How To Validate Engine Block Thermal Fatigue Under Cycle Loads

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Thermal Fatigue Background and Objectives

Engine block thermal fatigue is a critical issue in the automotive industry, affecting the longevity and performance of internal combustion engines. This phenomenon occurs due to the repeated heating and cooling cycles that engine blocks experience during operation. The thermal stresses induced by these cycles can lead to material fatigue, potentially resulting in cracks, deformation, or even catastrophic failure of the engine block.

The history of engine block thermal fatigue research dates back to the early days of automotive engineering. As engines became more powerful and efficient, the thermal loads on engine blocks increased, necessitating a deeper understanding of the fatigue mechanisms. Over the years, advancements in materials science, computational modeling, and testing methodologies have significantly contributed to our ability to predict and mitigate thermal fatigue issues.

The primary objective of validating engine block thermal fatigue under cyclic loads is to ensure the durability and reliability of engine blocks throughout their intended service life. This validation process aims to identify potential weak points in the engine block design, optimize material selection, and develop strategies to enhance the overall thermal fatigue resistance of the component.

Key technological trends in this field include the development of advanced simulation tools that can accurately model the complex thermal and mechanical interactions within the engine block. These tools incorporate multi-physics approaches, combining thermal analysis, structural mechanics, and fatigue modeling to provide a comprehensive understanding of the fatigue behavior under various operating conditions.

Another significant trend is the integration of real-time monitoring systems and sensors that can detect early signs of thermal fatigue in engine blocks. These technologies enable proactive maintenance strategies and help prevent unexpected failures during operation.

The evolution of materials used in engine block manufacturing has also played a crucial role in addressing thermal fatigue challenges. From traditional cast iron to lightweight aluminum alloys and even composite materials, engineers continually explore new options to balance strength, thermal conductivity, and fatigue resistance.

As the automotive industry shifts towards electrification and alternative powertrains, the relevance of engine block thermal fatigue research extends to new applications. For instance, the thermal management of battery packs and electric motors presents similar challenges, requiring adapted validation methodologies.

In conclusion, the validation of engine block thermal fatigue under cyclic loads remains a critical area of research and development in the automotive sector. The ongoing technological advancements and evolving industry needs continue to drive innovation in this field, with the ultimate goal of producing more reliable, efficient, and durable engines for future vehicles.

The history of engine block thermal fatigue research dates back to the early days of automotive engineering. As engines became more powerful and efficient, the thermal loads on engine blocks increased, necessitating a deeper understanding of the fatigue mechanisms. Over the years, advancements in materials science, computational modeling, and testing methodologies have significantly contributed to our ability to predict and mitigate thermal fatigue issues.

The primary objective of validating engine block thermal fatigue under cyclic loads is to ensure the durability and reliability of engine blocks throughout their intended service life. This validation process aims to identify potential weak points in the engine block design, optimize material selection, and develop strategies to enhance the overall thermal fatigue resistance of the component.

Key technological trends in this field include the development of advanced simulation tools that can accurately model the complex thermal and mechanical interactions within the engine block. These tools incorporate multi-physics approaches, combining thermal analysis, structural mechanics, and fatigue modeling to provide a comprehensive understanding of the fatigue behavior under various operating conditions.

Another significant trend is the integration of real-time monitoring systems and sensors that can detect early signs of thermal fatigue in engine blocks. These technologies enable proactive maintenance strategies and help prevent unexpected failures during operation.

The evolution of materials used in engine block manufacturing has also played a crucial role in addressing thermal fatigue challenges. From traditional cast iron to lightweight aluminum alloys and even composite materials, engineers continually explore new options to balance strength, thermal conductivity, and fatigue resistance.

As the automotive industry shifts towards electrification and alternative powertrains, the relevance of engine block thermal fatigue research extends to new applications. For instance, the thermal management of battery packs and electric motors presents similar challenges, requiring adapted validation methodologies.

