Engine Block Design For Hybrid Systems: Integration Considerations

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Engine Evolution

The evolution of hybrid engine technology has been a journey marked by significant milestones and continuous innovation. The concept of combining internal combustion engines with electric propulsion systems dates back to the late 19th century, but it wasn't until the late 20th century that hybrid technology began to gain serious traction in the automotive industry.

The modern era of hybrid vehicles began in the 1990s with the development of the Toyota Prius, which was introduced to the Japanese market in 1997 and globally in 2000. This marked a turning point in hybrid engine design, showcasing the potential for improved fuel efficiency and reduced emissions in mass-produced vehicles.

As hybrid technology matured, various configurations emerged. The parallel hybrid system, where both the internal combustion engine and electric motor can drive the wheels directly, became popular due to its versatility. Series hybrid systems, where the internal combustion engine acts primarily as a generator to power the electric motor, found applications in specific vehicle types, particularly in heavy-duty and commercial vehicles.

The plug-in hybrid electric vehicle (PHEV) represented the next significant evolution, offering extended electric-only driving range and the ability to charge from external power sources. This development bridged the gap between conventional hybrids and fully electric vehicles, addressing range anxiety while still providing significant emissions reductions.

Advancements in battery technology, particularly the shift from nickel-metal hydride to lithium-ion batteries, played a crucial role in improving the performance and efficiency of hybrid systems. This transition allowed for greater energy storage capacity, faster charging times, and improved power delivery.

Engine block design for hybrid systems has undergone continuous refinement to optimize integration with electric components. Engineers have focused on reducing weight, improving thermal management, and enhancing overall system efficiency. The challenge of packaging both internal combustion and electric propulsion components within a single vehicle has driven innovations in compact design and modular architectures.

Recent developments have seen the introduction of more sophisticated hybrid powertrains, such as Toyota's THS-III and Honda's i-MMD systems. These advanced designs aim to further optimize the synergy between electric and combustion power sources, offering seamless transitions and improved overall efficiency.

Looking forward, the evolution of hybrid engine technology is likely to continue with a focus on further electrification, potentially leading to the development of range-extended electric vehicles (REEVs) as a transitional technology. Additionally, the integration of hybrid systems with alternative fuels such as hydrogen and biofuels represents an area of ongoing research and development in the quest for even cleaner and more sustainable transportation solutions.

The modern era of hybrid vehicles began in the 1990s with the development of the Toyota Prius, which was introduced to the Japanese market in 1997 and globally in 2000. This marked a turning point in hybrid engine design, showcasing the potential for improved fuel efficiency and reduced emissions in mass-produced vehicles.

As hybrid technology matured, various configurations emerged. The parallel hybrid system, where both the internal combustion engine and electric motor can drive the wheels directly, became popular due to its versatility. Series hybrid systems, where the internal combustion engine acts primarily as a generator to power the electric motor, found applications in specific vehicle types, particularly in heavy-duty and commercial vehicles.

The plug-in hybrid electric vehicle (PHEV) represented the next significant evolution, offering extended electric-only driving range and the ability to charge from external power sources. This development bridged the gap between conventional hybrids and fully electric vehicles, addressing range anxiety while still providing significant emissions reductions.

Advancements in battery technology, particularly the shift from nickel-metal hydride to lithium-ion batteries, played a crucial role in improving the performance and efficiency of hybrid systems. This transition allowed for greater energy storage capacity, faster charging times, and improved power delivery.

Engine block design for hybrid systems has undergone continuous refinement to optimize integration with electric components. Engineers have focused on reducing weight, improving thermal management, and enhancing overall system efficiency. The challenge of packaging both internal combustion and electric propulsion components within a single vehicle has driven innovations in compact design and modular architectures.

Recent developments have seen the introduction of more sophisticated hybrid powertrains, such as Toyota's THS-III and Honda's i-MMD systems. These advanced designs aim to further optimize the synergy between electric and combustion power sources, offering seamless transitions and improved overall efficiency.

