How To Benchmark Engine Block Production Yield Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Block Yield Metrics Overview

Engine block yield metrics are crucial indicators in automotive manufacturing, providing insights into the efficiency and quality of the production process. These metrics encompass a range of measurements and analyses that evaluate the success rate of engine block production, from raw material to finished product. The primary focus is on quantifying the percentage of engine blocks that meet or exceed specified quality standards without requiring rework or scrapping.

Key components of engine block yield metrics include defect rates, first-pass yield, and overall equipment effectiveness (OEE). Defect rates measure the frequency of imperfections or failures in produced engine blocks, while first-pass yield indicates the percentage of blocks that pass all quality checks without any rework. OEE combines availability, performance, and quality to provide a comprehensive view of production efficiency.

These metrics are essential for benchmarking performance against industry standards and internal targets. They enable manufacturers to identify areas for improvement, optimize production processes, and reduce waste. By tracking yield metrics over time, companies can assess the impact of process changes, new technologies, or quality improvement initiatives on their engine block production.

Yield metrics also play a critical role in cost management and profitability analysis. Higher yield rates typically correlate with lower production costs, as fewer resources are wasted on defective parts or rework. This direct link to financial performance underscores the importance of accurate and consistent yield measurement in engine block manufacturing.

Advanced analytics and data collection systems are increasingly being employed to enhance the accuracy and timeliness of yield metrics. Real-time monitoring and predictive analytics can help identify potential issues before they impact yield, allowing for proactive interventions. These technologies also facilitate more granular analysis, enabling manufacturers to pinpoint specific stages or factors in the production process that may be affecting yield rates.

Benchmarking engine block yield metrics involves not only internal comparisons but also industry-wide standards. Manufacturers often participate in industry benchmarking studies or consortia to gauge their performance against competitors and identify best practices. This external perspective is valuable for setting realistic targets and driving continuous improvement in engine block production.

Key components of engine block yield metrics include defect rates, first-pass yield, and overall equipment effectiveness (OEE). Defect rates measure the frequency of imperfections or failures in produced engine blocks, while first-pass yield indicates the percentage of blocks that pass all quality checks without any rework. OEE combines availability, performance, and quality to provide a comprehensive view of production efficiency.

These metrics are essential for benchmarking performance against industry standards and internal targets. They enable manufacturers to identify areas for improvement, optimize production processes, and reduce waste. By tracking yield metrics over time, companies can assess the impact of process changes, new technologies, or quality improvement initiatives on their engine block production.

Yield metrics also play a critical role in cost management and profitability analysis. Higher yield rates typically correlate with lower production costs, as fewer resources are wasted on defective parts or rework. This direct link to financial performance underscores the importance of accurate and consistent yield measurement in engine block manufacturing.

Advanced analytics and data collection systems are increasingly being employed to enhance the accuracy and timeliness of yield metrics. Real-time monitoring and predictive analytics can help identify potential issues before they impact yield, allowing for proactive interventions. These technologies also facilitate more granular analysis, enabling manufacturers to pinpoint specific stages or factors in the production process that may be affecting yield rates.

Benchmarking engine block yield metrics involves not only internal comparisons but also industry-wide standards. Manufacturers often participate in industry benchmarking studies or consortia to gauge their performance against competitors and identify best practices. This external perspective is valuable for setting realistic targets and driving continuous improvement in engine block production.

Market Demand Analysis

The market demand for engine block production yield metrics benchmarking is driven by the automotive industry's relentless pursuit of efficiency, quality, and cost-effectiveness. As global competition intensifies and environmental regulations become more stringent, manufacturers are under increasing pressure to optimize their production processes and reduce waste.

Engine blocks, being critical components of internal combustion engines, play a vital role in vehicle performance and durability. The production yield of engine blocks directly impacts manufacturing costs, production schedules, and overall product quality. Consequently, there is a growing need for robust benchmarking tools and methodologies to assess and compare production yield metrics across different manufacturers and production lines.

The automotive industry's shift towards electric vehicles has not diminished the importance of engine block production for traditional combustion engines. In fact, it has heightened the need for efficiency in this sector, as manufacturers strive to maintain profitability in a changing market landscape. This transition period has created a unique demand for benchmarking tools that can help companies optimize their existing production processes while planning for future changes.

