Engine Block Machining Tolerances: Measurement And QA Procedures

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Machining Evolution and Objectives

Engine block machining has undergone significant evolution since the early days of automotive manufacturing. Initially, engine blocks were cast with minimal machining required. However, as engine performance demands increased, so did the need for precision in manufacturing processes. The evolution of engine block machining can be traced through several key phases, each marked by advancements in technology and manufacturing techniques.

In the 1950s and 1960s, manual machining processes were prevalent, with skilled machinists using lathes and milling machines to achieve the required tolerances. This era was characterized by time-consuming processes and limited consistency in production. The 1970s and 1980s saw the introduction of computer numerical control (CNC) machines, which revolutionized engine block machining by improving accuracy and repeatability.

The 1990s brought about the integration of coordinate measuring machines (CMMs) into the production process, allowing for more precise measurement and quality control. This period also saw the development of more sophisticated cutting tools and coolants, enabling faster machining speeds and improved surface finishes.

The turn of the millennium marked the beginning of the digital manufacturing era, with the introduction of advanced CAD/CAM systems and simulation software. These tools allowed engineers to optimize machining processes virtually before implementation, significantly reducing development time and costs.

Today, the objectives of engine block machining are focused on achieving ever-tighter tolerances while maintaining high production efficiency. Key goals include minimizing weight without compromising strength, improving fuel efficiency, and reducing emissions. Advanced machining centers now incorporate in-line measurement systems and adaptive control technologies to ensure consistent quality throughout the production run.

Looking forward, the industry is moving towards smart manufacturing concepts, integrating Internet of Things (IoT) devices and artificial intelligence to further enhance precision and efficiency. The ultimate objective is to achieve near-perfect tolerances consistently, with real-time quality assurance and predictive maintenance capabilities.

As engine designs continue to evolve, particularly with the rise of electric and hybrid powertrains, machining processes must adapt to new materials and geometries. The focus on lightweight construction and thermal management presents new challenges and opportunities for innovation in engine block machining technologies.

In the 1950s and 1960s, manual machining processes were prevalent, with skilled machinists using lathes and milling machines to achieve the required tolerances. This era was characterized by time-consuming processes and limited consistency in production. The 1970s and 1980s saw the introduction of computer numerical control (CNC) machines, which revolutionized engine block machining by improving accuracy and repeatability.

The 1990s brought about the integration of coordinate measuring machines (CMMs) into the production process, allowing for more precise measurement and quality control. This period also saw the development of more sophisticated cutting tools and coolants, enabling faster machining speeds and improved surface finishes.

The turn of the millennium marked the beginning of the digital manufacturing era, with the introduction of advanced CAD/CAM systems and simulation software. These tools allowed engineers to optimize machining processes virtually before implementation, significantly reducing development time and costs.

Today, the objectives of engine block machining are focused on achieving ever-tighter tolerances while maintaining high production efficiency. Key goals include minimizing weight without compromising strength, improving fuel efficiency, and reducing emissions. Advanced machining centers now incorporate in-line measurement systems and adaptive control technologies to ensure consistent quality throughout the production run.

Looking forward, the industry is moving towards smart manufacturing concepts, integrating Internet of Things (IoT) devices and artificial intelligence to further enhance precision and efficiency. The ultimate objective is to achieve near-perfect tolerances consistently, with real-time quality assurance and predictive maintenance capabilities.

As engine designs continue to evolve, particularly with the rise of electric and hybrid powertrains, machining processes must adapt to new materials and geometries. The focus on lightweight construction and thermal management presents new challenges and opportunities for innovation in engine block machining technologies.

Market Demand for Precision Engine Components

The demand for precision engine components has been steadily increasing in recent years, driven by several key factors in the automotive and industrial sectors. Engine manufacturers are constantly striving to improve fuel efficiency, reduce emissions, and enhance overall performance, which necessitates tighter tolerances and higher precision in engine block machining.

