Engine Block 3D Printing For Rapid Prototyping: Best Practices

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Evolution

The evolution of 3D printing technology has been a transformative journey in the manufacturing industry, particularly in the realm of rapid prototyping for engine blocks. This additive manufacturing process has revolutionized the way engineers and designers approach the creation of complex automotive components.

In its early stages, 3D printing was primarily used for creating simple plastic prototypes. However, as the technology advanced, it became capable of producing functional metal parts, including engine blocks. The shift from traditional manufacturing methods to 3D printing for engine block prototyping has been driven by the need for faster iteration cycles and reduced costs in the automotive industry.

The development of metal 3D printing techniques, such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), has been crucial in enabling the production of engine blocks. These methods allow for the creation of intricate internal structures and cooling channels that were previously impossible or extremely difficult to manufacture using conventional techniques.

As the technology matured, improvements in printing resolution, material properties, and post-processing techniques have significantly enhanced the quality and performance of 3D printed engine blocks. The ability to rapidly produce prototypes with complex geometries has accelerated the design and testing phases of engine development, leading to more efficient and innovative engine designs.

The integration of advanced software tools, such as topology optimization and generative design, has further pushed the boundaries of what is possible with 3D printed engine blocks. These tools allow engineers to create designs that are optimized for weight reduction and improved performance, taking full advantage of the design freedom offered by additive manufacturing.

Recent advancements in multi-material 3D printing have opened up new possibilities for engine block prototyping. This technology allows for the combination of different materials within a single print, enabling the creation of engine blocks with varying properties in different areas, such as heat-resistant alloys in critical zones and lighter materials in non-critical areas.

The ongoing development of large-format 3D printers has also played a significant role in making engine block prototyping more accessible. These machines can now accommodate the size requirements of full-scale engine blocks, eliminating the need for assembly of smaller printed components.

As the technology continues to evolve, we are seeing improvements in printing speed, material properties, and cost-effectiveness. These advancements are making 3D printing an increasingly viable option not just for prototyping, but also for low-volume production of engine blocks in specialized applications.

In its early stages, 3D printing was primarily used for creating simple plastic prototypes. However, as the technology advanced, it became capable of producing functional metal parts, including engine blocks. The shift from traditional manufacturing methods to 3D printing for engine block prototyping has been driven by the need for faster iteration cycles and reduced costs in the automotive industry.

The development of metal 3D printing techniques, such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), has been crucial in enabling the production of engine blocks. These methods allow for the creation of intricate internal structures and cooling channels that were previously impossible or extremely difficult to manufacture using conventional techniques.

As the technology matured, improvements in printing resolution, material properties, and post-processing techniques have significantly enhanced the quality and performance of 3D printed engine blocks. The ability to rapidly produce prototypes with complex geometries has accelerated the design and testing phases of engine development, leading to more efficient and innovative engine designs.

The integration of advanced software tools, such as topology optimization and generative design, has further pushed the boundaries of what is possible with 3D printed engine blocks. These tools allow engineers to create designs that are optimized for weight reduction and improved performance, taking full advantage of the design freedom offered by additive manufacturing.

Recent advancements in multi-material 3D printing have opened up new possibilities for engine block prototyping. This technology allows for the combination of different materials within a single print, enabling the creation of engine blocks with varying properties in different areas, such as heat-resistant alloys in critical zones and lighter materials in non-critical areas.

The ongoing development of large-format 3D printers has also played a significant role in making engine block prototyping more accessible. These machines can now accommodate the size requirements of full-scale engine blocks, eliminating the need for assembly of smaller printed components.

As the technology continues to evolve, we are seeing improvements in printing speed, material properties, and cost-effectiveness. These advancements are making 3D printing an increasingly viable option not just for prototyping, but also for low-volume production of engine blocks in specialized applications.

Market Demand Analysis

The market demand for engine block 3D printing in rapid prototyping has been steadily increasing, driven by the automotive industry's need for faster, more cost-effective product development cycles. This technology offers significant advantages in terms of reduced lead times, lower costs, and enhanced design flexibility compared to traditional manufacturing methods.

