Engine Block Material Choices For Turbocharged Applications

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharging Evolution

Turbocharging technology has undergone significant evolution since its inception in the early 20th century. Initially developed for aircraft engines, turbochargers found their way into automotive applications in the 1960s. The primary goal of turbocharging has always been to increase engine power output and efficiency by forcing more air into the combustion chamber.

In the 1970s and 1980s, turbocharging gained popularity in motorsports, particularly in Formula 1 racing. This period saw rapid advancements in turbocharger design, materials, and control systems. The introduction of electronic fuel injection and engine management systems in the 1980s further improved the reliability and performance of turbocharged engines.

The 1990s marked a shift towards more widespread adoption of turbocharging in production vehicles. Manufacturers began to focus on reducing turbo lag and improving overall drivability. Variable geometry turbochargers (VGT) emerged during this period, offering better low-end torque and improved responsiveness across a wider range of engine speeds.

The turn of the millennium brought about a new era of turbocharging, driven by the need for improved fuel efficiency and reduced emissions. Twin-scroll turbochargers and twin-turbo setups became more common, allowing for better exhaust gas management and power delivery. Simultaneously, advancements in materials science led to the development of lighter, more heat-resistant turbine wheels and compressor impellers.

In recent years, the focus has shifted towards downsized, turbocharged engines as a means of meeting increasingly stringent emissions regulations while maintaining or improving performance. This trend has led to the widespread adoption of small-displacement, high-output turbocharged engines across various vehicle segments.

The latest developments in turbocharging technology include electric turbochargers and e-boosting systems, which aim to eliminate turbo lag entirely. These systems use electric motors to spool up the turbocharger instantly, providing immediate boost pressure and improving overall engine responsiveness.

As the automotive industry moves towards electrification, turbocharging continues to evolve. Hybrid powertrains are incorporating advanced turbocharging systems to maximize the efficiency of internal combustion engines when paired with electric motors. Additionally, research is ongoing into the application of turbocharging technology in fuel cell systems for hydrogen-powered vehicles.

In the 1970s and 1980s, turbocharging gained popularity in motorsports, particularly in Formula 1 racing. This period saw rapid advancements in turbocharger design, materials, and control systems. The introduction of electronic fuel injection and engine management systems in the 1980s further improved the reliability and performance of turbocharged engines.

The 1990s marked a shift towards more widespread adoption of turbocharging in production vehicles. Manufacturers began to focus on reducing turbo lag and improving overall drivability. Variable geometry turbochargers (VGT) emerged during this period, offering better low-end torque and improved responsiveness across a wider range of engine speeds.

The turn of the millennium brought about a new era of turbocharging, driven by the need for improved fuel efficiency and reduced emissions. Twin-scroll turbochargers and twin-turbo setups became more common, allowing for better exhaust gas management and power delivery. Simultaneously, advancements in materials science led to the development of lighter, more heat-resistant turbine wheels and compressor impellers.

In recent years, the focus has shifted towards downsized, turbocharged engines as a means of meeting increasingly stringent emissions regulations while maintaining or improving performance. This trend has led to the widespread adoption of small-displacement, high-output turbocharged engines across various vehicle segments.

The latest developments in turbocharging technology include electric turbochargers and e-boosting systems, which aim to eliminate turbo lag entirely. These systems use electric motors to spool up the turbocharger instantly, providing immediate boost pressure and improving overall engine responsiveness.

As the automotive industry moves towards electrification, turbocharging continues to evolve. Hybrid powertrains are incorporating advanced turbocharging systems to maximize the efficiency of internal combustion engines when paired with electric motors. Additionally, research is ongoing into the application of turbocharging technology in fuel cell systems for hydrogen-powered vehicles.

Market Demand Analysis

The market demand for advanced engine block materials in turbocharged applications has been steadily increasing over the past decade. This growth is primarily driven by the automotive industry's push towards more efficient and powerful engines, coupled with stringent emissions regulations worldwide. Turbocharged engines, known for their ability to deliver higher power output from smaller displacements, have become increasingly popular in both passenger vehicles and commercial trucks.

The global market for turbocharged engines is expected to grow significantly in the coming years, with a corresponding increase in demand for suitable engine block materials. This demand is particularly strong in regions with strict fuel efficiency standards, such as Europe, North America, and parts of Asia. As automakers strive to meet these standards while maintaining or improving performance, the choice of engine block materials becomes crucial.

