How To Evaluate Coolant Flow Distribution In Engine Blocks

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Cooling Evolution

Engine cooling systems have undergone significant evolution since the early days of automotive engineering. The initial cooling methods relied on natural air flow and thermosiphon effects, which proved inadequate as engine power and efficiency increased. The introduction of water-cooled engines in the early 20th century marked a pivotal shift, utilizing a pump-driven circulation system to maintain optimal operating temperatures.

As engines became more powerful and compact, the need for more efficient cooling systems grew. The 1960s and 1970s saw the widespread adoption of pressurized cooling systems, which allowed for higher coolant temperatures and improved thermal efficiency. This period also witnessed the introduction of cross-flow radiators, replacing less efficient down-flow designs.

The late 20th century brought about significant advancements in coolant chemistry. Traditional water-based coolants were replaced by ethylene glycol mixtures, offering improved freeze protection and boiling point elevation. These developments allowed for smaller cooling system components and contributed to overall vehicle weight reduction.

Computer-aided design and computational fluid dynamics (CFD) emerged as game-changing tools in the 1990s and 2000s. These technologies enabled engineers to model and optimize coolant flow distribution within engine blocks with unprecedented precision. This led to more efficient cooling jacket designs and targeted cooling strategies for critical engine components.

The turn of the millennium saw a focus on reducing parasitic losses associated with cooling systems. Variable-speed electric water pumps and thermostat-controlled coolant flow became common, allowing for more precise temperature management and improved fuel efficiency. Additionally, the integration of exhaust gas recirculation (EGR) cooling into engine thermal management systems further enhanced overall engine efficiency and emissions control.

Recent years have witnessed a shift towards electrification and hybridization, presenting new challenges and opportunities in engine cooling. The need to cool power electronics and battery systems has led to the development of integrated thermal management systems that balance the cooling requirements of traditional internal combustion engines with those of electric powertrains.

Looking ahead, the evolution of engine cooling systems is likely to focus on further optimization of coolant flow distribution, leveraging advanced materials and manufacturing techniques such as 3D printing for complex cooling channel geometries. The integration of smart sensors and adaptive control systems promises to deliver real-time, demand-based cooling strategies that maximize efficiency across a wide range of operating conditions.

As engines became more powerful and compact, the need for more efficient cooling systems grew. The 1960s and 1970s saw the widespread adoption of pressurized cooling systems, which allowed for higher coolant temperatures and improved thermal efficiency. This period also witnessed the introduction of cross-flow radiators, replacing less efficient down-flow designs.

The late 20th century brought about significant advancements in coolant chemistry. Traditional water-based coolants were replaced by ethylene glycol mixtures, offering improved freeze protection and boiling point elevation. These developments allowed for smaller cooling system components and contributed to overall vehicle weight reduction.

Computer-aided design and computational fluid dynamics (CFD) emerged as game-changing tools in the 1990s and 2000s. These technologies enabled engineers to model and optimize coolant flow distribution within engine blocks with unprecedented precision. This led to more efficient cooling jacket designs and targeted cooling strategies for critical engine components.

The turn of the millennium saw a focus on reducing parasitic losses associated with cooling systems. Variable-speed electric water pumps and thermostat-controlled coolant flow became common, allowing for more precise temperature management and improved fuel efficiency. Additionally, the integration of exhaust gas recirculation (EGR) cooling into engine thermal management systems further enhanced overall engine efficiency and emissions control.

Recent years have witnessed a shift towards electrification and hybridization, presenting new challenges and opportunities in engine cooling. The need to cool power electronics and battery systems has led to the development of integrated thermal management systems that balance the cooling requirements of traditional internal combustion engines with those of electric powertrains.

Looking ahead, the evolution of engine cooling systems is likely to focus on further optimization of coolant flow distribution, leveraging advanced materials and manufacturing techniques such as 3D printing for complex cooling channel geometries. The integration of smart sensors and adaptive control systems promises to deliver real-time, demand-based cooling strategies that maximize efficiency across a wide range of operating conditions.

Coolant Flow Importance

Coolant flow distribution in engine blocks plays a crucial role in maintaining optimal engine performance, efficiency, and longevity. The primary function of the coolant system is to regulate engine temperature by dissipating excess heat generated during combustion. Proper coolant flow ensures uniform heat distribution, preventing localized hot spots that can lead to thermal stress, warping, or even catastrophic engine failure.

Evaluating coolant flow distribution is essential for several reasons. Firstly, it helps identify potential areas of inadequate cooling, which may result in reduced engine efficiency and increased fuel consumption. By optimizing coolant flow, engineers can enhance overall engine performance and reduce emissions. Secondly, accurate assessment of coolant distribution enables manufacturers to design more compact and lightweight engine blocks without compromising cooling effectiveness, contributing to improved vehicle fuel economy.

