Engine Block Casting Defect Detection: NDT Methods And Thresholds

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Casting Defect Detection Background and Objectives

Engine block casting defect detection has become a critical aspect of quality control in the automotive manufacturing industry. The process of casting engine blocks is complex and prone to various defects that can significantly impact the performance, durability, and safety of the final product. As the demand for high-performance, fuel-efficient engines continues to grow, the need for accurate and reliable defect detection methods has become paramount.

The primary objective of this technical research is to explore and evaluate non-destructive testing (NDT) methods and their corresponding thresholds for detecting casting defects in engine blocks. This investigation aims to identify the most effective techniques for early detection of flaws, thereby improving overall product quality and reducing manufacturing costs associated with defective parts.

Historically, engine block casting has relied on traditional inspection methods, such as visual examination and dimensional measurements. However, these techniques are limited in their ability to detect internal defects and micro-flaws that can lead to catastrophic failures. The evolution of NDT methods has opened up new possibilities for comprehensive defect detection, enabling manufacturers to identify issues that were previously undetectable.

The technological landscape of casting defect detection has seen significant advancements in recent years. From ultrasonic testing and radiography to eddy current and thermography, a wide array of NDT methods have been developed and refined. Each of these techniques offers unique advantages in terms of sensitivity, speed, and applicability to different types of defects.

As we delve into this research, we will explore the current state of engine block casting defect detection, focusing on the most promising NDT methods and their respective thresholds. We will examine how these technologies can be integrated into existing manufacturing processes to enhance quality control and reduce the likelihood of defective parts reaching the market.

Furthermore, this study will investigate the potential for combining multiple NDT methods to create a more robust and comprehensive detection system. By leveraging the strengths of various techniques, it may be possible to develop a multi-modal approach that addresses the full spectrum of potential casting defects.

The ultimate goal of this research is to establish a set of best practices and recommended thresholds for engine block casting defect detection. By doing so, we aim to contribute to the advancement of automotive manufacturing processes, ensuring higher quality standards and improved reliability of engine components.

The primary objective of this technical research is to explore and evaluate non-destructive testing (NDT) methods and their corresponding thresholds for detecting casting defects in engine blocks. This investigation aims to identify the most effective techniques for early detection of flaws, thereby improving overall product quality and reducing manufacturing costs associated with defective parts.

Historically, engine block casting has relied on traditional inspection methods, such as visual examination and dimensional measurements. However, these techniques are limited in their ability to detect internal defects and micro-flaws that can lead to catastrophic failures. The evolution of NDT methods has opened up new possibilities for comprehensive defect detection, enabling manufacturers to identify issues that were previously undetectable.

The technological landscape of casting defect detection has seen significant advancements in recent years. From ultrasonic testing and radiography to eddy current and thermography, a wide array of NDT methods have been developed and refined. Each of these techniques offers unique advantages in terms of sensitivity, speed, and applicability to different types of defects.

As we delve into this research, we will explore the current state of engine block casting defect detection, focusing on the most promising NDT methods and their respective thresholds. We will examine how these technologies can be integrated into existing manufacturing processes to enhance quality control and reduce the likelihood of defective parts reaching the market.

Furthermore, this study will investigate the potential for combining multiple NDT methods to create a more robust and comprehensive detection system. By leveraging the strengths of various techniques, it may be possible to develop a multi-modal approach that addresses the full spectrum of potential casting defects.

The ultimate goal of this research is to establish a set of best practices and recommended thresholds for engine block casting defect detection. By doing so, we aim to contribute to the advancement of automotive manufacturing processes, ensuring higher quality standards and improved reliability of engine components.

Market Demand for Engine Block Quality Assurance

The demand for engine block quality assurance has been steadily increasing in recent years, driven by several key factors in the automotive industry. Manufacturers are facing mounting pressure to produce high-performance, fuel-efficient engines while simultaneously reducing production costs and meeting stringent environmental regulations. This has led to a growing emphasis on detecting and preventing casting defects in engine blocks, which can significantly impact engine performance, durability, and overall vehicle reliability.

