How To Optimize Engine Block Wall Thickness For Weight And Strength

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Optimization Background and Objectives

Engine block optimization has been a critical focus in automotive engineering for decades, driven by the ever-increasing demands for improved fuel efficiency, reduced emissions, and enhanced performance. The challenge of optimizing engine block wall thickness for weight and strength represents a fundamental aspect of this ongoing pursuit, balancing the need for structural integrity with the imperative to reduce overall vehicle mass.

Historically, engine blocks were designed with thicker walls to ensure durability and reliability. However, as materials science and manufacturing technologies have advanced, engineers have sought ways to minimize wall thickness without compromising the engine's structural integrity. This optimization process aims to achieve a delicate balance between reducing weight, which directly impacts fuel consumption and emissions, and maintaining the necessary strength to withstand the extreme pressures and temperatures inherent in internal combustion engines.

The evolution of engine block design has been marked by significant milestones, including the transition from cast iron to aluminum alloys, the development of advanced casting techniques, and the integration of computer-aided design and simulation tools. These advancements have enabled more precise control over material distribution and wall thickness, allowing for increasingly sophisticated optimization strategies.

Current technological objectives in engine block optimization focus on several key areas. Firstly, there is a push towards further weight reduction, with targets often set at 15-20% lighter than previous generation designs. Secondly, engineers aim to improve thermal efficiency by optimizing heat dissipation through strategic wall thickness variations. Thirdly, there is a growing emphasis on enhancing manufacturability and reducing production costs while maintaining or improving structural integrity.

The pursuit of these objectives is driven by stringent regulatory requirements for fuel economy and emissions, as well as market demands for more efficient and environmentally friendly vehicles. Additionally, the rise of electric and hybrid powertrains has introduced new challenges and opportunities in engine design, necessitating a reevaluation of traditional approaches to block optimization.

As the automotive industry continues to evolve, the optimization of engine block wall thickness remains a critical area of research and development. Future technological goals include the exploration of novel materials, such as metal matrix composites and advanced alloys, which could offer superior strength-to-weight ratios. Furthermore, the integration of additive manufacturing techniques presents exciting possibilities for creating complex, optimized structures that were previously impossible to produce using conventional methods.

Historically, engine blocks were designed with thicker walls to ensure durability and reliability. However, as materials science and manufacturing technologies have advanced, engineers have sought ways to minimize wall thickness without compromising the engine's structural integrity. This optimization process aims to achieve a delicate balance between reducing weight, which directly impacts fuel consumption and emissions, and maintaining the necessary strength to withstand the extreme pressures and temperatures inherent in internal combustion engines.

The evolution of engine block design has been marked by significant milestones, including the transition from cast iron to aluminum alloys, the development of advanced casting techniques, and the integration of computer-aided design and simulation tools. These advancements have enabled more precise control over material distribution and wall thickness, allowing for increasingly sophisticated optimization strategies.

Current technological objectives in engine block optimization focus on several key areas. Firstly, there is a push towards further weight reduction, with targets often set at 15-20% lighter than previous generation designs. Secondly, engineers aim to improve thermal efficiency by optimizing heat dissipation through strategic wall thickness variations. Thirdly, there is a growing emphasis on enhancing manufacturability and reducing production costs while maintaining or improving structural integrity.

The pursuit of these objectives is driven by stringent regulatory requirements for fuel economy and emissions, as well as market demands for more efficient and environmentally friendly vehicles. Additionally, the rise of electric and hybrid powertrains has introduced new challenges and opportunities in engine design, necessitating a reevaluation of traditional approaches to block optimization.

As the automotive industry continues to evolve, the optimization of engine block wall thickness remains a critical area of research and development. Future technological goals include the exploration of novel materials, such as metal matrix composites and advanced alloys, which could offer superior strength-to-weight ratios. Furthermore, the integration of additive manufacturing techniques presents exciting possibilities for creating complex, optimized structures that were previously impossible to produce using conventional methods.