Automotive manufacturers are increasingly adopting 3D printing for engine block prototyping to accelerate their research and development processes. The ability to quickly produce functional prototypes allows for rapid iteration and testing, significantly reducing the time-to-market for new engine designs. This is particularly crucial in an industry where innovation and speed are key competitive factors.

The global automotive 3D printing market, which includes engine block prototyping, is experiencing robust growth. Market research indicates that this sector is expected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by the increasing adoption of additive manufacturing technologies across various automotive applications, including engine components.

Engine block 3D printing is not limited to the automotive sector alone. The aerospace and defense industries are also showing significant interest in this technology for developing lightweight, high-performance engine components. The ability to create complex geometries and internal structures that are difficult or impossible to achieve with traditional manufacturing methods is driving demand in these high-tech sectors.

Small-scale manufacturers and custom engine builders are another growing market segment for engine block 3D printing. These businesses benefit from the technology's ability to produce low-volume, highly customized engine components without the need for expensive tooling or molds. This democratization of manufacturing capabilities is opening up new opportunities for niche market players and innovators.

The demand for sustainable manufacturing solutions is also contributing to the growth of engine block 3D printing. The technology's ability to reduce material waste and energy consumption aligns well with the increasing focus on environmental sustainability in the automotive and manufacturing industries. This aspect is becoming increasingly important as regulations and consumer preferences shift towards more eco-friendly production methods.

However, challenges remain in terms of material properties and production scalability for mass manufacturing. As these challenges are addressed through ongoing research and development, the market demand for engine block 3D printing in rapid prototyping is expected to continue its upward trajectory, reshaping the landscape of automotive and engine manufacturing.

Automotive manufacturers are increasingly adopting 3D printing for engine block prototyping to accelerate their research and development processes. The ability to quickly produce functional prototypes allows for rapid iteration and testing, significantly reducing the time-to-market for new engine designs. This is particularly crucial in an industry where innovation and speed are key competitive factors.

The global automotive 3D printing market, which includes engine block prototyping, is experiencing robust growth. Market research indicates that this sector is expected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by the increasing adoption of additive manufacturing technologies across various automotive applications, including engine components.

Engine block 3D printing is not limited to the automotive sector alone. The aerospace and defense industries are also showing significant interest in this technology for developing lightweight, high-performance engine components. The ability to create complex geometries and internal structures that are difficult or impossible to achieve with traditional manufacturing methods is driving demand in these high-tech sectors.

Small-scale manufacturers and custom engine builders are another growing market segment for engine block 3D printing. These businesses benefit from the technology's ability to produce low-volume, highly customized engine components without the need for expensive tooling or molds. This democratization of manufacturing capabilities is opening up new opportunities for niche market players and innovators.

The demand for sustainable manufacturing solutions is also contributing to the growth of engine block 3D printing. The technology's ability to reduce material waste and energy consumption aligns well with the increasing focus on environmental sustainability in the automotive and manufacturing industries. This aspect is becoming increasingly important as regulations and consumer preferences shift towards more eco-friendly production methods.

However, challenges remain in terms of material properties and production scalability for mass manufacturing. As these challenges are addressed through ongoing research and development, the market demand for engine block 3D printing in rapid prototyping is expected to continue its upward trajectory, reshaping the landscape of automotive and engine manufacturing.

Technical Challenges

The 3D printing of engine blocks for rapid prototyping faces several significant technical challenges that need to be addressed for successful implementation. One of the primary obstacles is achieving the required material properties and structural integrity. Engine blocks are subjected to extreme temperatures, pressures, and mechanical stresses, which demand materials with high strength, thermal resistance, and durability. Current 3D printing technologies struggle to produce parts that can withstand these harsh operating conditions without compromising performance or longevity.

