How To Implement Modular Engine Block Designs For Volume Manufacturing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Modular Engine Design Evolution and Objectives

The evolution of modular engine block designs represents a significant shift in automotive manufacturing, driven by the need for increased efficiency, cost-effectiveness, and adaptability in production processes. This approach has its roots in the early 2000s when automotive manufacturers began exploring ways to streamline their production lines and reduce the complexity of engine manufacturing.

The concept of modular engine design stems from the idea of creating a standardized base engine architecture that can be easily modified to suit various vehicle applications. This approach allows for greater flexibility in production, enabling manufacturers to respond more quickly to market demands and reduce development costs for new engine variants.

One of the primary objectives of implementing modular engine block designs for volume manufacturing is to achieve economies of scale. By utilizing a common base architecture across multiple engine families, manufacturers can significantly reduce tooling and development costs. This standardization also leads to improved quality control and consistency in production, as fewer unique components and processes are required.

Another key goal is to enhance production flexibility. Modular designs allow for easier customization of engine specifications, such as displacement, power output, and fuel efficiency, without requiring a complete redesign of the engine block. This flexibility enables manufacturers to quickly adapt to changing market trends and regulatory requirements, such as increasingly stringent emissions standards.

Reducing time-to-market for new engine variants is also a crucial objective of modular engine block designs. By leveraging a common architecture, manufacturers can accelerate the development and testing processes for new engines, allowing them to introduce updated models more frequently and stay competitive in rapidly evolving markets.

Improving overall engine performance and efficiency is an ongoing objective in the evolution of modular engine designs. Engineers strive to create base architectures that can accommodate advanced technologies, such as direct injection, variable valve timing, and turbocharging, across multiple engine variants. This approach ensures that even entry-level models can benefit from cutting-edge technologies, improving overall fleet performance.

As the automotive industry moves towards electrification, a new objective for modular engine design has emerged: compatibility with hybrid powertrains. Modern modular engines are being developed with the flexibility to integrate electric motors and battery systems, allowing manufacturers to easily produce hybrid variants of existing models without significant redesigns.

In conclusion, the evolution of modular engine block designs for volume manufacturing is driven by objectives that align with the broader goals of the automotive industry: increased efficiency, reduced costs, improved flexibility, and enhanced performance. As technology continues to advance, these modular designs will likely play a crucial role in bridging the gap between traditional internal combustion engines and the electric powertrains of the future.

The concept of modular engine design stems from the idea of creating a standardized base engine architecture that can be easily modified to suit various vehicle applications. This approach allows for greater flexibility in production, enabling manufacturers to respond more quickly to market demands and reduce development costs for new engine variants.

One of the primary objectives of implementing modular engine block designs for volume manufacturing is to achieve economies of scale. By utilizing a common base architecture across multiple engine families, manufacturers can significantly reduce tooling and development costs. This standardization also leads to improved quality control and consistency in production, as fewer unique components and processes are required.

Another key goal is to enhance production flexibility. Modular designs allow for easier customization of engine specifications, such as displacement, power output, and fuel efficiency, without requiring a complete redesign of the engine block. This flexibility enables manufacturers to quickly adapt to changing market trends and regulatory requirements, such as increasingly stringent emissions standards.

Reducing time-to-market for new engine variants is also a crucial objective of modular engine block designs. By leveraging a common architecture, manufacturers can accelerate the development and testing processes for new engines, allowing them to introduce updated models more frequently and stay competitive in rapidly evolving markets.

Improving overall engine performance and efficiency is an ongoing objective in the evolution of modular engine designs. Engineers strive to create base architectures that can accommodate advanced technologies, such as direct injection, variable valve timing, and turbocharging, across multiple engine variants. This approach ensures that even entry-level models can benefit from cutting-edge technologies, improving overall fleet performance.

As the automotive industry moves towards electrification, a new objective for modular engine design has emerged: compatibility with hybrid powertrains. Modern modular engines are being developed with the flexibility to integrate electric motors and battery systems, allowing manufacturers to easily produce hybrid variants of existing models without significant redesigns.

