Engine Block Finishing Processes: Grinding, Honing, And QA Steps

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Finishing Evolution and Objectives

Engine block finishing processes have undergone significant evolution since the early days of automotive manufacturing. Initially, engine blocks were finished using rudimentary methods such as manual filing and scraping. As technology advanced, more sophisticated techniques emerged, leading to the development of precision grinding and honing processes.

The evolution of engine block finishing can be traced through several key stages. In the 1950s and 1960s, the introduction of automated grinding machines marked a significant leap forward in efficiency and precision. This was followed by the development of honing technology in the 1970s, which allowed for even finer surface finishes and improved cylinder roundness.

The 1980s and 1990s saw the integration of computer numerical control (CNC) systems into grinding and honing machines, enabling greater accuracy and repeatability. This period also witnessed the emergence of superfinishing techniques, which further enhanced the surface quality of engine blocks.

In recent years, the focus has shifted towards environmentally friendly and cost-effective finishing processes. This has led to the development of near-net-shape casting techniques that reduce the amount of material removal required during finishing, as well as the adoption of dry machining processes that minimize the use of coolants and lubricants.

The primary objectives of modern engine block finishing processes are multifaceted. Firstly, they aim to achieve precise dimensional accuracy, ensuring that cylinder bores meet stringent tolerances for optimal piston fit and engine performance. Secondly, these processes strive to create ideal surface finishes that promote proper oil retention and reduce friction between moving parts.

Another critical objective is to enhance the durability and longevity of engine blocks. This is achieved through processes that improve the material's surface hardness and wear resistance, such as thermal spray coatings or laser surface treatments. Additionally, finishing processes seek to minimize residual stresses in the material, which can lead to distortion or premature failure.

As environmental concerns gain prominence, a key objective of engine block finishing has become the reduction of energy consumption and waste generation. This has driven the development of more efficient machining strategies and the exploration of alternative finishing methods, such as electrochemical machining or abrasive flow machining.

Looking ahead, the future objectives of engine block finishing processes will likely focus on further improving precision, reducing manufacturing costs, and adapting to new materials and engine designs. As electric vehicles gain market share, finishing processes may need to evolve to address the unique requirements of electric motor housings and battery enclosures, presenting new challenges and opportunities for innovation in this field.

The evolution of engine block finishing can be traced through several key stages. In the 1950s and 1960s, the introduction of automated grinding machines marked a significant leap forward in efficiency and precision. This was followed by the development of honing technology in the 1970s, which allowed for even finer surface finishes and improved cylinder roundness.

The 1980s and 1990s saw the integration of computer numerical control (CNC) systems into grinding and honing machines, enabling greater accuracy and repeatability. This period also witnessed the emergence of superfinishing techniques, which further enhanced the surface quality of engine blocks.

In recent years, the focus has shifted towards environmentally friendly and cost-effective finishing processes. This has led to the development of near-net-shape casting techniques that reduce the amount of material removal required during finishing, as well as the adoption of dry machining processes that minimize the use of coolants and lubricants.

The primary objectives of modern engine block finishing processes are multifaceted. Firstly, they aim to achieve precise dimensional accuracy, ensuring that cylinder bores meet stringent tolerances for optimal piston fit and engine performance. Secondly, these processes strive to create ideal surface finishes that promote proper oil retention and reduce friction between moving parts.

Another critical objective is to enhance the durability and longevity of engine blocks. This is achieved through processes that improve the material's surface hardness and wear resistance, such as thermal spray coatings or laser surface treatments. Additionally, finishing processes seek to minimize residual stresses in the material, which can lead to distortion or premature failure.

As environmental concerns gain prominence, a key objective of engine block finishing has become the reduction of energy consumption and waste generation. This has driven the development of more efficient machining strategies and the exploration of alternative finishing methods, such as electrochemical machining or abrasive flow machining.

Looking ahead, the future objectives of engine block finishing processes will likely focus on further improving precision, reducing manufacturing costs, and adapting to new materials and engine designs. As electric vehicles gain market share, finishing processes may need to evolve to address the unique requirements of electric motor housings and battery enclosures, presenting new challenges and opportunities for innovation in this field.

Market Demand for Precision Engine Components

The demand for precision engine components has been steadily increasing in recent years, driven by several key factors in the automotive and industrial sectors. Engine manufacturers are constantly striving to improve fuel efficiency, reduce emissions, and enhance overall performance, which necessitates higher precision in engine block manufacturing and finishing processes.

