How To Document Casting Parameters For Consistent Engine Blocks

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Casting Parameter Documentation Goals

Documenting casting parameters for consistent engine block production is crucial for maintaining quality, reducing defects, and ensuring optimal performance. The primary goal of this documentation process is to establish a standardized approach that captures all critical variables affecting the casting outcome. This includes parameters such as mold design, material composition, pouring temperature, cooling rates, and post-casting treatments.

One key objective is to create a comprehensive database of casting parameters that can be easily accessed and updated by all relevant personnel. This database should include not only the optimal parameter values but also acceptable ranges and the potential impact of deviations. By doing so, it enables quick troubleshooting and adjustment during the production process, minimizing downtime and waste.

Another important goal is to implement a robust version control system for the documentation. As casting processes evolve and improvements are made, it's essential to track changes over time. This historical record can provide valuable insights into process optimization and help in root cause analysis when issues arise. It also ensures that all team members are working with the most up-to-date information, reducing the risk of errors due to outdated specifications.

Enhancing traceability is another critical objective of the documentation process. Each engine block should be linked to the specific set of casting parameters used in its production. This traceability allows for easier quality control, facilitates recalls if necessary, and provides data for continuous improvement initiatives. It also supports compliance with industry standards and regulatory requirements.

The documentation should aim to incorporate real-time monitoring and feedback mechanisms. By integrating sensor data and quality control measurements into the parameter documentation, it becomes possible to create a dynamic system that can alert operators to potential issues before they result in defective parts. This proactive approach can significantly improve overall production efficiency and quality.

Lastly, the documentation goals should include provisions for knowledge transfer and training. Well-documented casting parameters serve as an invaluable resource for training new personnel and maintaining consistency across shifts or production facilities. By capturing not just the what but also the why behind specific parameter choices, the documentation becomes a powerful tool for building and preserving institutional knowledge in the engine manufacturing process.

One key objective is to create a comprehensive database of casting parameters that can be easily accessed and updated by all relevant personnel. This database should include not only the optimal parameter values but also acceptable ranges and the potential impact of deviations. By doing so, it enables quick troubleshooting and adjustment during the production process, minimizing downtime and waste.

Another important goal is to implement a robust version control system for the documentation. As casting processes evolve and improvements are made, it's essential to track changes over time. This historical record can provide valuable insights into process optimization and help in root cause analysis when issues arise. It also ensures that all team members are working with the most up-to-date information, reducing the risk of errors due to outdated specifications.

Enhancing traceability is another critical objective of the documentation process. Each engine block should be linked to the specific set of casting parameters used in its production. This traceability allows for easier quality control, facilitates recalls if necessary, and provides data for continuous improvement initiatives. It also supports compliance with industry standards and regulatory requirements.

The documentation should aim to incorporate real-time monitoring and feedback mechanisms. By integrating sensor data and quality control measurements into the parameter documentation, it becomes possible to create a dynamic system that can alert operators to potential issues before they result in defective parts. This proactive approach can significantly improve overall production efficiency and quality.

Lastly, the documentation goals should include provisions for knowledge transfer and training. Well-documented casting parameters serve as an invaluable resource for training new personnel and maintaining consistency across shifts or production facilities. By capturing not just the what but also the why behind specific parameter choices, the documentation becomes a powerful tool for building and preserving institutional knowledge in the engine manufacturing process.

Market Demand for Consistent Engine Blocks

The market demand for consistent engine blocks has been steadily increasing in recent years, driven by the automotive industry's push for higher quality, improved performance, and enhanced fuel efficiency. Engine blocks serve as the foundation of internal combustion engines, and their consistency is crucial for ensuring optimal engine performance, reliability, and longevity.

Automotive manufacturers are facing increasing pressure to produce engines that meet stringent emissions regulations while delivering improved fuel economy. This has led to a growing emphasis on precision manufacturing techniques, including the need for consistent engine block casting. Inconsistencies in engine block production can lead to variations in engine performance, increased fuel consumption, and potential reliability issues, all of which can negatively impact a manufacturer's reputation and bottom line.

The global automotive engine market is expected to grow significantly in the coming years, with a particular focus on lightweight and high-performance engines. This trend is driving demand for advanced casting techniques and documentation processes that can ensure consistent engine block production. Manufacturers are seeking solutions that can help them achieve tighter tolerances, reduce defects, and improve overall product quality.