The global automotive engine market is projected to reach a substantial value in the coming years, with a significant portion attributed to engine block production. As vehicles become more complex and consumers demand higher quality and longer-lasting products, the need for advanced quality assurance methods in engine block manufacturing has become paramount. This trend is particularly evident in emerging markets, where rapid industrialization and increasing disposable incomes are fueling the demand for automobiles.

Non-destructive testing (NDT) methods for engine block casting defect detection have gained considerable traction in the market. These techniques allow manufacturers to identify flaws without damaging the components, thereby reducing waste and improving production efficiency. The adoption of NDT methods has been further accelerated by the automotive industry's shift towards lightweight materials and complex engine designs, which require more sophisticated quality control measures.

The market demand for engine block quality assurance is also being shaped by the rise of electric vehicles (EVs). While EVs do not require traditional internal combustion engines, they still utilize components similar to engine blocks for housing electric motors and power electronics. This transition has created a new segment within the quality assurance market, focusing on the unique requirements of EV powertrains.

Regulatory pressures play a significant role in driving the demand for enhanced engine block quality assurance. Stricter emissions standards and fuel efficiency requirements have pushed manufacturers to optimize engine performance, making the detection of even minor defects crucial. Additionally, safety regulations and consumer expectations for vehicle reliability have heightened the importance of thorough quality control processes in engine block production.

The aftermarket sector represents another substantial driver for engine block quality assurance. As vehicles age, the demand for replacement engine blocks and components increases, necessitating robust quality control measures to ensure the reliability of aftermarket parts. This has led to a growing market for NDT equipment and services in the automotive aftermarket industry.

In conclusion, the market demand for engine block quality assurance is robust and multifaceted, driven by technological advancements, regulatory requirements, and changing consumer expectations. As the automotive industry continues to evolve, the importance of accurate and efficient defect detection in engine block casting is expected to grow, creating opportunities for innovation in NDT methods and thresholds.

The global automotive engine market is projected to reach a substantial value in the coming years, with a significant portion attributed to engine block production. As vehicles become more complex and consumers demand higher quality and longer-lasting products, the need for advanced quality assurance methods in engine block manufacturing has become paramount. This trend is particularly evident in emerging markets, where rapid industrialization and increasing disposable incomes are fueling the demand for automobiles.

Non-destructive testing (NDT) methods for engine block casting defect detection have gained considerable traction in the market. These techniques allow manufacturers to identify flaws without damaging the components, thereby reducing waste and improving production efficiency. The adoption of NDT methods has been further accelerated by the automotive industry's shift towards lightweight materials and complex engine designs, which require more sophisticated quality control measures.

The market demand for engine block quality assurance is also being shaped by the rise of electric vehicles (EVs). While EVs do not require traditional internal combustion engines, they still utilize components similar to engine blocks for housing electric motors and power electronics. This transition has created a new segment within the quality assurance market, focusing on the unique requirements of EV powertrains.

Regulatory pressures play a significant role in driving the demand for enhanced engine block quality assurance. Stricter emissions standards and fuel efficiency requirements have pushed manufacturers to optimize engine performance, making the detection of even minor defects crucial. Additionally, safety regulations and consumer expectations for vehicle reliability have heightened the importance of thorough quality control processes in engine block production.

The aftermarket sector represents another substantial driver for engine block quality assurance. As vehicles age, the demand for replacement engine blocks and components increases, necessitating robust quality control measures to ensure the reliability of aftermarket parts. This has led to a growing market for NDT equipment and services in the automotive aftermarket industry.

In conclusion, the market demand for engine block quality assurance is robust and multifaceted, driven by technological advancements, regulatory requirements, and changing consumer expectations. As the automotive industry continues to evolve, the importance of accurate and efficient defect detection in engine block casting is expected to grow, creating opportunities for innovation in NDT methods and thresholds.

Current NDT Methods and Challenges in Casting Inspection

Non-destructive testing (NDT) methods play a crucial role in the quality control of engine block castings. Current inspection techniques primarily focus on detecting internal defects, surface imperfections, and dimensional inaccuracies. The most commonly employed NDT methods for engine block casting inspection include radiographic testing (RT), ultrasonic testing (UT), and visual inspection.