In conclusion, the validation of engine block thermal fatigue under cyclic loads remains a critical area of research and development in the automotive sector. The ongoing technological advancements and evolving industry needs continue to drive innovation in this field, with the ultimate goal of producing more reliable, efficient, and durable engines for future vehicles.

Market Demand for Engine Block Durability Testing

The market demand for engine block durability testing has been steadily increasing due to the automotive industry's focus on improving engine performance, fuel efficiency, and longevity. As vehicles are designed to operate under more extreme conditions and for longer periods, the need for robust engine block thermal fatigue validation has become paramount.

Engine manufacturers and automotive companies are facing increasing pressure to develop engines that can withstand higher temperatures and pressures while maintaining structural integrity over extended periods. This demand is driven by several factors, including stricter emissions regulations, consumer expectations for longer-lasting vehicles, and the trend towards downsized, turbocharged engines that operate at higher temperatures.

The global automotive engine market is projected to grow significantly in the coming years, with a corresponding increase in the demand for advanced testing methods. Engine block durability testing, particularly thermal fatigue validation under cyclic loads, is a critical component of this market growth. As engines become more complex and operate under more demanding conditions, the need for sophisticated testing procedures becomes more pronounced.

Thermal fatigue testing is especially crucial for high-performance and commercial vehicle engines, where the consequences of failure can be severe. The market for these specialized testing services and equipment is expanding, with companies investing in advanced testing facilities and technologies to meet the growing demand.

Furthermore, the shift towards electric and hybrid vehicles has not diminished the importance of engine block durability testing. In fact, it has created new challenges and opportunities in the market. Hybrid powertrains often subject internal combustion engines to more frequent start-stop cycles and variable load conditions, necessitating even more rigorous durability testing protocols.

The automotive aftermarket also contributes to the demand for engine block durability testing. As vehicle owners seek to extend the life of their engines or modify them for increased performance, there is a growing need for aftermarket parts that can withstand thermal fatigue. This has led to increased testing requirements for aftermarket manufacturers to ensure their products meet or exceed OEM standards.

In response to these market demands, testing equipment manufacturers are developing more sophisticated systems capable of simulating real-world conditions with greater accuracy. These advanced testing platforms often incorporate features such as precise temperature control, multi-axis load application, and real-time data acquisition and analysis capabilities.

Engine manufacturers and automotive companies are facing increasing pressure to develop engines that can withstand higher temperatures and pressures while maintaining structural integrity over extended periods. This demand is driven by several factors, including stricter emissions regulations, consumer expectations for longer-lasting vehicles, and the trend towards downsized, turbocharged engines that operate at higher temperatures.

The global automotive engine market is projected to grow significantly in the coming years, with a corresponding increase in the demand for advanced testing methods. Engine block durability testing, particularly thermal fatigue validation under cyclic loads, is a critical component of this market growth. As engines become more complex and operate under more demanding conditions, the need for sophisticated testing procedures becomes more pronounced.

Thermal fatigue testing is especially crucial for high-performance and commercial vehicle engines, where the consequences of failure can be severe. The market for these specialized testing services and equipment is expanding, with companies investing in advanced testing facilities and technologies to meet the growing demand.

Furthermore, the shift towards electric and hybrid vehicles has not diminished the importance of engine block durability testing. In fact, it has created new challenges and opportunities in the market. Hybrid powertrains often subject internal combustion engines to more frequent start-stop cycles and variable load conditions, necessitating even more rigorous durability testing protocols.

The automotive aftermarket also contributes to the demand for engine block durability testing. As vehicle owners seek to extend the life of their engines or modify them for increased performance, there is a growing need for aftermarket parts that can withstand thermal fatigue. This has led to increased testing requirements for aftermarket manufacturers to ensure their products meet or exceed OEM standards.

In response to these market demands, testing equipment manufacturers are developing more sophisticated systems capable of simulating real-world conditions with greater accuracy. These advanced testing platforms often incorporate features such as precise temperature control, multi-axis load application, and real-time data acquisition and analysis capabilities.