Looking forward, the evolution of hybrid engine technology is likely to continue with a focus on further electrification, potentially leading to the development of range-extended electric vehicles (REEVs) as a transitional technology. Additionally, the integration of hybrid systems with alternative fuels such as hydrogen and biofuels represents an area of ongoing research and development in the quest for even cleaner and more sustainable transportation solutions.

Market Demand Analysis

The market demand for hybrid engine block designs has been experiencing significant growth in recent years, driven by the increasing adoption of hybrid vehicles and the push for more fuel-efficient transportation solutions. As automotive manufacturers strive to meet stringent emissions regulations and consumer demands for improved fuel economy, the integration of hybrid systems into traditional internal combustion engines has become a critical focus area.

The global hybrid vehicle market has been expanding rapidly, with a compound annual growth rate (CAGR) projected to exceed 16% between 2021 and 2026. This growth is primarily fueled by government incentives, rising environmental awareness, and advancements in hybrid technology. Consequently, the demand for specialized engine block designs that can accommodate both conventional and electric powertrains has surged.

One of the key drivers of market demand is the need for engine blocks that can efficiently integrate hybrid components while maintaining or improving overall vehicle performance. Automotive manufacturers are seeking designs that allow for seamless incorporation of electric motors, power electronics, and battery systems without compromising the structural integrity or thermal management capabilities of the engine block.

The market for hybrid engine blocks is also influenced by the trend towards downsizing and lightweighting in the automotive industry. As manufacturers aim to reduce vehicle weight to improve fuel efficiency, there is a growing demand for engine block designs that utilize advanced materials and manufacturing techniques to achieve weight reduction without sacrificing durability or performance.

Another significant factor shaping market demand is the need for engine blocks that can support various hybrid configurations, from mild hybrids to full hybrids and plug-in hybrids. This versatility is crucial for automotive manufacturers looking to develop modular platforms that can accommodate different levels of electrification across their vehicle lineups.

The integration of hybrid systems also presents challenges in terms of thermal management and NVH (Noise, Vibration, and Harshness) control. As a result, there is a strong market demand for engine block designs that incorporate innovative cooling solutions and vibration damping features to address these issues effectively.

Furthermore, the market is witnessing increased demand for engine blocks that facilitate easier assembly and maintenance of hybrid powertrains. Designs that allow for modular integration of hybrid components and simplified servicing procedures are highly sought after by both manufacturers and end-users.

In conclusion, the market demand for engine block designs tailored for hybrid systems is robust and multifaceted. It is driven by the rapid growth of the hybrid vehicle market, the need for efficient integration of electric and conventional powertrains, lightweighting trends, versatility requirements, thermal management challenges, and ease of assembly and maintenance considerations. As the automotive industry continues its transition towards electrification, the demand for innovative engine block designs that address these integration considerations is expected to remain strong in the foreseeable future.

The global hybrid vehicle market has been expanding rapidly, with a compound annual growth rate (CAGR) projected to exceed 16% between 2021 and 2026. This growth is primarily fueled by government incentives, rising environmental awareness, and advancements in hybrid technology. Consequently, the demand for specialized engine block designs that can accommodate both conventional and electric powertrains has surged.

One of the key drivers of market demand is the need for engine blocks that can efficiently integrate hybrid components while maintaining or improving overall vehicle performance. Automotive manufacturers are seeking designs that allow for seamless incorporation of electric motors, power electronics, and battery systems without compromising the structural integrity or thermal management capabilities of the engine block.

The market for hybrid engine blocks is also influenced by the trend towards downsizing and lightweighting in the automotive industry. As manufacturers aim to reduce vehicle weight to improve fuel efficiency, there is a growing demand for engine block designs that utilize advanced materials and manufacturing techniques to achieve weight reduction without sacrificing durability or performance.

Another significant factor shaping market demand is the need for engine blocks that can support various hybrid configurations, from mild hybrids to full hybrids and plug-in hybrids. This versatility is crucial for automotive manufacturers looking to develop modular platforms that can accommodate different levels of electrification across their vehicle lineups.

The integration of hybrid systems also presents challenges in terms of thermal management and NVH (Noise, Vibration, and Harshness) control. As a result, there is a strong market demand for engine block designs that incorporate innovative cooling solutions and vibration damping features to address these issues effectively.