In addition to the automotive sector, other industries such as aerospace, marine, and industrial equipment manufacturing are also showing increased interest in consistent engine block production. These sectors require engines with high reliability and performance, further expanding the market for advanced casting parameter documentation and control systems.

The demand for electric vehicles (EVs) has been growing rapidly, which might seem to reduce the need for traditional engine blocks. However, this shift has actually intensified the focus on quality and consistency in internal combustion engine production. As manufacturers continue to produce hybrid vehicles and improve conventional engines, the importance of consistent engine blocks remains critical for maintaining competitiveness in the evolving automotive landscape.

Emerging markets, particularly in Asia and South America, are experiencing significant growth in automotive production. This expansion is creating new opportunities for engine block manufacturers and increasing the demand for technologies that can ensure consistency across global production facilities. Standardized documentation of casting parameters is becoming essential for maintaining quality control across diverse manufacturing locations and meeting international standards.

As the industry moves towards Industry 4.0 and smart manufacturing, there is a growing demand for digital solutions that can document and analyze casting parameters in real-time. This trend is driving investment in advanced sensors, data analytics, and artificial intelligence technologies that can help manufacturers achieve unprecedented levels of consistency in engine block production.

Automotive manufacturers are facing increasing pressure to produce engines that meet stringent emissions regulations while delivering improved fuel economy. This has led to a growing emphasis on precision manufacturing techniques, including the need for consistent engine block casting. Inconsistencies in engine block production can lead to variations in engine performance, increased fuel consumption, and potential reliability issues, all of which can negatively impact a manufacturer's reputation and bottom line.

The global automotive engine market is expected to grow significantly in the coming years, with a particular focus on lightweight and high-performance engines. This trend is driving demand for advanced casting techniques and documentation processes that can ensure consistent engine block production. Manufacturers are seeking solutions that can help them achieve tighter tolerances, reduce defects, and improve overall product quality.

In addition to the automotive sector, other industries such as aerospace, marine, and industrial equipment manufacturing are also showing increased interest in consistent engine block production. These sectors require engines with high reliability and performance, further expanding the market for advanced casting parameter documentation and control systems.

The demand for electric vehicles (EVs) has been growing rapidly, which might seem to reduce the need for traditional engine blocks. However, this shift has actually intensified the focus on quality and consistency in internal combustion engine production. As manufacturers continue to produce hybrid vehicles and improve conventional engines, the importance of consistent engine blocks remains critical for maintaining competitiveness in the evolving automotive landscape.

Emerging markets, particularly in Asia and South America, are experiencing significant growth in automotive production. This expansion is creating new opportunities for engine block manufacturers and increasing the demand for technologies that can ensure consistency across global production facilities. Standardized documentation of casting parameters is becoming essential for maintaining quality control across diverse manufacturing locations and meeting international standards.

As the industry moves towards Industry 4.0 and smart manufacturing, there is a growing demand for digital solutions that can document and analyze casting parameters in real-time. This trend is driving investment in advanced sensors, data analytics, and artificial intelligence technologies that can help manufacturers achieve unprecedented levels of consistency in engine block production.

Current Challenges in Casting Parameter Documentation

The documentation of casting parameters for consistent engine block production faces several significant challenges in the current manufacturing landscape. One of the primary issues is the complexity and variability inherent in the casting process. Engine blocks require precise specifications to ensure optimal performance and durability, yet the casting process involves numerous variables that can affect the final product quality.

A major challenge lies in capturing and standardizing the vast array of parameters involved in the casting process. These include mold design, material composition, pouring temperature, cooling rates, and post-casting treatments. Each of these factors can significantly impact the final engine block's properties, making comprehensive documentation crucial for consistency. However, the sheer number of parameters and their interdependencies make it difficult to create a standardized documentation format that is both comprehensive and user-friendly.

Another significant hurdle is the dynamic nature of the casting environment. Foundries often need to adjust parameters in real-time to account for variations in raw materials, environmental conditions, or equipment performance. Documenting these on-the-fly adjustments and understanding their impact on the final product can be challenging, especially in high-volume production settings.

The integration of legacy systems with modern digital documentation tools presents another obstacle. Many foundries still rely on traditional methods of record-keeping, which may not seamlessly interface with newer digital systems. This disconnect can lead to information silos, inconsistencies in data recording, and difficulties in tracking parameter changes over time.

Furthermore, the proprietary nature of casting processes in competitive industries often results in a reluctance to fully document or share best practices. This can hinder the development of industry-wide standards and make it difficult for new entrants to establish consistent casting parameters.