Radiographic testing utilizes X-rays or gamma rays to penetrate the casting and reveal internal defects such as porosity, inclusions, and shrinkage cavities. This method provides a comprehensive view of the casting's internal structure but requires specialized equipment and safety precautions due to radiation exposure. The challenge lies in interpreting complex geometries and achieving consistent image quality across varying material thicknesses.

Ultrasonic testing employs high-frequency sound waves to detect internal flaws and measure material thickness. It is particularly effective in identifying discontinuities, cracks, and laminations within the casting. However, the complex geometry of engine blocks can create difficulties in signal interpretation and probe positioning, potentially leading to missed defects or false indications.

Visual inspection, often enhanced by magnetic particle testing or dye penetrant testing, is used to detect surface defects such as cracks, cold shuts, and misruns. While these methods are relatively simple and cost-effective, they are limited to surface or near-surface defects and rely heavily on inspector expertise and environmental conditions.

One of the primary challenges in casting inspection is establishing appropriate acceptance criteria and defect thresholds. The diversity of engine block designs and materials necessitates tailored inspection protocols, making standardization difficult. Additionally, the interpretation of NDT results often requires significant expertise, leading to potential variability in defect classification and acceptance decisions.

Another challenge is the need for high-speed, automated inspection systems to meet production demands. While automated systems can improve consistency and throughput, they may struggle with complex geometries and subtle defect indications that human inspectors can more readily identify.

The integration of multiple NDT methods to create a comprehensive inspection strategy presents both opportunities and challenges. Combining techniques like CT scanning with traditional methods can provide more detailed defect characterization but increases complexity and cost.

Emerging technologies, such as phased array ultrasonic testing and digital radiography, offer improved defect detection capabilities and data management. However, their implementation requires significant investment in equipment and training, as well as validation against established methods.

As the automotive industry moves towards lighter, more efficient engine designs, the challenges in casting inspection are likely to intensify. Thinner walls and more intricate internal structures will demand even greater precision in defect detection and characterization, pushing the limits of current NDT methods and thresholds.

Radiographic testing utilizes X-rays or gamma rays to penetrate the casting and reveal internal defects such as porosity, inclusions, and shrinkage cavities. This method provides a comprehensive view of the casting's internal structure but requires specialized equipment and safety precautions due to radiation exposure. The challenge lies in interpreting complex geometries and achieving consistent image quality across varying material thicknesses.

Ultrasonic testing employs high-frequency sound waves to detect internal flaws and measure material thickness. It is particularly effective in identifying discontinuities, cracks, and laminations within the casting. However, the complex geometry of engine blocks can create difficulties in signal interpretation and probe positioning, potentially leading to missed defects or false indications.

Visual inspection, often enhanced by magnetic particle testing or dye penetrant testing, is used to detect surface defects such as cracks, cold shuts, and misruns. While these methods are relatively simple and cost-effective, they are limited to surface or near-surface defects and rely heavily on inspector expertise and environmental conditions.

One of the primary challenges in casting inspection is establishing appropriate acceptance criteria and defect thresholds. The diversity of engine block designs and materials necessitates tailored inspection protocols, making standardization difficult. Additionally, the interpretation of NDT results often requires significant expertise, leading to potential variability in defect classification and acceptance decisions.

Another challenge is the need for high-speed, automated inspection systems to meet production demands. While automated systems can improve consistency and throughput, they may struggle with complex geometries and subtle defect indications that human inspectors can more readily identify.

The integration of multiple NDT methods to create a comprehensive inspection strategy presents both opportunities and challenges. Combining techniques like CT scanning with traditional methods can provide more detailed defect characterization but increases complexity and cost.

Emerging technologies, such as phased array ultrasonic testing and digital radiography, offer improved defect detection capabilities and data management. However, their implementation requires significant investment in equipment and training, as well as validation against established methods.