In conclusion, the evolution of modular engine block designs for volume manufacturing is driven by objectives that align with the broader goals of the automotive industry: increased efficiency, reduced costs, improved flexibility, and enhanced performance. As technology continues to advance, these modular designs will likely play a crucial role in bridging the gap between traditional internal combustion engines and the electric powertrains of the future.

Market Demand for Efficient Engine Manufacturing

The automotive industry is experiencing a significant shift towards more efficient and flexible manufacturing processes, driving the demand for modular engine block designs. This trend is fueled by several factors, including the need for cost reduction, increased production flexibility, and improved sustainability in engine manufacturing.

Market research indicates a growing interest in modular engine block designs across various vehicle segments. Passenger cars, commercial vehicles, and even off-highway equipment manufacturers are exploring the benefits of modular approaches. The global market for modular engine blocks is projected to grow steadily over the next decade, with a compound annual growth rate (CAGR) exceeding the overall automotive market growth.

One of the primary drivers for this demand is the potential for cost savings in volume manufacturing. Modular designs allow for standardization of components across different engine families, reducing tooling costs and simplifying the supply chain. This standardization can lead to economies of scale, making it particularly attractive for large-scale production.

Flexibility in manufacturing is another key factor contributing to the market demand. Modular engine block designs enable manufacturers to quickly adapt to changing market conditions and consumer preferences. By using a common base architecture, companies can more easily introduce new engine variants or update existing models without significant retooling or production line modifications.

Environmental regulations and sustainability goals are also influencing the demand for efficient engine manufacturing solutions. Modular designs can facilitate the integration of new technologies and materials that improve fuel efficiency and reduce emissions. This adaptability is crucial as the industry navigates the transition towards electrification and alternative powertrains.

The aftermarket sector is showing interest in modular engine block designs as well. The potential for easier maintenance, repair, and upgrades appeals to both service providers and end-users. This could create additional revenue streams and extend the lifecycle of engines, further driving market demand.

Geographically, mature automotive markets in North America and Europe are leading the adoption of modular engine block designs. However, emerging markets in Asia and South America are expected to show significant growth in demand as they seek to modernize their manufacturing capabilities and improve competitiveness.

As the automotive industry continues to evolve, the demand for efficient engine manufacturing solutions is likely to intensify. Modular engine block designs offer a promising approach to meet these market needs, balancing cost-effectiveness, flexibility, and sustainability in volume manufacturing scenarios.

Market research indicates a growing interest in modular engine block designs across various vehicle segments. Passenger cars, commercial vehicles, and even off-highway equipment manufacturers are exploring the benefits of modular approaches. The global market for modular engine blocks is projected to grow steadily over the next decade, with a compound annual growth rate (CAGR) exceeding the overall automotive market growth.

One of the primary drivers for this demand is the potential for cost savings in volume manufacturing. Modular designs allow for standardization of components across different engine families, reducing tooling costs and simplifying the supply chain. This standardization can lead to economies of scale, making it particularly attractive for large-scale production.

Flexibility in manufacturing is another key factor contributing to the market demand. Modular engine block designs enable manufacturers to quickly adapt to changing market conditions and consumer preferences. By using a common base architecture, companies can more easily introduce new engine variants or update existing models without significant retooling or production line modifications.

Environmental regulations and sustainability goals are also influencing the demand for efficient engine manufacturing solutions. Modular designs can facilitate the integration of new technologies and materials that improve fuel efficiency and reduce emissions. This adaptability is crucial as the industry navigates the transition towards electrification and alternative powertrains.

The aftermarket sector is showing interest in modular engine block designs as well. The potential for easier maintenance, repair, and upgrades appeals to both service providers and end-users. This could create additional revenue streams and extend the lifecycle of engines, further driving market demand.

Geographically, mature automotive markets in North America and Europe are leading the adoption of modular engine block designs. However, emerging markets in Asia and South America are expected to show significant growth in demand as they seek to modernize their manufacturing capabilities and improve competitiveness.

As the automotive industry continues to evolve, the demand for efficient engine manufacturing solutions is likely to intensify. Modular engine block designs offer a promising approach to meet these market needs, balancing cost-effectiveness, flexibility, and sustainability in volume manufacturing scenarios.