Furthermore, understanding coolant flow patterns is critical for predicting and preventing premature wear of engine components. Uneven cooling can cause thermal expansion and contraction cycles, leading to accelerated wear on cylinder liners, pistons, and other critical parts. By ensuring uniform coolant distribution, manufacturers can extend engine life and reduce maintenance costs for end-users.

The importance of coolant flow evaluation extends beyond performance and durability considerations. It also plays a significant role in engine noise reduction. Proper coolant circulation helps dampen vibrations and absorb sound, contributing to a quieter and more comfortable driving experience. Additionally, efficient coolant flow is crucial for maintaining optimal oil temperature, which directly impacts lubrication effectiveness and engine protection.

In the context of modern engine design trends, such as downsizing and turbocharging, the importance of coolant flow evaluation becomes even more pronounced. These high-performance engines generate more heat in a smaller package, making efficient cooling paramount. Accurate assessment of coolant distribution allows engineers to implement advanced cooling strategies, such as targeted cooling for specific engine components or variable coolant flow systems that adapt to different operating conditions.

Lastly, evaluating coolant flow distribution is essential for developing robust computational fluid dynamics (CFD) models and simulation tools. These models enable engineers to predict cooling performance early in the design process, reducing the need for costly physical prototypes and accelerating product development cycles. As engine designs become increasingly complex, the ability to accurately simulate and optimize coolant flow becomes a critical competitive advantage in the automotive industry.

Evaluating coolant flow distribution is essential for several reasons. Firstly, it helps identify potential areas of inadequate cooling, which may result in reduced engine efficiency and increased fuel consumption. By optimizing coolant flow, engineers can enhance overall engine performance and reduce emissions. Secondly, accurate assessment of coolant distribution enables manufacturers to design more compact and lightweight engine blocks without compromising cooling effectiveness, contributing to improved vehicle fuel economy.

Furthermore, understanding coolant flow patterns is critical for predicting and preventing premature wear of engine components. Uneven cooling can cause thermal expansion and contraction cycles, leading to accelerated wear on cylinder liners, pistons, and other critical parts. By ensuring uniform coolant distribution, manufacturers can extend engine life and reduce maintenance costs for end-users.

The importance of coolant flow evaluation extends beyond performance and durability considerations. It also plays a significant role in engine noise reduction. Proper coolant circulation helps dampen vibrations and absorb sound, contributing to a quieter and more comfortable driving experience. Additionally, efficient coolant flow is crucial for maintaining optimal oil temperature, which directly impacts lubrication effectiveness and engine protection.

In the context of modern engine design trends, such as downsizing and turbocharging, the importance of coolant flow evaluation becomes even more pronounced. These high-performance engines generate more heat in a smaller package, making efficient cooling paramount. Accurate assessment of coolant distribution allows engineers to implement advanced cooling strategies, such as targeted cooling for specific engine components or variable coolant flow systems that adapt to different operating conditions.

Lastly, evaluating coolant flow distribution is essential for developing robust computational fluid dynamics (CFD) models and simulation tools. These models enable engineers to predict cooling performance early in the design process, reducing the need for costly physical prototypes and accelerating product development cycles. As engine designs become increasingly complex, the ability to accurately simulate and optimize coolant flow becomes a critical competitive advantage in the automotive industry.

Current Evaluation Methods

The evaluation of coolant flow distribution in engine blocks is crucial for ensuring optimal engine performance and longevity. Current evaluation methods employ a combination of computational and experimental techniques to assess the effectiveness of coolant circulation within the engine block.

Computational Fluid Dynamics (CFD) simulations are widely used to model and analyze coolant flow patterns. These simulations allow engineers to visualize the flow distribution, identify potential hotspots, and optimize the cooling system design. Advanced CFD software packages incorporate complex algorithms to account for various factors such as heat transfer, turbulence, and phase changes, providing a comprehensive understanding of the coolant behavior.

Experimental methods complement computational approaches, offering real-world validation of simulation results. Flow visualization techniques, such as Particle Image Velocimetry (PIV), are employed to observe coolant movement within transparent engine block models. This method involves injecting tracer particles into the coolant and using high-speed cameras to capture their motion, enabling researchers to map flow patterns and velocities accurately.

Thermal imaging is another valuable tool for evaluating coolant distribution. Infrared cameras are used to capture temperature variations across the engine block surface, highlighting areas of inefficient cooling. This non-invasive technique provides valuable insights into the effectiveness of the cooling system under various operating conditions.

Pressure drop measurements are conducted to assess the resistance to coolant flow within the engine block. By measuring pressure differences at various points in the cooling system, engineers can identify areas of high resistance and optimize the flow path to ensure uniform distribution.

Tracer studies involve introducing chemical or radioactive tracers into the coolant and monitoring their dispersion throughout the engine block. This method provides quantitative data on coolant residence times and distribution patterns, helping to identify areas of stagnation or poor circulation.