As the automotive industry moves towards lighter, more efficient engine designs, the challenges in casting inspection are likely to intensify. Thinner walls and more intricate internal structures will demand even greater precision in defect detection and characterization, pushing the limits of current NDT methods and thresholds.

Existing NDT Solutions for Engine Block Inspection

01 Visual inspection systems for engine block casting defects

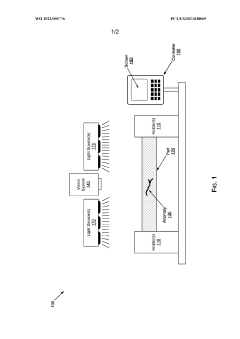

Advanced visual inspection systems are employed to detect defects in engine block castings. These systems use high-resolution cameras and sophisticated image processing algorithms to identify surface imperfections, cracks, and other visible defects. The technology allows for rapid and accurate detection of flaws that may compromise the integrity of the engine block.- Visual inspection systems for engine block casting defects: Advanced visual inspection systems are employed to detect defects in engine block castings. These systems use high-resolution cameras and sophisticated image processing algorithms to identify surface imperfections, porosity, and other visible defects. The technology allows for rapid and accurate detection of flaws that may compromise the integrity of the engine block.

- X-ray and CT scanning for internal defect detection: X-ray and computed tomography (CT) scanning techniques are utilized to detect internal defects in engine block castings. These non-destructive testing methods can reveal hidden flaws such as voids, inclusions, and cracks that are not visible on the surface. The technology provides a comprehensive analysis of the casting's internal structure, ensuring the overall quality of the engine block.

- Ultrasonic testing for engine block defect detection: Ultrasonic testing is employed to detect defects in engine block castings. This method uses high-frequency sound waves to penetrate the material and identify internal flaws. The technology is particularly effective in detecting discontinuities, cracks, and other structural abnormalities that may affect the performance and durability of the engine block.

- In-process monitoring and real-time defect detection: Advanced monitoring systems are integrated into the engine block casting process to detect defects in real-time. These systems use sensors, thermal imaging, and other technologies to continuously monitor the casting process and identify potential issues as they occur. This approach allows for immediate corrective actions and helps prevent the production of defective engine blocks.

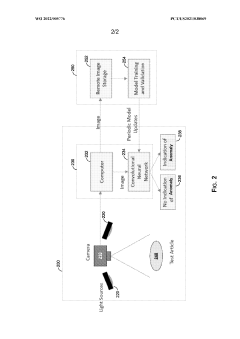

- Machine learning and AI-based defect detection: Machine learning and artificial intelligence algorithms are applied to enhance the accuracy and efficiency of engine block casting defect detection. These advanced technologies can analyze complex patterns in inspection data, learn from historical defect information, and improve the overall detection capabilities. The use of AI-driven systems enables more precise identification of subtle defects and reduces false positives in the inspection process.

02 Non-destructive testing methods for internal defects

Non-destructive testing techniques are utilized to detect internal defects in engine block castings. These methods include ultrasonic testing, X-ray imaging, and computed tomography, which can reveal hidden flaws such as porosity, inclusions, and internal cracks without damaging the casting. These techniques provide comprehensive inspection of the engine block's internal structure.Expand Specific Solutions03 Automated defect detection using machine learning

Machine learning algorithms are implemented to enhance the accuracy and efficiency of defect detection in engine block castings. These AI-powered systems can analyze complex patterns and learn from historical data to identify both known and novel defect types. The use of machine learning significantly reduces false positives and improves overall detection rates.Expand Specific Solutions04 In-line inspection during the casting process

Real-time monitoring and inspection systems are integrated into the engine block casting production line. These systems use sensors and advanced analytics to detect defects as they occur during the casting process. This approach allows for immediate corrective actions, reducing waste and improving overall production quality.Expand Specific Solutions05 Thermal imaging for defect detection

Thermal imaging technology is employed to identify defects in engine block castings. This method detects temperature variations that may indicate the presence of flaws such as inclusions, cracks, or areas of incomplete solidification. Thermal imaging can be particularly effective for detecting defects that may not be visible through conventional visual inspection methods.Expand Specific Solutions