Another major challenge lies in the precision and accuracy of the printing process. Engine blocks have complex internal geometries, including cooling channels, oil passages, and precise bore dimensions. Achieving the necessary tolerances and surface finishes with 3D printing technologies is difficult, especially when considering the potential for warping or shrinkage during the printing and post-processing stages. This challenge is further compounded by the need for consistent material properties throughout the entire printed structure.

The size of engine blocks also presents a significant hurdle for 3D printing technologies. Most industrial 3D printers have limited build volumes, making it challenging to produce full-size engine blocks in a single print. This limitation often necessitates printing the block in sections and then joining them together, which can introduce weaknesses and potential failure points in the final product.

Post-processing requirements pose another set of challenges. Engine blocks typically require extensive machining and finishing operations to achieve the required surface quality and dimensional accuracy. Developing efficient post-processing techniques that are compatible with 3D printed materials and structures is crucial for making the process economically viable and time-efficient.

Material selection and development represent a critical area of focus. While there have been advancements in metal 3D printing technologies, finding materials that can replicate the performance characteristics of traditional cast iron or aluminum alloys used in engine blocks remains a significant challenge. Researchers and engineers must develop new alloys or composite materials that are both printable and capable of meeting the demanding requirements of engine block applications.

Lastly, the integration of 3D printed engine blocks into existing manufacturing and quality control processes presents its own set of challenges. Developing new inspection and testing methodologies, as well as adapting current assembly lines and production workflows to accommodate 3D printed components, requires significant investment and innovation. Ensuring consistency and reliability across multiple prints and batches is also a major concern that needs to be addressed to make 3D printed engine blocks a viable option for rapid prototyping and potential production applications.

Another major challenge lies in the precision and accuracy of the printing process. Engine blocks have complex internal geometries, including cooling channels, oil passages, and precise bore dimensions. Achieving the necessary tolerances and surface finishes with 3D printing technologies is difficult, especially when considering the potential for warping or shrinkage during the printing and post-processing stages. This challenge is further compounded by the need for consistent material properties throughout the entire printed structure.

The size of engine blocks also presents a significant hurdle for 3D printing technologies. Most industrial 3D printers have limited build volumes, making it challenging to produce full-size engine blocks in a single print. This limitation often necessitates printing the block in sections and then joining them together, which can introduce weaknesses and potential failure points in the final product.

Post-processing requirements pose another set of challenges. Engine blocks typically require extensive machining and finishing operations to achieve the required surface quality and dimensional accuracy. Developing efficient post-processing techniques that are compatible with 3D printed materials and structures is crucial for making the process economically viable and time-efficient.

Material selection and development represent a critical area of focus. While there have been advancements in metal 3D printing technologies, finding materials that can replicate the performance characteristics of traditional cast iron or aluminum alloys used in engine blocks remains a significant challenge. Researchers and engineers must develop new alloys or composite materials that are both printable and capable of meeting the demanding requirements of engine block applications.

Lastly, the integration of 3D printed engine blocks into existing manufacturing and quality control processes presents its own set of challenges. Developing new inspection and testing methodologies, as well as adapting current assembly lines and production workflows to accommodate 3D printed components, requires significant investment and innovation. Ensuring consistency and reliability across multiple prints and batches is also a major concern that needs to be addressed to make 3D printed engine blocks a viable option for rapid prototyping and potential production applications.

Current 3D Solutions

01 3D printing techniques for engine block prototyping

Various 3D printing techniques are employed for rapid prototyping of engine blocks. These methods allow for quick creation of complex geometries and internal structures, enabling faster design iterations and testing. Advanced materials and printing processes are used to create functional prototypes that can withstand high temperatures and pressures.- 3D printing techniques for engine block prototyping: Various 3D printing techniques are employed for rapid prototyping of engine blocks. These methods allow for quick creation of complex geometries and internal structures, enabling faster design iterations and testing. Advanced materials and printing processes are used to create functional prototypes that can withstand high temperatures and pressures.

