How To Choose Between Aluminum And Cast Iron Engine Blocks

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Materials: Background and Objectives

The choice between aluminum and cast iron engine blocks has been a pivotal decision in automotive engineering for decades. This technological evolution traces back to the early 20th century when cast iron was the predominant material for engine blocks due to its durability, heat resistance, and cost-effectiveness. However, as the automotive industry progressed, the demand for lighter, more fuel-efficient vehicles led to the exploration of alternative materials.

Aluminum emerged as a viable contender in the 1960s, with its lightweight properties offering significant advantages in terms of vehicle performance and fuel economy. The transition from cast iron to aluminum engine blocks marks a significant milestone in automotive technology, reflecting the industry's ongoing pursuit of improved efficiency and reduced environmental impact.

The primary objective in selecting between aluminum and cast iron engine blocks is to optimize the balance between performance, durability, cost, and environmental considerations. This decision involves a complex interplay of factors including weight reduction, thermal management, manufacturing processes, and overall engine design.

Cast iron engine blocks have long been valued for their excellent wear resistance, thermal stability, and ability to dampen vibrations. These properties make them particularly suitable for heavy-duty applications and high-performance engines where durability is paramount. On the other hand, aluminum engine blocks offer substantial weight savings, typically reducing engine weight by 40-50% compared to cast iron counterparts. This weight reduction translates to improved fuel efficiency and enhanced vehicle dynamics.

The technological evolution in this field has led to significant advancements in both materials. Modern casting techniques and alloy compositions have improved the strength and durability of aluminum engine blocks, while innovations in cast iron manufacturing have resulted in thinner, lighter designs that maintain the material's inherent advantages.

As the automotive industry continues to face stringent emissions regulations and increasing demand for fuel-efficient vehicles, the choice of engine block material plays a crucial role in meeting these challenges. The ongoing research and development in this area aim to further enhance the properties of both materials, exploring new alloys, composite materials, and manufacturing techniques to push the boundaries of engine performance and efficiency.

Aluminum emerged as a viable contender in the 1960s, with its lightweight properties offering significant advantages in terms of vehicle performance and fuel economy. The transition from cast iron to aluminum engine blocks marks a significant milestone in automotive technology, reflecting the industry's ongoing pursuit of improved efficiency and reduced environmental impact.

The primary objective in selecting between aluminum and cast iron engine blocks is to optimize the balance between performance, durability, cost, and environmental considerations. This decision involves a complex interplay of factors including weight reduction, thermal management, manufacturing processes, and overall engine design.

Cast iron engine blocks have long been valued for their excellent wear resistance, thermal stability, and ability to dampen vibrations. These properties make them particularly suitable for heavy-duty applications and high-performance engines where durability is paramount. On the other hand, aluminum engine blocks offer substantial weight savings, typically reducing engine weight by 40-50% compared to cast iron counterparts. This weight reduction translates to improved fuel efficiency and enhanced vehicle dynamics.

The technological evolution in this field has led to significant advancements in both materials. Modern casting techniques and alloy compositions have improved the strength and durability of aluminum engine blocks, while innovations in cast iron manufacturing have resulted in thinner, lighter designs that maintain the material's inherent advantages.

As the automotive industry continues to face stringent emissions regulations and increasing demand for fuel-efficient vehicles, the choice of engine block material plays a crucial role in meeting these challenges. The ongoing research and development in this area aim to further enhance the properties of both materials, exploring new alloys, composite materials, and manufacturing techniques to push the boundaries of engine performance and efficiency.

Market Demand Analysis for Engine Block Materials

The global automotive industry has witnessed a significant shift in engine block material preferences over the past decade. Market demand for engine blocks has been increasingly influenced by factors such as fuel efficiency, emissions regulations, and vehicle performance requirements. Aluminum engine blocks have gained substantial market share, particularly in passenger vehicles and light-duty trucks, due to their lightweight properties and potential for improved fuel economy. This trend aligns with the growing consumer demand for more fuel-efficient vehicles and stricter government regulations on emissions.

However, cast iron engine blocks continue to maintain a strong presence in certain market segments, especially in heavy-duty vehicles, commercial trucks, and high-performance applications. The durability and cost-effectiveness of cast iron make it an attractive option for manufacturers in these sectors. The market demand for cast iron engine blocks remains stable, particularly in developing countries where cost considerations often outweigh fuel efficiency concerns.