Key Players in NDT Equipment and Automotive Casting Industries

The engine block casting defect detection market is in a growth phase, driven by increasing demand for quality assurance in automotive manufacturing. The market size is expanding as more manufacturers adopt advanced non-destructive testing (NDT) methods. Technologically, the field is evolving rapidly, with companies like Robert Bosch, Continental Automotive, and Siemens leading innovation in NDT techniques. These industry leaders are developing more sophisticated detection systems, integrating AI and machine learning to improve accuracy and efficiency. Emerging players like Weichai Power and China FAW are also making significant strides, particularly in the Asian market. The competition is intensifying as companies strive to offer more precise, cost-effective, and automated solutions for defect detection in engine block casting.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Engine Block Casting Defect Detection system utilizing a combination of Non-Destructive Testing (NDT) methods. Their approach integrates ultrasonic testing, eddy current testing, and X-ray computed tomography for comprehensive defect detection[1]. The system employs machine learning algorithms to analyze data from multiple NDT sources, improving detection accuracy and reducing false positives[3]. Ford has established specific thresholds for different types of defects, such as porosity, inclusions, and cracks, based on extensive testing and correlation with engine performance data[5]. The company has also implemented real-time monitoring during the casting process, allowing for immediate adjustments to prevent defect formation[7].

Strengths: Comprehensive multi-method approach, advanced data analytics, and real-time monitoring capabilities. Weaknesses: High initial implementation cost and complexity in integrating multiple NDT methods.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a novel approach to Engine Block Casting Defect Detection using a combination of acoustic emission testing and thermal imaging[2]. Their system utilizes an array of acoustic sensors strategically placed around the casting mold to detect and localize defects in real-time during the solidification process[4]. This is complemented by high-resolution thermal cameras that monitor temperature distribution, identifying potential areas of defect formation due to uneven cooling[6]. Toyota has developed proprietary algorithms that correlate acoustic and thermal data to predict defect likelihood with high accuracy. The company has established dynamic thresholds that adapt based on the specific alloy composition and casting conditions, ensuring optimal sensitivity across different engine block designs[8].

Strengths: Real-time defect detection during casting, non-contact methods reducing wear on equipment, and adaptive thresholds for various designs. Weaknesses: Potential limitations in detecting deep internal defects and sensitivity to environmental noise.

Core Innovations in Casting Defect Detection Techniques

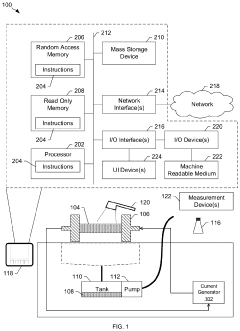

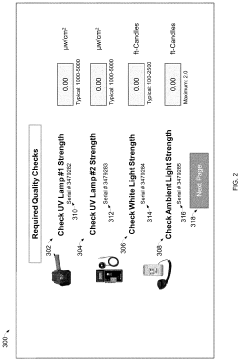

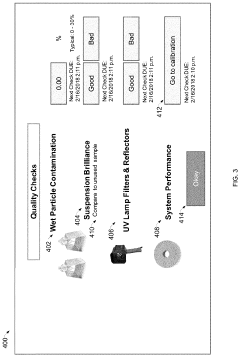

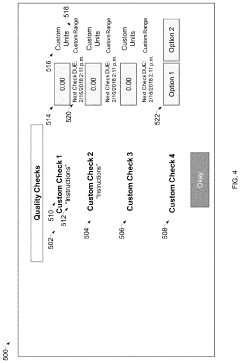

Systems and methods to use customized quality control tasks for non-destructive testing

PatentActiveUS11867774B2

Innovation

- The implementation of a user interface that provides a customizable checklist for operators to perform calibration and measurement checks, flagging problematic results and controlling equipment based on these checks, allowing for tailored task definitions and real-time monitoring within non-destructive testing systems.