Current Challenges in Modular Engine Block Production

The implementation of modular engine block designs for volume manufacturing faces several significant challenges in the current production landscape. One of the primary obstacles is the complexity of designing a modular system that can accommodate various engine configurations while maintaining structural integrity and performance. Engineers must develop a flexible architecture that allows for different cylinder arrangements, displacements, and power outputs without compromising the overall engine efficiency or durability.

Material selection and compatibility present another hurdle in modular engine block production. The diverse range of materials required for different components must be carefully chosen to ensure thermal stability, wear resistance, and corrosion protection across various engine variants. This challenge is compounded by the need to optimize weight reduction without sacrificing strength, particularly in high-performance applications.

Manufacturing processes pose a significant challenge in scaling modular engine block production. Traditional casting methods may struggle to achieve the precision and consistency required for interchangeable components across different engine configurations. Advanced manufacturing techniques such as 3D printing and precision machining are being explored, but they present their own set of challenges in terms of cost-effectiveness and production speed for high-volume manufacturing.

Quality control and tolerance management become increasingly complex in modular designs. The interchangeability of components demands extremely tight tolerances, which can be difficult to maintain consistently across large production volumes. This challenge is further exacerbated by the need for robust assembly processes that can accommodate the variability inherent in modular systems while ensuring proper fit and function.

Supply chain management presents a unique set of challenges for modular engine block production. The increased number of variants and components requires a more sophisticated inventory and logistics system. Balancing stock levels to meet demand for various configurations while minimizing excess inventory is a delicate task that impacts production efficiency and cost-effectiveness.

Regulatory compliance and emissions standards add another layer of complexity to modular engine block design. Engineers must ensure that all possible configurations meet current and future emissions regulations across different markets, which can be particularly challenging given the diverse range of potential engine variants.

Lastly, the initial investment required for developing and implementing a modular engine block system can be substantial. Companies must carefully weigh the long-term benefits of flexibility and scalability against the upfront costs of research, development, and retooling of production lines. This financial challenge can be a significant barrier to entry for smaller manufacturers or those operating in highly competitive markets with thin profit margins.

Material selection and compatibility present another hurdle in modular engine block production. The diverse range of materials required for different components must be carefully chosen to ensure thermal stability, wear resistance, and corrosion protection across various engine variants. This challenge is compounded by the need to optimize weight reduction without sacrificing strength, particularly in high-performance applications.

Manufacturing processes pose a significant challenge in scaling modular engine block production. Traditional casting methods may struggle to achieve the precision and consistency required for interchangeable components across different engine configurations. Advanced manufacturing techniques such as 3D printing and precision machining are being explored, but they present their own set of challenges in terms of cost-effectiveness and production speed for high-volume manufacturing.

Quality control and tolerance management become increasingly complex in modular designs. The interchangeability of components demands extremely tight tolerances, which can be difficult to maintain consistently across large production volumes. This challenge is further exacerbated by the need for robust assembly processes that can accommodate the variability inherent in modular systems while ensuring proper fit and function.

Supply chain management presents a unique set of challenges for modular engine block production. The increased number of variants and components requires a more sophisticated inventory and logistics system. Balancing stock levels to meet demand for various configurations while minimizing excess inventory is a delicate task that impacts production efficiency and cost-effectiveness.

Regulatory compliance and emissions standards add another layer of complexity to modular engine block design. Engineers must ensure that all possible configurations meet current and future emissions regulations across different markets, which can be particularly challenging given the diverse range of potential engine variants.

Lastly, the initial investment required for developing and implementing a modular engine block system can be substantial. Companies must carefully weigh the long-term benefits of flexibility and scalability against the upfront costs of research, development, and retooling of production lines. This financial challenge can be a significant barrier to entry for smaller manufacturers or those operating in highly competitive markets with thin profit margins.