Current Challenges in Thermal Fatigue Validation

Validating engine block thermal fatigue under cyclic loads presents several significant challenges in the current automotive engineering landscape. One of the primary difficulties lies in accurately simulating the complex thermal and mechanical stresses that an engine block experiences during operation. The cyclic nature of these loads, combined with the intricate geometry of modern engine blocks, makes it challenging to create representative test conditions that truly reflect real-world scenarios.

Another major hurdle is the time-consuming nature of thermal fatigue testing. Traditional methods often require extensive periods to complete, which can significantly delay product development cycles. This time constraint is particularly problematic in an industry where rapid innovation and time-to-market are crucial competitive factors. Moreover, the high costs associated with long-term testing and specialized equipment pose additional barriers to comprehensive validation processes.

The variability of operating conditions presents yet another challenge. Engine blocks are subjected to a wide range of temperatures, pressures, and load cycles depending on factors such as driving conditions, climate, and engine specifications. Capturing this diversity in a controlled testing environment is extremely difficult, potentially leading to incomplete or inaccurate fatigue assessments.

Material behavior under thermal cycling is also a complex issue. The repeated heating and cooling of engine block materials can lead to microstructural changes over time, affecting their mechanical properties. Accurately predicting and modeling these changes, especially for newer, lightweight materials being introduced in modern engine designs, remains a significant challenge in thermal fatigue validation.

Furthermore, the interaction between thermal fatigue and other failure modes, such as mechanical fatigue, corrosion, and wear, complicates the validation process. These interactions can lead to accelerated degradation or unexpected failure modes that may not be captured by focusing solely on thermal fatigue. Developing comprehensive test methodologies that account for these multi-factor effects is an ongoing challenge in the field.

Lastly, the increasing use of advanced materials and manufacturing techniques, such as additive manufacturing for engine blocks, introduces new variables into the thermal fatigue equation. These innovative approaches often lack extensive historical data, making it difficult to establish reliable baseline performance metrics and prediction models for long-term thermal fatigue behavior.

Another major hurdle is the time-consuming nature of thermal fatigue testing. Traditional methods often require extensive periods to complete, which can significantly delay product development cycles. This time constraint is particularly problematic in an industry where rapid innovation and time-to-market are crucial competitive factors. Moreover, the high costs associated with long-term testing and specialized equipment pose additional barriers to comprehensive validation processes.

The variability of operating conditions presents yet another challenge. Engine blocks are subjected to a wide range of temperatures, pressures, and load cycles depending on factors such as driving conditions, climate, and engine specifications. Capturing this diversity in a controlled testing environment is extremely difficult, potentially leading to incomplete or inaccurate fatigue assessments.

Material behavior under thermal cycling is also a complex issue. The repeated heating and cooling of engine block materials can lead to microstructural changes over time, affecting their mechanical properties. Accurately predicting and modeling these changes, especially for newer, lightweight materials being introduced in modern engine designs, remains a significant challenge in thermal fatigue validation.

Furthermore, the interaction between thermal fatigue and other failure modes, such as mechanical fatigue, corrosion, and wear, complicates the validation process. These interactions can lead to accelerated degradation or unexpected failure modes that may not be captured by focusing solely on thermal fatigue. Developing comprehensive test methodologies that account for these multi-factor effects is an ongoing challenge in the field.

Lastly, the increasing use of advanced materials and manufacturing techniques, such as additive manufacturing for engine blocks, introduces new variables into the thermal fatigue equation. These innovative approaches often lack extensive historical data, making it difficult to establish reliable baseline performance metrics and prediction models for long-term thermal fatigue behavior.