In the automotive industry, the push for more fuel-efficient vehicles has led to the development of smaller, more powerful engines. These engines require extremely precise machining to maintain optimal compression ratios and minimize friction losses. The growing market for hybrid and electric vehicles also demands high-precision components for their internal combustion engines, as these powertrains often operate under more varied and demanding conditions.

The commercial vehicle sector, including trucks and buses, is another significant driver of demand for precision engine components. With stricter emissions regulations being implemented globally, engine manufacturers are required to produce more efficient and cleaner engines. This has resulted in the adoption of advanced technologies such as high-pressure fuel injection systems and variable valve timing, which rely heavily on precisely machined engine blocks.

In the industrial sector, the demand for precision engine components is fueled by the need for more reliable and efficient power generation equipment. Stationary engines used in power plants, marine applications, and off-highway equipment require high-precision machining to ensure longevity and optimal performance under demanding operating conditions.

The aerospace industry also contributes to the growing market for precision engine components. Aircraft engines must meet stringent safety and performance standards, driving the need for extremely tight tolerances in engine block machining. As the aerospace sector continues to expand, particularly in emerging markets, the demand for high-precision engine components is expected to grow accordingly.

Geographically, the market for precision engine components is strongest in regions with established automotive and industrial manufacturing bases. North America, Europe, and East Asia are currently the largest markets, with China showing particularly rapid growth due to its expanding automotive and industrial sectors. Emerging markets in Southeast Asia and South America are also expected to contribute significantly to future demand growth.

The increasing focus on quality assurance and reliability across industries has further bolstered the demand for precision-machined engine components. Manufacturers are investing in advanced measurement and quality control technologies to ensure consistent adherence to tight tolerances, driving innovation in both machining processes and quality assurance procedures.

In the automotive industry, the push for more fuel-efficient vehicles has led to the development of smaller, more powerful engines. These engines require extremely precise machining to maintain optimal compression ratios and minimize friction losses. The growing market for hybrid and electric vehicles also demands high-precision components for their internal combustion engines, as these powertrains often operate under more varied and demanding conditions.

The commercial vehicle sector, including trucks and buses, is another significant driver of demand for precision engine components. With stricter emissions regulations being implemented globally, engine manufacturers are required to produce more efficient and cleaner engines. This has resulted in the adoption of advanced technologies such as high-pressure fuel injection systems and variable valve timing, which rely heavily on precisely machined engine blocks.

In the industrial sector, the demand for precision engine components is fueled by the need for more reliable and efficient power generation equipment. Stationary engines used in power plants, marine applications, and off-highway equipment require high-precision machining to ensure longevity and optimal performance under demanding operating conditions.

The aerospace industry also contributes to the growing market for precision engine components. Aircraft engines must meet stringent safety and performance standards, driving the need for extremely tight tolerances in engine block machining. As the aerospace sector continues to expand, particularly in emerging markets, the demand for high-precision engine components is expected to grow accordingly.

Geographically, the market for precision engine components is strongest in regions with established automotive and industrial manufacturing bases. North America, Europe, and East Asia are currently the largest markets, with China showing particularly rapid growth due to its expanding automotive and industrial sectors. Emerging markets in Southeast Asia and South America are also expected to contribute significantly to future demand growth.

The increasing focus on quality assurance and reliability across industries has further bolstered the demand for precision-machined engine components. Manufacturers are investing in advanced measurement and quality control technologies to ensure consistent adherence to tight tolerances, driving innovation in both machining processes and quality assurance procedures.

Current Challenges in Engine Block Machining

Engine block machining faces several significant challenges in today's automotive manufacturing landscape. One of the primary issues is achieving and maintaining tight tolerances across complex geometries. As engine designs become more sophisticated to meet stringent emissions and performance standards, the precision required in machining critical surfaces has increased dramatically.

The demand for lighter, more fuel-efficient engines has led to the adoption of thinner-walled designs and advanced materials, which pose additional machining difficulties. These materials often exhibit different cutting characteristics and require specialized tooling and machining strategies to achieve the desired surface finish and dimensional accuracy.