Advanced sensor technologies are increasingly being integrated into engine blocks to provide real-time monitoring of coolant flow and temperature. These sensors can be strategically placed to gather data from critical areas, allowing for continuous evaluation and adjustment of the cooling system performance.

Computational and experimental methods are often used in conjunction, with iterative processes refining both simulation models and physical prototypes. This integrated approach allows for a more comprehensive evaluation of coolant flow distribution, leading to improved engine designs with enhanced thermal management capabilities.

As technology advances, new evaluation methods are emerging, such as the use of machine learning algorithms to analyze large datasets from multiple sources, providing more accurate predictions of coolant behavior under various operating conditions. These developments continue to enhance our ability to optimize engine cooling systems for improved efficiency and reliability.

Computational Fluid Dynamics (CFD) simulations are widely used to model and analyze coolant flow patterns. These simulations allow engineers to visualize the flow distribution, identify potential hotspots, and optimize the cooling system design. Advanced CFD software packages incorporate complex algorithms to account for various factors such as heat transfer, turbulence, and phase changes, providing a comprehensive understanding of the coolant behavior.

Experimental methods complement computational approaches, offering real-world validation of simulation results. Flow visualization techniques, such as Particle Image Velocimetry (PIV), are employed to observe coolant movement within transparent engine block models. This method involves injecting tracer particles into the coolant and using high-speed cameras to capture their motion, enabling researchers to map flow patterns and velocities accurately.

Thermal imaging is another valuable tool for evaluating coolant distribution. Infrared cameras are used to capture temperature variations across the engine block surface, highlighting areas of inefficient cooling. This non-invasive technique provides valuable insights into the effectiveness of the cooling system under various operating conditions.

Pressure drop measurements are conducted to assess the resistance to coolant flow within the engine block. By measuring pressure differences at various points in the cooling system, engineers can identify areas of high resistance and optimize the flow path to ensure uniform distribution.

Tracer studies involve introducing chemical or radioactive tracers into the coolant and monitoring their dispersion throughout the engine block. This method provides quantitative data on coolant residence times and distribution patterns, helping to identify areas of stagnation or poor circulation.

Advanced sensor technologies are increasingly being integrated into engine blocks to provide real-time monitoring of coolant flow and temperature. These sensors can be strategically placed to gather data from critical areas, allowing for continuous evaluation and adjustment of the cooling system performance.

Computational and experimental methods are often used in conjunction, with iterative processes refining both simulation models and physical prototypes. This integrated approach allows for a more comprehensive evaluation of coolant flow distribution, leading to improved engine designs with enhanced thermal management capabilities.

As technology advances, new evaluation methods are emerging, such as the use of machine learning algorithms to analyze large datasets from multiple sources, providing more accurate predictions of coolant behavior under various operating conditions. These developments continue to enhance our ability to optimize engine cooling systems for improved efficiency and reliability.

Flow Distribution Solutions

01 Optimized coolant flow distribution in engine blocks

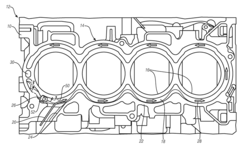

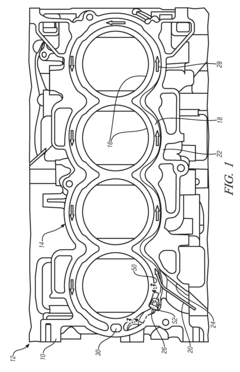

Engine blocks are designed with specific coolant flow paths to ensure efficient heat dissipation. These designs incorporate strategically placed channels and passages to distribute coolant evenly throughout the engine, targeting critical areas such as cylinder walls and combustion chambers. The optimized flow distribution helps maintain consistent engine temperatures and prevents localized hot spots.- Optimized coolant flow distribution channels: Engine blocks are designed with optimized coolant flow distribution channels to ensure efficient heat dissipation. These channels are strategically placed to provide uniform cooling across critical engine components, reducing hot spots and improving overall engine performance.

- Coolant jacket design improvements: Advanced coolant jacket designs are implemented in engine blocks to enhance coolant flow distribution. These improvements include variable cross-section passages, flow directors, and strategically placed baffles to guide coolant to high-heat areas and maintain consistent temperatures throughout the engine.

- Integration of coolant pumps and flow control systems: Engine blocks incorporate integrated coolant pumps and flow control systems to regulate coolant distribution. These systems use sensors and electronic controls to adjust coolant flow based on engine load and temperature, ensuring optimal cooling efficiency and reducing power consumption.

- Multi-circuit cooling systems: Advanced engine blocks utilize multi-circuit cooling systems to provide targeted cooling for different engine components. These systems allow for independent control of coolant flow to cylinder heads, engine block, and other critical areas, optimizing heat management and improving overall engine efficiency.