- Material selection for 3D printed engine blocks: Specific materials are chosen for 3D printing engine block prototypes to simulate the properties of production materials. These may include metal powders, high-performance polymers, or composite materials that can withstand the harsh conditions of an engine environment. The selection process considers factors such as thermal conductivity, strength, and durability.

- Post-processing of 3D printed engine block prototypes: After 3D printing, engine block prototypes undergo various post-processing treatments to enhance their properties. This may include heat treatment, surface finishing, or infiltration with other materials to improve strength and functionality. These processes aim to create prototypes that more closely resemble the final production parts.

- Integration of sensors and monitoring systems: Advanced prototyping techniques incorporate sensors and monitoring systems directly into 3D printed engine blocks. This allows for real-time data collection during testing, providing valuable insights into performance, thermal behavior, and stress distribution. The integration of these systems enables more efficient optimization of engine block designs.

- Hybrid manufacturing approaches: Combining 3D printing with traditional manufacturing methods creates hybrid approaches for engine block prototyping. This may involve 3D printing complex internal structures and then finishing the exterior using conventional machining techniques. Such hybrid methods leverage the strengths of both additive and subtractive manufacturing to produce highly accurate and functional prototypes.

02 Material selection for 3D printed engine blocks

Selecting appropriate materials for 3D printing engine blocks is crucial for achieving desired properties. Materials are chosen based on their ability to withstand high temperatures, mechanical stress, and chemical resistance. Composite materials and metal alloys are often used to improve the performance and durability of the printed engine blocks.Expand Specific Solutions03 Post-processing techniques for 3D printed engine blocks

After 3D printing, engine block prototypes undergo various post-processing techniques to enhance their properties. These may include heat treatment, surface finishing, and machining to improve dimensional accuracy and surface quality. Post-processing helps achieve the required mechanical properties and ensures the prototype meets performance standards.Expand Specific Solutions04 Design optimization for 3D printed engine blocks

Advanced design optimization techniques are used to create engine block designs suitable for 3D printing. This includes topology optimization, generative design, and simulation-driven design approaches. These methods help reduce weight, improve cooling efficiency, and enhance overall performance while ensuring manufacturability through 3D printing processes.Expand Specific Solutions05 Quality control and testing of 3D printed engine block prototypes

Rigorous quality control measures and testing procedures are implemented for 3D printed engine block prototypes. This includes non-destructive testing methods, dimensional accuracy checks, and performance testing under simulated operating conditions. These processes ensure that the prototypes meet the required specifications and can be used for further development and validation.Expand Specific Solutions

Industry Leaders

The engine block 3D printing for rapid prototyping market is in its growth stage, with increasing adoption across automotive and aerospace industries. The market size is expanding rapidly, driven by the demand for faster and more cost-effective prototyping solutions. Technologically, the field is advancing quickly, with companies like 3D Systems, Stratasys, and XYZprinting leading innovation. These firms are developing more sophisticated printers capable of handling complex geometries and materials. However, the technology is not yet fully mature, with ongoing challenges in material properties, surface finish, and scalability. Emerging players like AIM3D are introducing novel approaches to reduce costs and expand material options, indicating a dynamic and competitive landscape.

3D Systems, Inc.

Technical Solution: 3D Systems has developed advanced 3D printing technologies specifically for engine block rapid prototyping. Their approach utilizes Direct Metal Printing (DMP) technology, which allows for the creation of complex geometries with high precision. The process involves layer-by-layer construction using metal powders that are selectively melted by a laser, enabling the production of engine blocks with intricate internal cooling channels and optimized designs for weight reduction[1]. 3D Systems' ProX DMP 320 printer, designed for high productivity and repeatability, can produce engine block prototypes up to 275 x 275 x 420 mm in size[2]. The company has also developed specialized software solutions that integrate with their hardware to streamline the design-to-manufacturing process, reducing iteration times and improving overall efficiency in engine block prototyping[3].

Strengths: High precision and ability to create complex geometries; Specialized software integration for streamlined workflow. Weaknesses: High initial investment cost; Limited material options compared to traditional manufacturing.

Jabil, Inc.

