to their diverse electrochemical properties and stability. These materials exhibit various oxidation states, which enable them to participate in redox reactions efficiently. Metal oxides such as titanium dioxide, manganese oxide, and nickel oxide offer high theoretical capacity, good cycling stability, and environmental compatibility, making them valuable for energy storage applications and electrochemical sensors.

- Conductive polymer electrode materials: Conductive polymers represent an important class of electrode materials with tunable electrical properties and mechanical flexibility. These materials combine the electrical properties of metals with the processing advantages of polymers. Their conductivity can be modified through doping processes, and they offer advantages such as lightweight construction, flexibility, and solution processability, making them suitable for flexible electronics, sensors, and energy storage devices.

- Composite electrode materials: Composite electrode materials combine different components to achieve enhanced performance characteristics that cannot be obtained from single materials. These composites typically integrate conductive additives, active materials, and binders to optimize electrical conductivity, mechanical stability, and electrochemical activity. By synergistically combining materials with complementary properties, composites can overcome limitations of individual components, resulting in improved capacity, cycling stability, and rate capability for various electrochemical applications.

- Temperature and environmental stability of electrode materials: The performance and longevity of electrode materials are significantly influenced by their stability under various temperature and environmental conditions. Materials must maintain their structural integrity, electrical conductivity, and electrochemical activity across operating temperature ranges and in the presence of electrolytes or reactive species. Understanding thermal expansion coefficients, chemical resistance, and degradation mechanisms is crucial for developing electrodes that can withstand harsh conditions while maintaining consistent performance in applications ranging from high-temperature fuel cells to corrosive environments.

02 Metal oxide electrode materials

Metal oxide materials are crucial components in electrode design, offering high theoretical capacity, good stability, and tunable properties. These materials include transition metal oxides such as lithium cobalt oxide, manganese dioxide, and titanium dioxide. The electrochemical properties of metal oxide electrodes can be enhanced through doping, nanostructuring, and composite formation, improving their conductivity, cycle life, and energy density for applications in batteries and electrochemical sensors.Expand Specific Solutions03 Polymer-based electrode materials

Polymer-based electrode materials offer flexibility, processability, and customizable properties for various electrochemical applications. Conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS provide good electrical conductivity while maintaining mechanical flexibility. These materials can be synthesized through various methods and combined with other materials to form composites with enhanced properties. Polymer electrodes are particularly valuable in flexible electronics, wearable devices, and biomedical applications.Expand Specific Solutions04 Composite electrode materials

Composite electrode materials combine different components to achieve synergistic properties that overcome limitations of single-material electrodes. These composites typically integrate high-capacity materials with conductive additives and binders to optimize electrical conductivity, mechanical stability, and electrochemical performance. Common combinations include metal oxide/carbon, polymer/inorganic, and multi-metal composites. The interface engineering between components plays a crucial role in determining the overall performance of composite electrodes in energy storage and conversion devices.Expand Specific Solutions05 Novel electrode materials for specific applications

Specialized electrode materials are being developed for specific applications with unique requirements. These include high-temperature resistant electrodes for extreme environments, biocompatible materials for medical devices, and nanomaterials with tailored surface properties. Advanced manufacturing techniques such as 3D printing and atomic layer deposition enable precise control over electrode architecture and composition. These novel materials often exhibit exceptional properties such as ultra-high conductivity, self-healing capabilities, or stimulus-responsive behavior for next-generation electronic and energy devices.Expand Specific Solutions

Leading Organizations in Neuromorphic Hardware Development

Neuromorphic computing electrode materials are in an early growth phase, with the market expanding as research transitions to commercial applications. The global market is projected to reach significant scale as brain-inspired computing gains traction in AI applications. Leading players represent diverse sectors: IBM and Applied Materials bring semiconductor expertise; research institutions like IMEC, Electronics & Telecommunications Research Institute, and Carnegie Mellon University contribute fundamental innovations; while specialized companies like Neuronano and Advanced Neuromodulation Systems focus on neural interface technologies. The technology remains in development with varying maturity levels across different electrode materials, with significant research collaboration between industry and academia driving progress toward more efficient, biocompatible solutions.

International Business Machines Corp.