Market Demand for Lightweight Engine Blocks

The automotive industry is experiencing a significant shift towards lightweight vehicles to improve fuel efficiency and reduce emissions. This trend has created a growing market demand for lightweight engine blocks, which are crucial components in achieving overall vehicle weight reduction. As environmental regulations become more stringent and consumers increasingly prioritize fuel economy, manufacturers are under pressure to develop innovative solutions for engine block design.

The global market for lightweight engine blocks is projected to expand substantially in the coming years. This growth is driven by several factors, including the need to meet stricter fuel economy standards, the rise of electric and hybrid vehicles, and the increasing adoption of advanced materials in automotive manufacturing. Lightweight engine blocks offer numerous benefits, such as improved performance, reduced fuel consumption, and lower emissions, making them attractive to both manufacturers and consumers.

In the passenger vehicle segment, there is a particularly strong demand for lightweight engine blocks. As automakers strive to meet Corporate Average Fuel Economy (CAFE) standards and reduce their carbon footprint, they are increasingly turning to lightweight materials and innovative design techniques. This trend is especially pronounced in regions with stringent emissions regulations, such as Europe and North America.

The commercial vehicle sector is also showing growing interest in lightweight engine blocks. Fleet operators are recognizing the potential for significant fuel savings and reduced operating costs over the lifetime of their vehicles. As a result, manufacturers of trucks, buses, and other commercial vehicles are investing in research and development to optimize engine block designs for weight reduction without compromising strength and durability.

The racing and high-performance automotive sectors have long been at the forefront of lightweight engine block technology. These industries serve as important drivers for innovation, often pioneering new materials and manufacturing techniques that eventually find their way into mainstream automotive production. The demand for lightweight, high-strength engine blocks in motorsports continues to push the boundaries of what is possible in engine design.

Emerging markets, particularly in Asia-Pacific, are expected to contribute significantly to the growth of the lightweight engine block market. As these regions experience rapid urbanization and increasing vehicle ownership, there is a growing emphasis on fuel efficiency and environmental sustainability. This presents a substantial opportunity for manufacturers to introduce lightweight engine block technologies to these markets.

The market demand for lightweight engine blocks is also influenced by advancements in manufacturing technologies. Innovations in casting techniques, such as thin-wall casting and high-pressure die casting, are enabling the production of engine blocks with optimized wall thickness and improved strength-to-weight ratios. These technological advancements are making lightweight engine blocks more cost-effective and accessible to a broader range of vehicle manufacturers.

The global market for lightweight engine blocks is projected to expand substantially in the coming years. This growth is driven by several factors, including the need to meet stricter fuel economy standards, the rise of electric and hybrid vehicles, and the increasing adoption of advanced materials in automotive manufacturing. Lightweight engine blocks offer numerous benefits, such as improved performance, reduced fuel consumption, and lower emissions, making them attractive to both manufacturers and consumers.

In the passenger vehicle segment, there is a particularly strong demand for lightweight engine blocks. As automakers strive to meet Corporate Average Fuel Economy (CAFE) standards and reduce their carbon footprint, they are increasingly turning to lightweight materials and innovative design techniques. This trend is especially pronounced in regions with stringent emissions regulations, such as Europe and North America.

The commercial vehicle sector is also showing growing interest in lightweight engine blocks. Fleet operators are recognizing the potential for significant fuel savings and reduced operating costs over the lifetime of their vehicles. As a result, manufacturers of trucks, buses, and other commercial vehicles are investing in research and development to optimize engine block designs for weight reduction without compromising strength and durability.

The racing and high-performance automotive sectors have long been at the forefront of lightweight engine block technology. These industries serve as important drivers for innovation, often pioneering new materials and manufacturing techniques that eventually find their way into mainstream automotive production. The demand for lightweight, high-strength engine blocks in motorsports continues to push the boundaries of what is possible in engine design.

Emerging markets, particularly in Asia-Pacific, are expected to contribute significantly to the growth of the lightweight engine block market. As these regions experience rapid urbanization and increasing vehicle ownership, there is a growing emphasis on fuel efficiency and environmental sustainability. This presents a substantial opportunity for manufacturers to introduce lightweight engine block technologies to these markets.