Technical Solution: Jabil employs a multi-technology approach to engine block rapid prototyping, leveraging both additive manufacturing and traditional methods. Their Additive Manufacturing Network includes various 3D printing technologies such as SLS, SLA, and metal 3D printing, allowing for flexible material choices and scalable production[10]. For engine block prototyping, Jabil utilizes high-performance thermoplastics and metal powders, enabling the creation of functional prototypes that can withstand rigorous testing. Their proprietary Jabil Additive software platform integrates design, simulation, and production planning, streamlining the prototyping workflow[11]. Jabil's approach also incorporates Design for Additive Manufacturing (DfAM) principles, optimizing engine block designs for weight reduction and improved thermal management[12].

Strengths: Diverse range of 3D printing technologies; Integrated software platform for streamlined workflow. Weaknesses: Less specialized in automotive applications compared to some competitors; Potential for longer lead times due to multi-technology approach.

Key Innovations

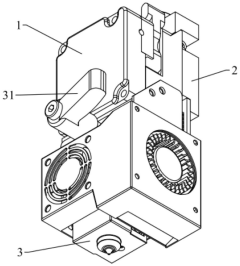

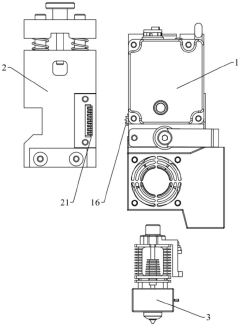

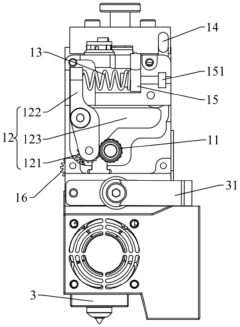

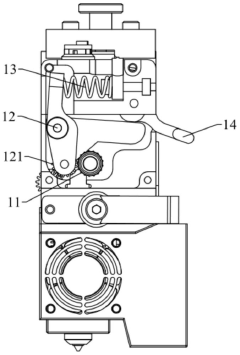

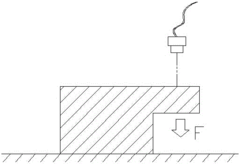

A kind of extrusion device and 3D printer

PatentActiveCN112936868B

Innovation

- An extrusion device is designed that includes an extrusion fixed wheel and an extrusion moving wheel. Through the cooperation of the feeding wrench and the elastic member, the extrusion moving wheel can be moved closer and farther away, simplifying the feeding operation, and through the driving gear and driven gear. Gears increase extrusion force.

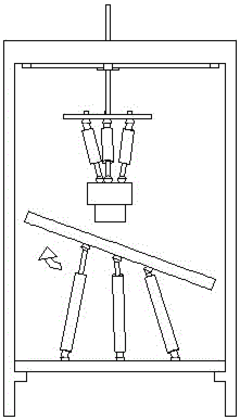

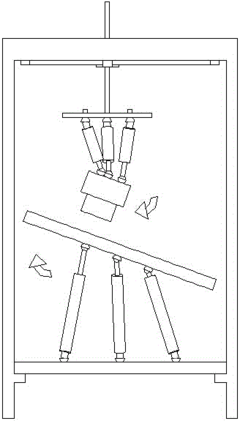

Multidimensional angle 3D printer

PatentActiveCN105965896A

Innovation

- A multi-dimensional angle 3D printer is designed, which uses an adjustable printing nozzle and printing platform, realizes free movement and angle adjustment of the XYZ axis through a three-dimensional motion mechanism and a multi-dimensional adjustment device, and combines angle sensors and height sensors for coordinated control.

Material Considerations

Material selection is a critical factor in the successful implementation of engine block 3D printing for rapid prototyping. The choice of materials significantly impacts the performance, durability, and manufacturability of the engine block prototypes. Traditionally, engine blocks are manufactured using cast iron or aluminum alloys due to their excellent mechanical properties and thermal conductivity. However, 3D printing introduces new possibilities and challenges in material selection.