Existing Modular Engine Block Design Solutions

01 Modular engine block design for efficient manufacturing

Modular engine block designs allow for more efficient volume manufacturing processes. These designs typically involve separating the engine block into multiple components that can be produced and assembled separately. This approach enables parallel production lines, reduces complexity in individual parts, and allows for easier customization of engine configurations.- Modular engine block design for efficient manufacturing: Modular engine block designs allow for more efficient volume manufacturing processes. These designs typically involve separating the engine block into multiple components that can be manufactured independently and then assembled. This approach enables parallel production lines, reduces complexity in individual parts, and allows for easier customization of engine configurations.

- Advanced manufacturing techniques for modular engine blocks: Volume manufacturing of modular engine blocks often employs advanced manufacturing techniques such as precision casting, 3D printing, and automated assembly processes. These methods improve production efficiency, reduce material waste, and ensure consistent quality across large production runs. They also allow for the integration of complex internal structures that can enhance engine performance and efficiency.

- Standardization and interchangeability in modular designs: Standardization of components and interfaces is crucial in modular engine block designs for volume manufacturing. This approach allows for interchangeability of parts across different engine models, reducing inventory complexity and enabling more flexible production schedules. It also facilitates easier maintenance and repairs in the field.

- Materials selection for modular engine blocks: The choice of materials plays a significant role in modular engine block designs for volume manufacturing. Advanced alloys, composites, and hybrid materials are often used to optimize weight, strength, thermal management, and production costs. These materials are selected to withstand the high temperatures and pressures of engine operation while also being suitable for efficient manufacturing processes.

- Quality control and testing in volume production: Implementing robust quality control and testing procedures is essential in the volume manufacturing of modular engine blocks. This includes in-line inspection systems, automated testing stations, and advanced metrology techniques to ensure each component and assembled engine block meets stringent performance and reliability standards. These processes are integrated into the production line to maintain high throughput while ensuring product quality.

02 Advanced manufacturing techniques for modular engine blocks

Volume manufacturing of modular engine blocks often employs advanced manufacturing techniques such as precision casting, 3D printing, and automated assembly processes. These methods improve production efficiency, reduce material waste, and ensure consistent quality across large production volumes. They also allow for the integration of complex internal structures that can enhance engine performance and efficiency.Expand Specific Solutions03 Standardization and interchangeability in modular designs

Standardization of components and interfaces is crucial in modular engine block designs for volume manufacturing. This approach allows for interchangeability of parts across different engine models, reducing inventory complexity and enabling more flexible production lines. It also facilitates easier maintenance and repairs in the field, as standardized components can be more readily replaced.Expand Specific Solutions04 Materials selection for modular engine blocks

The choice of materials plays a significant role in the design and manufacturing of modular engine blocks. Advanced alloys, composites, and hybrid materials are often used to optimize weight, strength, and thermal properties. These materials are selected to withstand the high temperatures and pressures of engine operation while also being suitable for high-volume manufacturing processes.Expand Specific Solutions05 Quality control and testing in volume production

Ensuring consistent quality in the volume manufacturing of modular engine blocks requires robust quality control and testing procedures. This includes in-line inspection systems, automated testing equipment, and advanced metrology techniques. These processes help maintain tight tolerances, detect defects early in the production cycle, and ensure that each modular component meets performance and reliability standards before final assembly.Expand Specific Solutions

Key Players in Modular Engine Manufacturing

The modular engine block design for volume manufacturing is in a mature stage of development, with significant market potential due to increasing demand for efficient and cost-effective production methods. The global market for this technology is substantial, driven by the automotive industry's need for flexible and scalable manufacturing solutions. Key players like Robert Bosch GmbH, MAHLE Filtersysteme GmbH, and Honda Motor Co., Ltd. have made significant advancements in this field, leveraging their extensive experience in automotive engineering. These companies, along with others such as General Motors LLC and AVL List GmbH, are continuously refining their modular engine block designs to improve manufacturing efficiency and reduce costs. The technology's maturity is evident in its widespread adoption across various automotive manufacturers, indicating a highly competitive landscape with ongoing innovation.