The market demand for lightweight engine blocks is also influenced by advancements in manufacturing technologies. Innovations in casting techniques, such as thin-wall casting and high-pressure die casting, are enabling the production of engine blocks with optimized wall thickness and improved strength-to-weight ratios. These technological advancements are making lightweight engine blocks more cost-effective and accessible to a broader range of vehicle manufacturers.

Current Challenges in Engine Block Wall Thickness Design

Engine block wall thickness design faces several significant challenges in the pursuit of optimizing weight and strength. One of the primary issues is the complex interplay between material reduction and structural integrity. As manufacturers strive to decrease engine weight for improved fuel efficiency and performance, they must carefully balance this goal against the need to maintain sufficient strength to withstand the high pressures and temperatures generated during engine operation.

The non-uniform stress distribution across the engine block presents another major challenge. Different areas of the block experience varying levels of mechanical and thermal stress, making it difficult to apply a uniform wall thickness. This necessitates a sophisticated approach to design, where thickness must be tailored to specific regions based on their unique stress profiles.

Material selection adds another layer of complexity to the optimization process. While lightweight materials such as aluminum alloys offer significant weight savings, they may not provide the same level of strength and durability as traditional cast iron. Engineers must carefully evaluate the trade-offs between material properties, manufacturability, and cost when selecting the optimal material for engine block construction.

Advanced manufacturing techniques, such as precision casting and 3D printing, offer new possibilities for optimizing wall thickness. However, integrating these technologies into existing production processes presents its own set of challenges, including the need for new tooling, quality control measures, and potential changes to the supply chain.

The increasing demand for engine downsizing and turbocharging further complicates wall thickness design. Smaller engines with higher power outputs generate greater thermal and mechanical stresses, requiring innovative solutions to maintain structural integrity without significantly increasing weight.

Simulation and modeling tools play a crucial role in optimizing engine block design, but they also present challenges. While finite element analysis (FEA) and computational fluid dynamics (CFD) provide valuable insights, the accuracy of these simulations depends on the quality of input data and the sophistication of the models. Validating simulation results against real-world performance remains a critical and often time-consuming process.

Regulatory pressures for improved fuel efficiency and reduced emissions add another dimension to the challenge. Designers must not only optimize for weight and strength but also ensure that the engine block design contributes to overall engine efficiency and meets increasingly stringent environmental standards.

Lastly, the cost implications of advanced optimization techniques cannot be overlooked. While thinner walls may reduce material costs, the increased complexity in design and manufacturing processes can offset these savings. Striking the right balance between performance improvements and economic viability remains a persistent challenge in engine block wall thickness design.

The non-uniform stress distribution across the engine block presents another major challenge. Different areas of the block experience varying levels of mechanical and thermal stress, making it difficult to apply a uniform wall thickness. This necessitates a sophisticated approach to design, where thickness must be tailored to specific regions based on their unique stress profiles.

Material selection adds another layer of complexity to the optimization process. While lightweight materials such as aluminum alloys offer significant weight savings, they may not provide the same level of strength and durability as traditional cast iron. Engineers must carefully evaluate the trade-offs between material properties, manufacturability, and cost when selecting the optimal material for engine block construction.

Advanced manufacturing techniques, such as precision casting and 3D printing, offer new possibilities for optimizing wall thickness. However, integrating these technologies into existing production processes presents its own set of challenges, including the need for new tooling, quality control measures, and potential changes to the supply chain.

The increasing demand for engine downsizing and turbocharging further complicates wall thickness design. Smaller engines with higher power outputs generate greater thermal and mechanical stresses, requiring innovative solutions to maintain structural integrity without significantly increasing weight.

Simulation and modeling tools play a crucial role in optimizing engine block design, but they also present challenges. While finite element analysis (FEA) and computational fluid dynamics (CFD) provide valuable insights, the accuracy of these simulations depends on the quality of input data and the sophistication of the models. Validating simulation results against real-world performance remains a critical and often time-consuming process.