Aluminum alloys have emerged as a preferred material for many turbocharged engine applications due to their lightweight properties and excellent heat dissipation characteristics. The market for aluminum engine blocks in turbocharged engines has seen substantial growth, especially in the passenger car segment. This trend is likely to continue as manufacturers seek to reduce overall vehicle weight to improve fuel efficiency.

However, there is also a growing demand for high-strength materials that can withstand the increased thermal and mechanical stresses associated with turbocharged engines. This has led to renewed interest in advanced iron alloys and composite materials. The commercial vehicle sector, in particular, shows a strong demand for materials that can provide durability and longevity under high-load conditions.

The aftermarket and performance sectors also contribute significantly to the demand for specialized engine block materials. As enthusiasts and racing teams push the limits of turbocharged engines, there is a constant search for materials that can handle extreme boost pressures and temperatures.

Emerging markets, particularly in Asia and South America, are expected to drive future growth in the turbocharged engine market. As these regions adopt more stringent emissions standards and consumers demand more powerful and efficient vehicles, the need for advanced engine block materials will increase.

The shift towards electrification in the automotive industry presents both challenges and opportunities for engine block material suppliers. While the long-term trend may reduce demand for internal combustion engines, it is likely to accelerate the need for lightweight and high-performance materials in the near to medium term, as manufacturers seek to maximize the efficiency of hybrid powertrains.

The global market for turbocharged engines is expected to grow significantly in the coming years, with a corresponding increase in demand for suitable engine block materials. This demand is particularly strong in regions with strict fuel efficiency standards, such as Europe, North America, and parts of Asia. As automakers strive to meet these standards while maintaining or improving performance, the choice of engine block materials becomes crucial.

Aluminum alloys have emerged as a preferred material for many turbocharged engine applications due to their lightweight properties and excellent heat dissipation characteristics. The market for aluminum engine blocks in turbocharged engines has seen substantial growth, especially in the passenger car segment. This trend is likely to continue as manufacturers seek to reduce overall vehicle weight to improve fuel efficiency.

However, there is also a growing demand for high-strength materials that can withstand the increased thermal and mechanical stresses associated with turbocharged engines. This has led to renewed interest in advanced iron alloys and composite materials. The commercial vehicle sector, in particular, shows a strong demand for materials that can provide durability and longevity under high-load conditions.

The aftermarket and performance sectors also contribute significantly to the demand for specialized engine block materials. As enthusiasts and racing teams push the limits of turbocharged engines, there is a constant search for materials that can handle extreme boost pressures and temperatures.

Emerging markets, particularly in Asia and South America, are expected to drive future growth in the turbocharged engine market. As these regions adopt more stringent emissions standards and consumers demand more powerful and efficient vehicles, the need for advanced engine block materials will increase.

The shift towards electrification in the automotive industry presents both challenges and opportunities for engine block material suppliers. While the long-term trend may reduce demand for internal combustion engines, it is likely to accelerate the need for lightweight and high-performance materials in the near to medium term, as manufacturers seek to maximize the efficiency of hybrid powertrains.

Current Challenges

The current challenges in engine block material choices for turbocharged applications are multifaceted and complex. One of the primary issues is the increased thermal and mechanical stress placed on engine components due to the higher power output and operating temperatures associated with turbocharging. This necessitates materials that can withstand these extreme conditions while maintaining structural integrity over extended periods.

Weight reduction remains a significant challenge, as manufacturers strive to improve fuel efficiency and overall vehicle performance. Traditional cast iron engine blocks, while durable, contribute substantially to vehicle weight. The automotive industry is thus pushed to explore lighter alternatives that do not compromise on strength or durability.

Cost-effectiveness is another crucial factor. While advanced materials like aluminum alloys and composites offer promising solutions, their higher production costs can be prohibitive for mass-market applications. Balancing material performance with economic viability is an ongoing struggle for engine designers and manufacturers.

Thermal management presents a unique set of challenges in turbocharged engines. The increased heat generation requires materials with superior thermal conductivity to efficiently dissipate heat and prevent localized hot spots that could lead to premature wear or failure. However, these materials must also maintain their structural properties at elevated temperatures.

Durability and longevity are paramount concerns, particularly in high-performance and commercial applications. The materials chosen must resist fatigue, creep, and corrosion under the intense conditions created by turbocharging. This is especially challenging given the cyclical nature of engine operation and the varied environmental conditions vehicles may encounter.