For 3D printed engine block prototypes, metal powders are the primary materials of choice. Aluminum alloys, particularly AlSi10Mg, have gained popularity due to their lightweight properties, good thermal conductivity, and compatibility with selective laser melting (SLM) processes. These alloys offer a balance between strength and weight reduction, which is crucial for modern engine design. Steel alloys, such as maraging steel, are also used for their high strength and heat resistance, especially in high-performance engine applications.

The particle size distribution of metal powders plays a vital role in the quality of the printed engine block. Finer particles generally result in better surface finish and higher density, but they can also lead to increased processing challenges. A typical particle size range of 15-45 μm is often used for SLM processes in engine block prototyping.

Additive manufacturing also allows for the exploration of novel materials and composites that were previously difficult to implement in traditional manufacturing methods. For instance, metal matrix composites (MMCs) reinforced with ceramic particles can enhance the wear resistance and thermal properties of engine blocks. However, the use of such advanced materials requires careful consideration of their processability and post-processing requirements.

The thermal properties of the chosen material are particularly important for engine block applications. Materials with high thermal conductivity help in efficient heat dissipation, which is crucial for maintaining optimal engine performance. Additionally, the coefficient of thermal expansion must be considered to ensure dimensional stability across the wide temperature range experienced by engine blocks during operation.

When selecting materials for 3D printed engine block prototypes, it is essential to consider the entire lifecycle of the prototype. This includes not only the printing process but also post-processing treatments such as heat treatment, surface finishing, and potential machining operations. The material's response to these treatments can significantly affect the final properties of the prototype.

Lastly, the cost and availability of materials should be factored into the selection process. While some exotic alloys may offer superior properties, their high cost or limited availability could make them impractical for rapid prototyping applications. Striking a balance between performance, manufacturability, and cost is key to successful material selection in engine block 3D printing for rapid prototyping.

For 3D printed engine block prototypes, metal powders are the primary materials of choice. Aluminum alloys, particularly AlSi10Mg, have gained popularity due to their lightweight properties, good thermal conductivity, and compatibility with selective laser melting (SLM) processes. These alloys offer a balance between strength and weight reduction, which is crucial for modern engine design. Steel alloys, such as maraging steel, are also used for their high strength and heat resistance, especially in high-performance engine applications.

The particle size distribution of metal powders plays a vital role in the quality of the printed engine block. Finer particles generally result in better surface finish and higher density, but they can also lead to increased processing challenges. A typical particle size range of 15-45 μm is often used for SLM processes in engine block prototyping.

Additive manufacturing also allows for the exploration of novel materials and composites that were previously difficult to implement in traditional manufacturing methods. For instance, metal matrix composites (MMCs) reinforced with ceramic particles can enhance the wear resistance and thermal properties of engine blocks. However, the use of such advanced materials requires careful consideration of their processability and post-processing requirements.

The thermal properties of the chosen material are particularly important for engine block applications. Materials with high thermal conductivity help in efficient heat dissipation, which is crucial for maintaining optimal engine performance. Additionally, the coefficient of thermal expansion must be considered to ensure dimensional stability across the wide temperature range experienced by engine blocks during operation.

When selecting materials for 3D printed engine block prototypes, it is essential to consider the entire lifecycle of the prototype. This includes not only the printing process but also post-processing treatments such as heat treatment, surface finishing, and potential machining operations. The material's response to these treatments can significantly affect the final properties of the prototype.

Lastly, the cost and availability of materials should be factored into the selection process. While some exotic alloys may offer superior properties, their high cost or limited availability could make them impractical for rapid prototyping applications. Striking a balance between performance, manufacturability, and cost is key to successful material selection in engine block 3D printing for rapid prototyping.

Quality Control Methods

Quality control is paramount in the 3D printing of engine blocks for rapid prototyping. Implementing robust quality control methods ensures the production of high-quality, reliable prototypes that accurately represent the final product. A comprehensive quality control strategy for engine block 3D printing should encompass several key areas.