- 3D-printed coolant channels and flow optimization: Innovative manufacturing techniques, such as 3D printing, are used to create complex coolant channel geometries within engine blocks. This allows for intricate flow paths and optimized coolant distribution, resulting in improved heat transfer and more uniform engine temperatures.

02 Coolant jacket design for improved thermal management

Advanced coolant jacket designs are implemented in engine blocks to enhance thermal management. These designs feature carefully engineered geometries that promote turbulent flow, increasing heat transfer efficiency. The jackets may include baffles, ribs, or variable cross-sections to direct coolant flow and optimize cooling in high-heat areas of the engine.Expand Specific Solutions03 Integration of coolant flow control systems

Modern engine blocks incorporate coolant flow control systems to dynamically manage coolant distribution. These systems may include electronically controlled valves, pumps, or thermostats that adjust coolant flow based on engine operating conditions. By actively regulating coolant distribution, these systems improve overall engine efficiency and reduce warm-up times.Expand Specific Solutions04 Innovative materials and manufacturing techniques for coolant passages

Engine blocks utilize advanced materials and manufacturing techniques to create more efficient coolant passages. These may include 3D-printed cores for complex internal geometries, composite materials with enhanced thermal properties, or surface treatments to reduce friction and improve flow characteristics. These innovations allow for more intricate and effective coolant distribution networks within the engine block.Expand Specific Solutions05 Coolant flow optimization for specific engine configurations

Coolant flow distribution is tailored to specific engine configurations, such as inline, V-type, or boxer engines. The design considers factors like cylinder arrangement, head gasket interfaces, and auxiliary component placement. Custom coolant routing solutions are developed to address the unique thermal challenges of each engine layout, ensuring optimal performance across various engine types.Expand Specific Solutions

Key Engine Manufacturers

The evaluation of coolant flow distribution in engine blocks is a critical aspect of automotive engineering, currently in a mature stage of development. The market for this technology is substantial, driven by the global automotive industry's continuous pursuit of improved engine efficiency and performance. Major players like Ford, GM, Toyota, and Honda have established expertise in this field, leveraging advanced computational fluid dynamics (CFD) and experimental techniques. Emerging technologies, such as 3D printing for rapid prototyping and AI-driven optimization algorithms, are being adopted by companies like AVL List and Cummins to enhance coolant flow analysis. The competitive landscape is characterized by a mix of traditional automakers and specialized engineering firms, with ongoing research at institutions like Zhejiang University contributing to technological advancements.

Ford Global Technologies LLC

Technical Solution: Ford employs advanced Computational Fluid Dynamics (CFD) simulations to evaluate coolant flow distribution in engine blocks. Their approach integrates detailed 3D models of engine geometry with sophisticated fluid dynamics algorithms to predict coolant behavior under various operating conditions. Ford's method incorporates thermal mapping to identify potential hotspots and optimize coolant jacket design. They utilize a multi-phase flow model to account for both liquid and vapor phases of the coolant, enhancing accuracy in high-temperature regions[1]. Additionally, Ford has developed a novel sensor-based system that uses strategically placed temperature and flow sensors to validate CFD results and provide real-time monitoring of coolant distribution during engine operation[3].

Strengths: Comprehensive CFD modeling, real-time monitoring capabilities, and integration of experimental data with simulations. Weaknesses: High computational requirements and potential for model simplifications that may not capture all real-world complexities.

GM Global Technology Operations LLC

Technical Solution: GM's approach to evaluating coolant flow distribution combines advanced simulation techniques with innovative experimental methods. They utilize a proprietary CFD software that incorporates conjugate heat transfer models to simultaneously analyze coolant flow and heat dissipation in engine blocks. GM has developed a unique "transparent engine" technology, using optically clear engine blocks made from specialized polymers, allowing for direct visualization of coolant flow patterns using high-speed cameras and laser-induced fluorescence[2]. This method provides invaluable data for validating CFD models and identifying flow anomalies. Furthermore, GM employs Particle Image Velocimetry (PIV) techniques to quantify coolant velocities and turbulence levels in critical areas of the engine block[4].

Strengths: Direct visualization capabilities, advanced CFD modeling, and integration of experimental and computational methods. Weaknesses: High cost of specialized equipment and potential limitations in scaling transparent engine technology to all engine types.