Technical Solution: IBM has pioneered neuromorphic computing through their TrueNorth and subsequent architectures, focusing on advanced electrode materials for synaptic devices. Their approach utilizes phase-change memory (PCM) materials as artificial synapses, where the crystalline state changes correlate to synaptic weight modifications[1]. IBM's electrode material research centers on optimizing the interface between electrodes and phase-change materials, employing carbon nanotubes (CNTs) as electrodes to enhance conductivity and thermal efficiency[3]. Their recent developments include chalcogenide-based materials (particularly Ge-Sb-Te compounds) with precisely engineered electrodes that enable multi-level resistance states, crucial for mimicking biological synaptic plasticity[5]. IBM has also explored titanium nitride (TiN) electrodes with hafnium oxide-based resistive switching materials, demonstrating reliable switching behavior with retention times exceeding 10 years at operating temperatures[7].

Strengths: IBM's electrode materials demonstrate exceptional endurance (>10^9 cycles) and multi-level storage capabilities, enabling complex neural network implementations. Their integration with CMOS technology provides a practical path to commercial neuromorphic systems. Weaknesses: Current implementations still face challenges with energy efficiency compared to biological systems, and the variability between devices remains higher than desired for large-scale neural networks.

Interuniversitair Micro-Electronica Centrum VZW

Technical Solution: IMEC has developed innovative electrode material solutions for neuromorphic computing focusing on hafnium oxide (HfO2) based resistive random-access memory (RRAM) devices. Their approach utilizes carefully engineered electrode materials, particularly TiN/Ti bilayers for the bottom electrode and platinum or TiN for the top electrode, creating an asymmetric structure that facilitates controlled oxygen vacancy movement[2]. This configuration enables precise modulation of synaptic weights through gradual resistance changes. IMEC's research has demonstrated that electrode material selection significantly impacts the forming voltage, SET/RESET characteristics, and overall reliability of neuromorphic devices[4]. Their recent advancements include doping the HfO2 layer with aluminum to create engineered oxygen vacancy profiles at the electrode interfaces, resulting in improved analog switching behavior with over 100 distinguishable resistance states[6]. IMEC has also pioneered 3D stacking of these devices using through-silicon vias with specialized electrode materials to increase integration density while maintaining thermal stability[8].

Strengths: IMEC's electrode materials demonstrate excellent scalability down to 10nm feature sizes while maintaining functional properties, and their CMOS-compatible fabrication processes facilitate integration with conventional semiconductor manufacturing. Their devices show good retention characteristics (>10 years) at operating temperatures. Weaknesses: The technology still faces challenges with cycle-to-cycle and device-to-device variability, particularly at accelerated operating speeds, and requires further optimization to reduce forming voltages for practical neuromorphic applications.

Critical Patents and Research on Neuromorphic Electrode Materials

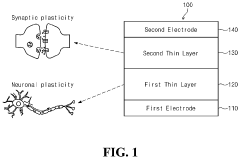

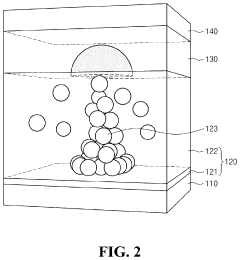

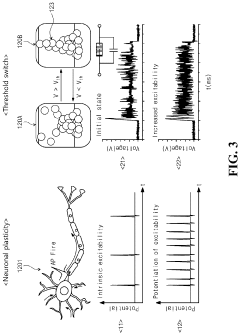

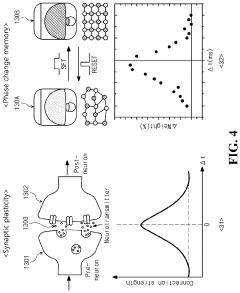

Neuromorphic memory element simultaneously implementing volatile and non-volatile feature for emulation of neuron and synapse

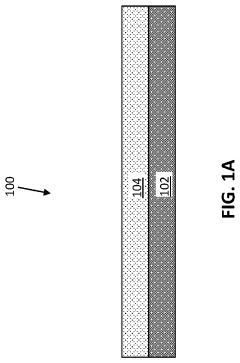

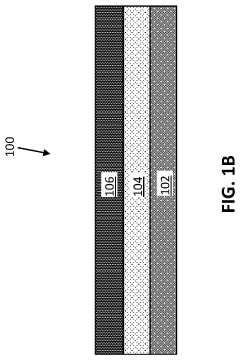

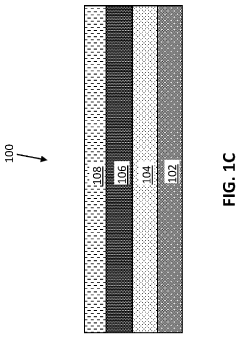

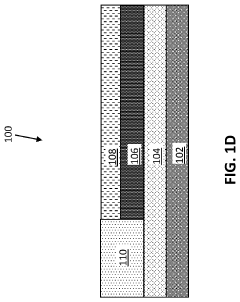

PatentPendingUS20240008292A1

Innovation

- A neuromorphic memory element is developed, combining volatile and non-volatile features in a single element to emulate neurons and synapses, utilizing a threshold switching portion and a phase change memory portion with specific materials like silver-doped silicon dioxide and GST or AIST materials, respectively, to enable efficient energy use and parallel operation.