The automotive industry's push towards electrification has also impacted the market demand for traditional engine blocks. As electric vehicles gain market share, the overall demand for internal combustion engine components, including engine blocks, is expected to decline in the long term. This shift has prompted engine block manufacturers to diversify their product offerings and explore new materials and manufacturing techniques to remain competitive.

Regional variations in market demand are notable. In North America and Europe, stringent emissions regulations and consumer preferences for fuel-efficient vehicles have driven a stronger demand for aluminum engine blocks. In contrast, emerging markets in Asia and Africa still show a preference for cast iron engine blocks due to their lower cost and perceived reliability.

The aftermarket and replacement parts sector also plays a significant role in shaping market demand. The longevity of cast iron engine blocks has created a substantial aftermarket for replacement parts and rebuilds, particularly in older vehicle models. This sector continues to support demand for cast iron components, even as new vehicle production shifts towards aluminum.

Manufacturing capabilities and supply chain considerations also influence market demand. The availability of raw materials, production costs, and existing manufacturing infrastructure all play roles in determining which engine block material is preferred in different regions and market segments. As a result, the global market for engine blocks remains diverse, with both aluminum and cast iron maintaining significant market shares in their respective niches.

However, cast iron engine blocks continue to maintain a strong presence in certain market segments, especially in heavy-duty vehicles, commercial trucks, and high-performance applications. The durability and cost-effectiveness of cast iron make it an attractive option for manufacturers in these sectors. The market demand for cast iron engine blocks remains stable, particularly in developing countries where cost considerations often outweigh fuel efficiency concerns.

The automotive industry's push towards electrification has also impacted the market demand for traditional engine blocks. As electric vehicles gain market share, the overall demand for internal combustion engine components, including engine blocks, is expected to decline in the long term. This shift has prompted engine block manufacturers to diversify their product offerings and explore new materials and manufacturing techniques to remain competitive.

Regional variations in market demand are notable. In North America and Europe, stringent emissions regulations and consumer preferences for fuel-efficient vehicles have driven a stronger demand for aluminum engine blocks. In contrast, emerging markets in Asia and Africa still show a preference for cast iron engine blocks due to their lower cost and perceived reliability.

The aftermarket and replacement parts sector also plays a significant role in shaping market demand. The longevity of cast iron engine blocks has created a substantial aftermarket for replacement parts and rebuilds, particularly in older vehicle models. This sector continues to support demand for cast iron components, even as new vehicle production shifts towards aluminum.

Manufacturing capabilities and supply chain considerations also influence market demand. The availability of raw materials, production costs, and existing manufacturing infrastructure all play roles in determining which engine block material is preferred in different regions and market segments. As a result, the global market for engine blocks remains diverse, with both aluminum and cast iron maintaining significant market shares in their respective niches.

Current State and Challenges in Engine Block Manufacturing

The current state of engine block manufacturing is characterized by a dynamic interplay between traditional cast iron and modern aluminum technologies. Cast iron engine blocks have long been the industry standard, valued for their durability, heat dissipation properties, and cost-effectiveness. However, the automotive industry's shift towards lighter, more fuel-efficient vehicles has propelled aluminum engine blocks to the forefront of manufacturing considerations.

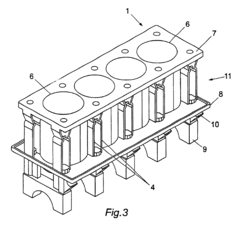

Aluminum engine blocks have gained significant traction due to their lightweight properties, which contribute to overall vehicle weight reduction and improved fuel economy. The manufacturing process for aluminum blocks has evolved to include high-pressure die casting and low-pressure sand casting techniques, allowing for complex designs and improved structural integrity. These advancements have addressed many of the historical concerns regarding aluminum's strength and durability in engine applications.

Despite the growing popularity of aluminum, cast iron remains a viable option for certain applications, particularly in heavy-duty and high-performance engines where strength and thermal stability are paramount. The manufacturing of cast iron blocks continues to benefit from well-established processes and a deep industry knowledge base.

One of the primary challenges in engine block manufacturing today is balancing performance requirements with environmental regulations and consumer demands for fuel efficiency. This has led to the development of hybrid designs that combine aluminum blocks with cast iron cylinder liners, aiming to harness the benefits of both materials.

