Engine Block Surface Treatments To Reduce Seizure Risk

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Treatment Background and Objectives

Engine block surface treatments have been a critical area of research and development in the automotive industry for decades. The primary objective of these treatments is to enhance the durability, performance, and efficiency of internal combustion engines. Historically, engine blocks have been subjected to various surface treatments to improve their wear resistance, reduce friction, and prevent seizure, which occurs when two moving parts in an engine become locked together due to excessive heat or friction.

The evolution of engine block surface treatments can be traced back to the early days of automotive manufacturing. Initially, basic machining processes were used to create smooth surfaces on engine blocks. As technology advanced, more sophisticated treatments emerged, including various coating techniques, surface hardening processes, and chemical treatments. These advancements were driven by the need for engines that could withstand higher temperatures, pressures, and speeds while maintaining optimal performance and fuel efficiency.

In recent years, the focus on reducing seizure risk has become increasingly important due to the trend towards more compact and powerful engines. This has led to higher thermal and mechanical stresses on engine components, making them more susceptible to seizure. Consequently, the development of advanced surface treatments has become a key area of research for engine manufacturers and materials scientists.

The current technological landscape for engine block surface treatments encompasses a wide range of techniques. These include thermal spraying, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma nitriding, and various electroplating processes. Each of these methods offers unique advantages in terms of wear resistance, friction reduction, and seizure prevention. However, they also come with their own set of challenges, such as cost-effectiveness, scalability, and compatibility with different engine materials and designs.

The primary goal of research in this field is to develop surface treatments that can effectively reduce the risk of seizure while simultaneously improving other aspects of engine performance. This involves finding the optimal balance between hardness, lubricity, thermal conductivity, and adhesion to the base material. Additionally, researchers aim to create treatments that are environmentally friendly, cost-effective, and suitable for mass production.

As engine technology continues to evolve, with trends towards electrification and alternative fuels, the objectives of engine block surface treatment research are also expanding. There is a growing emphasis on developing treatments that can adapt to these new technologies while still addressing the fundamental issue of seizure prevention. This includes exploring novel materials and nanotechnology-based solutions that can provide superior protection against seizure under a wide range of operating conditions.

The evolution of engine block surface treatments can be traced back to the early days of automotive manufacturing. Initially, basic machining processes were used to create smooth surfaces on engine blocks. As technology advanced, more sophisticated treatments emerged, including various coating techniques, surface hardening processes, and chemical treatments. These advancements were driven by the need for engines that could withstand higher temperatures, pressures, and speeds while maintaining optimal performance and fuel efficiency.

In recent years, the focus on reducing seizure risk has become increasingly important due to the trend towards more compact and powerful engines. This has led to higher thermal and mechanical stresses on engine components, making them more susceptible to seizure. Consequently, the development of advanced surface treatments has become a key area of research for engine manufacturers and materials scientists.

The current technological landscape for engine block surface treatments encompasses a wide range of techniques. These include thermal spraying, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma nitriding, and various electroplating processes. Each of these methods offers unique advantages in terms of wear resistance, friction reduction, and seizure prevention. However, they also come with their own set of challenges, such as cost-effectiveness, scalability, and compatibility with different engine materials and designs.

The primary goal of research in this field is to develop surface treatments that can effectively reduce the risk of seizure while simultaneously improving other aspects of engine performance. This involves finding the optimal balance between hardness, lubricity, thermal conductivity, and adhesion to the base material. Additionally, researchers aim to create treatments that are environmentally friendly, cost-effective, and suitable for mass production.

As engine technology continues to evolve, with trends towards electrification and alternative fuels, the objectives of engine block surface treatment research are also expanding. There is a growing emphasis on developing treatments that can adapt to these new technologies while still addressing the fundamental issue of seizure prevention. This includes exploring novel materials and nanotechnology-based solutions that can provide superior protection against seizure under a wide range of operating conditions.

Market Analysis for Anti-Seizure Engine Technologies

The market for anti-seizure engine technologies has experienced significant growth in recent years, driven by increasing demand for more reliable and efficient engines across various industries. The global automotive industry, in particular, has been a major contributor to this growth, with stringent emission regulations and the need for improved fuel efficiency pushing manufacturers to develop more advanced engine technologies.

The market size for anti-seizure engine technologies is substantial, with estimates suggesting a value of several billion dollars annually. This market encompasses a wide range of products and services, including surface treatments, coatings, lubricants, and advanced materials designed to reduce the risk of engine seizure. The automotive sector accounts for the largest share of this market, followed by aerospace, marine, and industrial applications.