Methods and systems for non-destructive testing (NDT) with trained artificial intelligence based processing

PatentWO2022005776A1

Innovation

- Implementing a trained artificial intelligence-based processing system that utilizes deep learning techniques, such as convolutional neural networks (CNNs), to analyze images and identify anomalies without the need for reference images or complex image processing, reducing the reliance on operator expertise and enhancing detection accuracy.

Environmental Impact of NDT Methods in Foundries

The environmental impact of Non-Destructive Testing (NDT) methods in foundries, particularly in the context of engine block casting defect detection, is a critical consideration for sustainable manufacturing practices. While NDT techniques are essential for ensuring product quality and safety, their implementation can have varying effects on the environment.

Radiographic testing, a common NDT method used in foundries, involves the use of ionizing radiation. This technique, while effective for detecting internal defects in engine blocks, raises concerns about radiation exposure and waste management. Proper shielding and controlled exposure times are necessary to minimize risks to workers and the environment. Additionally, the disposal of radioactive materials used in this process requires strict adherence to environmental regulations.

Ultrasonic testing, another widely used NDT method, generally has a lower environmental impact compared to radiographic testing. It uses high-frequency sound waves to detect defects, eliminating the need for hazardous materials. However, the coupling agents used in ultrasonic testing, often oil-based substances, may contribute to water pollution if not properly managed and disposed of.

Magnetic particle inspection, commonly employed for surface and near-surface defect detection in ferromagnetic materials like cast iron engine blocks, utilizes magnetic fields and fine magnetic particles. While this method is relatively eco-friendly, the disposal of used magnetic particles and cleaning solutions must be carefully managed to prevent soil and water contamination.

Dye penetrant testing, effective for detecting surface-breaking defects, involves the use of chemical penetrants and developers. These substances can be potentially harmful to the environment if released untreated. Proper containment, recycling, and disposal systems are crucial to mitigate the risk of soil and groundwater contamination.

Energy consumption is another environmental consideration across all NDT methods. The equipment used in these processes, particularly in automated inspection systems, can contribute significantly to a foundry's overall energy footprint. Implementing energy-efficient technologies and optimizing inspection processes can help reduce this impact.

As the automotive industry moves towards more sustainable practices, there is a growing emphasis on developing and adopting environmentally friendly NDT methods. Research into green NDT technologies, such as biodegradable penetrants and energy-efficient inspection systems, is gaining traction. These innovations aim to maintain high detection standards while minimizing environmental impact.

The thresholds for acceptable defects in engine block castings also play a role in environmental considerations. Overly stringent thresholds may lead to increased rejection rates, resulting in more waste and energy consumption for remanufacturing. Balancing quality requirements with environmental impact is crucial for sustainable foundry operations.

Radiographic testing, a common NDT method used in foundries, involves the use of ionizing radiation. This technique, while effective for detecting internal defects in engine blocks, raises concerns about radiation exposure and waste management. Proper shielding and controlled exposure times are necessary to minimize risks to workers and the environment. Additionally, the disposal of radioactive materials used in this process requires strict adherence to environmental regulations.

Ultrasonic testing, another widely used NDT method, generally has a lower environmental impact compared to radiographic testing. It uses high-frequency sound waves to detect defects, eliminating the need for hazardous materials. However, the coupling agents used in ultrasonic testing, often oil-based substances, may contribute to water pollution if not properly managed and disposed of.

Magnetic particle inspection, commonly employed for surface and near-surface defect detection in ferromagnetic materials like cast iron engine blocks, utilizes magnetic fields and fine magnetic particles. While this method is relatively eco-friendly, the disposal of used magnetic particles and cleaning solutions must be carefully managed to prevent soil and water contamination.

Dye penetrant testing, effective for detecting surface-breaking defects, involves the use of chemical penetrants and developers. These substances can be potentially harmful to the environment if released untreated. Proper containment, recycling, and disposal systems are crucial to mitigate the risk of soil and groundwater contamination.

Energy consumption is another environmental consideration across all NDT methods. The equipment used in these processes, particularly in automated inspection systems, can contribute significantly to a foundry's overall energy footprint. Implementing energy-efficient technologies and optimizing inspection processes can help reduce this impact.