Material selection also presents a significant challenge, as manufacturers must consider factors such as thermal conductivity, wear resistance, and cost-effectiveness. The decision between aluminum and cast iron is not always straightforward and often depends on specific engine requirements, production volumes, and target market segments.

Manufacturing processes themselves face ongoing challenges, including the need for precision in machining and assembly to ensure proper sealing and alignment of engine components. For aluminum blocks, controlling porosity and ensuring consistent material properties throughout the casting process remain critical issues.

Additionally, the industry is grappling with sustainability concerns, pushing for more environmentally friendly manufacturing processes and materials. This includes efforts to increase the use of recycled aluminum and develop more energy-efficient casting and machining techniques.

As the automotive industry continues to evolve, engine block manufacturers must also contend with the rise of electric vehicles, which may ultimately reduce demand for traditional internal combustion engines. This shift is prompting manufacturers to diversify their capabilities and explore new materials and manufacturing techniques to remain competitive in a changing market landscape.

Aluminum engine blocks have gained significant traction due to their lightweight properties, which contribute to overall vehicle weight reduction and improved fuel economy. The manufacturing process for aluminum blocks has evolved to include high-pressure die casting and low-pressure sand casting techniques, allowing for complex designs and improved structural integrity. These advancements have addressed many of the historical concerns regarding aluminum's strength and durability in engine applications.

Despite the growing popularity of aluminum, cast iron remains a viable option for certain applications, particularly in heavy-duty and high-performance engines where strength and thermal stability are paramount. The manufacturing of cast iron blocks continues to benefit from well-established processes and a deep industry knowledge base.

One of the primary challenges in engine block manufacturing today is balancing performance requirements with environmental regulations and consumer demands for fuel efficiency. This has led to the development of hybrid designs that combine aluminum blocks with cast iron cylinder liners, aiming to harness the benefits of both materials.

Material selection also presents a significant challenge, as manufacturers must consider factors such as thermal conductivity, wear resistance, and cost-effectiveness. The decision between aluminum and cast iron is not always straightforward and often depends on specific engine requirements, production volumes, and target market segments.

Manufacturing processes themselves face ongoing challenges, including the need for precision in machining and assembly to ensure proper sealing and alignment of engine components. For aluminum blocks, controlling porosity and ensuring consistent material properties throughout the casting process remain critical issues.

Additionally, the industry is grappling with sustainability concerns, pushing for more environmentally friendly manufacturing processes and materials. This includes efforts to increase the use of recycled aluminum and develop more energy-efficient casting and machining techniques.

As the automotive industry continues to evolve, engine block manufacturers must also contend with the rise of electric vehicles, which may ultimately reduce demand for traditional internal combustion engines. This shift is prompting manufacturers to diversify their capabilities and explore new materials and manufacturing techniques to remain competitive in a changing market landscape.

Existing Solutions for Aluminum vs Cast Iron Engine Blocks

01 Engine block design and manufacturing

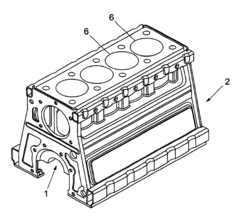

This category focuses on the design and manufacturing processes of engine blocks. It includes innovations in block construction, material selection, and production techniques to improve performance, durability, and efficiency. Advanced manufacturing methods and design optimizations are employed to create lightweight yet strong engine blocks that can withstand high pressures and temperatures.- Engine block design and manufacturing: Engine blocks are fundamental components in internal combustion engines. Various designs and manufacturing methods are employed to improve performance, durability, and efficiency. This includes innovations in materials, casting techniques, and structural designs to optimize weight, strength, and heat dissipation.

- Cooling systems for engine blocks: Effective cooling is crucial for engine block performance and longevity. Innovations in this area focus on improving coolant circulation, enhancing heat transfer, and developing advanced cooling channel designs. These improvements help maintain optimal operating temperatures and prevent overheating.

- Sealing and gasket technologies: Proper sealing is essential to prevent leaks and maintain engine performance. Advancements in gasket materials, designs, and sealing techniques aim to improve the reliability and durability of engine block assemblies, particularly in high-pressure and high-temperature environments.

- Engine block reinforcement and vibration reduction: Techniques to reinforce engine blocks and reduce vibration are crucial for improving engine performance and longevity. This includes structural modifications, the use of advanced materials, and innovative mounting systems to enhance rigidity and dampen vibrations.