The human factor also plays a significant role in the challenges of parameter documentation. Experienced foundry workers often rely on tacit knowledge and intuition to make adjustments, which can be difficult to quantify and document. Capturing this expertise in a format that can be consistently applied across different shifts or locations is a persistent challenge.

Lastly, the evolving regulatory landscape and increasing demands for sustainability add another layer of complexity to parameter documentation. Foundries must now track and report on environmental impact factors, energy efficiency, and material traceability, all of which need to be integrated into the casting parameter documentation process.

A major challenge lies in capturing and standardizing the vast array of parameters involved in the casting process. These include mold design, material composition, pouring temperature, cooling rates, and post-casting treatments. Each of these factors can significantly impact the final engine block's properties, making comprehensive documentation crucial for consistency. However, the sheer number of parameters and their interdependencies make it difficult to create a standardized documentation format that is both comprehensive and user-friendly.

Another significant hurdle is the dynamic nature of the casting environment. Foundries often need to adjust parameters in real-time to account for variations in raw materials, environmental conditions, or equipment performance. Documenting these on-the-fly adjustments and understanding their impact on the final product can be challenging, especially in high-volume production settings.

The integration of legacy systems with modern digital documentation tools presents another obstacle. Many foundries still rely on traditional methods of record-keeping, which may not seamlessly interface with newer digital systems. This disconnect can lead to information silos, inconsistencies in data recording, and difficulties in tracking parameter changes over time.

Furthermore, the proprietary nature of casting processes in competitive industries often results in a reluctance to fully document or share best practices. This can hinder the development of industry-wide standards and make it difficult for new entrants to establish consistent casting parameters.

The human factor also plays a significant role in the challenges of parameter documentation. Experienced foundry workers often rely on tacit knowledge and intuition to make adjustments, which can be difficult to quantify and document. Capturing this expertise in a format that can be consistently applied across different shifts or locations is a persistent challenge.

Lastly, the evolving regulatory landscape and increasing demands for sustainability add another layer of complexity to parameter documentation. Foundries must now track and report on environmental impact factors, energy efficiency, and material traceability, all of which need to be integrated into the casting parameter documentation process.

Existing Solutions for Casting Parameter Documentation

01 Engine block design for improved consistency

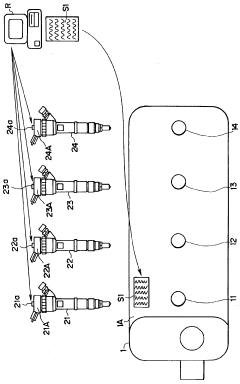

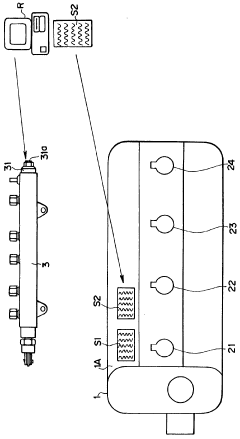

Innovative designs in engine blocks aim to enhance consistency in performance and durability. These designs focus on optimizing the structure to distribute forces evenly, reduce vibration, and improve thermal management. Advanced materials and manufacturing techniques are employed to create engine blocks with more uniform properties throughout.- Engine block design for improved consistency: Engine blocks are designed with specific features to enhance consistency in performance and durability. This includes optimizing the cylinder bore geometry, improving coolant flow paths, and incorporating reinforcement structures to minimize distortion under thermal and mechanical stress.

- Material selection for engine blocks: The choice of materials for engine blocks plays a crucial role in maintaining consistency. Advanced alloys and composite materials are used to improve thermal management, reduce weight, and enhance overall engine performance while ensuring dimensional stability across various operating conditions.

- Manufacturing processes for consistent engine blocks: Specialized manufacturing techniques are employed to produce engine blocks with high consistency. These may include precision casting methods, advanced machining processes, and quality control measures to ensure uniform material properties and dimensional accuracy across production batches.

- Cooling system integration for thermal consistency: Engine blocks are designed with integrated cooling systems to maintain consistent operating temperatures. This involves optimizing coolant channels, incorporating temperature sensors, and implementing advanced thermal management strategies to ensure uniform heat distribution and prevent localized hot spots.

- Quality control and testing for engine block consistency: Rigorous quality control measures and testing protocols are implemented to ensure consistency in engine block production. This includes dimensional inspections, material composition analysis, and performance testing under simulated operating conditions to verify uniformity and reliability across manufactured units.