Key market drivers include the growing emphasis on vehicle performance and durability, increasing consumer expectations for longer-lasting engines, and the rising costs associated with engine failures and repairs. Additionally, the trend towards downsized engines with higher power outputs has intensified the need for more effective anti-seizure technologies, as these engines often operate under higher temperatures and pressures.

Geographically, North America and Europe lead the market for anti-seizure engine technologies, owing to their well-established automotive industries and stringent regulatory environments. However, the Asia-Pacific region is experiencing the fastest growth, driven by rapid industrialization, increasing vehicle production, and rising disposable incomes in countries like China and India.

The market is characterized by intense competition among major players, including global automotive suppliers, chemical companies, and specialized coating manufacturers. These companies are investing heavily in research and development to create innovative solutions that offer superior protection against engine seizure while meeting increasingly stringent performance and environmental standards.

Looking ahead, the market for anti-seizure engine technologies is expected to continue its growth trajectory. Factors such as the ongoing electrification of vehicles, the development of hybrid powertrains, and the push for more sustainable transportation solutions are likely to create new opportunities and challenges for anti-seizure technologies. As engines become more complex and operate under more extreme conditions, the demand for advanced surface treatments and materials to prevent seizure is anticipated to increase further.

The market size for anti-seizure engine technologies is substantial, with estimates suggesting a value of several billion dollars annually. This market encompasses a wide range of products and services, including surface treatments, coatings, lubricants, and advanced materials designed to reduce the risk of engine seizure. The automotive sector accounts for the largest share of this market, followed by aerospace, marine, and industrial applications.

Key market drivers include the growing emphasis on vehicle performance and durability, increasing consumer expectations for longer-lasting engines, and the rising costs associated with engine failures and repairs. Additionally, the trend towards downsized engines with higher power outputs has intensified the need for more effective anti-seizure technologies, as these engines often operate under higher temperatures and pressures.

Geographically, North America and Europe lead the market for anti-seizure engine technologies, owing to their well-established automotive industries and stringent regulatory environments. However, the Asia-Pacific region is experiencing the fastest growth, driven by rapid industrialization, increasing vehicle production, and rising disposable incomes in countries like China and India.

The market is characterized by intense competition among major players, including global automotive suppliers, chemical companies, and specialized coating manufacturers. These companies are investing heavily in research and development to create innovative solutions that offer superior protection against engine seizure while meeting increasingly stringent performance and environmental standards.

Looking ahead, the market for anti-seizure engine technologies is expected to continue its growth trajectory. Factors such as the ongoing electrification of vehicles, the development of hybrid powertrains, and the push for more sustainable transportation solutions are likely to create new opportunities and challenges for anti-seizure technologies. As engines become more complex and operate under more extreme conditions, the demand for advanced surface treatments and materials to prevent seizure is anticipated to increase further.

Current Challenges in Engine Block Surface Treatments

Engine block surface treatments play a crucial role in reducing seizure risk, yet several challenges persist in this field. One of the primary issues is achieving uniform coating thickness across complex engine block geometries. The intricate design of modern engine blocks, with their various channels and cavities, makes it difficult to apply consistent surface treatments. This non-uniformity can lead to areas of weakness where seizure is more likely to occur.

Another significant challenge is the selection of appropriate coating materials that can withstand the extreme conditions within an engine. The ideal surface treatment must resist high temperatures, withstand corrosive environments, and maintain its integrity under constant friction. Finding a material that meets all these requirements while remaining cost-effective for mass production is an ongoing struggle for manufacturers.

The adhesion of surface treatments to the engine block substrate presents another hurdle. Poor adhesion can result in coating delamination, exposing the underlying metal and increasing seizure risk. Ensuring strong bonding between the treatment and the engine block material, typically cast iron or aluminum alloys, requires careful consideration of surface preparation techniques and coating application methods.

Durability of surface treatments over the engine's lifespan is a persistent challenge. As engines are subjected to thousands of thermal cycles and millions of rotations, the surface treatment must maintain its protective properties. Degradation of the coating over time can lead to increased friction, wear, and ultimately, a higher risk of seizure. Developing treatments that can withstand these long-term stresses without significant deterioration remains a key focus area for researchers.

The environmental impact of surface treatment processes is becoming an increasingly important consideration. Many traditional coating methods involve the use of hazardous materials or produce harmful byproducts. Balancing the need for effective seizure prevention with environmental regulations and sustainability goals presents a complex challenge for the industry.