In the automotive industry, stringent environmental regulations and consumer demand for more fuel-efficient vehicles have pushed manufacturers to develop engines with tighter tolerances and smoother surfaces. This trend has led to a growing market for advanced grinding and honing technologies that can achieve the required level of precision in engine block finishing.

The aerospace and marine industries also contribute significantly to the demand for precision engine components. These sectors require engines with exceptional reliability and performance, often operating under extreme conditions. As a result, there is a continuous need for high-precision finishing processes that can ensure the longevity and efficiency of engine blocks in these applications.

Furthermore, the rise of electric and hybrid vehicles has not diminished the importance of precision engine components. While these vehicles rely less on traditional internal combustion engines, they still require high-precision components for their powertrains and auxiliary systems. This shift has created new opportunities for precision finishing technologies in the production of electric motor housings and battery enclosures.

In the industrial sector, the demand for precision engine components extends to power generation, construction equipment, and agricultural machinery. These applications often require engines capable of withstanding heavy loads and prolonged operation, making the quality of engine block finishing crucial for their performance and durability.

The market for precision engine components is also influenced by advancements in materials science. As manufacturers explore the use of lighter and stronger materials for engine blocks, such as aluminum alloys and composites, there is a growing need for finishing processes that can effectively work with these new materials while maintaining high precision.

Quality assurance (QA) steps in engine block finishing have become increasingly important as manufacturers aim to reduce defects and improve product consistency. This has led to a rising demand for advanced measurement and inspection technologies that can integrate seamlessly with grinding and honing processes, ensuring that finished engine blocks meet the exacting standards required by modern applications.

In the automotive industry, stringent environmental regulations and consumer demand for more fuel-efficient vehicles have pushed manufacturers to develop engines with tighter tolerances and smoother surfaces. This trend has led to a growing market for advanced grinding and honing technologies that can achieve the required level of precision in engine block finishing.

The aerospace and marine industries also contribute significantly to the demand for precision engine components. These sectors require engines with exceptional reliability and performance, often operating under extreme conditions. As a result, there is a continuous need for high-precision finishing processes that can ensure the longevity and efficiency of engine blocks in these applications.

Furthermore, the rise of electric and hybrid vehicles has not diminished the importance of precision engine components. While these vehicles rely less on traditional internal combustion engines, they still require high-precision components for their powertrains and auxiliary systems. This shift has created new opportunities for precision finishing technologies in the production of electric motor housings and battery enclosures.

In the industrial sector, the demand for precision engine components extends to power generation, construction equipment, and agricultural machinery. These applications often require engines capable of withstanding heavy loads and prolonged operation, making the quality of engine block finishing crucial for their performance and durability.

The market for precision engine components is also influenced by advancements in materials science. As manufacturers explore the use of lighter and stronger materials for engine blocks, such as aluminum alloys and composites, there is a growing need for finishing processes that can effectively work with these new materials while maintaining high precision.

Quality assurance (QA) steps in engine block finishing have become increasingly important as manufacturers aim to reduce defects and improve product consistency. This has led to a rising demand for advanced measurement and inspection technologies that can integrate seamlessly with grinding and honing processes, ensuring that finished engine blocks meet the exacting standards required by modern applications.

Current Challenges in Engine Block Finishing

Engine block finishing processes face several significant challenges in today's automotive manufacturing landscape. One of the primary issues is achieving consistent surface quality across different engine block materials. As manufacturers increasingly adopt lightweight materials like aluminum alloys, traditional finishing techniques often struggle to provide uniform results, leading to variations in performance and durability.

Another major challenge lies in meeting ever-tightening tolerances for engine block dimensions. Modern engines demand extremely precise specifications to ensure optimal performance and efficiency. However, achieving these tight tolerances consistently across high-volume production runs remains a significant hurdle for many manufacturers.

The complexity of engine block geometries also poses a substantial challenge for finishing processes. With the trend towards more compact and efficient engine designs, internal passages and cavities have become increasingly intricate. This complexity makes it difficult for traditional grinding and honing tools to access all areas of the engine block, potentially leaving some surfaces inadequately finished.

Environmental concerns and regulations present another set of challenges for engine block finishing. Many traditional finishing processes involve the use of lubricants and coolants that can be environmentally harmful. Manufacturers are under pressure to adopt more eco-friendly finishing methods without compromising on quality or productivity.