Regulatory pressures for improved fuel efficiency and reduced emissions add another dimension to the challenge. Designers must not only optimize for weight and strength but also ensure that the engine block design contributes to overall engine efficiency and meets increasingly stringent environmental standards.

Lastly, the cost implications of advanced optimization techniques cannot be overlooked. While thinner walls may reduce material costs, the increased complexity in design and manufacturing processes can offset these savings. Striking the right balance between performance improvements and economic viability remains a persistent challenge in engine block wall thickness design.

Existing Methods for Engine Block Wall Thickness Optimization

01 Optimizing engine block wall thickness

Engine block wall thickness is crucial for balancing structural integrity and weight reduction. Manufacturers optimize wall thickness to enhance engine performance, fuel efficiency, and durability while minimizing material usage. Advanced design techniques and materials allow for thinner walls without compromising strength.- Optimizing engine block wall thickness: Engine block wall thickness is a critical factor in engine design, affecting performance, weight, and durability. Manufacturers optimize wall thickness to balance strength and heat dissipation while minimizing weight. Advanced materials and manufacturing techniques allow for thinner walls without compromising structural integrity.

- Cooling system integration with engine block design: The wall thickness of engine blocks is closely related to the cooling system design. Thicker walls may provide better heat absorption but can hinder heat dissipation. Engineers must consider coolant flow paths and heat transfer efficiency when determining optimal wall thickness for different sections of the engine block.

- Material selection for engine block construction: The choice of material for engine block construction influences the required wall thickness. Advanced alloys and composite materials can allow for thinner walls while maintaining strength and thermal properties. This can lead to lighter engines with improved fuel efficiency and performance.

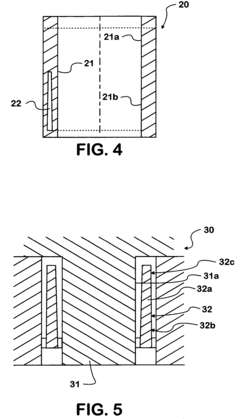

- Manufacturing techniques affecting wall thickness: Advancements in manufacturing processes, such as precision casting and 3D printing, enable more complex and optimized engine block designs. These techniques allow for variable wall thicknesses within the same block, optimizing strength and weight distribution based on specific load requirements and thermal conditions.

- Stress analysis and simulation in wall thickness design: Modern engine block design relies heavily on computer-aided engineering and finite element analysis to determine optimal wall thicknesses. These tools allow engineers to simulate various operating conditions and stress distributions, ensuring that wall thicknesses are optimized for durability, performance, and efficiency across different engine components.

02 Variable wall thickness design

Engine blocks can be designed with variable wall thicknesses to address specific stress points and thermal loads. Thicker walls are used in high-stress areas, while thinner walls are employed in less critical regions to reduce overall weight. This approach optimizes material distribution and enhances engine efficiency.Expand Specific Solutions03 Cooling system integration

Wall thickness design is closely related to the integration of cooling systems within the engine block. Proper wall thickness allows for efficient heat dissipation and the incorporation of cooling channels, improving overall engine thermal management and performance.Expand Specific Solutions04 Material selection for wall thickness reduction

Advanced materials, such as high-strength alloys and composites, enable the reduction of engine block wall thickness while maintaining or improving structural integrity. These materials allow for lighter engine designs without compromising performance or durability.Expand Specific Solutions05 Manufacturing techniques for precise wall thickness control

Innovative manufacturing processes, including precision casting and 3D printing, allow for more accurate control of engine block wall thickness. These techniques enable the production of complex geometries and optimized wall profiles, resulting in improved engine performance and efficiency.Expand Specific Solutions

Key Players in Automotive Engine Manufacturing

The optimization of engine block wall thickness for weight and strength is a critical challenge in the automotive industry, currently in a mature phase but with ongoing innovation. The market for this technology is substantial, driven by the global automotive sector's push for fuel efficiency and emissions reduction. Technologically, it's well-developed but continually evolving, with companies like Ford Global Technologies, BMW, and Honda Motor Co. leading advancements. These firms, along with others such as Mazda and Nissan, are investing heavily in research and development to further refine engine block designs, balancing the need for lightweight construction with structural integrity and performance requirements.