- Integration of sensors and electronic systems: Modern engine blocks increasingly incorporate sensors and electronic systems for improved monitoring and control. These innovations enable real-time performance tracking, predictive maintenance, and enhanced engine management, contributing to better efficiency and reduced emissions.

02 Cooling systems for engine blocks

This category covers cooling systems integrated into engine blocks. It includes innovations in coolant passages, heat dissipation methods, and temperature regulation mechanisms. These systems are crucial for maintaining optimal engine performance and preventing overheating, which can lead to engine damage or failure.Expand Specific Solutions03 Sealing and gasket technologies

This category encompasses sealing and gasket technologies used in engine blocks. It includes innovations in materials and designs for head gaskets, oil seals, and other sealing components. These technologies are essential for preventing leaks, maintaining compression, and ensuring proper engine function under various operating conditions.Expand Specific Solutions04 Engine block reinforcement and support structures

This category focuses on reinforcement and support structures for engine blocks. It includes innovations in block stiffening techniques, mounting systems, and vibration damping solutions. These advancements aim to improve engine stability, reduce noise and vibration, and extend the overall lifespan of the engine.Expand Specific Solutions05 Engine block materials and coatings

This category covers advancements in materials and coatings used for engine blocks. It includes innovations in alloy compositions, surface treatments, and protective coatings. These developments aim to enhance wear resistance, reduce friction, improve heat dissipation, and increase overall engine efficiency and longevity.Expand Specific Solutions

Key Players in Engine Block Manufacturing Industry

The competition landscape for choosing between aluminum and cast iron engine blocks is characterized by a mature market with established players and evolving technological trends. The global automotive engine block market, valued at over $20 billion, is experiencing steady growth driven by increasing vehicle production. Technologically, both materials have their merits, with aluminum gaining popularity due to its lightweight properties and fuel efficiency benefits. However, cast iron remains relevant for its durability and cost-effectiveness. Key players like GM Global Technology Operations, Ford Global Technologies, and Nemak are investing in R&D to improve both materials' performance. The industry is also seeing a shift towards hybrid solutions and alternative materials, reflecting the automotive sector's focus on sustainability and efficiency.

GM Global Technology Operations LLC

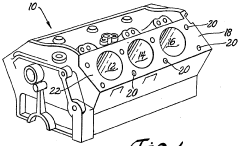

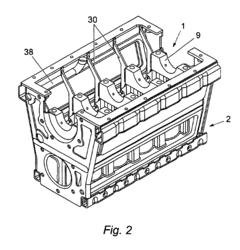

Technical Solution: GM employs a hybrid approach, utilizing both aluminum and cast iron engine blocks depending on the specific vehicle and performance requirements. For high-performance and lightweight applications, GM uses aluminum engine blocks with cast-in-place iron cylinder liners[1]. This technology combines the lightweight properties of aluminum with the durability of iron. For heavy-duty applications, GM still utilizes cast iron blocks, particularly in their truck engines, due to their superior strength and durability[2]. GM has also developed advanced casting techniques for both materials, including lost foam casting for iron blocks and high-pressure die casting for aluminum blocks, to optimize weight, strength, and manufacturing efficiency[3].

Strengths: Flexibility to choose optimal material for each application, advanced manufacturing techniques. Weaknesses: Higher production complexity, potential increased costs due to maintaining dual material expertise.

Ford Global Technologies LLC

Technical Solution: Ford has been at the forefront of aluminum engine block technology, particularly with their EcoBoost engine series. They utilize high-pressure die-cast aluminum blocks with cast-in-place iron cylinder liners for many of their engines[4]. For larger displacement engines, especially in trucks, Ford employs a Compacted Graphite Iron (CGI) technology, which offers improved strength and durability compared to traditional cast iron while being lighter[5]. Ford's aluminum blocks often incorporate advanced thermal management systems, including precision cooling passages, to optimize heat dissipation and improve efficiency[6]. They have also developed proprietary coatings for aluminum cylinder bores in some applications, eliminating the need for iron liners and further reducing weight[7].

Strengths: Leadership in aluminum engine technology, innovative use of CGI for heavy-duty applications. Weaknesses: Higher initial tooling costs for aluminum casting, potential durability concerns in extreme duty cycles.