Existing Thermal Fatigue Validation Techniques

01 Cooling system design for engine blocks

Improved cooling system designs are crucial for mitigating thermal fatigue in engine blocks. These designs may include optimized coolant flow paths, enhanced heat dissipation mechanisms, and strategic placement of cooling channels. Such improvements help to maintain more uniform temperatures across the engine block, reducing thermal stress and fatigue.- Cooling system design for engine blocks: Improved cooling system designs are crucial for mitigating thermal fatigue in engine blocks. These designs may include optimized coolant flow paths, enhanced heat dissipation mechanisms, and strategic placement of cooling channels. Such improvements help to maintain more uniform temperatures across the engine block, reducing thermal stress and fatigue.

- Material selection and treatment: Selecting appropriate materials and applying specific treatments can enhance the engine block's resistance to thermal fatigue. This may involve using high-strength alloys, implementing heat treatment processes, or applying protective coatings. These measures can improve the material's ability to withstand repeated thermal cycling and reduce the risk of fatigue-related failures.

- Structural design optimization: Optimizing the structural design of engine blocks can significantly reduce thermal fatigue. This may include reinforcing critical areas, implementing stress-relieving features, or redesigning components to better distribute thermal loads. Advanced computer-aided engineering tools are often used to analyze and improve the block's geometry for enhanced durability.

- Thermal management systems: Implementing advanced thermal management systems can help control temperature fluctuations and reduce thermal fatigue in engine blocks. These systems may include smart cooling strategies, variable coolant flow control, or the integration of phase-change materials. By maintaining more consistent operating temperatures, these systems can significantly extend the engine block's lifespan.

- Fatigue monitoring and predictive maintenance: Developing methods for real-time monitoring of engine block thermal fatigue and implementing predictive maintenance strategies can help prevent catastrophic failures. This may involve the use of sensors, data analytics, and machine learning algorithms to detect early signs of fatigue and schedule maintenance before critical damage occurs.

02 Material selection and treatment

Selecting appropriate materials and applying specific treatments can enhance the engine block's resistance to thermal fatigue. This may involve using high-strength alloys, implementing heat treatment processes, or applying protective coatings. These measures can improve the material's ability to withstand repeated thermal cycling and reduce the risk of fatigue-related failures.Expand Specific Solutions03 Structural design optimization

Optimizing the structural design of engine blocks can help distribute thermal stresses more evenly and reduce localized hot spots. This may include modifications to the block's geometry, reinforcement of critical areas, or the integration of stress-relief features. Such design improvements can significantly enhance the engine block's resistance to thermal fatigue.Expand Specific Solutions04 Thermal management systems

Advanced thermal management systems can be implemented to control and regulate engine block temperatures more effectively. These may include smart cooling systems, variable coolant flow control, or the use of auxiliary cooling devices. By maintaining more consistent temperatures and reducing thermal fluctuations, these systems can help mitigate thermal fatigue effects.Expand Specific Solutions05 Fatigue monitoring and predictive maintenance

Implementing fatigue monitoring systems and predictive maintenance strategies can help detect early signs of thermal fatigue and prevent catastrophic failures. This may involve the use of sensors, data analytics, and machine learning algorithms to assess the engine block's condition and predict potential fatigue-related issues before they become critical.Expand Specific Solutions

Key Players in Engine Testing Industry

The thermal fatigue validation of engine blocks under cyclic loads is a critical aspect of engine development, currently in a mature stage of industry evolution. The market for this technology is substantial, driven by the automotive and heavy machinery sectors. Companies like Scania CV AB, Weichai Power, and Caterpillar, Inc. are at the forefront, leveraging advanced simulation and testing methods. Academic institutions such as Zhejiang University and Xi'an Jiaotong University contribute to research advancements. The technology's maturity is evident in the sophisticated approaches employed by manufacturers like Hyundai Motor Co., Ltd. and Kia Corp., integrating thermal analysis into their design processes. This competitive landscape reflects a well-established field with ongoing refinements in methodology and application.