Dr. Ing. h.c. F. Porsche AG

Technical Solution: Porsche has developed a modular engine block design strategy that emphasizes high performance and manufacturing precision for their sports car engines. Their approach focuses on creating a flexible architecture that can support both traditional internal combustion and hybrid powertrains. Porsche utilizes advanced materials such as high-strength aluminum alloys and incorporates innovative cooling designs to manage high thermal loads. The modular blocks feature integrated dry-sump oiling systems and provisions for direct fuel injection, allowing for commonality across different engine variants[12]. Porsche employs precision machining techniques and advanced surface treatments to achieve tight tolerances and superior wear resistance. The company utilizes modular tooling and flexible assembly lines to accommodate different engine configurations within the same manufacturing process[14].

Strengths: High-performance capabilities, adaptability to future powertrain technologies. Weaknesses: Higher production costs due to premium materials and precision manufacturing, potentially limited applicability to high-volume, lower-cost vehicle segments.

Honda Motor Co., Ltd.

Technical Solution: Honda has implemented a modular engine block design approach that focuses on efficiency and adaptability for global manufacturing. Their strategy involves creating a universal engine architecture that can be easily modified for different displacement volumes and power outputs. Honda utilizes advanced casting techniques and lightweight materials to produce engine blocks that balance performance and fuel efficiency. The modular design incorporates standardized mounting points for accessories and transmission interfaces, allowing for streamlined assembly across various vehicle models[8]. Honda's engine blocks feature precision-machined cylinder bores with plateau honing for improved oil retention and reduced friction. The company employs robotic assembly and automated quality control systems to ensure consistency in high-volume production[10].

Strengths: Improved global manufacturing efficiency, reduced development time for new engine variants. Weaknesses: Potential limitations in extreme performance applications, challenges in balancing global standardization with regional market requirements.

Innovative Modular Engine Block Technologies

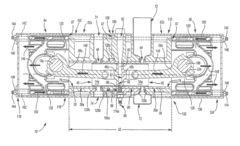

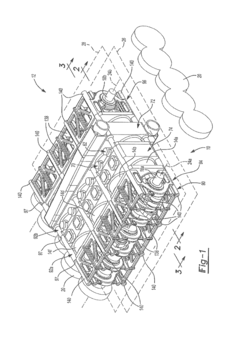

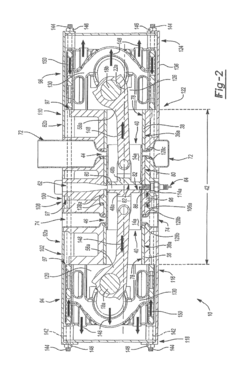

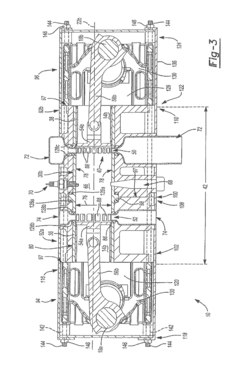

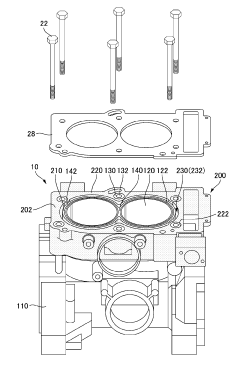

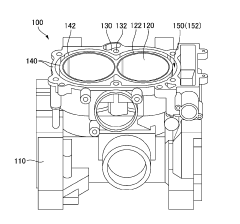

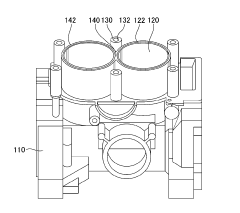

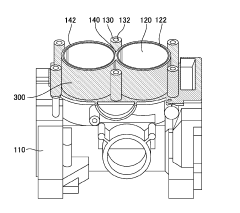

Engine block construction for opposed piston engine

PatentActiveUS10072604B2

Innovation

- The engine block is designed with multiple segments that allow easier installation of cylinder liners by aligning bores to receive the liners, providing improved access and eliminating the need for complex machining, with intermediate support collars for enhanced liner stability.

Engine block and manufacturing method for engine block

PatentActiveJP2022189374A

Innovation

- An adhesive application step applies adhesive to a predetermined region of the cylinder portion's outer peripheral surface, followed by mounting a resin block to create an engine block with a resin block that covers the metal block, utilizing thermosetting resin with low thermal conductivity and specific expansion coefficients to reduce thermal damage and weight.