Core Innovations in Engine Block Material Technology

Aluminum alloy for engine blocks

PatentWO2005010224A1

Innovation

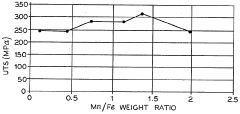

- An aluminum alloy composition with a specific range of silicon, iron, manganese, copper, magnesium, and rare earth elements, optimized for fluidity, strength, and machinability, providing enhanced wear resistance and dimensional stability without the need for special processing or liners.

Cylinder block and method of fabrication thereof

PatentInactiveUS6886522B1

Innovation

- A method involving a cast core and a wrought framework, where the core handles internal loads and the framework manages engine mounting and torque loads, using materials like steel or light alloys, and joining techniques like laser welding to optimize strength and stiffness-to-weight ratio, with features like siamesed cylinders and captive fasteners for enhanced structural rigidity and manufacturing flexibility.

Environmental Impact of Engine Block Materials

The choice between aluminum and cast iron engine blocks has significant environmental implications throughout the lifecycle of a vehicle. Aluminum engine blocks generally offer a more favorable environmental profile due to their lighter weight, which contributes to improved fuel efficiency and reduced emissions during the vehicle's operational life. The production of aluminum, however, is energy-intensive and can result in higher initial environmental impacts compared to cast iron.

Cast iron engine blocks, while heavier, have a lower environmental impact during the manufacturing phase. The production process for cast iron is less energy-intensive and generates fewer emissions compared to aluminum smelting. However, the increased weight of cast iron blocks leads to higher fuel consumption and emissions over the vehicle's lifespan, potentially offsetting the initial environmental benefits.

Recycling plays a crucial role in the environmental assessment of both materials. Aluminum has a significant advantage in this aspect, as it is highly recyclable with minimal loss of quality. The recycling process for aluminum requires only about 5% of the energy needed for primary production, significantly reducing its overall environmental footprint. Cast iron, while also recyclable, typically undergoes downcycling processes that limit its reuse in high-quality applications.

The environmental impact of engine block materials extends beyond production and use phases. End-of-life considerations, such as disposal and recycling infrastructure, are essential factors. Aluminum's high value in the recycling market incentivizes its recovery and reuse, potentially leading to a more circular material flow. Cast iron, while less valuable, is still widely recycled but may require more energy-intensive processes for separation and purification.

Regional factors also influence the environmental impact of engine block materials. The source of electricity used in production, local recycling capabilities, and transportation distances all contribute to the overall environmental profile. In regions with predominantly renewable energy sources, the production of aluminum becomes more environmentally favorable, potentially tipping the balance in its favor.

Considering the entire lifecycle, the choice between aluminum and cast iron engine blocks involves balancing immediate production impacts against long-term operational benefits. As vehicle electrification progresses, the weight reduction offered by aluminum becomes increasingly crucial for extending battery range and reducing overall energy consumption, further enhancing its environmental advantages in future automotive applications.

Cast iron engine blocks, while heavier, have a lower environmental impact during the manufacturing phase. The production process for cast iron is less energy-intensive and generates fewer emissions compared to aluminum smelting. However, the increased weight of cast iron blocks leads to higher fuel consumption and emissions over the vehicle's lifespan, potentially offsetting the initial environmental benefits.

Recycling plays a crucial role in the environmental assessment of both materials. Aluminum has a significant advantage in this aspect, as it is highly recyclable with minimal loss of quality. The recycling process for aluminum requires only about 5% of the energy needed for primary production, significantly reducing its overall environmental footprint. Cast iron, while also recyclable, typically undergoes downcycling processes that limit its reuse in high-quality applications.

The environmental impact of engine block materials extends beyond production and use phases. End-of-life considerations, such as disposal and recycling infrastructure, are essential factors. Aluminum's high value in the recycling market incentivizes its recovery and reuse, potentially leading to a more circular material flow. Cast iron, while less valuable, is still widely recycled but may require more energy-intensive processes for separation and purification.

Regional factors also influence the environmental impact of engine block materials. The source of electricity used in production, local recycling capabilities, and transportation distances all contribute to the overall environmental profile. In regions with predominantly renewable energy sources, the production of aluminum becomes more environmentally favorable, potentially tipping the balance in its favor.

Considering the entire lifecycle, the choice between aluminum and cast iron engine blocks involves balancing immediate production impacts against long-term operational benefits. As vehicle electrification progresses, the weight reduction offered by aluminum becomes increasingly crucial for extending battery range and reducing overall energy consumption, further enhancing its environmental advantages in future automotive applications.