Another major challenge is the need for consistent quality across high-volume production runs. Engine blocks are typically manufactured in large quantities, and maintaining uniform tolerances across thousands of units is a significant hurdle. Variations in material properties, tool wear, and machine dynamics can all contribute to inconsistencies in the final product.

The integration of in-line measurement and quality assurance procedures presents its own set of challenges. Traditional post-process inspection methods are often too slow and inefficient for modern production lines. Implementing real-time measurement systems that can provide immediate feedback without slowing down the manufacturing process is a complex task that requires advanced sensor technologies and data processing capabilities.

Environmental factors also play a crucial role in machining precision. Temperature fluctuations in the manufacturing environment can cause thermal expansion and contraction of both the workpiece and machine tools, leading to dimensional variations. Controlling these environmental variables to ensure consistent machining results is an ongoing challenge.

Furthermore, the industry faces a skills gap in precision machining. As CNC technology becomes more advanced, there is a growing need for highly skilled operators and programmers who can optimize machining processes and troubleshoot complex issues. Training and retaining this specialized workforce is a significant challenge for many manufacturers.

Lastly, the cost pressures in the automotive industry demand continuous improvements in machining efficiency without compromising quality. Balancing the need for high-precision machining with the requirements for faster cycle times and reduced production costs remains a persistent challenge in engine block manufacturing.

The demand for lighter, more fuel-efficient engines has led to the adoption of thinner-walled designs and advanced materials, which pose additional machining difficulties. These materials often exhibit different cutting characteristics and require specialized tooling and machining strategies to achieve the desired surface finish and dimensional accuracy.

Another major challenge is the need for consistent quality across high-volume production runs. Engine blocks are typically manufactured in large quantities, and maintaining uniform tolerances across thousands of units is a significant hurdle. Variations in material properties, tool wear, and machine dynamics can all contribute to inconsistencies in the final product.

The integration of in-line measurement and quality assurance procedures presents its own set of challenges. Traditional post-process inspection methods are often too slow and inefficient for modern production lines. Implementing real-time measurement systems that can provide immediate feedback without slowing down the manufacturing process is a complex task that requires advanced sensor technologies and data processing capabilities.

Environmental factors also play a crucial role in machining precision. Temperature fluctuations in the manufacturing environment can cause thermal expansion and contraction of both the workpiece and machine tools, leading to dimensional variations. Controlling these environmental variables to ensure consistent machining results is an ongoing challenge.

Furthermore, the industry faces a skills gap in precision machining. As CNC technology becomes more advanced, there is a growing need for highly skilled operators and programmers who can optimize machining processes and troubleshoot complex issues. Training and retaining this specialized workforce is a significant challenge for many manufacturers.

Lastly, the cost pressures in the automotive industry demand continuous improvements in machining efficiency without compromising quality. Balancing the need for high-precision machining with the requirements for faster cycle times and reduced production costs remains a persistent challenge in engine block manufacturing.

Existing QA Procedures for Engine Blocks

01 Precision machining techniques for engine block tolerances

Advanced machining techniques are employed to achieve tight tolerances in engine block manufacturing. These methods include CNC machining, precision boring, and honing processes to ensure accurate cylinder dimensions, surface finish, and alignment. The use of high-precision tools and equipment helps maintain consistency and reduce variations in critical engine block components.- Precision machining techniques for engine blocks: Advanced machining techniques are employed to achieve tight tolerances in engine block manufacturing. These methods include computer-controlled milling, boring, and honing processes to ensure precise dimensions and surface finishes. The use of high-precision tools and equipment allows for consistent and accurate machining of critical engine block features such as cylinder bores, bearing surfaces, and mounting points.

- Thermal management during machining: Temperature control is crucial during engine block machining to maintain dimensional stability and achieve tight tolerances. Techniques such as coolant application, thermal compensation algorithms, and temperature-controlled machining environments are used to minimize thermal expansion and contraction effects. This ensures that the machined components remain within specified tolerances throughout the manufacturing process.