Materials and Manufacturing Processes

The implementation of modular engine block designs for volume manufacturing requires careful consideration of materials and manufacturing processes. Advanced materials such as high-strength aluminum alloys and compacted graphite iron (CGI) are increasingly used in modern engine block designs. These materials offer improved strength-to-weight ratios, thermal conductivity, and durability compared to traditional cast iron blocks.

Aluminum alloys, particularly those in the 300 series, are favored for their lightweight properties and excellent heat dissipation characteristics. These alloys often incorporate silicon and copper for enhanced strength and wear resistance. CGI, on the other hand, provides a balance between the strength of gray cast iron and the weight advantages of aluminum, making it suitable for high-performance and heavy-duty applications.

The manufacturing processes for modular engine blocks have evolved to accommodate these advanced materials and complex designs. High-pressure die casting (HPDC) is a prevalent method for producing aluminum engine blocks, offering high production rates and dimensional accuracy. This process involves injecting molten aluminum into a steel die at high pressure, allowing for the creation of intricate internal passages and precise external features.

For CGI engine blocks, the lost foam casting process has gained popularity. This technique uses expendable polystyrene foam patterns that are coated with ceramic slurry and embedded in sand. When molten metal is poured into the mold, it vaporizes the foam, leaving a precise casting. This method allows for the production of complex geometries with minimal post-casting machining.

Additive manufacturing technologies, such as 3D printing, are also emerging as potential methods for producing modular engine block components. While not yet suitable for high-volume production, these techniques offer unprecedented design flexibility and the ability to create optimized internal structures that were previously impossible to manufacture.

Post-casting processes play a crucial role in achieving the required precision and surface finish for modular engine blocks. Computer Numerical Control (CNC) machining is extensively used to finish critical surfaces, create precise bolt holes, and ensure proper mating of modular components. Advanced metrology techniques, including coordinate measuring machines (CMMs) and 3D scanning, are employed to verify dimensional accuracy and maintain tight tolerances across modular interfaces.

Surface treatments and coatings are applied to enhance wear resistance and reduce friction in critical areas of the engine block. Nikasil plating, for instance, is commonly used to coat cylinder bores in aluminum blocks, providing improved durability and heat transfer properties. Thermal spraying techniques are also utilized to apply wear-resistant coatings to specific areas of the engine block, further enhancing its performance and longevity.

Aluminum alloys, particularly those in the 300 series, are favored for their lightweight properties and excellent heat dissipation characteristics. These alloys often incorporate silicon and copper for enhanced strength and wear resistance. CGI, on the other hand, provides a balance between the strength of gray cast iron and the weight advantages of aluminum, making it suitable for high-performance and heavy-duty applications.

The manufacturing processes for modular engine blocks have evolved to accommodate these advanced materials and complex designs. High-pressure die casting (HPDC) is a prevalent method for producing aluminum engine blocks, offering high production rates and dimensional accuracy. This process involves injecting molten aluminum into a steel die at high pressure, allowing for the creation of intricate internal passages and precise external features.

For CGI engine blocks, the lost foam casting process has gained popularity. This technique uses expendable polystyrene foam patterns that are coated with ceramic slurry and embedded in sand. When molten metal is poured into the mold, it vaporizes the foam, leaving a precise casting. This method allows for the production of complex geometries with minimal post-casting machining.

Additive manufacturing technologies, such as 3D printing, are also emerging as potential methods for producing modular engine block components. While not yet suitable for high-volume production, these techniques offer unprecedented design flexibility and the ability to create optimized internal structures that were previously impossible to manufacture.

Post-casting processes play a crucial role in achieving the required precision and surface finish for modular engine blocks. Computer Numerical Control (CNC) machining is extensively used to finish critical surfaces, create precise bolt holes, and ensure proper mating of modular components. Advanced metrology techniques, including coordinate measuring machines (CMMs) and 3D scanning, are employed to verify dimensional accuracy and maintain tight tolerances across modular interfaces.