Cost-effectiveness is another major hurdle in the widespread adoption of advanced surface treatments. While some high-performance coatings show excellent seizure resistance, their application processes may be too expensive for mass-market vehicles. Finding a balance between performance and cost that allows for implementation across various vehicle segments is an ongoing challenge.

Lastly, the integration of surface treatments with other engine technologies poses significant challenges. As engines become more advanced, incorporating features like direct injection or variable compression ratios, the surface treatment must be compatible with these innovations without compromising their functionality or the overall engine performance.

Another significant challenge is the selection of appropriate coating materials that can withstand the extreme conditions within an engine. The ideal surface treatment must resist high temperatures, withstand corrosive environments, and maintain its integrity under constant friction. Finding a material that meets all these requirements while remaining cost-effective for mass production is an ongoing struggle for manufacturers.

The adhesion of surface treatments to the engine block substrate presents another hurdle. Poor adhesion can result in coating delamination, exposing the underlying metal and increasing seizure risk. Ensuring strong bonding between the treatment and the engine block material, typically cast iron or aluminum alloys, requires careful consideration of surface preparation techniques and coating application methods.

Durability of surface treatments over the engine's lifespan is a persistent challenge. As engines are subjected to thousands of thermal cycles and millions of rotations, the surface treatment must maintain its protective properties. Degradation of the coating over time can lead to increased friction, wear, and ultimately, a higher risk of seizure. Developing treatments that can withstand these long-term stresses without significant deterioration remains a key focus area for researchers.

The environmental impact of surface treatment processes is becoming an increasingly important consideration. Many traditional coating methods involve the use of hazardous materials or produce harmful byproducts. Balancing the need for effective seizure prevention with environmental regulations and sustainability goals presents a complex challenge for the industry.

Cost-effectiveness is another major hurdle in the widespread adoption of advanced surface treatments. While some high-performance coatings show excellent seizure resistance, their application processes may be too expensive for mass-market vehicles. Finding a balance between performance and cost that allows for implementation across various vehicle segments is an ongoing challenge.

Lastly, the integration of surface treatments with other engine technologies poses significant challenges. As engines become more advanced, incorporating features like direct injection or variable compression ratios, the surface treatment must be compatible with these innovations without compromising their functionality or the overall engine performance.

Existing Anti-Seizure Surface Treatment Solutions

01 Surface coatings to reduce friction

Various surface coatings can be applied to engine block surfaces to reduce friction and minimize the risk of seizure. These coatings, such as ceramic or polymer-based materials, create a low-friction interface between moving parts, enhancing durability and reducing wear. The coatings can be applied through methods like thermal spraying or chemical vapor deposition, providing a protective layer that withstands high temperatures and pressures in the engine environment.- Surface coatings to reduce friction and wear: Various surface coatings can be applied to engine block surfaces to reduce friction and wear, thereby decreasing the risk of seizure. These coatings may include ceramic-based materials, diamond-like carbon (DLC) coatings, or other advanced materials that provide a low-friction surface and improved wear resistance.

- Thermal barrier coatings for improved heat management: Applying thermal barrier coatings to engine block surfaces can help manage heat distribution and reduce thermal stress, which in turn lowers the risk of seizure. These coatings typically consist of ceramic materials that provide insulation and protect the underlying metal from extreme temperatures.

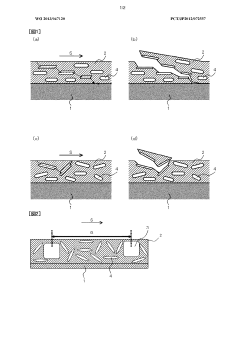

- Surface texturing for improved oil retention: Implementing specific surface texturing techniques on engine block surfaces can enhance oil retention and distribution. This improved lubrication helps reduce friction and the risk of seizure. Techniques may include laser etching, micro-dimpling, or other methods to create controlled surface patterns.

- Advanced material selection for engine block components: Utilizing advanced materials in engine block construction can inherently reduce the risk of seizure. This may include the use of high-strength alloys, composite materials, or materials with superior thermal properties that can better withstand the extreme conditions within an engine.

- Precision machining and surface finishing techniques: Employing high-precision machining and advanced surface finishing techniques can significantly improve the surface quality of engine block components. This results in better dimensional accuracy, reduced surface roughness, and improved mating between moving parts, all of which contribute to lowering the risk of seizure.