Three-terminal neuromorphic vertical sensing

PatentActiveUS10936944B2

Innovation

- A vertically integrated lithium intercalation device is developed, featuring a conductive and lithium ion permeable layer as a drain, decoupling device footprint and channel resistance, and facilitating uniform ionic and electrical control, reducing ionic diffusion paths and enhancing response times.

Energy Efficiency Considerations for Neuromorphic Hardware

Energy efficiency represents a critical factor in the development and implementation of neuromorphic hardware systems. Traditional von Neumann computing architectures face significant energy constraints when simulating neural networks, consuming orders of magnitude more power than the human brain for comparable computational tasks. Neuromorphic computing aims to address this limitation by mimicking the brain's energy-efficient information processing mechanisms.

Electrode material selection plays a fundamental role in determining the energy consumption profile of neuromorphic devices. Materials with lower resistivity can reduce ohmic losses during signal transmission, while those with appropriate work functions can minimize energy barriers at interfaces. Recent advancements in two-dimensional materials such as graphene and transition metal dichalcogenides (TMDs) have demonstrated promising energy efficiency characteristics, with power consumption as low as picojoules per synaptic event.

The dynamic power consumption in neuromorphic systems is heavily influenced by the switching properties of electrode materials. Materials exhibiting steep subthreshold slopes can significantly reduce the energy required for state transitions. Phase-change materials and certain metal oxides have demonstrated sub-100mV/decade switching characteristics, approaching the theoretical Boltzmann limit of 60mV/decade at room temperature.

Leakage current represents another crucial energy consideration, particularly for large-scale neuromorphic implementations. Novel electrode configurations utilizing high-k dielectric interfaces and engineered band alignments have shown the potential to reduce standby power by up to 90% compared to conventional CMOS-based neural accelerators. These improvements are essential for edge computing applications where power availability is severely constrained.

Thermal management considerations must also be addressed when selecting electrode materials. Materials with higher thermal conductivity can more effectively dissipate heat generated during operation, preventing performance degradation and extending device lifetime. Diamond-like carbon and certain metal nitrides have emerged as promising candidates for thermally efficient electrode interfaces in high-density neuromorphic arrays.

The scaling relationship between energy efficiency and computational density presents unique challenges for neuromorphic hardware. As device dimensions shrink below 10nm, quantum effects begin to dominate, potentially increasing energy dissipation per computational operation. However, innovative electrode geometries such as three-dimensional vertical structures can maintain energy efficiency while increasing functional density, achieving theoretical energy efficiencies approaching 10^-14 J per synaptic operation.

Electrode material selection plays a fundamental role in determining the energy consumption profile of neuromorphic devices. Materials with lower resistivity can reduce ohmic losses during signal transmission, while those with appropriate work functions can minimize energy barriers at interfaces. Recent advancements in two-dimensional materials such as graphene and transition metal dichalcogenides (TMDs) have demonstrated promising energy efficiency characteristics, with power consumption as low as picojoules per synaptic event.

The dynamic power consumption in neuromorphic systems is heavily influenced by the switching properties of electrode materials. Materials exhibiting steep subthreshold slopes can significantly reduce the energy required for state transitions. Phase-change materials and certain metal oxides have demonstrated sub-100mV/decade switching characteristics, approaching the theoretical Boltzmann limit of 60mV/decade at room temperature.

Leakage current represents another crucial energy consideration, particularly for large-scale neuromorphic implementations. Novel electrode configurations utilizing high-k dielectric interfaces and engineered band alignments have shown the potential to reduce standby power by up to 90% compared to conventional CMOS-based neural accelerators. These improvements are essential for edge computing applications where power availability is severely constrained.

Thermal management considerations must also be addressed when selecting electrode materials. Materials with higher thermal conductivity can more effectively dissipate heat generated during operation, preventing performance degradation and extending device lifetime. Diamond-like carbon and certain metal nitrides have emerged as promising candidates for thermally efficient electrode interfaces in high-density neuromorphic arrays.