Cost-Benefit Analysis of Aluminum vs Cast Iron Blocks

When considering the choice between aluminum and cast iron engine blocks, a comprehensive cost-benefit analysis is crucial. The initial cost of aluminum blocks is generally higher than that of cast iron due to more expensive raw materials and manufacturing processes. However, the long-term benefits of aluminum blocks often outweigh this initial investment.

Aluminum blocks offer significant weight reduction, typically 20-30% lighter than their cast iron counterparts. This weight saving translates to improved fuel efficiency and overall vehicle performance. The reduced mass also contributes to better handling and acceleration, enhancing the driving experience. Additionally, aluminum's superior thermal conductivity allows for more efficient heat dissipation, potentially improving engine cooling and reducing the risk of overheating.

Cast iron blocks, while heavier, offer advantages in terms of durability and cost-effectiveness. They are more resistant to wear and tear, making them suitable for high-stress applications and heavy-duty vehicles. The lower initial cost of cast iron blocks can be attractive for budget-conscious manufacturers or in markets where fuel efficiency is less prioritized.

Maintenance costs should also be factored into the analysis. Aluminum blocks may require more frequent inspections and specialized repair techniques, potentially increasing long-term maintenance expenses. Conversely, cast iron blocks are generally easier and less expensive to repair, which can be advantageous for vehicles expected to have long service lives.

Environmental considerations play an increasingly important role in this decision. The lighter weight of aluminum blocks contributes to reduced emissions over the vehicle's lifetime due to improved fuel efficiency. However, the production of aluminum is more energy-intensive than cast iron, resulting in higher initial environmental impact. The recyclability of both materials should be considered, with aluminum having an edge in this aspect.

Manufacturing complexity is another factor to consider. Aluminum blocks often require more sophisticated casting and machining processes, which can increase production costs and complexity. Cast iron, being a more traditional material, benefits from well-established manufacturing techniques and infrastructure.

Ultimately, the choice between aluminum and cast iron engine blocks depends on the specific application, target market, and long-term strategic goals of the manufacturer. For high-performance vehicles and those prioritizing fuel efficiency, aluminum blocks often provide a competitive edge. For heavy-duty applications or markets where initial cost is a primary concern, cast iron remains a viable option. A thorough analysis of all these factors, including initial costs, long-term benefits, environmental impact, and manufacturing considerations, is essential for making an informed decision.

Aluminum blocks offer significant weight reduction, typically 20-30% lighter than their cast iron counterparts. This weight saving translates to improved fuel efficiency and overall vehicle performance. The reduced mass also contributes to better handling and acceleration, enhancing the driving experience. Additionally, aluminum's superior thermal conductivity allows for more efficient heat dissipation, potentially improving engine cooling and reducing the risk of overheating.

Cast iron blocks, while heavier, offer advantages in terms of durability and cost-effectiveness. They are more resistant to wear and tear, making them suitable for high-stress applications and heavy-duty vehicles. The lower initial cost of cast iron blocks can be attractive for budget-conscious manufacturers or in markets where fuel efficiency is less prioritized.

Maintenance costs should also be factored into the analysis. Aluminum blocks may require more frequent inspections and specialized repair techniques, potentially increasing long-term maintenance expenses. Conversely, cast iron blocks are generally easier and less expensive to repair, which can be advantageous for vehicles expected to have long service lives.

Environmental considerations play an increasingly important role in this decision. The lighter weight of aluminum blocks contributes to reduced emissions over the vehicle's lifetime due to improved fuel efficiency. However, the production of aluminum is more energy-intensive than cast iron, resulting in higher initial environmental impact. The recyclability of both materials should be considered, with aluminum having an edge in this aspect.

Manufacturing complexity is another factor to consider. Aluminum blocks often require more sophisticated casting and machining processes, which can increase production costs and complexity. Cast iron, being a more traditional material, benefits from well-established manufacturing techniques and infrastructure.

Ultimately, the choice between aluminum and cast iron engine blocks depends on the specific application, target market, and long-term strategic goals of the manufacturer. For high-performance vehicles and those prioritizing fuel efficiency, aluminum blocks often provide a competitive edge. For heavy-duty applications or markets where initial cost is a primary concern, cast iron remains a viable option. A thorough analysis of all these factors, including initial costs, long-term benefits, environmental impact, and manufacturing considerations, is essential for making an informed decision.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!