The integration of automation and robotics in finishing processes, while offering potential benefits, also introduces new challenges. Ensuring consistent quality across automated finishing lines requires sophisticated sensing and control systems, as well as careful process optimization. Many manufacturers struggle to balance the benefits of automation with the need for human expertise in quality control.

Quality assurance steps in engine block finishing face their own set of challenges. Non-destructive testing methods must evolve to keep pace with new materials and more complex engine designs. Detecting subtle defects in finished engine blocks, particularly in hard-to-reach areas, remains a significant technical challenge.

Lastly, the industry faces a skills gap in the workforce. As finishing processes become more technologically advanced, there is a growing need for workers with specialized skills in areas such as CNC machining, metrology, and process control. Training and retaining skilled workers in these areas is an ongoing challenge for many manufacturers in the engine block finishing sector.

Another major challenge lies in meeting ever-tightening tolerances for engine block dimensions. Modern engines demand extremely precise specifications to ensure optimal performance and efficiency. However, achieving these tight tolerances consistently across high-volume production runs remains a significant hurdle for many manufacturers.

The complexity of engine block geometries also poses a substantial challenge for finishing processes. With the trend towards more compact and efficient engine designs, internal passages and cavities have become increasingly intricate. This complexity makes it difficult for traditional grinding and honing tools to access all areas of the engine block, potentially leaving some surfaces inadequately finished.

Environmental concerns and regulations present another set of challenges for engine block finishing. Many traditional finishing processes involve the use of lubricants and coolants that can be environmentally harmful. Manufacturers are under pressure to adopt more eco-friendly finishing methods without compromising on quality or productivity.

The integration of automation and robotics in finishing processes, while offering potential benefits, also introduces new challenges. Ensuring consistent quality across automated finishing lines requires sophisticated sensing and control systems, as well as careful process optimization. Many manufacturers struggle to balance the benefits of automation with the need for human expertise in quality control.

Quality assurance steps in engine block finishing face their own set of challenges. Non-destructive testing methods must evolve to keep pace with new materials and more complex engine designs. Detecting subtle defects in finished engine blocks, particularly in hard-to-reach areas, remains a significant technical challenge.

Lastly, the industry faces a skills gap in the workforce. As finishing processes become more technologically advanced, there is a growing need for workers with specialized skills in areas such as CNC machining, metrology, and process control. Training and retaining skilled workers in these areas is an ongoing challenge for many manufacturers in the engine block finishing sector.

State-of-the-Art Finishing Processes

01 Surface finishing techniques for engine blocks

Various surface finishing techniques are employed to improve the performance and durability of engine blocks. These techniques may include honing, grinding, or polishing to achieve the desired surface roughness and texture. The specific finishing process can affect factors such as oil retention, wear resistance, and overall engine efficiency.- Surface finishing techniques for engine blocks: Various surface finishing techniques are employed to improve the performance and durability of engine blocks. These techniques may include honing, grinding, or polishing to achieve the desired surface roughness and texture. The specific method chosen depends on the material of the engine block and the intended application.

- Coating applications for engine block surfaces: Coatings are applied to engine block surfaces to enhance wear resistance, reduce friction, and improve overall performance. These coatings may include thermal spray coatings, electroplated layers, or specialized polymer coatings. The choice of coating depends on factors such as operating conditions and desired properties.

- Measurement and inspection of engine block surface finish: Accurate measurement and inspection of engine block surface finish are crucial for quality control. Various methods and devices are used to assess surface roughness, waviness, and other parameters. These may include optical measurement systems, profilometers, or specialized inspection equipment designed for engine block surfaces.

- Innovative materials for engine block construction: New materials are being developed and utilized for engine block construction to improve performance and reduce weight. These may include advanced alloys, composite materials, or hybrid structures. The choice of material can significantly impact the surface finish requirements and manufacturing processes.

- Surface treatment processes for improved engine block performance: Various surface treatment processes are applied to engine block surfaces to enhance their properties. These may include heat treatments, chemical treatments, or mechanical processes that alter the surface characteristics. Such treatments can improve wear resistance, reduce friction, and extend the lifespan of the engine block.