Manufacturing processes pose another hurdle. Some advanced materials that offer excellent properties may be difficult to cast or machine, requiring new production techniques or significant modifications to existing manufacturing lines. This can lead to increased production complexity and costs.

Environmental considerations add another layer of complexity to material selection. With increasing focus on sustainability, materials must not only perform well but also be recyclable and have a minimal environmental impact throughout their lifecycle. This includes considerations for end-of-life disposal and the potential for material recovery and reuse.

Lastly, the compatibility of engine block materials with other engine components and fluids is a critical challenge. The chosen material must interact favorably with coolants, lubricants, and adjacent components, ensuring long-term reliability and performance of the entire engine system.

Weight reduction remains a significant challenge, as manufacturers strive to improve fuel efficiency and overall vehicle performance. Traditional cast iron engine blocks, while durable, contribute substantially to vehicle weight. The automotive industry is thus pushed to explore lighter alternatives that do not compromise on strength or durability.

Cost-effectiveness is another crucial factor. While advanced materials like aluminum alloys and composites offer promising solutions, their higher production costs can be prohibitive for mass-market applications. Balancing material performance with economic viability is an ongoing struggle for engine designers and manufacturers.

Thermal management presents a unique set of challenges in turbocharged engines. The increased heat generation requires materials with superior thermal conductivity to efficiently dissipate heat and prevent localized hot spots that could lead to premature wear or failure. However, these materials must also maintain their structural properties at elevated temperatures.

Durability and longevity are paramount concerns, particularly in high-performance and commercial applications. The materials chosen must resist fatigue, creep, and corrosion under the intense conditions created by turbocharging. This is especially challenging given the cyclical nature of engine operation and the varied environmental conditions vehicles may encounter.

Manufacturing processes pose another hurdle. Some advanced materials that offer excellent properties may be difficult to cast or machine, requiring new production techniques or significant modifications to existing manufacturing lines. This can lead to increased production complexity and costs.

Environmental considerations add another layer of complexity to material selection. With increasing focus on sustainability, materials must not only perform well but also be recyclable and have a minimal environmental impact throughout their lifecycle. This includes considerations for end-of-life disposal and the potential for material recovery and reuse.

Lastly, the compatibility of engine block materials with other engine components and fluids is a critical challenge. The chosen material must interact favorably with coolants, lubricants, and adjacent components, ensuring long-term reliability and performance of the entire engine system.

Existing Solutions

01 Lightweight alloy materials for engine blocks

Engine blocks are increasingly being manufactured using lightweight alloy materials, such as aluminum alloys, to reduce overall vehicle weight and improve fuel efficiency. These materials offer a good balance of strength, thermal conductivity, and weight reduction compared to traditional cast iron blocks.- Lightweight alloy materials for engine blocks: Engine blocks are increasingly being manufactured using lightweight alloy materials, such as aluminum alloys, to reduce overall vehicle weight and improve fuel efficiency. These materials offer a good balance of strength, thermal conductivity, and weight reduction compared to traditional cast iron blocks.

- Thermal management and material properties: The material properties of engine blocks are crucial for effective thermal management. Materials with high thermal conductivity help dissipate heat efficiently, while those with low thermal expansion coefficients maintain dimensional stability under varying temperatures. Coatings and surface treatments can be applied to enhance these properties.

- Composite and hybrid materials for engine blocks: Innovative composite and hybrid materials are being developed for engine blocks to combine the benefits of different materials. These may include metal matrix composites, fiber-reinforced polymers, or hybrid structures that use multiple materials in different parts of the block to optimize performance and weight.

- Wear-resistant and high-strength materials: Engine blocks require materials with high wear resistance and strength to withstand the mechanical stresses and friction during operation. Advanced alloys, surface treatments, and coatings are used to enhance these properties, particularly in high-stress areas such as cylinder bores and bearing surfaces.

- Manufacturing processes and material selection: The choice of engine block materials is closely tied to manufacturing processes. Casting, forging, and advanced manufacturing techniques like 3D printing influence material selection and final properties. The manufacturing process can be optimized to enhance material properties such as grain structure, porosity, and surface finish.