Furthermore, the market is witnessing increased demand for engine blocks that facilitate easier assembly and maintenance of hybrid powertrains. Designs that allow for modular integration of hybrid components and simplified servicing procedures are highly sought after by both manufacturers and end-users.

In conclusion, the market demand for engine block designs tailored for hybrid systems is robust and multifaceted. It is driven by the rapid growth of the hybrid vehicle market, the need for efficient integration of electric and conventional powertrains, lightweighting trends, versatility requirements, thermal management challenges, and ease of assembly and maintenance considerations. As the automotive industry continues its transition towards electrification, the demand for innovative engine block designs that address these integration considerations is expected to remain strong in the foreseeable future.

Technical Challenges

The integration of hybrid systems into engine block design presents several significant technical challenges that require innovative solutions. One of the primary obstacles is the need for compact packaging to accommodate both the internal combustion engine (ICE) and electric motor components within a limited space. This necessitates a complete redesign of traditional engine block layouts to optimize spatial efficiency while maintaining structural integrity and performance.

Thermal management poses another critical challenge in hybrid engine block design. The combination of ICE and electric powertrain components generates complex heat profiles that must be effectively managed to ensure optimal performance and longevity of both systems. Engineers must develop advanced cooling strategies that can handle the diverse thermal requirements of combustion engines and electric motors simultaneously.

Material selection and compatibility present additional hurdles in hybrid engine block design. The integration of electric components introduces new considerations for electromagnetic interference (EMI) shielding and corrosion resistance. Engineers must carefully select materials that can withstand the high temperatures and pressures of combustion engines while also providing the necessary electrical insulation and EMI protection for electric components.

Vibration and noise reduction become more complex in hybrid systems due to the interplay between ICE and electric motor operations. The engine block design must incorporate advanced damping and isolation techniques to minimize noise, vibration, and harshness (NVH) levels, ensuring a smooth and quiet driving experience across various operating modes.

Weight reduction remains a persistent challenge in hybrid engine block design. The addition of electric components inherently increases the overall weight of the powertrain system. Engineers must explore lightweight materials and innovative structural designs to offset this weight gain without compromising strength or durability.

Manufacturability and cost-effectiveness present significant obstacles in the development of hybrid engine blocks. The increased complexity of these systems often requires more sophisticated manufacturing processes and quality control measures. Balancing the need for advanced features with production feasibility and cost constraints is a delicate task that demands careful consideration throughout the design process.

Lastly, ensuring seamless integration between the ICE and electric components at the software and control system level poses a substantial challenge. The engine block design must accommodate sensors, actuators, and wiring harnesses necessary for precise control and coordination of both power sources. This integration must be robust enough to handle the dynamic switching between power modes and optimize overall system efficiency.

Thermal management poses another critical challenge in hybrid engine block design. The combination of ICE and electric powertrain components generates complex heat profiles that must be effectively managed to ensure optimal performance and longevity of both systems. Engineers must develop advanced cooling strategies that can handle the diverse thermal requirements of combustion engines and electric motors simultaneously.

Material selection and compatibility present additional hurdles in hybrid engine block design. The integration of electric components introduces new considerations for electromagnetic interference (EMI) shielding and corrosion resistance. Engineers must carefully select materials that can withstand the high temperatures and pressures of combustion engines while also providing the necessary electrical insulation and EMI protection for electric components.

Vibration and noise reduction become more complex in hybrid systems due to the interplay between ICE and electric motor operations. The engine block design must incorporate advanced damping and isolation techniques to minimize noise, vibration, and harshness (NVH) levels, ensuring a smooth and quiet driving experience across various operating modes.

Weight reduction remains a persistent challenge in hybrid engine block design. The addition of electric components inherently increases the overall weight of the powertrain system. Engineers must explore lightweight materials and innovative structural designs to offset this weight gain without compromising strength or durability.

Manufacturability and cost-effectiveness present significant obstacles in the development of hybrid engine blocks. The increased complexity of these systems often requires more sophisticated manufacturing processes and quality control measures. Balancing the need for advanced features with production feasibility and cost constraints is a delicate task that demands careful consideration throughout the design process.