- In-process measurement and quality control: Real-time measurement and quality control systems are integrated into the machining process to monitor and adjust tolerances during engine block production. These systems use sensors, probes, and advanced metrology equipment to continuously measure critical dimensions and surface characteristics. Automated feedback loops allow for immediate adjustments to maintain tight tolerances and ensure consistent quality across production runs.

- Innovative materials and coatings for improved tolerances: The use of advanced materials and coatings in engine block manufacturing contributes to achieving tighter machining tolerances. These may include high-strength alloys, composite materials, or specialized surface treatments that enhance wear resistance and dimensional stability. Such innovations allow for more precise machining and help maintain tolerances over the engine's operational lifetime.

- Adaptive machining strategies for complex geometries: Engine blocks often feature complex geometries that require adaptive machining strategies to maintain tight tolerances. These strategies may involve multi-axis machining, tool path optimization, and dynamic tool compensation. Advanced software and machine learning algorithms are used to analyze part geometry and adjust machining parameters in real-time, ensuring that tolerances are met even for intricate features and varying material properties.

02 Measurement and quality control systems for engine block tolerances

Sophisticated measurement and quality control systems are implemented to monitor and maintain engine block machining tolerances. These systems may include laser scanning, coordinate measuring machines (CMM), and in-line inspection technologies. Real-time data analysis and feedback loops help adjust machining parameters to ensure consistent adherence to specified tolerances throughout the production process.Expand Specific Solutions03 Thermal management considerations in engine block machining

Thermal management plays a crucial role in maintaining machining tolerances for engine blocks. Temperature control systems and strategies are employed to minimize thermal expansion and contraction during the machining process. This includes controlled cooling of the workpiece, temperature-compensated tooling, and environmental control of the machining area to ensure dimensional stability and accuracy.Expand Specific Solutions04 Material selection and treatment for improved machinability

The choice of engine block materials and their treatment significantly impacts machining tolerances. Advanced alloys and heat treatment processes are utilized to enhance machinability while maintaining the required strength and durability. Techniques such as stress relieving and controlled cooling after casting help minimize internal stresses and distortion during machining, leading to improved tolerance control.Expand Specific Solutions05 Adaptive machining strategies for engine block tolerances

Adaptive machining strategies are implemented to compensate for variations in raw castings and maintain tight tolerances during engine block production. These strategies involve real-time adjustments to cutting parameters, tool paths, and machining sequences based on in-process measurements and feedback. Machine learning algorithms and artificial intelligence are increasingly used to optimize these adaptive processes for improved accuracy and efficiency.Expand Specific Solutions

Key Players in Engine Manufacturing Industry

The engine block machining tolerances market is in a mature stage, characterized by established players and well-defined quality assurance procedures. The global market size for precision machining in the automotive sector is substantial, driven by the demand for high-performance engines and stringent emission regulations. Technologically, the field is advanced, with companies like Robert Bosch, Continental Automotive, and Caterpillar leading in innovation. These firms, along with others such as Honda Motor and Renault, have developed sophisticated measurement and QA procedures, integrating advanced sensors, AI-driven analytics, and automated inspection systems to ensure micron-level precision in engine block manufacturing.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced engine block machining systems that utilize high-precision CNC machines and in-line measurement technologies. Their approach integrates real-time quality control with adaptive machining processes. The system employs multiple coordinate measuring machines (CMMs) strategically placed along the production line to continuously monitor critical dimensions[1]. Machine learning algorithms analyze measurement data to detect trends and automatically adjust machining parameters, ensuring tolerances are maintained throughout the production run[3]. Bosch's system also incorporates laser scanning and optical measurement techniques for rapid inspection of complex geometries, allowing for 100% part inspection without compromising production speed[5].

Strengths: High precision, real-time adaptive control, and comprehensive quality assurance. Weaknesses: High initial investment cost and complexity in implementation and maintenance.