02 Coating applications for engine block surfaces

Coatings can be applied to engine block surfaces to enhance their properties. These coatings may include thermal barrier coatings, wear-resistant coatings, or friction-reducing coatings. The application of such coatings can improve heat management, reduce friction, and extend the lifespan of the engine block.Expand Specific Solutions03 Measurement and inspection of engine block surface finish

Accurate measurement and inspection of engine block surface finish are crucial for quality control. Various methods and devices are used to assess surface roughness, waviness, and other parameters. These may include optical measurement systems, profilometers, or specialized inspection equipment designed for engine block surfaces.Expand Specific Solutions04 Surface treatment processes for engine blocks

Engine blocks may undergo various surface treatment processes to improve their properties. These can include chemical treatments, heat treatments, or mechanical processes such as shot peening. These treatments aim to enhance the surface hardness, corrosion resistance, or other specific characteristics of the engine block material.Expand Specific Solutions05 Innovative materials and manufacturing techniques for engine blocks

New materials and manufacturing techniques are being developed to improve engine block performance and surface finish. These may include advanced alloys, composite materials, or novel manufacturing processes such as 3D printing. These innovations aim to optimize weight, strength, and surface characteristics of engine blocks.Expand Specific Solutions

Key Players in Engine Manufacturing Industry

The engine block finishing processes market is in a mature stage, characterized by established technologies and a stable competitive landscape. The global market size for these processes is substantial, driven by the automotive and heavy machinery industries. Major players like Ford, Toyota, and Nissan dominate, leveraging their extensive manufacturing capabilities. Technological maturity is high, with companies like Caterpillar and Cummins focusing on incremental improvements in precision and efficiency. Emerging players such as ELGAN-Diamantwerkzeuge and Wuxi Best Precision Machinery are introducing specialized solutions, particularly in diamond tooling and precision parts, to capture niche segments within this well-established market.

Ford Global Technologies LLC

Technical Solution: Ford has developed a high-efficiency engine block finishing process that focuses on reducing cycle time while maintaining superior quality. Their approach utilizes a dual-spindle CNC grinding system that can process two cylinder bores simultaneously, increasing throughput by up to 50%[17]. Ford's honing process incorporates a novel oscillating tool path that improves cylindricity and reduces bore distortion[19]. For QA, Ford employs a combination of in-line laser profilometry and eddy current testing to ensure both dimensional accuracy and surface integrity[21]. They have also implemented a digital twin system that allows real-time monitoring and adjustment of the finishing process based on historical data and predictive modeling[23].

Strengths: High production efficiency, advanced process control, comprehensive in-line quality assurance. Weaknesses: High initial capital investment, potential complexity in maintenance and calibration of advanced systems.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced engine block finishing process that combines precision grinding and honing techniques. Their method utilizes a multi-stage honing process with diamond-coated abrasives to achieve superior surface finish and cylindricity[1]. The company employs a closed-loop feedback system that continuously monitors and adjusts the honing parameters in real-time, ensuring consistent quality across production runs[3]. Toyota's QA steps include high-precision coordinate measuring machines (CMMs) and optical scanning technology to verify dimensional accuracy to within microns[5]. They have also implemented AI-powered visual inspection systems that can detect surface defects with 99.9% accuracy[7].

Strengths: Exceptional surface finish quality, high consistency across production, advanced QA technology. Weaknesses: Potentially higher production costs, longer processing time compared to simpler methods.

Innovations in QA for Engine Block Production

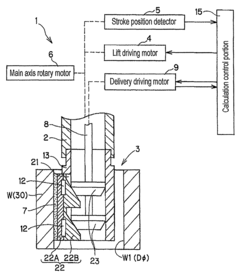

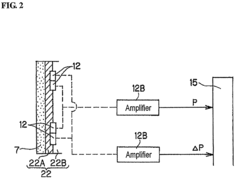

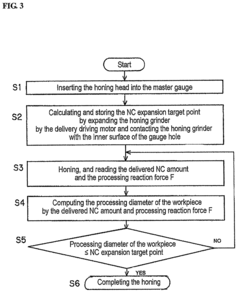

Honing method and honing control device

PatentInactiveUS7874893B2

Innovation

- A honing control device with a honing head that includes a processing reaction force sensor and an expansion mechanism, using a master gauge to set a target expansion amount, and adjusting the grinder's movement based on detected forces to achieve precise honing without damaging coatings, allowing for accurate diameter measurement and completion of the honing process.