Lastly, ensuring seamless integration between the ICE and electric components at the software and control system level poses a substantial challenge. The engine block design must accommodate sensors, actuators, and wiring harnesses necessary for precise control and coordination of both power sources. This integration must be robust enough to handle the dynamic switching between power modes and optimize overall system efficiency.

Current Design Solutions

01 Engine block design optimization

Optimizing engine block design involves integrating various components to improve performance, efficiency, and durability. This includes considerations for cooling systems, lubrication channels, and structural integrity. Advanced design techniques may incorporate lightweight materials and innovative geometries to reduce weight while maintaining strength.- Engine block design optimization: Optimizing engine block design for improved integration, focusing on structural enhancements, weight reduction, and efficient cooling systems. This includes innovative casting techniques and material selection to enhance overall engine performance and durability.

- Integration of electronic components: Incorporating electronic components and sensors directly into the engine block for enhanced monitoring and control. This integration allows for real-time data collection, improved engine management, and more efficient operation.

- Modular engine block design: Developing modular engine block designs that allow for easier assembly, maintenance, and customization. This approach enables more flexible manufacturing processes and facilitates the integration of various engine components.

- Thermal management solutions: Implementing advanced thermal management solutions within the engine block to improve heat dissipation and maintain optimal operating temperatures. This includes innovative cooling channels, materials with enhanced thermal properties, and integrated heat exchangers.

- Manufacturing process improvements: Enhancing manufacturing processes for engine block integration, including advanced casting techniques, 3D printing applications, and precision machining methods. These improvements aim to increase production efficiency, reduce costs, and improve overall engine block quality.

02 Integration of electronic systems

Modern engine blocks increasingly incorporate electronic systems for improved control and monitoring. This integration may include sensors, actuators, and control modules directly into the engine block structure. Such integration enhances engine management, diagnostics, and overall performance while potentially reducing complexity and improving reliability.Expand Specific Solutions03 Modular engine block design

Modular approaches to engine block design allow for greater flexibility in manufacturing and customization. This concept involves creating standardized components or sections that can be combined in various ways to create different engine configurations. Such modularity can lead to cost savings in production and easier maintenance or upgrades.Expand Specific Solutions04 Thermal management integration

Integrating advanced thermal management systems directly into the engine block is crucial for optimizing performance and efficiency. This may include innovative cooling passages, integrated heat exchangers, or smart temperature control systems. Effective thermal management integration can lead to improved fuel efficiency, reduced emissions, and extended engine life.Expand Specific Solutions05 Manufacturing process innovations

Advancements in manufacturing processes play a key role in engine block integration. This includes new casting techniques, 3D printing of complex components, and innovative joining methods. These processes allow for the creation of more intricate and efficient engine block designs, potentially integrating functions that were previously separate components.Expand Specific Solutions

Key Industry Players

The engine block design for hybrid systems integration is in a dynamic phase of development, reflecting the automotive industry's transition towards electrification. The market is expanding rapidly, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. Major players like BMW, Mercedes-Benz, and GM are investing heavily in this technology, leveraging their extensive experience in traditional powertrains. Emerging companies such as BYD and Chery are also making significant strides, particularly in the Chinese market. The technology is maturing, with established suppliers like Bosch and ZF Friedrichshafen providing critical components. However, there's still room for innovation, especially in optimizing the integration of electric and combustion systems within the engine block.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed an innovative engine block design for hybrid systems that integrates both combustion and electric powertrains. Their approach focuses on a modular architecture that allows for flexible integration of different hybrid configurations. The design incorporates a compact, lightweight aluminum engine block with integrated electric motor housing, reducing overall weight and improving packaging efficiency. BMW's solution also features advanced thermal management systems to optimize the performance of both the combustion engine and electric components. The engine block utilizes a split-cooling system that separately regulates temperatures for the combustion chamber and electric motor, enhancing overall system efficiency[1][3]. Additionally, BMW has implemented a novel crankcase ventilation system that minimizes oil consumption and emissions in hybrid operation modes.