The scaling relationship between energy efficiency and computational density presents unique challenges for neuromorphic hardware. As device dimensions shrink below 10nm, quantum effects begin to dominate, potentially increasing energy dissipation per computational operation. However, innovative electrode geometries such as three-dimensional vertical structures can maintain energy efficiency while increasing functional density, achieving theoretical energy efficiencies approaching 10^-14 J per synaptic operation.

Scalability and Integration Pathways for Electrode Materials

The scalability and integration of electrode materials represent critical factors in advancing neuromorphic computing from laboratory demonstrations to practical, commercial applications. Current electrode materials face significant challenges when transitioning to large-scale manufacturing processes, particularly in maintaining consistent electrical properties and structural integrity across larger substrates.

Manufacturing techniques must evolve to accommodate the unique requirements of neuromorphic computing electrodes. Traditional lithographic approaches used in conventional semiconductor fabrication require adaptation for the complex, three-dimensional structures often needed in biomimetic neural networks. Advanced deposition methods such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) show promise for creating the precise, uniform electrode layers necessary for reliable neuromorphic operation.

Integration with existing CMOS technology presents another crucial pathway for electrode material development. Hybrid approaches that combine conventional silicon-based circuitry with specialized neuromorphic components offer a pragmatic transition strategy. This requires electrode materials that can withstand standard semiconductor processing conditions while maintaining their unique neuromorphic properties.

Thermal management becomes increasingly important as integration density increases. Electrode materials must dissipate heat efficiently to prevent performance degradation and ensure long-term reliability. Novel composite materials incorporating high thermal conductivity components show potential for addressing this challenge without compromising electrical characteristics.

3D integration strategies represent a promising direction for maximizing computational density. Vertical stacking of neuromorphic elements requires electrode materials that can form reliable interconnects between layers while maintaining signal integrity. Recent advances in through-silicon via (TSV) technology and monolithic 3D integration provide potential solutions for these interconnection challenges.

Standardization of electrode material specifications and testing protocols will accelerate industry adoption. Currently, the lack of unified benchmarks makes it difficult to compare different materials and approaches objectively. Establishing standard metrics for parameters such as switching endurance, retention time, and energy efficiency would facilitate more rapid development cycles and clearer commercialization pathways.

Cost considerations ultimately determine commercial viability. While exotic materials may offer superior performance in laboratory settings, practical implementation requires balancing performance with economic factors. Research into earth-abundant alternatives to rare or precious metals used in current electrode formulations represents an important direction for ensuring long-term scalability.

Manufacturing techniques must evolve to accommodate the unique requirements of neuromorphic computing electrodes. Traditional lithographic approaches used in conventional semiconductor fabrication require adaptation for the complex, three-dimensional structures often needed in biomimetic neural networks. Advanced deposition methods such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) show promise for creating the precise, uniform electrode layers necessary for reliable neuromorphic operation.

Integration with existing CMOS technology presents another crucial pathway for electrode material development. Hybrid approaches that combine conventional silicon-based circuitry with specialized neuromorphic components offer a pragmatic transition strategy. This requires electrode materials that can withstand standard semiconductor processing conditions while maintaining their unique neuromorphic properties.

Thermal management becomes increasingly important as integration density increases. Electrode materials must dissipate heat efficiently to prevent performance degradation and ensure long-term reliability. Novel composite materials incorporating high thermal conductivity components show potential for addressing this challenge without compromising electrical characteristics.

3D integration strategies represent a promising direction for maximizing computational density. Vertical stacking of neuromorphic elements requires electrode materials that can form reliable interconnects between layers while maintaining signal integrity. Recent advances in through-silicon via (TSV) technology and monolithic 3D integration provide potential solutions for these interconnection challenges.

Standardization of electrode material specifications and testing protocols will accelerate industry adoption. Currently, the lack of unified benchmarks makes it difficult to compare different materials and approaches objectively. Establishing standard metrics for parameters such as switching endurance, retention time, and energy efficiency would facilitate more rapid development cycles and clearer commercialization pathways.

Cost considerations ultimately determine commercial viability. While exotic materials may offer superior performance in laboratory settings, practical implementation requires balancing performance with economic factors. Research into earth-abundant alternatives to rare or precious metals used in current electrode formulations represents an important direction for ensuring long-term scalability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!