Material verification is a critical first step. Before printing begins, the raw materials must be thoroughly tested to ensure they meet the required specifications. This includes checking the composition, purity, and particle size distribution of metal powders used in the printing process. Regular batch testing and certification from suppliers can help maintain consistent material quality.

Pre-print machine calibration is essential for achieving dimensional accuracy and surface finish. This involves regular maintenance and calibration of the 3D printer, including alignment of print heads, verification of build platform levelness, and optimization of laser or electron beam parameters. Implementing a standardized calibration procedure before each print job helps maintain consistency across multiple builds.

In-process monitoring plays a crucial role in detecting and correcting issues during the printing process. Advanced 3D printers equipped with real-time monitoring systems can track key parameters such as temperature distribution, layer thickness, and material deposition rates. Machine learning algorithms can be employed to analyze this data and identify potential defects or anomalies as they occur, allowing for immediate corrective action.

Post-print inspection is a multi-faceted process that ensures the final product meets all specifications. Non-destructive testing methods such as X-ray computed tomography (CT) scanning can reveal internal structures and potential defects without damaging the prototype. Surface metrology techniques, including 3D scanning and profilometry, can verify dimensional accuracy and surface finish quality.

Mechanical testing is crucial for validating the structural integrity of the printed engine blocks. This may include tensile strength tests, hardness measurements, and fatigue testing to ensure the prototype can withstand the intended operating conditions. Specialized testing rigs may be required to simulate the specific stresses and loads experienced by an engine block during operation.

Thermal analysis is particularly important for engine block prototypes. Thermal imaging and heat cycling tests can reveal potential issues with heat dissipation and thermal expansion. This information is vital for optimizing the design and material selection to ensure proper engine performance under various operating temperatures.

Documentation and traceability are essential components of a robust quality control system. Each prototype should be assigned a unique identifier, with detailed records kept of all materials, process parameters, and test results. This information not only aids in troubleshooting and continuous improvement but also provides valuable data for future design iterations and production scaling.

Material verification is a critical first step. Before printing begins, the raw materials must be thoroughly tested to ensure they meet the required specifications. This includes checking the composition, purity, and particle size distribution of metal powders used in the printing process. Regular batch testing and certification from suppliers can help maintain consistent material quality.

Pre-print machine calibration is essential for achieving dimensional accuracy and surface finish. This involves regular maintenance and calibration of the 3D printer, including alignment of print heads, verification of build platform levelness, and optimization of laser or electron beam parameters. Implementing a standardized calibration procedure before each print job helps maintain consistency across multiple builds.

In-process monitoring plays a crucial role in detecting and correcting issues during the printing process. Advanced 3D printers equipped with real-time monitoring systems can track key parameters such as temperature distribution, layer thickness, and material deposition rates. Machine learning algorithms can be employed to analyze this data and identify potential defects or anomalies as they occur, allowing for immediate corrective action.

Post-print inspection is a multi-faceted process that ensures the final product meets all specifications. Non-destructive testing methods such as X-ray computed tomography (CT) scanning can reveal internal structures and potential defects without damaging the prototype. Surface metrology techniques, including 3D scanning and profilometry, can verify dimensional accuracy and surface finish quality.

Mechanical testing is crucial for validating the structural integrity of the printed engine blocks. This may include tensile strength tests, hardness measurements, and fatigue testing to ensure the prototype can withstand the intended operating conditions. Specialized testing rigs may be required to simulate the specific stresses and loads experienced by an engine block during operation.

Thermal analysis is particularly important for engine block prototypes. Thermal imaging and heat cycling tests can reveal potential issues with heat dissipation and thermal expansion. This information is vital for optimizing the design and material selection to ensure proper engine performance under various operating temperatures.

Documentation and traceability are essential components of a robust quality control system. Each prototype should be assigned a unique identifier, with detailed records kept of all materials, process parameters, and test results. This information not only aids in troubleshooting and continuous improvement but also provides valuable data for future design iterations and production scaling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!