02 Textured surface treatments

Engineered surface textures can be applied to engine block surfaces to improve oil retention and distribution. These micro-textures, created through processes like laser etching or chemical etching, form small reservoirs that hold lubricant and help maintain a consistent oil film between moving parts. This approach reduces friction and the likelihood of metal-to-metal contact, thereby decreasing the risk of seizure under high-load conditions.Expand Specific Solutions03 Heat treatment processes

Specialized heat treatment processes can be employed to enhance the surface properties of engine block materials. These treatments, such as nitriding or carburizing, alter the microstructure of the surface layer, increasing hardness and wear resistance. By improving the material's ability to withstand high temperatures and mechanical stresses, these processes help reduce the risk of seizure and extend the engine's operational life.Expand Specific Solutions04 Advanced material selection

The choice of materials for engine block construction plays a crucial role in mitigating seizure risk. Advanced alloys, such as aluminum-silicon alloys with improved thermal properties or cast iron with optimized graphite structures, can be selected to enhance heat dissipation and reduce thermal expansion. These materials help maintain proper clearances between moving parts under various operating conditions, reducing the likelihood of seizure.Expand Specific Solutions05 Precision machining and surface finishing

High-precision machining techniques and advanced surface finishing processes can be applied to engine block surfaces to achieve optimal smoothness and dimensional accuracy. These processes, which may include honing, lapping, or superfinishing, help create surfaces with minimal roughness and precise geometries. The resulting smooth surfaces reduce friction, improve oil film formation, and maintain consistent clearances, all of which contribute to lowering the risk of engine seizure.Expand Specific Solutions

Key Players in Engine Block Treatment Industry

The research on engine block surface treatments to reduce seizure risk is in a mature stage of development, with significant market potential in the automotive and industrial machinery sectors. The global market for engine components is substantial, driven by the continuous growth of the automotive industry and the need for more efficient and durable engines. Major players in this field include established automotive manufacturers like Toyota, Honda, and Ford, as well as specialized component manufacturers such as MAHLE, Federal-Mogul, and Teikoku Piston Ring. These companies have demonstrated advanced technological capabilities in surface treatment technologies, leveraging their extensive R&D resources and industry experience to develop innovative solutions for reducing engine seizure risks.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced surface treatment process for engine blocks to reduce seizure risk. Their method involves a combination of plasma electrolytic oxidation (PEO) and diamond-like carbon (DLC) coating [1]. The PEO process creates a hard, wear-resistant oxide layer on the aluminum surface, while the DLC coating provides excellent lubricity and further wear protection. This dual-layer approach significantly enhances the surface hardness and reduces friction, leading to improved engine performance and longevity [3]. Toyota has also implemented a nano-scale surface texturing technique to create microscopic oil retention pockets, further reducing the risk of metal-to-metal contact and seizure [5].

Strengths: Excellent wear resistance, reduced friction, and improved oil retention. Weaknesses: Potentially higher production costs and complexity in the manufacturing process.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a novel surface treatment technique for engine blocks called "Ford Plasma Transferred Wire Arc" (F-PTWA) [2]. This process involves spraying a thin layer of steel onto the cylinder bores of aluminum engine blocks. The F-PTWA coating is approximately 150 microns thick and provides excellent wear resistance and reduced friction [4]. Ford has also developed a proprietary post-coating surface finishing process that creates a cross-hatch pattern, enhancing oil retention and further reducing the risk of seizure. Additionally, Ford has implemented advanced thermal management techniques in their engine designs to minimize thermal expansion and maintain consistent surface properties [6].

Strengths: Lightweight aluminum blocks with steel-like durability, improved fuel efficiency. Weaknesses: Specialized equipment required for coating application, potential for coating delamination under extreme conditions.

Core Innovations in Engine Block Surface Treatments

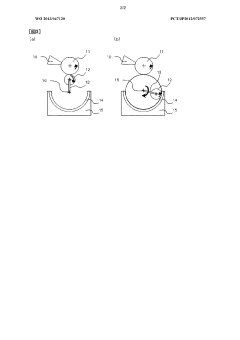

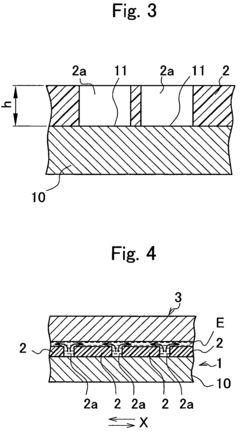

Sliding bearing

PatentWO2013047120A1

Innovation

- A plain bearing with a resin coating layer containing 20-50 vol% plate-shaped solid lubricants and 5-30 vol% adjustment particles, where the resin binder is primarily PAI with optional PA and EP, and calcium carbonate, ensuring an orientation strength ratio of 75-85% for the (0, 0, L) plane, and a film thickness of 2-10 μm, which improves sliding properties and prevents peeling.