Method of manufacturing and engine block

PatentInactiveEP2760627A1

Innovation

- A method involving the removal of material from the top deck of an engine block to create recessed areas around openings like cylinder bores and fluid passages, followed by the positioning of inserts within these areas, allowing for overlapping inserts to secure and reinforce the structure.

Environmental Impact of Finishing Processes

The environmental impact of engine block finishing processes, including grinding, honing, and quality assurance steps, is a critical consideration in modern manufacturing. These processes, while essential for achieving precise tolerances and surface finishes, can have significant environmental implications if not managed properly.

Grinding and honing operations typically involve the use of abrasive materials and lubricants, which can generate particulate matter and potentially harmful aerosols. These emissions, if not adequately controlled, may contribute to air pollution and pose health risks to workers and surrounding communities. Additionally, the fine metal particles produced during these processes can contaminate water systems if not properly filtered and disposed of.

The use of cutting fluids and coolants in these finishing processes also raises environmental concerns. Many traditional fluids contain petroleum-based oils or synthetic compounds that can be harmful to aquatic ecosystems if released into water bodies. Moreover, the disposal of spent cutting fluids requires careful management to prevent soil and groundwater contamination.

Energy consumption is another significant environmental factor in engine block finishing. The high-precision machinery used in grinding and honing operations often requires substantial electrical power, contributing to the overall carbon footprint of the manufacturing process. Implementing energy-efficient equipment and optimizing process parameters can help mitigate this impact.

Waste generation is a notable issue, particularly in terms of metal swarf and worn abrasives. While metal waste can often be recycled, the mixed nature of grinding and honing debris can complicate recycling efforts. Proper waste segregation and management practices are crucial to maximize recycling potential and minimize landfill contributions.

Quality assurance steps, while less directly impactful, can indirectly affect environmental outcomes. Stringent QA processes can reduce the likelihood of defective parts entering the market, thereby minimizing waste associated with product recalls or premature failures. However, QA processes that involve chemical treatments or extensive testing may have their own environmental considerations.

To address these environmental challenges, manufacturers are increasingly adopting cleaner technologies and sustainable practices. This includes the use of biodegradable cutting fluids, advanced filtration systems for air and water emissions, and closed-loop recycling systems for process materials. Some companies are also exploring dry machining techniques to reduce or eliminate the need for cutting fluids altogether.

Regulatory compliance plays a crucial role in shaping the environmental impact of these processes. Stringent environmental regulations in many countries have pushed manufacturers to invest in pollution control technologies and adopt more sustainable practices. This regulatory landscape continues to evolve, driving ongoing improvements in the environmental performance of engine block finishing operations.

Grinding and honing operations typically involve the use of abrasive materials and lubricants, which can generate particulate matter and potentially harmful aerosols. These emissions, if not adequately controlled, may contribute to air pollution and pose health risks to workers and surrounding communities. Additionally, the fine metal particles produced during these processes can contaminate water systems if not properly filtered and disposed of.

The use of cutting fluids and coolants in these finishing processes also raises environmental concerns. Many traditional fluids contain petroleum-based oils or synthetic compounds that can be harmful to aquatic ecosystems if released into water bodies. Moreover, the disposal of spent cutting fluids requires careful management to prevent soil and groundwater contamination.

Energy consumption is another significant environmental factor in engine block finishing. The high-precision machinery used in grinding and honing operations often requires substantial electrical power, contributing to the overall carbon footprint of the manufacturing process. Implementing energy-efficient equipment and optimizing process parameters can help mitigate this impact.

Waste generation is a notable issue, particularly in terms of metal swarf and worn abrasives. While metal waste can often be recycled, the mixed nature of grinding and honing debris can complicate recycling efforts. Proper waste segregation and management practices are crucial to maximize recycling potential and minimize landfill contributions.

Quality assurance steps, while less directly impactful, can indirectly affect environmental outcomes. Stringent QA processes can reduce the likelihood of defective parts entering the market, thereby minimizing waste associated with product recalls or premature failures. However, QA processes that involve chemical treatments or extensive testing may have their own environmental considerations.

To address these environmental challenges, manufacturers are increasingly adopting cleaner technologies and sustainable practices. This includes the use of biodegradable cutting fluids, advanced filtration systems for air and water emissions, and closed-loop recycling systems for process materials. Some companies are also exploring dry machining techniques to reduce or eliminate the need for cutting fluids altogether.