02 Thermal management and material properties

Engine block materials must possess specific thermal properties to manage heat effectively. This includes high thermal conductivity to dissipate heat quickly, low thermal expansion to maintain dimensional stability, and resistance to thermal fatigue. Materials are selected and engineered to optimize these properties for improved engine performance and longevity.Expand Specific Solutions03 Wear-resistant coatings and surface treatments

To enhance the durability and performance of engine blocks, various surface treatments and coatings are applied. These treatments can improve wear resistance, reduce friction, and enhance oil retention. Examples include plasma spraying, anodizing, and the application of ceramic or composite coatings to critical surfaces within the engine block.Expand Specific Solutions04 Composite and hybrid materials

Advanced engine block designs incorporate composite and hybrid materials to optimize performance. This may include metal matrix composites, fiber-reinforced polymers, or hybrid structures combining different materials. These innovative approaches aim to achieve an optimal balance of strength, weight reduction, and thermal management.Expand Specific Solutions05 Material selection for specific engine types

The choice of engine block materials varies depending on the specific engine type and application. For instance, high-performance engines may require materials with superior strength and heat resistance, while engines for everyday vehicles might prioritize cost-effectiveness and ease of manufacturing. Material selection considers factors such as operating temperatures, power output, and expected lifespan.Expand Specific Solutions

Key Industry Players

The competitive landscape for engine block material choices in turbocharged applications is characterized by a mature market with established players and ongoing innovation. The industry is in a phase of technological refinement, driven by the need for lightweight, durable materials that can withstand high pressures and temperatures. Major automotive manufacturers like Ford, Caterpillar, BorgWarner, and Mercedes-Benz are at the forefront, investing heavily in research and development. The market size is substantial, given the widespread use of turbocharged engines in various sectors. Companies such as MAHLE Ventiltrieb and Eisenwerk Brühl are specializing in engine components, while research institutions like Chongqing University contribute to advancing material science in this field.

Ford Global Technologies LLC

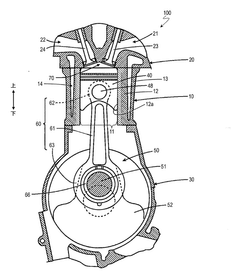

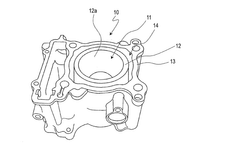

Technical Solution: Ford has developed advanced aluminum alloy engine blocks for turbocharged applications, utilizing a high-pressure die-casting process. This technology incorporates specialized heat treatment and cooling strategies to enhance material properties. The company has implemented a proprietary alloy composition that includes silicon, copper, and magnesium to improve strength and thermal conductivity[1][3]. Ford's engine blocks feature integrated water jackets and oil galleries, reducing weight while maintaining structural integrity. The design also incorporates cast-in iron cylinder liners for improved durability and heat dissipation in high-performance turbocharged engines[2].

Strengths: Lightweight construction, improved thermal management, and enhanced durability for turbocharged applications. Weaknesses: Higher production costs compared to traditional iron blocks, and potential long-term reliability concerns in extreme operating conditions.

BorgWarner, Inc.

Technical Solution: BorgWarner has pioneered the use of compacted graphite iron (CGI) for turbocharged engine blocks. This material offers superior strength-to-weight ratio compared to traditional gray cast iron. The company's CGI engine blocks are manufactured using a patented casting process that ensures consistent graphite structure throughout the material[4]. BorgWarner has also developed advanced cooling channel designs within the CGI blocks to manage the higher thermal loads of turbocharged engines. Their technology includes integrated turbocharger mounting points and reinforced bearing areas to withstand increased cylinder pressures[5]. The company has successfully implemented CGI blocks in various high-performance and commercial vehicle applications.

Strengths: Excellent strength and stiffness, improved fatigue resistance, and better thermal conductivity than aluminum. Weaknesses: Higher material and manufacturing costs, and increased weight compared to aluminum alternatives.

Core Innovations

Motor block having molded cylinder sleeves comprising a plurality of material layers and method for producing the cylinder sleeves

PatentInactiveEP2214850A1

Innovation

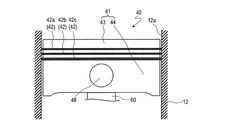

- The engine block features cast-in cylinder liners with multiple layers of different strength materials, including a high-strength aluminum alloy sleeve and a wear-resistant Al-Si alloy track, produced through centrifugal casting or extrusion, allowing for a one-piece, integral design with continuous material gradients and reduced need for additional coatings.

Internal combustion engine and transportation device

PatentWO2023112125A1

Innovation

- The engine features a cylinder block with a sliding surface having a ten-point average roughness of 0.5 μm or less, a primary silicon grain crushing rate of 20% or less, and an area ratio of primary silicon grains of 8% or more, ensuring a uniform oil film and reduced friction, while maintaining sufficient seizure resistance without the need for crosshatch grooves.