Caterpillar, Inc.

Technical Solution: Caterpillar has implemented a comprehensive Engine Block Machining Tolerance system that combines advanced machining techniques with rigorous quality assurance procedures. Their approach utilizes a network of high-precision CNC machining centers equipped with on-machine probing systems for in-process measurement[2]. The company has developed proprietary software that integrates machining data with quality control metrics, allowing for real-time adjustments to maintain tight tolerances. Caterpillar's system also incorporates thermal compensation algorithms to account for temperature-induced dimensional changes during the machining process[4]. Additionally, they employ a final inspection stage using state-of-the-art CMM technology with accuracy levels down to 2 microns for critical engine block features[6].

Strengths: Robust in-process control, high accuracy, and integration of thermal compensation. Weaknesses: System complexity may require specialized training for operators and maintenance personnel.

Innovative Measurement Techniques Analysis

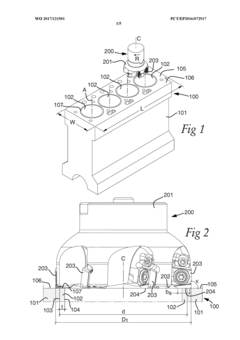

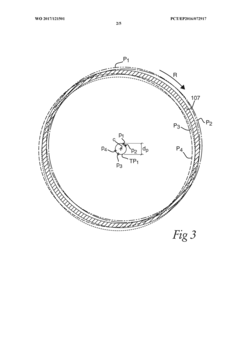

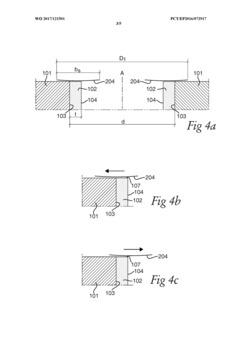

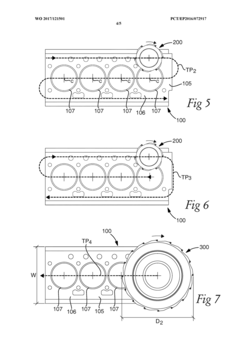

A method for machining a top side of an engine block

PatentWO2017121501A1

Innovation

- A method using a milling tool with a diameter that ensures the cutting edge always overlaps the inner wall of the cylinder liner, employing a helical tool path and wiper inserts to prevent frittering and scratches, and utilizing the same tool for both machining steps with minimum quantity lubrication to improve surface finish and efficiency.

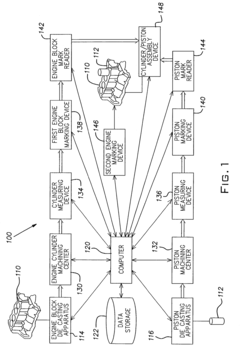

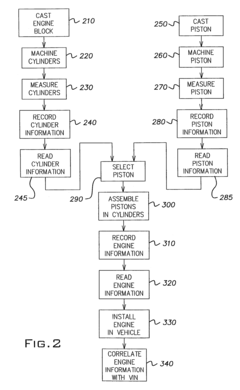

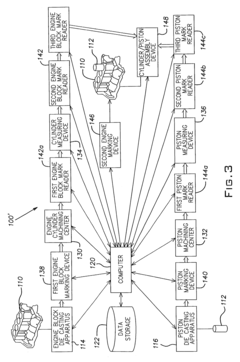

Assembly, tolerance matching and post-manufacturing quality assurance method

PatentInactiveUS6988314B2

Innovation

- A system and method that measures and records the actual diameters of pistons and cylinders, matching them to achieve a predetermined piston clearance tolerance, and correlates this information with a vehicle identification number for easy retrieval in case of engine issues.

Environmental Impact of Machining Processes

The environmental impact of machining processes in engine block manufacturing is a critical consideration in the automotive industry's pursuit of sustainability. Machining operations, particularly those involved in achieving precise tolerances for engine blocks, can have significant environmental implications. These processes often require substantial energy consumption, generate waste materials, and may involve the use of potentially harmful cutting fluids and lubricants.