Surface treatments and coatings are applied to enhance wear resistance and reduce friction in critical areas of the engine block. Nikasil plating, for instance, is commonly used to coat cylinder bores in aluminum blocks, providing improved durability and heat transfer properties. Thermal spraying techniques are also utilized to apply wear-resistant coatings to specific areas of the engine block, further enhancing its performance and longevity.

Environmental Impact and Sustainability

The implementation of modular engine block designs for volume manufacturing presents significant opportunities for enhancing environmental sustainability in the automotive industry. This approach allows for more efficient use of materials and energy throughout the production process, potentially reducing the overall environmental footprint of engine manufacturing.

Modular designs enable manufacturers to optimize material usage by creating standardized components that can be used across multiple engine variants. This standardization reduces waste and minimizes the need for unique tooling and production processes, leading to decreased energy consumption and resource utilization. Furthermore, the ability to easily replace or upgrade individual modules can extend the lifespan of engines, reducing the frequency of complete engine replacements and associated environmental impacts.

The manufacturing process for modular engine blocks can be designed to incorporate more environmentally friendly materials and production techniques. For instance, lightweight alloys can be used in specific modules to reduce overall engine weight, contributing to improved fuel efficiency and reduced emissions during the vehicle's operational life. Additionally, advanced manufacturing technologies such as 3D printing can be employed for certain modules, allowing for more precise material deposition and reduced waste compared to traditional casting methods.

Modular designs also facilitate easier disassembly and recycling at the end of an engine's life cycle. By separating the engine block into distinct modules, it becomes more feasible to sort and recycle materials efficiently, potentially increasing the percentage of recyclable components and reducing landfill waste. This approach aligns with circular economy principles, promoting the reuse and repurposing of materials in the automotive industry.

The implementation of modular engine block designs can contribute to reduced transportation-related emissions in the supply chain. Standardized modules can be produced closer to assembly plants, minimizing the need for long-distance shipping of large, complex engine components. This localized production strategy can significantly decrease the carbon footprint associated with logistics and transportation in engine manufacturing.

Moreover, the flexibility offered by modular designs allows for easier integration of future eco-friendly technologies. As new materials or more sustainable manufacturing processes emerge, individual modules can be updated or replaced without necessitating a complete redesign of the entire engine block. This adaptability ensures that engines can evolve to meet increasingly stringent environmental regulations and consumer demands for greener vehicles.

Modular designs enable manufacturers to optimize material usage by creating standardized components that can be used across multiple engine variants. This standardization reduces waste and minimizes the need for unique tooling and production processes, leading to decreased energy consumption and resource utilization. Furthermore, the ability to easily replace or upgrade individual modules can extend the lifespan of engines, reducing the frequency of complete engine replacements and associated environmental impacts.

The manufacturing process for modular engine blocks can be designed to incorporate more environmentally friendly materials and production techniques. For instance, lightweight alloys can be used in specific modules to reduce overall engine weight, contributing to improved fuel efficiency and reduced emissions during the vehicle's operational life. Additionally, advanced manufacturing technologies such as 3D printing can be employed for certain modules, allowing for more precise material deposition and reduced waste compared to traditional casting methods.

Modular designs also facilitate easier disassembly and recycling at the end of an engine's life cycle. By separating the engine block into distinct modules, it becomes more feasible to sort and recycle materials efficiently, potentially increasing the percentage of recyclable components and reducing landfill waste. This approach aligns with circular economy principles, promoting the reuse and repurposing of materials in the automotive industry.

The implementation of modular engine block designs can contribute to reduced transportation-related emissions in the supply chain. Standardized modules can be produced closer to assembly plants, minimizing the need for long-distance shipping of large, complex engine components. This localized production strategy can significantly decrease the carbon footprint associated with logistics and transportation in engine manufacturing.

Moreover, the flexibility offered by modular designs allows for easier integration of future eco-friendly technologies. As new materials or more sustainable manufacturing processes emerge, individual modules can be updated or replaced without necessitating a complete redesign of the entire engine block. This adaptability ensures that engines can evolve to meet increasingly stringent environmental regulations and consumer demands for greener vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!