02 Cooling system integration for uniform temperature

Engine block consistency is improved by integrating advanced cooling systems. These systems ensure uniform temperature distribution across the engine block, preventing localized thermal stress and deformation. Techniques include precision coolant channel design, targeted cooling for high-stress areas, and the use of advanced coolants with superior heat transfer properties.Expand Specific Solutions03 Manufacturing processes for consistent engine blocks

Advancements in manufacturing processes contribute to the production of more consistent engine blocks. These include precision casting techniques, computer-controlled machining, and quality control measures throughout the production line. The focus is on achieving tight tolerances and uniform material properties to ensure consistency across all produced engine blocks.Expand Specific Solutions04 Material selection for enhanced consistency

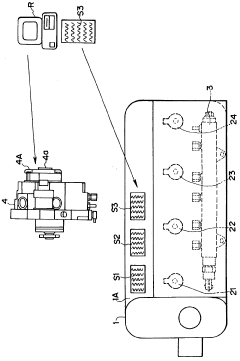

The choice of materials plays a crucial role in achieving engine block consistency. Advanced alloys and composite materials are selected for their uniform properties, resistance to thermal expansion, and ability to maintain structural integrity under varying conditions. These materials contribute to more consistent performance and longevity of the engine block.Expand Specific Solutions05 Monitoring and control systems for maintaining consistency

Sophisticated monitoring and control systems are implemented to maintain engine block consistency during operation. These systems use sensors and advanced algorithms to detect and compensate for variations in temperature, pressure, and mechanical stress. Real-time adjustments help maintain optimal operating conditions and ensure consistent performance over the engine's lifetime.Expand Specific Solutions

Key Players in Engine Block Manufacturing

The competitive landscape for documenting casting parameters for consistent engine blocks is characterized by a mature market with established players and evolving technologies. The industry is in a consolidation phase, with major automotive manufacturers and specialized engineering firms dominating the field. Market size is substantial, driven by the global demand for high-quality engine components. Technologically, the field is advancing, with companies like GM Global Technology Operations, Ford Global Technologies, and Honda Motor Co. leading innovation. Cummins, Inc. and Toyota Motor Corp. are also significant players, contributing to the development of advanced casting techniques and documentation processes. The technology's maturity is evident, but ongoing research focuses on improving consistency, efficiency, and sustainability in engine block production.

GM Global Technology Operations LLC

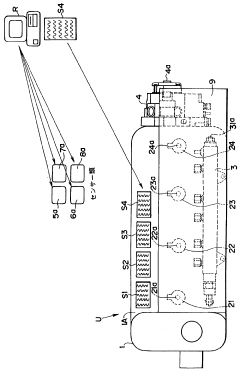

Technical Solution: GM employs advanced digital documentation systems for casting parameters, utilizing a combination of 3D modeling, simulation software, and real-time data collection. Their approach involves creating detailed digital twins of engine blocks, which incorporate precise casting specifications. These digital models are integrated with manufacturing execution systems (MES) to ensure consistent production parameters across global facilities[1]. GM also utilizes machine learning algorithms to analyze historical casting data, optimizing parameters for improved quality and efficiency[3]. The company has implemented a centralized database system that stores and manages all casting parameters, allowing for version control and easy access by engineers worldwide[5].

Strengths: Comprehensive digital integration, global standardization, and data-driven optimization. Weaknesses: High initial implementation costs and potential cybersecurity risks associated with centralized data storage.

Ford Global Technologies LLC

Technical Solution: Ford has developed a proprietary Casting Parameter Management System (CPMS) that meticulously documents and controls all aspects of the engine block casting process. This system incorporates real-time monitoring of key variables such as temperature, pressure, and flow rates, ensuring consistency across production lines[2]. Ford's approach also includes the use of augmented reality (AR) tools for visual documentation and training, allowing technicians to access casting parameters and instructions in real-time on the factory floor[4]. Additionally, Ford has implemented blockchain technology to create an immutable record of casting parameters, ensuring traceability and preventing unauthorized modifications[6].

Strengths: Real-time monitoring capabilities, innovative use of AR for documentation, and enhanced security through blockchain. Weaknesses: Potential complexity in system integration and high training requirements for staff.

Core Innovations in Casting Process Control

Method of standardizing component characteristic codes in production system for vehicle, and control device for vehicle utilizing standardized characteristic codes

PatentWO2003100538A1

Innovation

- A method where optically readable codes are recorded on each component and stored in a unified format, allowing for easy reading and storage, enabling the creation of a single sheet or electronic medium for component characteristics, which can be easily attached to the unit and read during assembly, facilitating unified display or storage of component characteristic codes.