Environmental Impact

The environmental impact of engine block material choices for turbocharged applications is a critical consideration in the automotive industry's pursuit of sustainability. Turbocharging technology, while improving engine efficiency and performance, places increased thermal and mechanical stress on engine components, necessitating careful material selection to balance durability with environmental concerns.

Traditional cast iron engine blocks, known for their strength and durability, have significant environmental drawbacks. The production of cast iron is energy-intensive and generates substantial greenhouse gas emissions. Additionally, the weight of cast iron blocks contributes to increased fuel consumption and emissions throughout the vehicle's lifecycle. However, cast iron's recyclability partially mitigates its environmental impact.

Aluminum alloys have gained popularity as a more environmentally friendly alternative. The production of aluminum engine blocks generally has a lower carbon footprint compared to cast iron, primarily due to reduced energy requirements during manufacturing. The lighter weight of aluminum blocks also contributes to improved fuel efficiency and reduced emissions during vehicle operation. Furthermore, aluminum is highly recyclable, allowing for closed-loop material cycles that minimize waste and resource depletion.

Composite materials, such as metal matrix composites (MMCs) and carbon fiber reinforced polymers (CFRPs), are emerging as potential eco-friendly options for turbocharged engine blocks. These materials offer significant weight reduction and improved thermal management, potentially leading to enhanced engine efficiency and reduced emissions. However, the environmental impact of composite production and end-of-life recycling challenges must be carefully evaluated.

The use of advanced manufacturing techniques, such as 3D printing and selective laser melting, can further reduce the environmental footprint of engine block production. These processes minimize material waste and enable the creation of optimized designs that maximize performance while minimizing material usage. Additionally, these techniques allow for the use of novel materials and alloys that may offer superior environmental performance.

Lifecycle assessment (LCA) studies are crucial in evaluating the overall environmental impact of different engine block materials. These assessments consider factors such as raw material extraction, manufacturing processes, use-phase emissions, and end-of-life disposal or recycling. Recent LCA studies have shown that the choice of engine block material can significantly influence a vehicle's total lifecycle emissions and resource consumption.

As environmental regulations become increasingly stringent, manufacturers are exploring innovative material solutions that balance performance requirements with sustainability goals. This includes the development of bio-based materials and the incorporation of recycled content in engine block production. These efforts aim to reduce the automotive industry's reliance on virgin materials and minimize the overall environmental footprint of engine manufacturing.

Traditional cast iron engine blocks, known for their strength and durability, have significant environmental drawbacks. The production of cast iron is energy-intensive and generates substantial greenhouse gas emissions. Additionally, the weight of cast iron blocks contributes to increased fuel consumption and emissions throughout the vehicle's lifecycle. However, cast iron's recyclability partially mitigates its environmental impact.

Aluminum alloys have gained popularity as a more environmentally friendly alternative. The production of aluminum engine blocks generally has a lower carbon footprint compared to cast iron, primarily due to reduced energy requirements during manufacturing. The lighter weight of aluminum blocks also contributes to improved fuel efficiency and reduced emissions during vehicle operation. Furthermore, aluminum is highly recyclable, allowing for closed-loop material cycles that minimize waste and resource depletion.

Composite materials, such as metal matrix composites (MMCs) and carbon fiber reinforced polymers (CFRPs), are emerging as potential eco-friendly options for turbocharged engine blocks. These materials offer significant weight reduction and improved thermal management, potentially leading to enhanced engine efficiency and reduced emissions. However, the environmental impact of composite production and end-of-life recycling challenges must be carefully evaluated.

The use of advanced manufacturing techniques, such as 3D printing and selective laser melting, can further reduce the environmental footprint of engine block production. These processes minimize material waste and enable the creation of optimized designs that maximize performance while minimizing material usage. Additionally, these techniques allow for the use of novel materials and alloys that may offer superior environmental performance.

Lifecycle assessment (LCA) studies are crucial in evaluating the overall environmental impact of different engine block materials. These assessments consider factors such as raw material extraction, manufacturing processes, use-phase emissions, and end-of-life disposal or recycling. Recent LCA studies have shown that the choice of engine block material can significantly influence a vehicle's total lifecycle emissions and resource consumption.