As the automotive industry moves towards more sustainable practices, there is a growing emphasis on developing and adopting environmentally friendly NDT methods. Research into green NDT technologies, such as biodegradable penetrants and energy-efficient inspection systems, is gaining traction. These innovations aim to maintain high detection standards while minimizing environmental impact.

The thresholds for acceptable defects in engine block castings also play a role in environmental considerations. Overly stringent thresholds may lead to increased rejection rates, resulting in more waste and energy consumption for remanufacturing. Balancing quality requirements with environmental impact is crucial for sustainable foundry operations.

Standardization of NDT Thresholds for Engine Block Casting

The standardization of Non-Destructive Testing (NDT) thresholds for engine block casting is a critical aspect of quality control in the automotive industry. This process involves establishing consistent and reliable criteria for detecting defects in engine blocks during the manufacturing process. The primary goal is to ensure that all engine blocks meet the required quality standards before they are integrated into vehicles.

NDT methods commonly used for engine block inspection include ultrasonic testing, radiographic testing, and eddy current testing. Each of these methods has its own set of parameters and thresholds that need to be standardized. Ultrasonic testing, for instance, requires the establishment of specific amplitude thresholds for different types of defects, such as porosity or inclusions. Radiographic testing involves setting density thresholds to identify voids or cracks in the casting.

The standardization process typically begins with a comprehensive analysis of historical data from engine block inspections. This data is used to identify patterns in defect occurrence and to determine the sensitivity of various NDT methods in detecting these defects. Statistical analysis plays a crucial role in this stage, helping to establish baseline thresholds that balance detection accuracy with practical manufacturing constraints.

One of the key challenges in standardizing NDT thresholds is accounting for the variability in engine block designs and materials. Different engine block models may require slightly different threshold settings due to variations in geometry or alloy composition. To address this, a matrix of thresholds may be developed, taking into account factors such as wall thickness, material properties, and critical areas of the engine block.

Collaboration between NDT equipment manufacturers, automotive engineers, and quality control specialists is essential in developing standardized thresholds. This collaborative effort ensures that the thresholds are both technically sound and practically implementable in a production environment. Regular review and updating of these standards are necessary to keep pace with advancements in NDT technology and changes in engine block design.

The implementation of standardized NDT thresholds often involves the use of automated inspection systems. These systems are programmed with the established thresholds and can quickly and consistently evaluate engine blocks against these criteria. This automation not only improves the speed and efficiency of the inspection process but also reduces the potential for human error in defect detection.

NDT methods commonly used for engine block inspection include ultrasonic testing, radiographic testing, and eddy current testing. Each of these methods has its own set of parameters and thresholds that need to be standardized. Ultrasonic testing, for instance, requires the establishment of specific amplitude thresholds for different types of defects, such as porosity or inclusions. Radiographic testing involves setting density thresholds to identify voids or cracks in the casting.

The standardization process typically begins with a comprehensive analysis of historical data from engine block inspections. This data is used to identify patterns in defect occurrence and to determine the sensitivity of various NDT methods in detecting these defects. Statistical analysis plays a crucial role in this stage, helping to establish baseline thresholds that balance detection accuracy with practical manufacturing constraints.

One of the key challenges in standardizing NDT thresholds is accounting for the variability in engine block designs and materials. Different engine block models may require slightly different threshold settings due to variations in geometry or alloy composition. To address this, a matrix of thresholds may be developed, taking into account factors such as wall thickness, material properties, and critical areas of the engine block.

Collaboration between NDT equipment manufacturers, automotive engineers, and quality control specialists is essential in developing standardized thresholds. This collaborative effort ensures that the thresholds are both technically sound and practically implementable in a production environment. Regular review and updating of these standards are necessary to keep pace with advancements in NDT technology and changes in engine block design.

The implementation of standardized NDT thresholds often involves the use of automated inspection systems. These systems are programmed with the established thresholds and can quickly and consistently evaluate engine blocks against these criteria. This automation not only improves the speed and efficiency of the inspection process but also reduces the potential for human error in defect detection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!