Innovative Sensing Tech

Engine block assembly for internal combustion engine

PatentActiveUS20110214630A1

Innovation

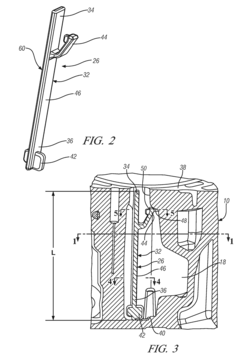

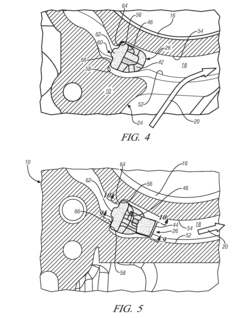

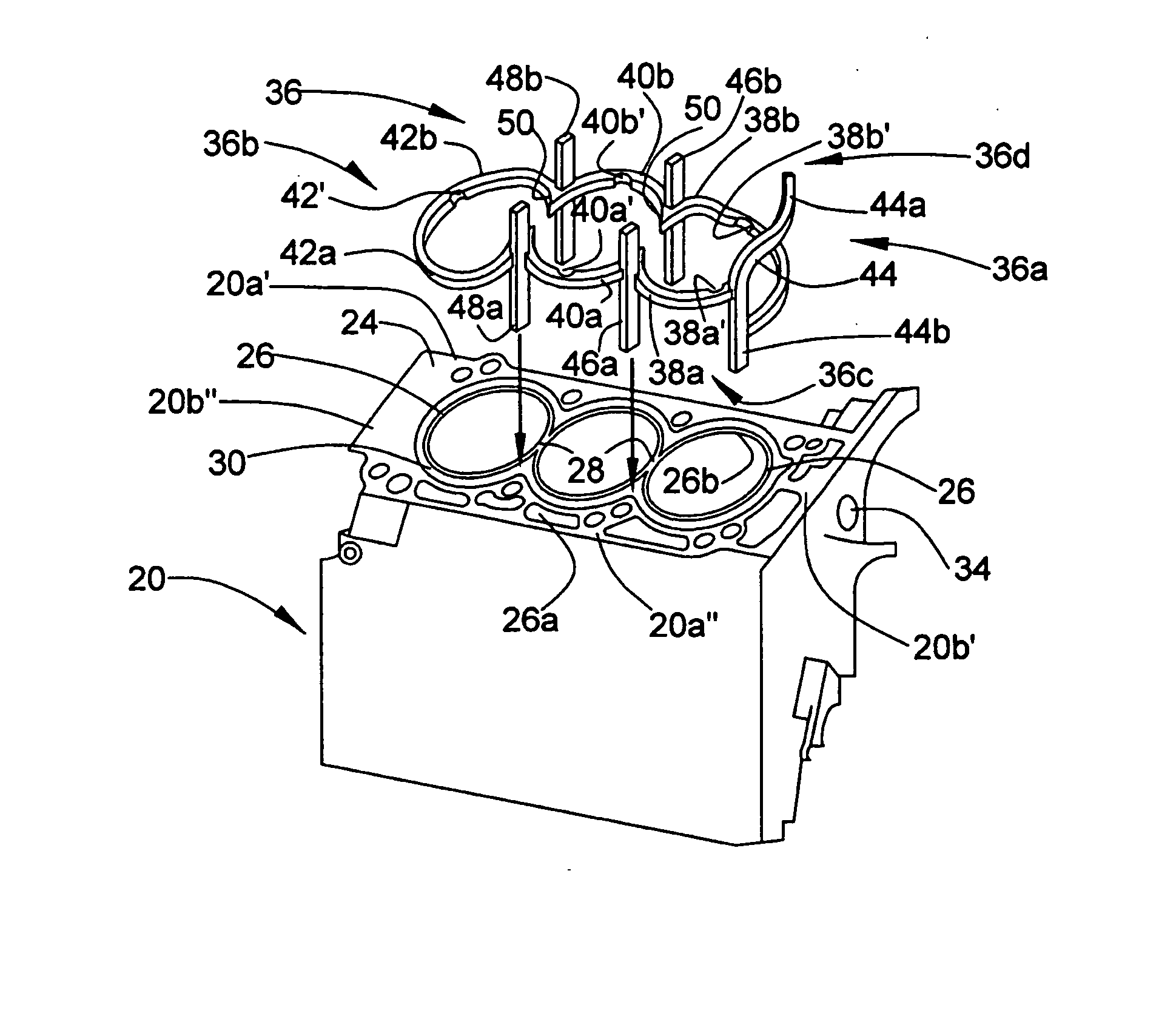

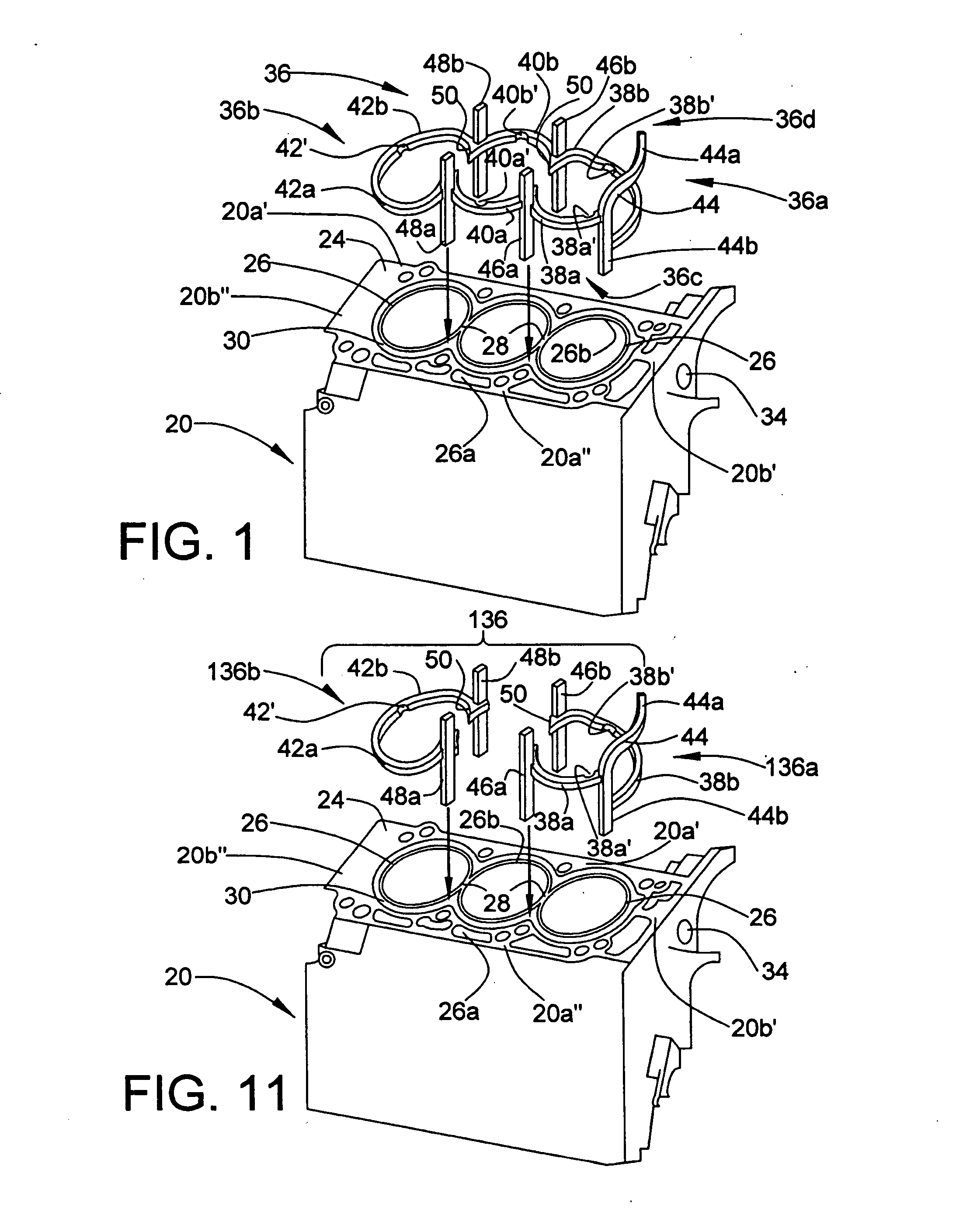

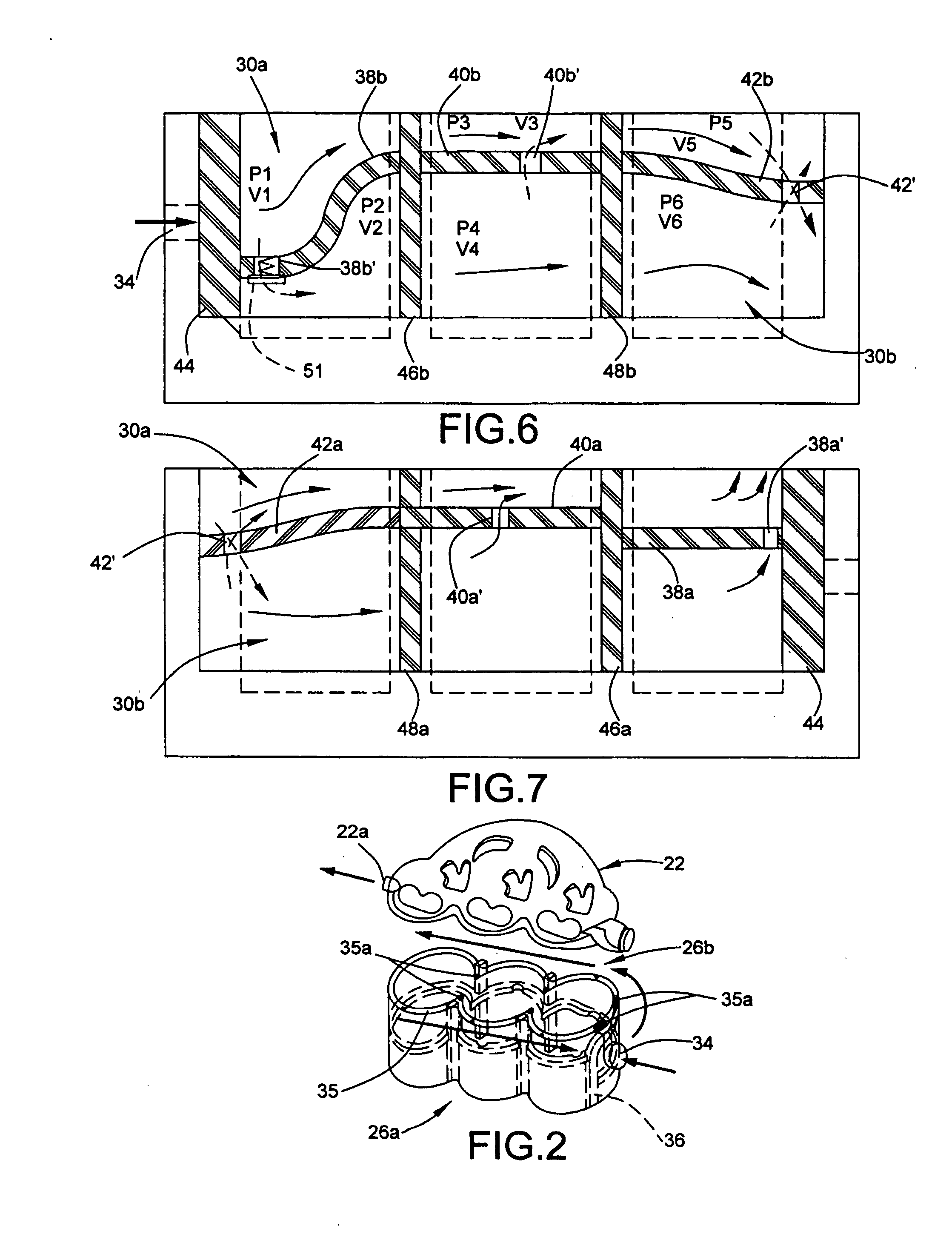

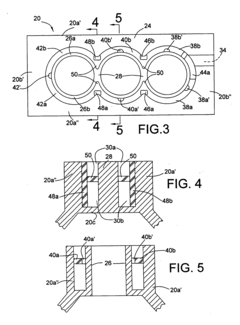

- The engine block assembly incorporates a longitudinally extending coolant baffle with sealing shoulders to direct and seal coolant flow within the water jacket, ensuring effective circulation and heat removal by engaging the baffle sealing face with opposed sealing shoulders, which are designed to accommodate non-parallel side walls and provide a passive seal.

Cylinder block cooling arrangement for multi-cylinder internal combustion engine

PatentInactiveUS20050235930A1

Innovation

- An insert with arcuate members and support members is placed in the engine block's water jacket to create vertically offset sub-jackets, optimizing coolant flow and distribution based on engine speed, enhancing cooling efficiency at conjoined and upper cylinder regions.