As environmental regulations become increasingly stringent, manufacturers are exploring innovative material solutions that balance performance requirements with sustainability goals. This includes the development of bio-based materials and the incorporation of recycled content in engine block production. These efforts aim to reduce the automotive industry's reliance on virgin materials and minimize the overall environmental footprint of engine manufacturing.

Cost-Benefit Analysis

When evaluating engine block material choices for turbocharged applications, a comprehensive cost-benefit analysis is crucial for making informed decisions. The primary materials under consideration are cast iron, aluminum alloys, and in some cases, advanced composites. Each material presents distinct advantages and drawbacks in terms of cost, performance, and manufacturing processes.

Cast iron, traditionally used in engine blocks, offers excellent durability and heat resistance at a relatively low cost. The material's inherent strength allows for thinner cylinder walls, potentially reducing overall engine weight. However, cast iron's higher density compared to aluminum results in a heavier engine, which can negatively impact fuel efficiency and vehicle performance.

Aluminum alloys, on the other hand, provide significant weight reduction benefits. The lighter engine block contributes to improved fuel economy and better overall vehicle dynamics. Aluminum also offers superior heat dissipation properties, which is particularly advantageous in turbocharged applications where heat management is critical. The initial cost of aluminum is higher than cast iron, but this can be offset by fuel savings over the vehicle's lifetime.

Manufacturing processes for aluminum engine blocks are generally more complex and expensive than those for cast iron. Techniques such as high-pressure die casting or lost foam casting are often employed, requiring specialized equipment and expertise. However, these processes can lead to improved dimensional accuracy and surface finish, potentially reducing post-casting machining costs.

Durability considerations in turbocharged applications favor cast iron due to its superior strength and wear resistance. Aluminum blocks often require additional reinforcement or specialized treatments like cylinder liners to withstand the increased stresses of forced induction. These additional processes increase production costs but are necessary to ensure longevity and reliability.

From a lifecycle perspective, aluminum's recyclability offers long-term cost benefits and aligns with sustainability goals. The ability to recycle aluminum engine blocks at the end of their service life can offset initial material costs and reduce environmental impact. Cast iron, while also recyclable, typically has a lower reclamation value.

In conclusion, the cost-benefit analysis of engine block materials for turbocharged applications must consider initial costs, manufacturing complexity, performance characteristics, durability, and long-term environmental impact. While aluminum alloys generally offer superior performance and efficiency benefits, the higher initial costs and manufacturing complexities must be carefully weighed against these advantages. The optimal choice depends on specific application requirements, production volumes, and long-term strategic goals of the manufacturer.

Cast iron, traditionally used in engine blocks, offers excellent durability and heat resistance at a relatively low cost. The material's inherent strength allows for thinner cylinder walls, potentially reducing overall engine weight. However, cast iron's higher density compared to aluminum results in a heavier engine, which can negatively impact fuel efficiency and vehicle performance.

Aluminum alloys, on the other hand, provide significant weight reduction benefits. The lighter engine block contributes to improved fuel economy and better overall vehicle dynamics. Aluminum also offers superior heat dissipation properties, which is particularly advantageous in turbocharged applications where heat management is critical. The initial cost of aluminum is higher than cast iron, but this can be offset by fuel savings over the vehicle's lifetime.

Manufacturing processes for aluminum engine blocks are generally more complex and expensive than those for cast iron. Techniques such as high-pressure die casting or lost foam casting are often employed, requiring specialized equipment and expertise. However, these processes can lead to improved dimensional accuracy and surface finish, potentially reducing post-casting machining costs.

Durability considerations in turbocharged applications favor cast iron due to its superior strength and wear resistance. Aluminum blocks often require additional reinforcement or specialized treatments like cylinder liners to withstand the increased stresses of forced induction. These additional processes increase production costs but are necessary to ensure longevity and reliability.

From a lifecycle perspective, aluminum's recyclability offers long-term cost benefits and aligns with sustainability goals. The ability to recycle aluminum engine blocks at the end of their service life can offset initial material costs and reduce environmental impact. Cast iron, while also recyclable, typically has a lower reclamation value.

In conclusion, the cost-benefit analysis of engine block materials for turbocharged applications must consider initial costs, manufacturing complexity, performance characteristics, durability, and long-term environmental impact. While aluminum alloys generally offer superior performance and efficiency benefits, the higher initial costs and manufacturing complexities must be carefully weighed against these advantages. The optimal choice depends on specific application requirements, production volumes, and long-term strategic goals of the manufacturer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!