Regulatory compliance plays a crucial role in shaping the environmental impact of these processes. Stringent environmental regulations in many countries have pushed manufacturers to invest in pollution control technologies and adopt more sustainable practices. This regulatory landscape continues to evolve, driving ongoing improvements in the environmental performance of engine block finishing operations.

Cost-Efficiency in Engine Block Manufacturing

Cost-efficiency in engine block manufacturing is a critical factor in the automotive industry, directly impacting the overall production costs and competitiveness of vehicle manufacturers. The finishing processes, including grinding, honing, and quality assurance steps, play a significant role in determining the final cost of engine blocks.

Grinding, as the initial finishing process, removes excess material and achieves the desired surface finish on the engine block. Optimizing this step can lead to substantial cost savings. Advanced grinding technologies, such as high-speed grinding and creep feed grinding, have shown promise in reducing cycle times and improving material removal rates. These techniques can significantly decrease the overall processing time, thereby reducing labor costs and increasing production throughput.

Honing, the subsequent finishing process, is crucial for achieving the precise cylindrical geometry and surface finish required for optimal engine performance. Innovations in honing technology, such as diamond honing tools and adaptive honing systems, have improved the efficiency and accuracy of this process. These advancements not only enhance the quality of the finished product but also reduce the time and resources required for the honing operation.

Quality assurance (QA) steps are essential for ensuring that engine blocks meet the required specifications. Implementing automated inspection systems and in-line measurement technologies can greatly improve the efficiency of QA processes. These systems can detect defects and deviations in real-time, reducing the need for manual inspections and minimizing the risk of defective parts progressing through the production line.

Integrating these processes into a streamlined production flow is key to maximizing cost-efficiency. Implementing lean manufacturing principles and just-in-time production strategies can help reduce inventory costs and minimize waste. Additionally, the use of advanced data analytics and machine learning algorithms can optimize process parameters, predict maintenance needs, and identify areas for continuous improvement.

Investing in energy-efficient equipment and processes can also contribute to long-term cost savings. Modern grinding and honing machines with improved energy management systems can significantly reduce power consumption. Furthermore, implementing heat recovery systems and optimizing coolant usage can lead to additional energy savings and reduced environmental impact.

By focusing on these aspects of engine block finishing processes, manufacturers can achieve substantial improvements in cost-efficiency without compromising on quality. The continuous evolution of these technologies and methodologies presents ongoing opportunities for automotive companies to enhance their competitiveness in the global market.

Grinding, as the initial finishing process, removes excess material and achieves the desired surface finish on the engine block. Optimizing this step can lead to substantial cost savings. Advanced grinding technologies, such as high-speed grinding and creep feed grinding, have shown promise in reducing cycle times and improving material removal rates. These techniques can significantly decrease the overall processing time, thereby reducing labor costs and increasing production throughput.

Honing, the subsequent finishing process, is crucial for achieving the precise cylindrical geometry and surface finish required for optimal engine performance. Innovations in honing technology, such as diamond honing tools and adaptive honing systems, have improved the efficiency and accuracy of this process. These advancements not only enhance the quality of the finished product but also reduce the time and resources required for the honing operation.

Quality assurance (QA) steps are essential for ensuring that engine blocks meet the required specifications. Implementing automated inspection systems and in-line measurement technologies can greatly improve the efficiency of QA processes. These systems can detect defects and deviations in real-time, reducing the need for manual inspections and minimizing the risk of defective parts progressing through the production line.

Integrating these processes into a streamlined production flow is key to maximizing cost-efficiency. Implementing lean manufacturing principles and just-in-time production strategies can help reduce inventory costs and minimize waste. Additionally, the use of advanced data analytics and machine learning algorithms can optimize process parameters, predict maintenance needs, and identify areas for continuous improvement.

Investing in energy-efficient equipment and processes can also contribute to long-term cost savings. Modern grinding and honing machines with improved energy management systems can significantly reduce power consumption. Furthermore, implementing heat recovery systems and optimizing coolant usage can lead to additional energy savings and reduced environmental impact.

By focusing on these aspects of engine block finishing processes, manufacturers can achieve substantial improvements in cost-efficiency without compromising on quality. The continuous evolution of these technologies and methodologies presents ongoing opportunities for automotive companies to enhance their competitiveness in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!