Strengths: Modular design allows for easy adaptation to different hybrid configurations. Lightweight construction improves fuel efficiency. Advanced thermal management enhances overall system performance. Weaknesses: Potentially higher production costs due to complex integration. May require specialized manufacturing processes.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive engine block design solution for hybrid systems that focuses on seamless integration of electrical components with traditional combustion engine architecture. Their approach utilizes a scalable platform that accommodates various hybrid configurations, from mild hybrids to plug-in hybrids. The design incorporates advanced materials and manufacturing techniques to create a compact, lightweight engine block that houses both the combustion engine and electric motor components. Bosch's solution features integrated cooling channels for efficient thermal management of both powertrains, as well as a sophisticated oil circulation system that serves both the combustion engine and electric motor bearings[2]. The design also includes provisions for integrating power electronics and high-voltage cabling within the engine block structure, minimizing external connections and improving overall system reliability.

Strengths: Scalable platform suitable for various hybrid configurations. Integrated cooling and lubrication systems improve efficiency. Compact design reduces overall vehicle weight. Weaknesses: May require significant retooling for existing production lines. Potential challenges in servicing due to high integration of components.

Core Innovations

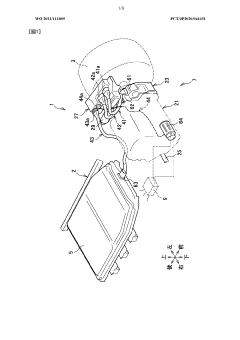

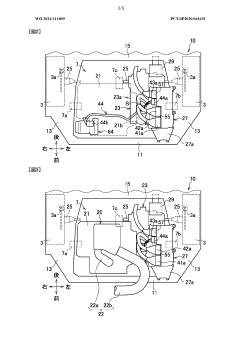

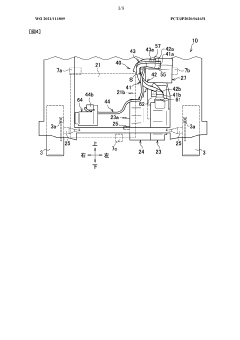

Vehicle drive unit

PatentWO2021111809A1

Innovation

- The vehicle drive unit positions the second electric motor behind the first electric motor in the longitudinal direction and offset upward, creating a predetermined space for the terminal blocks, which are located inside the outer edge of the electric unit, thereby reducing the likelihood of damage during collisions.

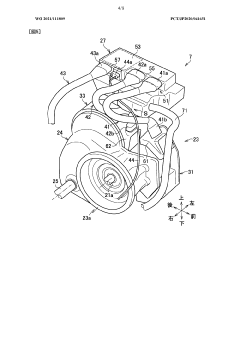

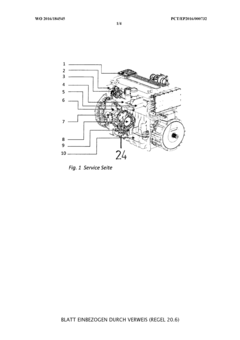

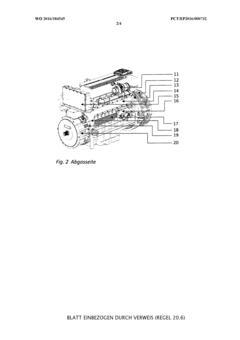

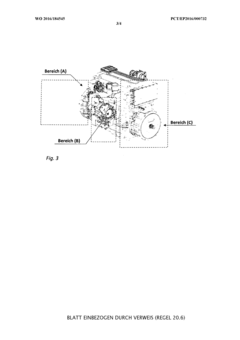

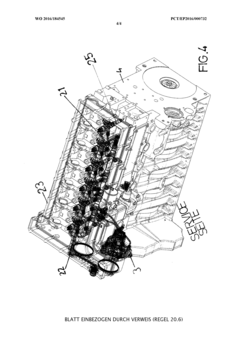

Internal combustion engine comprising at least one electric motor

PatentWO2016184545A1

Innovation

- The integration of at least one electric motor on the crankcase, a control unit, and a high-voltage converter, along with strategic component arrangements such as the common rail in the cylinder head cover and cable harness, provides installation space and assembly advantages, enabling flexible hybrid system integration and expanded customer applications.