Ford Global Technologies LLC

Technical Solution: Ford has implemented a comprehensive engine block optimization strategy that combines traditional engineering methods with cutting-edge digital technologies. Their approach utilizes a multi-objective optimization algorithm that simultaneously considers weight reduction, structural integrity, NVH (Noise, Vibration, and Harshness) characteristics, and thermal management. Ford's process involves creating a parametric CAD model of the engine block and using high-performance computing clusters to run millions of simulations. The company has also integrated real-world test data from their extensive fleet to validate and refine their digital models. This data-driven approach has enabled Ford to achieve up to 15% weight reduction in their engine blocks while improving overall engine performance and efficiency[7][8].

Strengths: Balanced approach considering multiple performance factors, integration of real-world data for validation. Weaknesses: Extensive computational resources required, potential complexity in managing large datasets.

Bayerische Motoren Werke AG

Technical Solution: BMW employs a multi-disciplinary approach to engine block wall thickness optimization. They utilize advanced simulation software that combines computational fluid dynamics (CFD) with structural analysis to simultaneously optimize for thermal management and mechanical strength. BMW's process involves creating a digital twin of the engine block and running thousands of simulations with varying wall thicknesses. The company has implemented machine learning algorithms to predict optimal configurations based on historical data, significantly reducing the time required for optimization. This approach has led to engine blocks that are up to 25% lighter than traditional designs while maintaining BMW's high-performance standards[2][5].

Strengths: Holistic optimization considering multiple factors, reduced development time through AI integration. Weaknesses: High initial investment in software and expertise required.

Innovative Materials and Design Approaches for Engine Blocks

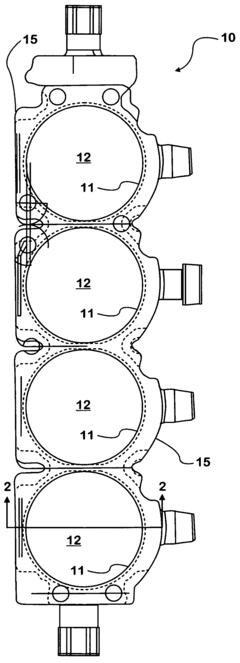

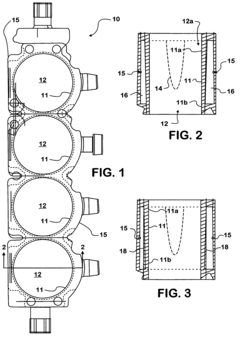

Engine block casting and method of manufacture

PatentWO2006019698A3

Innovation

- Variable wall thickness design for cylinder-forming walls, decreasing from combustion chamber end to the opposite end.

- Optimized balance between minimal explosion-resistant thickness and reduced thickness for weight reduction.

- Enables reduced engine block size and weight, and/or increased engine displacement.

Engine block casting and method of manufacture

PatentActiveUS7958633B2

Innovation

- The engine block casting features cylindrical cavity-forming walls that taper from thicker combustion chamber ends to thinner ends, allowing for coolant passages and reducing weight, enabling a more compact and lightweight design with enhanced heat transfer capabilities.

Environmental Impact of Lightweight Engine Blocks

The environmental impact of lightweight engine blocks is a crucial consideration in the automotive industry's pursuit of fuel efficiency and reduced emissions. As manufacturers strive to optimize engine block wall thickness for weight and strength, the resulting lightweight designs offer significant environmental benefits throughout the vehicle's lifecycle.

Lightweight engine blocks, typically made from aluminum alloys, contribute to overall vehicle weight reduction. This translates to improved fuel economy and decreased greenhouse gas emissions during the vehicle's operational phase. Studies have shown that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel efficiency. Consequently, the cumulative effect of widespread adoption of lightweight engine blocks could result in substantial reductions in global carbon dioxide emissions from the transportation sector.