Energy consumption is a primary concern in machining processes. High-precision machining equipment, such as computer numerical control (CNC) machines, require substantial power to operate. The energy demand is further increased by the need for cooling systems, hydraulic pumps, and auxiliary equipment. As engine block tolerances become tighter, the machining time and energy requirements often increase proportionally, leading to a higher carbon footprint for the manufacturing process.

Waste generation is another significant environmental aspect of engine block machining. Metal chips and swarf produced during cutting operations can be substantial in volume and may contain traces of cutting fluids or coolants. While many of these metal wastes can be recycled, the process of collection, sorting, and recycling itself has environmental implications. Additionally, the fine metal particles generated during machining can pose air quality concerns if not properly controlled.

The use of cutting fluids and lubricants in machining processes presents both environmental and health challenges. These fluids, often containing mineral oils or synthetic compounds, can be harmful if released into the environment. Proper management, recycling, and disposal of these fluids are essential to minimize environmental impact. Moreover, the mist and vapors from these fluids can affect air quality in the manufacturing environment, necessitating effective ventilation and filtration systems.

Water usage in machining processes, particularly for cooling and cleaning, is another environmental consideration. The treatment and disposal of wastewater from these processes require careful management to prevent contamination of water sources. Additionally, the chemicals used in water treatment processes can themselves have environmental implications if not properly handled.

To address these environmental concerns, the industry is increasingly focusing on sustainable machining practices. This includes the development of dry machining techniques, which reduce or eliminate the need for cutting fluids. Minimum quantity lubrication (MQL) systems are also being adopted to minimize fluid usage while maintaining machining efficiency. Furthermore, advancements in machine tool design and control systems are improving energy efficiency and reducing waste generation.

The implementation of closed-loop recycling systems for cutting fluids and metal chips is becoming more common, reducing waste and conserving resources. Additionally, the adoption of more environmentally friendly cutting fluids, such as vegetable-based oils, is gaining traction in the industry. These alternatives offer improved biodegradability and reduced toxicity compared to traditional petroleum-based fluids.

Energy consumption is a primary concern in machining processes. High-precision machining equipment, such as computer numerical control (CNC) machines, require substantial power to operate. The energy demand is further increased by the need for cooling systems, hydraulic pumps, and auxiliary equipment. As engine block tolerances become tighter, the machining time and energy requirements often increase proportionally, leading to a higher carbon footprint for the manufacturing process.

Waste generation is another significant environmental aspect of engine block machining. Metal chips and swarf produced during cutting operations can be substantial in volume and may contain traces of cutting fluids or coolants. While many of these metal wastes can be recycled, the process of collection, sorting, and recycling itself has environmental implications. Additionally, the fine metal particles generated during machining can pose air quality concerns if not properly controlled.

The use of cutting fluids and lubricants in machining processes presents both environmental and health challenges. These fluids, often containing mineral oils or synthetic compounds, can be harmful if released into the environment. Proper management, recycling, and disposal of these fluids are essential to minimize environmental impact. Moreover, the mist and vapors from these fluids can affect air quality in the manufacturing environment, necessitating effective ventilation and filtration systems.

Water usage in machining processes, particularly for cooling and cleaning, is another environmental consideration. The treatment and disposal of wastewater from these processes require careful management to prevent contamination of water sources. Additionally, the chemicals used in water treatment processes can themselves have environmental implications if not properly handled.

To address these environmental concerns, the industry is increasingly focusing on sustainable machining practices. This includes the development of dry machining techniques, which reduce or eliminate the need for cutting fluids. Minimum quantity lubrication (MQL) systems are also being adopted to minimize fluid usage while maintaining machining efficiency. Furthermore, advancements in machine tool design and control systems are improving energy efficiency and reducing waste generation.