Method for casting engine block

PatentInactiveJP2020037117A

Innovation

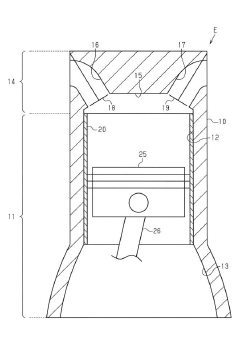

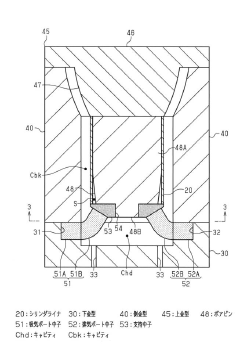

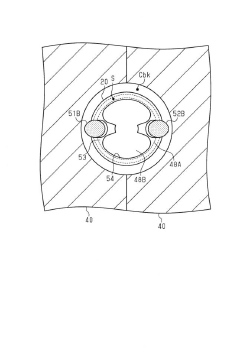

- A method involving a mold configuration where a bore pin is supported by a support core, with the cylinder liner contacting the core's upper surface, ensuring stable positioning during casting, and using cores for intake and exhaust ports to maintain alignment and support during molten metal injection.

Quality Control Standards for Engine Block Casting

Quality control standards play a crucial role in ensuring consistent and high-quality engine block casting. These standards encompass a wide range of parameters and processes that must be carefully documented and monitored throughout the production cycle. The primary focus is on maintaining precise control over the casting parameters to achieve uniform engine block properties and performance.

One of the key aspects of quality control in engine block casting is the establishment of comprehensive documentation procedures. This involves creating detailed records of all casting parameters, including melt composition, pouring temperature, mold design, cooling rates, and post-casting treatments. By meticulously documenting these parameters, manufacturers can ensure repeatability and traceability in their production processes.

The implementation of statistical process control (SPC) techniques is essential for maintaining consistent quality in engine block casting. SPC involves the use of statistical methods to monitor and control the casting process, allowing for early detection of deviations from established standards. This proactive approach enables manufacturers to make timely adjustments and prevent the production of defective engine blocks.

Material specifications form another critical component of quality control standards. These specifications define the exact composition and properties of the alloys used in engine block casting. Strict adherence to these specifications is necessary to ensure that the final product meets the required mechanical and thermal properties. Regular material testing and analysis should be conducted to verify compliance with these specifications.

Dimensional accuracy is a key factor in engine block quality. Quality control standards must include precise tolerances for all critical dimensions of the engine block. Advanced measurement techniques, such as coordinate measuring machines (CMMs) and 3D scanning, are employed to verify that cast engine blocks meet these dimensional requirements. Any deviations from the specified tolerances must be carefully documented and addressed.

Non-destructive testing (NDT) methods are integral to quality control in engine block casting. These techniques, including radiography, ultrasonic testing, and magnetic particle inspection, allow for the detection of internal defects without damaging the cast parts. Quality control standards should specify the types of NDT to be performed, the frequency of testing, and the acceptance criteria for different types of defects.

The establishment of a robust quality management system (QMS) is essential for implementing and maintaining quality control standards in engine block casting. This system should encompass all aspects of the production process, from raw material sourcing to final product inspection. Regular audits and continuous improvement initiatives should be incorporated into the QMS to ensure ongoing adherence to quality standards and to drive process enhancements.

One of the key aspects of quality control in engine block casting is the establishment of comprehensive documentation procedures. This involves creating detailed records of all casting parameters, including melt composition, pouring temperature, mold design, cooling rates, and post-casting treatments. By meticulously documenting these parameters, manufacturers can ensure repeatability and traceability in their production processes.

The implementation of statistical process control (SPC) techniques is essential for maintaining consistent quality in engine block casting. SPC involves the use of statistical methods to monitor and control the casting process, allowing for early detection of deviations from established standards. This proactive approach enables manufacturers to make timely adjustments and prevent the production of defective engine blocks.

Material specifications form another critical component of quality control standards. These specifications define the exact composition and properties of the alloys used in engine block casting. Strict adherence to these specifications is necessary to ensure that the final product meets the required mechanical and thermal properties. Regular material testing and analysis should be conducted to verify compliance with these specifications.