Thermal Management Impact

The thermal management impact of coolant flow distribution in engine blocks is a critical factor in overall engine performance and longevity. Proper coolant flow ensures efficient heat dissipation, preventing localized hot spots and maintaining optimal operating temperatures across the engine. This distribution directly affects the thermal stress on engine components, influencing their durability and lifespan.

Effective coolant flow distribution contributes to uniform temperature control throughout the engine block. This uniformity is essential for maintaining consistent thermal expansion rates, which in turn helps preserve the structural integrity of the engine and reduces the risk of warping or cracking. Moreover, it plays a crucial role in preventing thermal fatigue, a common cause of engine failure in high-performance and heavy-duty applications.

The impact of coolant flow distribution extends beyond the engine block itself. It significantly influences the efficiency of the entire cooling system, including radiators and heat exchangers. Optimized flow patterns can enhance the overall heat transfer capacity of the system, potentially allowing for more compact cooling designs or improved fuel efficiency through reduced parasitic losses.

In modern engine designs, particularly those with high power density or those used in extreme operating conditions, the thermal management impact becomes even more pronounced. Adequate coolant flow distribution is essential for managing the increased heat loads associated with turbocharging, direct injection, and higher compression ratios. It also plays a vital role in supporting advanced combustion strategies and emissions control technologies, which often rely on precise temperature control.

Furthermore, the thermal management impact of coolant flow distribution has implications for engine warm-up times and cold-start emissions. Properly designed flow patterns can accelerate engine warm-up, reducing fuel consumption and emissions during the critical initial operating period. This aspect is particularly relevant in the context of increasingly stringent emissions regulations and the growing focus on real-world driving emissions.