The production process of lightweight engine blocks also presents environmental considerations. While aluminum production is energy-intensive, the long-term benefits of weight reduction often outweigh the initial environmental costs. Advanced manufacturing techniques, such as high-pressure die casting and lost foam casting, have improved the efficiency of aluminum engine block production, reducing energy consumption and waste generation.

Recycling plays a vital role in mitigating the environmental impact of lightweight engine blocks. Aluminum is highly recyclable, with the potential to be reprocessed multiple times without significant loss of quality. The automotive industry has established efficient recycling systems for end-of-life vehicles, ensuring that a large percentage of aluminum engine blocks are recovered and reused. This circular economy approach significantly reduces the need for primary aluminum production, thereby conserving natural resources and energy.

The durability and longevity of lightweight engine blocks also contribute to their environmental profile. Advanced alloys and optimized designs ensure that these components can withstand the rigors of long-term use, potentially extending vehicle lifespan and reducing the frequency of replacements. This durability factor is crucial in minimizing the overall environmental impact associated with manufacturing and disposing of automotive components.

However, the environmental benefits of lightweight engine blocks must be balanced against potential challenges. The increased complexity of some lightweight designs may require more sophisticated manufacturing processes, potentially increasing energy consumption during production. Additionally, the use of certain alloying elements or coatings to enhance performance may introduce new environmental considerations in terms of material sourcing and end-of-life management.

In conclusion, the optimization of engine block wall thickness for weight and strength, resulting in lightweight designs, offers significant environmental advantages. These benefits are realized through improved fuel efficiency, reduced emissions, and enhanced recyclability. As the automotive industry continues to innovate in this area, further environmental gains are expected, contributing to the sector's overall sustainability efforts.

Lightweight engine blocks, typically made from aluminum alloys, contribute to overall vehicle weight reduction. This translates to improved fuel economy and decreased greenhouse gas emissions during the vehicle's operational phase. Studies have shown that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel efficiency. Consequently, the cumulative effect of widespread adoption of lightweight engine blocks could result in substantial reductions in global carbon dioxide emissions from the transportation sector.

The production process of lightweight engine blocks also presents environmental considerations. While aluminum production is energy-intensive, the long-term benefits of weight reduction often outweigh the initial environmental costs. Advanced manufacturing techniques, such as high-pressure die casting and lost foam casting, have improved the efficiency of aluminum engine block production, reducing energy consumption and waste generation.

Recycling plays a vital role in mitigating the environmental impact of lightweight engine blocks. Aluminum is highly recyclable, with the potential to be reprocessed multiple times without significant loss of quality. The automotive industry has established efficient recycling systems for end-of-life vehicles, ensuring that a large percentage of aluminum engine blocks are recovered and reused. This circular economy approach significantly reduces the need for primary aluminum production, thereby conserving natural resources and energy.

The durability and longevity of lightweight engine blocks also contribute to their environmental profile. Advanced alloys and optimized designs ensure that these components can withstand the rigors of long-term use, potentially extending vehicle lifespan and reducing the frequency of replacements. This durability factor is crucial in minimizing the overall environmental impact associated with manufacturing and disposing of automotive components.

However, the environmental benefits of lightweight engine blocks must be balanced against potential challenges. The increased complexity of some lightweight designs may require more sophisticated manufacturing processes, potentially increasing energy consumption during production. Additionally, the use of certain alloying elements or coatings to enhance performance may introduce new environmental considerations in terms of material sourcing and end-of-life management.

In conclusion, the optimization of engine block wall thickness for weight and strength, resulting in lightweight designs, offers significant environmental advantages. These benefits are realized through improved fuel efficiency, reduced emissions, and enhanced recyclability. As the automotive industry continues to innovate in this area, further environmental gains are expected, contributing to the sector's overall sustainability efforts.

Cost-Benefit Analysis of Optimized Engine Block Designs

Optimizing engine block wall thickness for weight and strength presents a significant opportunity for cost savings and performance improvements in automotive manufacturing. This cost-benefit analysis examines the financial implications of implementing optimized engine block designs, considering both the initial investment required and the long-term benefits.