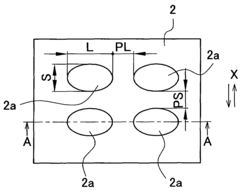

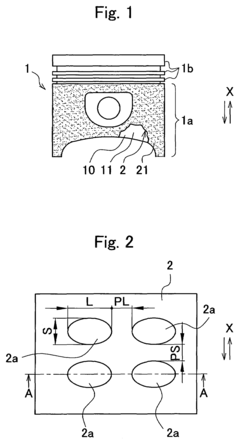

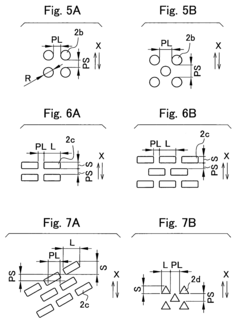

Piston for internal combustion engine

PatentActiveUS7287459B2

Innovation

- A resinous coating layer with regularly arranged concaves is formed on the skirt part of the piston, reducing frictional resistance in both solid contact and complex lubrication regions through a chemical coating treatment without mechanical surface processing.

Environmental Impact of Surface Treatment Processes

Surface treatment processes for engine blocks, while crucial for reducing seizure risk, can have significant environmental impacts. These processes often involve the use of chemicals, energy-intensive operations, and the generation of waste materials. The environmental consequences of these treatments span air, water, and soil pollution, as well as resource depletion and energy consumption.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during surface treatment processes. Many coating and cleaning operations emit VOCs, which contribute to air pollution and can have adverse effects on human health and the environment. Additionally, some surface treatments may involve the use of heavy metals or other toxic substances, which can contaminate water sources if not properly managed.

Water pollution is another significant issue associated with engine block surface treatments. Processes such as chemical etching, electroplating, and washing can generate wastewater containing various contaminants, including oils, greases, metal ions, and treatment chemicals. If not adequately treated before discharge, this wastewater can harm aquatic ecosystems and potentially enter the food chain.

The energy consumption of surface treatment processes also contributes to their environmental footprint. Many treatments require high temperatures or electrical energy for operations such as thermal spraying, anodizing, or heat treatment. This energy use translates to increased greenhouse gas emissions and contributes to climate change if the energy source is not renewable.

Waste generation is a further environmental concern. Surface treatment processes can produce solid waste in the form of spent abrasives, sludge from wastewater treatment, and discarded coating materials. Proper disposal or recycling of these wastes is essential to prevent soil contamination and reduce the burden on landfills.

To mitigate these environmental impacts, the industry is increasingly focusing on developing more sustainable surface treatment processes. This includes the adoption of water-based or solvent-free coatings, implementation of closed-loop systems for water and chemical recycling, and the use of more energy-efficient equipment. Additionally, there is a growing emphasis on life cycle assessment to evaluate the overall environmental impact of different surface treatment options and guide decision-making towards more sustainable choices.

Regulatory frameworks also play a crucial role in addressing the environmental impacts of surface treatments. Many countries have implemented strict regulations governing emissions, waste disposal, and the use of hazardous substances in industrial processes. Compliance with these regulations drives innovation in cleaner technologies and more environmentally friendly surface treatment methods for engine blocks.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during surface treatment processes. Many coating and cleaning operations emit VOCs, which contribute to air pollution and can have adverse effects on human health and the environment. Additionally, some surface treatments may involve the use of heavy metals or other toxic substances, which can contaminate water sources if not properly managed.

Water pollution is another significant issue associated with engine block surface treatments. Processes such as chemical etching, electroplating, and washing can generate wastewater containing various contaminants, including oils, greases, metal ions, and treatment chemicals. If not adequately treated before discharge, this wastewater can harm aquatic ecosystems and potentially enter the food chain.

The energy consumption of surface treatment processes also contributes to their environmental footprint. Many treatments require high temperatures or electrical energy for operations such as thermal spraying, anodizing, or heat treatment. This energy use translates to increased greenhouse gas emissions and contributes to climate change if the energy source is not renewable.

Waste generation is a further environmental concern. Surface treatment processes can produce solid waste in the form of spent abrasives, sludge from wastewater treatment, and discarded coating materials. Proper disposal or recycling of these wastes is essential to prevent soil contamination and reduce the burden on landfills.