Emissions Regulations

Emissions regulations play a crucial role in shaping the design and development of hybrid engine blocks. As governments worldwide intensify their efforts to combat climate change and reduce air pollution, automotive manufacturers face increasingly stringent emission standards. These regulations directly impact the integration considerations for hybrid systems, particularly in engine block design.

The primary focus of emissions regulations for hybrid vehicles is the reduction of greenhouse gases, particularly carbon dioxide (CO2), as well as other pollutants such as nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC). To meet these standards, engine block designs for hybrid systems must incorporate advanced technologies and innovative solutions.

One of the key challenges in engine block design for hybrid systems is balancing the need for reduced emissions with performance and efficiency requirements. This often involves optimizing the combustion process, improving thermal management, and integrating advanced aftertreatment systems. Engineers must consider the interaction between the internal combustion engine and the electric powertrain components to achieve optimal emissions reduction across various operating conditions.

Emissions regulations also influence the materials and manufacturing processes used in engine block design. Lightweight materials, such as aluminum alloys and composite materials, are increasingly favored to reduce overall vehicle weight and improve fuel efficiency. However, these materials must also meet durability and thermal management requirements specific to hybrid systems.

The integration of start-stop technology in hybrid systems presents another challenge for engine block design. Frequent engine restarts can lead to increased wear and emissions during cold starts. To address this, designers must incorporate robust materials and advanced lubrication systems to minimize wear and ensure rapid warm-up times, thereby reducing cold-start emissions.

Furthermore, emissions regulations are driving the development of more sophisticated engine control systems. These systems must seamlessly integrate with the hybrid powertrain to optimize fuel consumption and emissions across various driving modes. This requires careful consideration of sensor placement, thermal management, and software integration within the engine block design.

As emissions standards continue to evolve, engine block designs for hybrid systems must also anticipate future regulatory requirements. This forward-looking approach often involves incorporating flexibility into the design to accommodate potential upgrades or modifications to meet future standards without requiring a complete redesign.

The primary focus of emissions regulations for hybrid vehicles is the reduction of greenhouse gases, particularly carbon dioxide (CO2), as well as other pollutants such as nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC). To meet these standards, engine block designs for hybrid systems must incorporate advanced technologies and innovative solutions.

One of the key challenges in engine block design for hybrid systems is balancing the need for reduced emissions with performance and efficiency requirements. This often involves optimizing the combustion process, improving thermal management, and integrating advanced aftertreatment systems. Engineers must consider the interaction between the internal combustion engine and the electric powertrain components to achieve optimal emissions reduction across various operating conditions.

Emissions regulations also influence the materials and manufacturing processes used in engine block design. Lightweight materials, such as aluminum alloys and composite materials, are increasingly favored to reduce overall vehicle weight and improve fuel efficiency. However, these materials must also meet durability and thermal management requirements specific to hybrid systems.

The integration of start-stop technology in hybrid systems presents another challenge for engine block design. Frequent engine restarts can lead to increased wear and emissions during cold starts. To address this, designers must incorporate robust materials and advanced lubrication systems to minimize wear and ensure rapid warm-up times, thereby reducing cold-start emissions.

Furthermore, emissions regulations are driving the development of more sophisticated engine control systems. These systems must seamlessly integrate with the hybrid powertrain to optimize fuel consumption and emissions across various driving modes. This requires careful consideration of sensor placement, thermal management, and software integration within the engine block design.

As emissions standards continue to evolve, engine block designs for hybrid systems must also anticipate future regulatory requirements. This forward-looking approach often involves incorporating flexibility into the design to accommodate potential upgrades or modifications to meet future standards without requiring a complete redesign.

Material Advancements

Material advancements play a crucial role in the evolution of engine block design for hybrid systems. As the automotive industry shifts towards more efficient and environmentally friendly powertrains, the integration of hybrid technologies demands innovative materials that can meet the unique challenges posed by these complex systems.