The implementation of closed-loop recycling systems for cutting fluids and metal chips is becoming more common, reducing waste and conserving resources. Additionally, the adoption of more environmentally friendly cutting fluids, such as vegetable-based oils, is gaining traction in the industry. These alternatives offer improved biodegradability and reduced toxicity compared to traditional petroleum-based fluids.

Industry Standards and Regulations

Industry standards and regulations play a crucial role in ensuring the quality and consistency of engine block machining tolerances. These standards are established by various organizations and regulatory bodies to maintain safety, performance, and reliability across the automotive industry.

The International Organization for Standardization (ISO) has developed several standards relevant to engine block machining tolerances. ISO 1101 provides guidelines for geometrical tolerancing, which is essential for maintaining precise dimensions in engine block manufacturing. Additionally, ISO 2768 sets general tolerances for linear and angular dimensions, which are applicable to engine block machining processes.

In the United States, the Society of Automotive Engineers (SAE) has established standards specific to engine manufacturing. SAE J1086 outlines the recommended practices for engine testing and performance evaluation, which indirectly influence machining tolerances. The American Society of Mechanical Engineers (ASME) also contributes to the field with standards such as ASME Y14.5, which defines dimensioning and tolerancing principles.

European regulations, including those set by the European Committee for Standardization (CEN), provide additional guidelines for engine manufacturing. The EN 1591 standard, for instance, focuses on flanges and their joints, which are critical components in engine block assembly.

Quality assurance procedures for engine block machining are often guided by ISO 9001 standards, which provide a framework for quality management systems. These standards ensure that manufacturers implement consistent processes for measuring and maintaining machining tolerances.

Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe also influence engine block manufacturing standards. Their emissions regulations indirectly affect machining tolerances by requiring precise engine components to meet stringent performance and efficiency criteria.

Compliance with these standards and regulations is typically verified through rigorous testing and certification processes. Many manufacturers employ third-party testing laboratories to ensure their engine blocks meet or exceed the required tolerances. This independent verification helps maintain industry-wide consistency and consumer confidence in engine quality.

As technology advances, these standards and regulations are periodically reviewed and updated to reflect new manufacturing capabilities and environmental concerns. This ongoing evolution ensures that engine block machining tolerances continue to improve, leading to more efficient and reliable engines across the automotive industry.

The International Organization for Standardization (ISO) has developed several standards relevant to engine block machining tolerances. ISO 1101 provides guidelines for geometrical tolerancing, which is essential for maintaining precise dimensions in engine block manufacturing. Additionally, ISO 2768 sets general tolerances for linear and angular dimensions, which are applicable to engine block machining processes.

In the United States, the Society of Automotive Engineers (SAE) has established standards specific to engine manufacturing. SAE J1086 outlines the recommended practices for engine testing and performance evaluation, which indirectly influence machining tolerances. The American Society of Mechanical Engineers (ASME) also contributes to the field with standards such as ASME Y14.5, which defines dimensioning and tolerancing principles.

European regulations, including those set by the European Committee for Standardization (CEN), provide additional guidelines for engine manufacturing. The EN 1591 standard, for instance, focuses on flanges and their joints, which are critical components in engine block assembly.

Quality assurance procedures for engine block machining are often guided by ISO 9001 standards, which provide a framework for quality management systems. These standards ensure that manufacturers implement consistent processes for measuring and maintaining machining tolerances.

Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe also influence engine block manufacturing standards. Their emissions regulations indirectly affect machining tolerances by requiring precise engine components to meet stringent performance and efficiency criteria.

Compliance with these standards and regulations is typically verified through rigorous testing and certification processes. Many manufacturers employ third-party testing laboratories to ensure their engine blocks meet or exceed the required tolerances. This independent verification helps maintain industry-wide consistency and consumer confidence in engine quality.

As technology advances, these standards and regulations are periodically reviewed and updated to reflect new manufacturing capabilities and environmental concerns. This ongoing evolution ensures that engine block machining tolerances continue to improve, leading to more efficient and reliable engines across the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!