The primary costs associated with optimizing engine block wall thickness include research and development expenses, tooling modifications, and potential changes to manufacturing processes. R&D costs encompass computer-aided design (CAD) software, finite element analysis (FEA) tools, and engineering labor for design optimization. Tooling modifications may involve updating casting molds or machining equipment to accommodate new wall thickness specifications. Manufacturing process changes could require retraining of personnel and adjustments to quality control procedures.

On the benefit side, optimized engine block designs offer substantial advantages. Reduced wall thickness, where structurally feasible, leads to decreased material usage, resulting in lower raw material costs per unit. This weight reduction also contributes to improved fuel efficiency in vehicles, enhancing their market appeal and potentially increasing sales. Furthermore, optimized designs can lead to improved engine performance, such as better heat dissipation and reduced vibration, which may command premium pricing or increase customer satisfaction.

Long-term cost savings are a crucial factor in this analysis. While initial investments may be significant, the recurring savings in material costs and potential increases in sales volume can offset these expenses over time. Additionally, the improved fuel efficiency resulting from lighter engine blocks can contribute to meeting increasingly stringent emissions regulations, potentially avoiding costly penalties or the need for additional emissions control technologies.

It is important to consider the scalability of the optimization process. Once the initial research and development phase is complete, the optimized designs can be applied across multiple engine models and production lines, amplifying the cost benefits. This scalability factor significantly enhances the return on investment for the optimization initiative.

However, potential risks must also be factored into the cost-benefit analysis. These include the possibility of unforeseen manufacturing challenges, increased warranty claims if the optimized designs prove less durable in real-world conditions, and the need for ongoing refinement of the optimization process as new materials or manufacturing techniques become available.

In conclusion, while the initial costs of optimizing engine block wall thickness can be substantial, the long-term benefits in terms of material savings, improved performance, and regulatory compliance present a compelling case for investment. The exact cost-benefit ratio will depend on the specific circumstances of each manufacturer, including production volume, target market, and existing manufacturing capabilities. A phased implementation approach, starting with high-volume models, may offer the best balance of risk management and return on investment.

The primary costs associated with optimizing engine block wall thickness include research and development expenses, tooling modifications, and potential changes to manufacturing processes. R&D costs encompass computer-aided design (CAD) software, finite element analysis (FEA) tools, and engineering labor for design optimization. Tooling modifications may involve updating casting molds or machining equipment to accommodate new wall thickness specifications. Manufacturing process changes could require retraining of personnel and adjustments to quality control procedures.

On the benefit side, optimized engine block designs offer substantial advantages. Reduced wall thickness, where structurally feasible, leads to decreased material usage, resulting in lower raw material costs per unit. This weight reduction also contributes to improved fuel efficiency in vehicles, enhancing their market appeal and potentially increasing sales. Furthermore, optimized designs can lead to improved engine performance, such as better heat dissipation and reduced vibration, which may command premium pricing or increase customer satisfaction.

Long-term cost savings are a crucial factor in this analysis. While initial investments may be significant, the recurring savings in material costs and potential increases in sales volume can offset these expenses over time. Additionally, the improved fuel efficiency resulting from lighter engine blocks can contribute to meeting increasingly stringent emissions regulations, potentially avoiding costly penalties or the need for additional emissions control technologies.

It is important to consider the scalability of the optimization process. Once the initial research and development phase is complete, the optimized designs can be applied across multiple engine models and production lines, amplifying the cost benefits. This scalability factor significantly enhances the return on investment for the optimization initiative.

However, potential risks must also be factored into the cost-benefit analysis. These include the possibility of unforeseen manufacturing challenges, increased warranty claims if the optimized designs prove less durable in real-world conditions, and the need for ongoing refinement of the optimization process as new materials or manufacturing techniques become available.

In conclusion, while the initial costs of optimizing engine block wall thickness can be substantial, the long-term benefits in terms of material savings, improved performance, and regulatory compliance present a compelling case for investment. The exact cost-benefit ratio will depend on the specific circumstances of each manufacturer, including production volume, target market, and existing manufacturing capabilities. A phased implementation approach, starting with high-volume models, may offer the best balance of risk management and return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!