One of the primary considerations in material selection for hybrid engine blocks is weight reduction. Lightweight materials such as aluminum alloys and magnesium alloys have gained significant traction in recent years. These materials offer excellent strength-to-weight ratios, allowing for reduced overall vehicle weight and improved fuel efficiency. Advanced aluminum alloys, in particular, have been engineered to withstand higher temperatures and pressures, making them suitable for the demanding conditions of hybrid powertrains.

Thermal management is another critical aspect driving material advancements in hybrid engine block design. The integration of electric motors and combustion engines in close proximity necessitates materials with superior heat dissipation properties. Composite materials, such as metal matrix composites (MMCs), have shown promise in this regard. These materials combine the lightweight properties of aluminum with the thermal conductivity of materials like silicon carbide or graphene, resulting in improved heat management capabilities.

Durability and longevity are also key factors influencing material choices. Hybrid systems often experience frequent start-stop cycles and varying load conditions, which can lead to increased wear and fatigue. To address this, researchers are exploring the use of advanced coatings and surface treatments. Plasma electrolytic oxidation (PEO) coatings, for instance, can enhance the wear resistance and corrosion protection of aluminum engine blocks, extending their lifespan in hybrid applications.

The integration of electric components within the engine block has led to the development of materials with enhanced electromagnetic shielding properties. Engineered polymers and composite materials with embedded conductive elements are being investigated to protect sensitive electronic components from electromagnetic interference while maintaining the structural integrity of the engine block.

Additive manufacturing techniques have opened up new possibilities in material design for hybrid engine blocks. 3D printing allows for the creation of complex geometries and internal structures that were previously impossible with traditional manufacturing methods. This enables the incorporation of features such as integrated cooling channels and optimized load-bearing structures, further enhancing the performance and efficiency of hybrid powertrains.

As environmental concerns continue to drive innovation, biodegradable and recyclable materials are also being explored for certain components of hybrid engine blocks. While not suitable for the entire structure, these materials could be used for non-critical parts, reducing the environmental impact of hybrid vehicles at the end of their lifecycle.

One of the primary considerations in material selection for hybrid engine blocks is weight reduction. Lightweight materials such as aluminum alloys and magnesium alloys have gained significant traction in recent years. These materials offer excellent strength-to-weight ratios, allowing for reduced overall vehicle weight and improved fuel efficiency. Advanced aluminum alloys, in particular, have been engineered to withstand higher temperatures and pressures, making them suitable for the demanding conditions of hybrid powertrains.

Thermal management is another critical aspect driving material advancements in hybrid engine block design. The integration of electric motors and combustion engines in close proximity necessitates materials with superior heat dissipation properties. Composite materials, such as metal matrix composites (MMCs), have shown promise in this regard. These materials combine the lightweight properties of aluminum with the thermal conductivity of materials like silicon carbide or graphene, resulting in improved heat management capabilities.

Durability and longevity are also key factors influencing material choices. Hybrid systems often experience frequent start-stop cycles and varying load conditions, which can lead to increased wear and fatigue. To address this, researchers are exploring the use of advanced coatings and surface treatments. Plasma electrolytic oxidation (PEO) coatings, for instance, can enhance the wear resistance and corrosion protection of aluminum engine blocks, extending their lifespan in hybrid applications.

The integration of electric components within the engine block has led to the development of materials with enhanced electromagnetic shielding properties. Engineered polymers and composite materials with embedded conductive elements are being investigated to protect sensitive electronic components from electromagnetic interference while maintaining the structural integrity of the engine block.

Additive manufacturing techniques have opened up new possibilities in material design for hybrid engine blocks. 3D printing allows for the creation of complex geometries and internal structures that were previously impossible with traditional manufacturing methods. This enables the incorporation of features such as integrated cooling channels and optimized load-bearing structures, further enhancing the performance and efficiency of hybrid powertrains.

As environmental concerns continue to drive innovation, biodegradable and recyclable materials are also being explored for certain components of hybrid engine blocks. While not suitable for the entire structure, these materials could be used for non-critical parts, reducing the environmental impact of hybrid vehicles at the end of their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!