Scania CV AB

Technical Solution: Scania CV AB utilizes a comprehensive approach to validate engine block thermal fatigue under cyclic loads. Their method combines advanced simulation techniques with extensive physical testing. Scania employs high-fidelity Finite Element Analysis (FEA) models that incorporate detailed geometry of the engine block, including cooling channels and critical stress concentration areas[13]. They use a coupled thermo-mechanical analysis to simulate the interaction between thermal expansion and mechanical stresses during engine operation. Scania's approach includes the use of sub-modeling techniques to focus on critical areas with higher mesh resolution, improving prediction accuracy[14]. For physical validation, they employ strain gauges and thermocouples in strategically placed locations on test engines, which are then subjected to accelerated durability cycles. This data is used to calibrate and validate their simulation models. Scania also considers the effects of different operating conditions, such as cold starts and full-load operations, in their fatigue analysis[15].

Strengths: Integration of advanced simulation with extensive physical testing, expertise in heavy-duty engines, and consideration of various operating conditions. Weaknesses: Potential challenges in accurately modeling all material behaviors under extreme conditions and the high cost of comprehensive physical testing.

Weichai Power

Technical Solution: Weichai Power utilizes a combination of experimental and numerical methods to validate engine block thermal fatigue. Their approach includes the use of strain gauges and thermocouples strategically placed on critical areas of the engine block during dynamometer testing[4]. This data is then used to calibrate and validate their Finite Element Models (FEM). Weichai's numerical analysis incorporates both thermal and structural simulations, considering the effects of coolant flow, combustion heat, and mechanical loads. They employ a damage accumulation model based on the Manson-Coffin relationship to predict fatigue life under varying temperature and load conditions[5]. Weichai also implements accelerated testing procedures, subjecting engine blocks to extreme thermal cycling to simulate long-term fatigue effects in a shorter timeframe[6].

Strengths: Strong integration of experimental and numerical methods, expertise in heavy-duty diesel engines. Weaknesses: Potential limitations in simulating all real-world operating conditions, reliance on empirical data for model validation.

Core Innovations in Cycle Load Testing

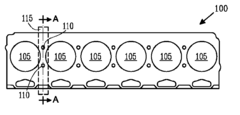

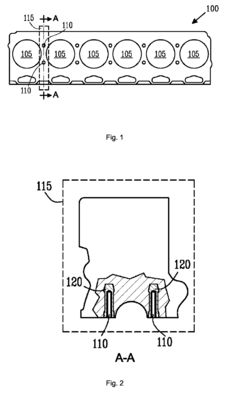

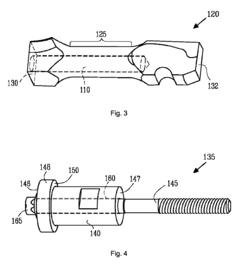

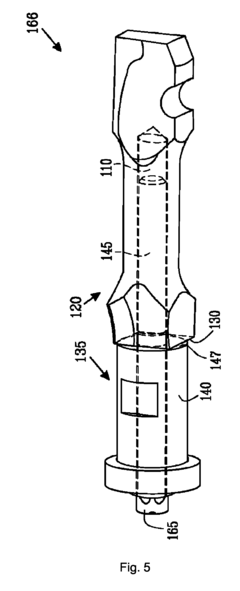

Engine block durability test

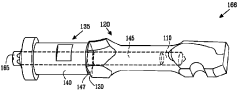

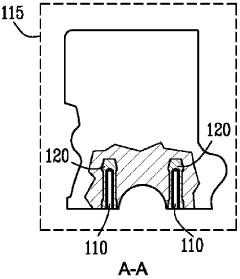

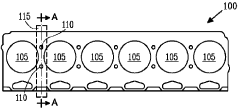

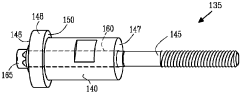

PatentWO2007091962A1

Innovation

- A method involving the removal of test specimens from engine blocks to create test assemblies with engaged dummy components, allowing for individual load case testing of bolt hole areas, reducing engine block consumption, and increasing testing frequency.