To mitigate these environmental impacts, the industry is increasingly focusing on developing more sustainable surface treatment processes. This includes the adoption of water-based or solvent-free coatings, implementation of closed-loop systems for water and chemical recycling, and the use of more energy-efficient equipment. Additionally, there is a growing emphasis on life cycle assessment to evaluate the overall environmental impact of different surface treatment options and guide decision-making towards more sustainable choices.

Regulatory frameworks also play a crucial role in addressing the environmental impacts of surface treatments. Many countries have implemented strict regulations governing emissions, waste disposal, and the use of hazardous substances in industrial processes. Compliance with these regulations drives innovation in cleaner technologies and more environmentally friendly surface treatment methods for engine blocks.

Cost-Benefit Analysis of Advanced Surface Treatments

The implementation of advanced surface treatments for engine blocks represents a significant investment for manufacturers, necessitating a thorough cost-benefit analysis. Initial costs for these treatments can be substantial, including equipment acquisition, process development, and staff training. However, the long-term benefits often outweigh these upfront expenses.

One of the primary advantages of advanced surface treatments is the reduction in warranty claims and associated costs. By minimizing the risk of engine seizure, manufacturers can significantly decrease the number of costly repairs and replacements. This not only saves on direct expenses but also helps maintain brand reputation and customer loyalty, which have intangible but substantial long-term value.

Improved engine performance and longevity resulting from these treatments can lead to increased customer satisfaction and potentially higher sales. Engines with advanced surface treatments may command premium pricing, offsetting the additional production costs and potentially increasing profit margins.

From an operational perspective, these treatments can lead to reduced scrap rates and improved manufacturing efficiency. The enhanced surface properties allow for tighter tolerances and more consistent production, potentially reducing overall manufacturing costs in the long run.

Environmental benefits should also be considered in the cost-benefit analysis. Engines with advanced surface treatments typically have lower friction, leading to improved fuel efficiency and reduced emissions. This can help manufacturers meet increasingly stringent environmental regulations and avoid potential fines or penalties.

The analysis should also account for the competitive advantage gained through the implementation of these advanced technologies. Being at the forefront of engine technology can position a company as an industry leader, potentially leading to increased market share and new business opportunities.

However, it's crucial to consider the scalability of these treatments across different engine models and production volumes. The cost-effectiveness may vary depending on the specific application and production scale, requiring a nuanced approach to implementation.

In conclusion, while the initial investment in advanced surface treatments for engine blocks can be significant, the long-term benefits in terms of reduced warranty costs, improved performance, operational efficiency, and competitive advantage often justify the expenditure. A comprehensive cost-benefit analysis should consider both immediate financial impacts and long-term strategic advantages to make an informed decision on implementation.

One of the primary advantages of advanced surface treatments is the reduction in warranty claims and associated costs. By minimizing the risk of engine seizure, manufacturers can significantly decrease the number of costly repairs and replacements. This not only saves on direct expenses but also helps maintain brand reputation and customer loyalty, which have intangible but substantial long-term value.

Improved engine performance and longevity resulting from these treatments can lead to increased customer satisfaction and potentially higher sales. Engines with advanced surface treatments may command premium pricing, offsetting the additional production costs and potentially increasing profit margins.

From an operational perspective, these treatments can lead to reduced scrap rates and improved manufacturing efficiency. The enhanced surface properties allow for tighter tolerances and more consistent production, potentially reducing overall manufacturing costs in the long run.

Environmental benefits should also be considered in the cost-benefit analysis. Engines with advanced surface treatments typically have lower friction, leading to improved fuel efficiency and reduced emissions. This can help manufacturers meet increasingly stringent environmental regulations and avoid potential fines or penalties.

The analysis should also account for the competitive advantage gained through the implementation of these advanced technologies. Being at the forefront of engine technology can position a company as an industry leader, potentially leading to increased market share and new business opportunities.

However, it's crucial to consider the scalability of these treatments across different engine models and production volumes. The cost-effectiveness may vary depending on the specific application and production scale, requiring a nuanced approach to implementation.

In conclusion, while the initial investment in advanced surface treatments for engine blocks can be significant, the long-term benefits in terms of reduced warranty costs, improved performance, operational efficiency, and competitive advantage often justify the expenditure. A comprehensive cost-benefit analysis should consider both immediate financial impacts and long-term strategic advantages to make an informed decision on implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!