Effective coolant flow distribution contributes to uniform temperature control throughout the engine block. This uniformity is essential for maintaining consistent thermal expansion rates, which in turn helps preserve the structural integrity of the engine and reduces the risk of warping or cracking. Moreover, it plays a crucial role in preventing thermal fatigue, a common cause of engine failure in high-performance and heavy-duty applications.

The impact of coolant flow distribution extends beyond the engine block itself. It significantly influences the efficiency of the entire cooling system, including radiators and heat exchangers. Optimized flow patterns can enhance the overall heat transfer capacity of the system, potentially allowing for more compact cooling designs or improved fuel efficiency through reduced parasitic losses.

In modern engine designs, particularly those with high power density or those used in extreme operating conditions, the thermal management impact becomes even more pronounced. Adequate coolant flow distribution is essential for managing the increased heat loads associated with turbocharging, direct injection, and higher compression ratios. It also plays a vital role in supporting advanced combustion strategies and emissions control technologies, which often rely on precise temperature control.

Furthermore, the thermal management impact of coolant flow distribution has implications for engine warm-up times and cold-start emissions. Properly designed flow patterns can accelerate engine warm-up, reducing fuel consumption and emissions during the critical initial operating period. This aspect is particularly relevant in the context of increasingly stringent emissions regulations and the growing focus on real-world driving emissions.

Simulation Software Advancements

Simulation software advancements have revolutionized the evaluation of coolant flow distribution in engine blocks, offering unprecedented accuracy and efficiency. Modern computational fluid dynamics (CFD) tools have evolved to handle complex geometries and multi-phase flows, enabling engineers to model and analyze coolant behavior with remarkable precision.

Recent developments in mesh generation algorithms have significantly improved the ability to create high-quality computational grids for intricate engine block designs. Adaptive meshing techniques now allow for automatic refinement in critical areas, such as narrow passages and heat-sensitive regions, ensuring optimal resolution where it matters most.

Parallel computing capabilities have dramatically reduced simulation times, allowing for more extensive parametric studies and design iterations. GPU acceleration, in particular, has enabled real-time visualization of flow patterns, enhancing engineers' ability to identify potential issues quickly.

Advanced turbulence models, specifically tailored for automotive cooling systems, have been integrated into leading CFD packages. These models account for the unique characteristics of coolant flow in engine blocks, including temperature-dependent properties and phase change phenomena.

Machine learning algorithms are increasingly being incorporated into simulation workflows, offering predictive capabilities for optimizing coolant jacket designs. These AI-driven tools can rapidly explore vast design spaces and suggest improvements based on historical data and simulation results.

Coupled thermal-fluid simulations have become more robust, allowing for simultaneous analysis of coolant flow and heat transfer within the engine block. This integrated approach provides a more comprehensive understanding of the cooling system's performance under various operating conditions.

Virtual reality (VR) and augmented reality (AR) interfaces are emerging as powerful tools for visualizing and interacting with simulation results. Engineers can now immerse themselves in 3D representations of coolant flow, gaining intuitive insights that were previously difficult to obtain from traditional 2D plots.

Advancements in cloud-based simulation platforms have democratized access to high-performance computing resources, enabling smaller companies and research institutions to leverage sophisticated CFD tools for engine block analysis. This has accelerated innovation and knowledge sharing across the automotive industry.

Recent developments in mesh generation algorithms have significantly improved the ability to create high-quality computational grids for intricate engine block designs. Adaptive meshing techniques now allow for automatic refinement in critical areas, such as narrow passages and heat-sensitive regions, ensuring optimal resolution where it matters most.

Parallel computing capabilities have dramatically reduced simulation times, allowing for more extensive parametric studies and design iterations. GPU acceleration, in particular, has enabled real-time visualization of flow patterns, enhancing engineers' ability to identify potential issues quickly.

Advanced turbulence models, specifically tailored for automotive cooling systems, have been integrated into leading CFD packages. These models account for the unique characteristics of coolant flow in engine blocks, including temperature-dependent properties and phase change phenomena.

Machine learning algorithms are increasingly being incorporated into simulation workflows, offering predictive capabilities for optimizing coolant jacket designs. These AI-driven tools can rapidly explore vast design spaces and suggest improvements based on historical data and simulation results.

Coupled thermal-fluid simulations have become more robust, allowing for simultaneous analysis of coolant flow and heat transfer within the engine block. This integrated approach provides a more comprehensive understanding of the cooling system's performance under various operating conditions.

Virtual reality (VR) and augmented reality (AR) interfaces are emerging as powerful tools for visualizing and interacting with simulation results. Engineers can now immerse themselves in 3D representations of coolant flow, gaining intuitive insights that were previously difficult to obtain from traditional 2D plots.

Advancements in cloud-based simulation platforms have democratized access to high-performance computing resources, enabling smaller companies and research institutions to leverage sophisticated CFD tools for engine block analysis. This has accelerated innovation and knowledge sharing across the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!