Engine block durability test

PatentInactiveUS7921708B2

Innovation

- A method involving the removal of test specimens from engine blocks, specifically including bolt holes, to create test assemblies that are subjected to pulsating fatigue tests, allowing for individual load case evaluation and reduced engine block consumption, enabling higher testing frequencies and more precise stress control.

Environmental Impact of Engine Testing

Engine testing, while crucial for validating thermal fatigue under cyclic loads, has significant environmental implications that must be carefully considered. The process of repeatedly subjecting engine blocks to extreme temperature fluctuations and mechanical stresses consumes substantial energy and resources. This energy-intensive testing contributes to increased carbon emissions, particularly when fossil fuels are used to power the testing facilities.

The use of specialized coolants and lubricants during thermal fatigue testing can also pose environmental risks. These substances may contain harmful chemicals that, if not properly managed, can contaminate soil and water sources. Proper disposal and recycling protocols are essential to mitigate these risks and minimize the environmental footprint of testing procedures.

Noise pollution is another environmental concern associated with engine testing. The repeated cycling of engines at various loads and speeds can generate significant noise levels, potentially affecting nearby communities and wildlife. Implementing sound-dampening technologies and conducting tests in purpose-built facilities can help address this issue.

Water usage is a critical factor in engine thermal fatigue testing. Large volumes of water are often required for cooling systems and temperature regulation during cyclic load tests. This high water consumption can strain local water resources, especially in water-scarce regions. Implementing water recycling systems and exploring alternative cooling methods can help reduce the overall water footprint of testing operations.

The materials used in engine block construction and testing equipment also have environmental implications. The production and disposal of these materials, including metals and composites, contribute to resource depletion and potential environmental contamination. Adopting sustainable material choices and implementing effective recycling programs for test components can help mitigate these impacts.

Advancements in virtual simulation and digital twin technologies offer promising alternatives to reduce the environmental impact of physical engine testing. These computational methods can significantly decrease the need for extensive physical testing, thereby reducing energy consumption, material waste, and overall environmental footprint. However, it's important to note that while these digital solutions are increasingly accurate, they still require validation through some level of physical testing.

In conclusion, while engine block thermal fatigue testing under cyclic loads is essential for ensuring product reliability and safety, it's crucial to balance these needs with environmental considerations. Implementing more sustainable testing practices, exploring alternative technologies, and optimizing resource use can help minimize the ecological impact of these necessary validation processes.

The use of specialized coolants and lubricants during thermal fatigue testing can also pose environmental risks. These substances may contain harmful chemicals that, if not properly managed, can contaminate soil and water sources. Proper disposal and recycling protocols are essential to mitigate these risks and minimize the environmental footprint of testing procedures.

Noise pollution is another environmental concern associated with engine testing. The repeated cycling of engines at various loads and speeds can generate significant noise levels, potentially affecting nearby communities and wildlife. Implementing sound-dampening technologies and conducting tests in purpose-built facilities can help address this issue.

Water usage is a critical factor in engine thermal fatigue testing. Large volumes of water are often required for cooling systems and temperature regulation during cyclic load tests. This high water consumption can strain local water resources, especially in water-scarce regions. Implementing water recycling systems and exploring alternative cooling methods can help reduce the overall water footprint of testing operations.

The materials used in engine block construction and testing equipment also have environmental implications. The production and disposal of these materials, including metals and composites, contribute to resource depletion and potential environmental contamination. Adopting sustainable material choices and implementing effective recycling programs for test components can help mitigate these impacts.

Advancements in virtual simulation and digital twin technologies offer promising alternatives to reduce the environmental impact of physical engine testing. These computational methods can significantly decrease the need for extensive physical testing, thereby reducing energy consumption, material waste, and overall environmental footprint. However, it's important to note that while these digital solutions are increasingly accurate, they still require validation through some level of physical testing.