Dimensional accuracy is a key factor in engine block quality. Quality control standards must include precise tolerances for all critical dimensions of the engine block. Advanced measurement techniques, such as coordinate measuring machines (CMMs) and 3D scanning, are employed to verify that cast engine blocks meet these dimensional requirements. Any deviations from the specified tolerances must be carefully documented and addressed.

Non-destructive testing (NDT) methods are integral to quality control in engine block casting. These techniques, including radiography, ultrasonic testing, and magnetic particle inspection, allow for the detection of internal defects without damaging the cast parts. Quality control standards should specify the types of NDT to be performed, the frequency of testing, and the acceptance criteria for different types of defects.

The establishment of a robust quality management system (QMS) is essential for implementing and maintaining quality control standards in engine block casting. This system should encompass all aspects of the production process, from raw material sourcing to final product inspection. Regular audits and continuous improvement initiatives should be incorporated into the QMS to ensure ongoing adherence to quality standards and to drive process enhancements.

Environmental Impact of Casting Processes

The environmental impact of casting processes for engine block production is a critical consideration in the automotive industry. Traditional casting methods, particularly sand casting and die casting, have significant environmental implications. These processes consume substantial energy, generate waste materials, and emit pollutants that can harm air and water quality.

Energy consumption is a major concern in casting operations. The melting of metal alloys requires high temperatures, typically achieved through the use of fossil fuels or electricity. This energy-intensive process contributes to greenhouse gas emissions and climate change. Additionally, the heating and cooling cycles involved in casting consume considerable amounts of water, potentially straining local water resources.

Waste generation is another environmental challenge. Sand casting, for instance, produces large quantities of spent sand that must be disposed of or recycled. While efforts are made to reclaim and reuse sand, a significant portion still ends up in landfills. Die casting generates less solid waste but produces more hazardous liquid waste in the form of die lubricants and coolants.

Air emissions from casting processes include particulate matter, volatile organic compounds (VOCs), and metal fumes. These pollutants can have adverse effects on local air quality and pose health risks to workers and nearby communities. Proper filtration and ventilation systems are essential to mitigate these impacts, but they add to the overall energy consumption of the process.

Water pollution is also a concern, particularly from the quenching and cooling processes used in casting. Wastewater from these operations may contain oils, metal particles, and other contaminants that require treatment before discharge.

To address these environmental challenges, the industry is exploring more sustainable casting techniques. These include the use of inorganic binders in sand casting to reduce VOC emissions, the implementation of closed-loop water systems to minimize water consumption and pollution, and the adoption of more energy-efficient furnaces and heat recovery systems.

Documenting casting parameters for consistent engine blocks plays a crucial role in minimizing environmental impact. Precise control and documentation of parameters such as temperature, pressure, and material composition can lead to reduced scrap rates, lower energy consumption, and decreased waste generation. By optimizing these parameters, manufacturers can produce higher quality engine blocks with fewer defects, thereby reducing the need for rework or replacement parts.

Energy consumption is a major concern in casting operations. The melting of metal alloys requires high temperatures, typically achieved through the use of fossil fuels or electricity. This energy-intensive process contributes to greenhouse gas emissions and climate change. Additionally, the heating and cooling cycles involved in casting consume considerable amounts of water, potentially straining local water resources.

Waste generation is another environmental challenge. Sand casting, for instance, produces large quantities of spent sand that must be disposed of or recycled. While efforts are made to reclaim and reuse sand, a significant portion still ends up in landfills. Die casting generates less solid waste but produces more hazardous liquid waste in the form of die lubricants and coolants.

Air emissions from casting processes include particulate matter, volatile organic compounds (VOCs), and metal fumes. These pollutants can have adverse effects on local air quality and pose health risks to workers and nearby communities. Proper filtration and ventilation systems are essential to mitigate these impacts, but they add to the overall energy consumption of the process.

Water pollution is also a concern, particularly from the quenching and cooling processes used in casting. Wastewater from these operations may contain oils, metal particles, and other contaminants that require treatment before discharge.

To address these environmental challenges, the industry is exploring more sustainable casting techniques. These include the use of inorganic binders in sand casting to reduce VOC emissions, the implementation of closed-loop water systems to minimize water consumption and pollution, and the adoption of more energy-efficient furnaces and heat recovery systems.

Documenting casting parameters for consistent engine blocks plays a crucial role in minimizing environmental impact. Precise control and documentation of parameters such as temperature, pressure, and material composition can lead to reduced scrap rates, lower energy consumption, and decreased waste generation. By optimizing these parameters, manufacturers can produce higher quality engine blocks with fewer defects, thereby reducing the need for rework or replacement parts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!