In conclusion, while engine block thermal fatigue testing under cyclic loads is essential for ensuring product reliability and safety, it's crucial to balance these needs with environmental considerations. Implementing more sustainable testing practices, exploring alternative technologies, and optimizing resource use can help minimize the ecological impact of these necessary validation processes.

Simulation and Virtual Testing Advancements

Simulation and virtual testing have revolutionized the validation process for engine block thermal fatigue under cyclic loads. These advancements have significantly reduced the need for physical prototypes, saving time and resources while improving the accuracy of predictions. Finite Element Analysis (FEA) has emerged as a cornerstone technology in this field, allowing engineers to create detailed digital models of engine blocks and simulate complex thermal and mechanical stresses.

Modern simulation software incorporates sophisticated algorithms that can accurately model the behavior of materials under varying temperature conditions and cyclic loading. These tools can predict areas of high stress concentration, potential crack initiation sites, and overall fatigue life of the engine block. The ability to simulate thousands of thermal cycles in a fraction of the time required for physical testing has dramatically accelerated the design and validation process.

Virtual testing environments now include multi-physics simulations that can simultaneously account for thermal expansion, fluid dynamics of coolant flow, and mechanical stresses. This holistic approach provides a more comprehensive understanding of the engine block's performance under real-world conditions. Advanced meshing techniques and adaptive mesh refinement have further enhanced the precision of these simulations, allowing for more accurate results in critical areas without excessive computational overhead.

The integration of machine learning and artificial intelligence into simulation software has opened new possibilities for optimization. These technologies can analyze vast amounts of simulation data to identify patterns and suggest design improvements that may not be immediately apparent to human engineers. This has led to the development of more robust and efficient engine block designs that can better withstand thermal fatigue.

Virtual reality (VR) and augmented reality (AR) technologies have also found applications in the visualization of simulation results. Engineers can now immerse themselves in 3D representations of stress distributions and thermal gradients, gaining intuitive insights into the behavior of engine blocks under cyclic loads. This enhanced visualization capability facilitates better communication between design teams and accelerates the decision-making process.

As computational power continues to increase, the fidelity and scale of simulations are expanding. Cloud computing and parallel processing techniques now enable engineers to run multiple complex simulations simultaneously, exploring a wider range of design variables and operating conditions. This has led to more comprehensive validation processes and increased confidence in the reliability of engine block designs before physical prototyping begins.

Modern simulation software incorporates sophisticated algorithms that can accurately model the behavior of materials under varying temperature conditions and cyclic loading. These tools can predict areas of high stress concentration, potential crack initiation sites, and overall fatigue life of the engine block. The ability to simulate thousands of thermal cycles in a fraction of the time required for physical testing has dramatically accelerated the design and validation process.

Virtual testing environments now include multi-physics simulations that can simultaneously account for thermal expansion, fluid dynamics of coolant flow, and mechanical stresses. This holistic approach provides a more comprehensive understanding of the engine block's performance under real-world conditions. Advanced meshing techniques and adaptive mesh refinement have further enhanced the precision of these simulations, allowing for more accurate results in critical areas without excessive computational overhead.

The integration of machine learning and artificial intelligence into simulation software has opened new possibilities for optimization. These technologies can analyze vast amounts of simulation data to identify patterns and suggest design improvements that may not be immediately apparent to human engineers. This has led to the development of more robust and efficient engine block designs that can better withstand thermal fatigue.

Virtual reality (VR) and augmented reality (AR) technologies have also found applications in the visualization of simulation results. Engineers can now immerse themselves in 3D representations of stress distributions and thermal gradients, gaining intuitive insights into the behavior of engine blocks under cyclic loads. This enhanced visualization capability facilitates better communication between design teams and accelerates the decision-making process.

As computational power continues to increase, the fidelity and scale of simulations are expanding. Cloud computing and parallel processing techniques now enable engineers to run multiple complex simulations simultaneously, exploring a wider range of design variables and operating conditions. This has led to more comprehensive validation processes and increased confidence in the reliability of engine block designs before physical prototyping begins.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!