Tier 1 suppliers and OEMs are particularly interested in benchmarking solutions that can provide real-time insights into production yield metrics. These stakeholders seek to identify best practices, pinpoint areas for improvement, and make data-driven decisions to enhance their competitive edge. The ability to compare performance against industry standards and competitors is crucial for strategic planning and resource allocation.

Furthermore, the increasing adoption of Industry 4.0 technologies in manufacturing has created new opportunities for advanced benchmarking solutions. The integration of IoT sensors, big data analytics, and machine learning algorithms enables more sophisticated and accurate yield metrics tracking. This technological advancement has expanded the market for benchmarking tools that can handle complex data sets and provide actionable insights.

The global nature of automotive manufacturing also contributes to the demand for standardized benchmarking methodologies. As production facilities are spread across different countries and regions, companies require consistent metrics and evaluation criteria to ensure fair comparisons and identify global best practices. This need for standardization presents a significant market opportunity for benchmarking solution providers.

In conclusion, the market demand for engine block production yield metrics benchmarking is robust and multifaceted. It is driven by the need for operational excellence, cost reduction, and quality improvement in a highly competitive and evolving industry. As manufacturers continue to seek ways to optimize their processes and maintain their market position, the demand for sophisticated benchmarking tools and methodologies is expected to grow steadily in the coming years.

Engine blocks, being critical components of internal combustion engines, play a vital role in vehicle performance and durability. The production yield of engine blocks directly impacts manufacturing costs, production schedules, and overall product quality. Consequently, there is a growing need for robust benchmarking tools and methodologies to assess and compare production yield metrics across different manufacturers and production lines.

The automotive industry's shift towards electric vehicles has not diminished the importance of engine block production for traditional combustion engines. In fact, it has heightened the need for efficiency in this sector, as manufacturers strive to maintain profitability in a changing market landscape. This transition period has created a unique demand for benchmarking tools that can help companies optimize their existing production processes while planning for future changes.

Tier 1 suppliers and OEMs are particularly interested in benchmarking solutions that can provide real-time insights into production yield metrics. These stakeholders seek to identify best practices, pinpoint areas for improvement, and make data-driven decisions to enhance their competitive edge. The ability to compare performance against industry standards and competitors is crucial for strategic planning and resource allocation.

Furthermore, the increasing adoption of Industry 4.0 technologies in manufacturing has created new opportunities for advanced benchmarking solutions. The integration of IoT sensors, big data analytics, and machine learning algorithms enables more sophisticated and accurate yield metrics tracking. This technological advancement has expanded the market for benchmarking tools that can handle complex data sets and provide actionable insights.

The global nature of automotive manufacturing also contributes to the demand for standardized benchmarking methodologies. As production facilities are spread across different countries and regions, companies require consistent metrics and evaluation criteria to ensure fair comparisons and identify global best practices. This need for standardization presents a significant market opportunity for benchmarking solution providers.

In conclusion, the market demand for engine block production yield metrics benchmarking is robust and multifaceted. It is driven by the need for operational excellence, cost reduction, and quality improvement in a highly competitive and evolving industry. As manufacturers continue to seek ways to optimize their processes and maintain their market position, the demand for sophisticated benchmarking tools and methodologies is expected to grow steadily in the coming years.

Current Yield Challenges

Engine block production yield is a critical metric in automotive manufacturing, serving as a key indicator of process efficiency and product quality. However, the industry currently faces several significant challenges in accurately benchmarking and improving these yield metrics.

One of the primary challenges is the lack of standardized measurement methodologies across different manufacturers and production facilities. This inconsistency makes it difficult to compare yield metrics between companies or even between different plants within the same organization. Without a unified approach, benchmarking becomes a complex and often unreliable process, hindering industry-wide improvements and best practice sharing.

Another major hurdle is the complexity of modern engine block production processes. With the integration of advanced materials, intricate designs, and sophisticated manufacturing techniques, isolating the factors affecting yield becomes increasingly challenging. This complexity makes it difficult to identify the root causes of yield losses and implement targeted improvements.

Data collection and analysis present another significant challenge. Many production lines still rely on manual data entry or outdated systems, leading to potential inaccuracies and delays in reporting. Real-time monitoring and analysis of yield metrics are often lacking, preventing timely interventions and continuous improvement initiatives.

The variability in production environments also poses a challenge to consistent yield benchmarking. Factors such as equipment conditions, raw material quality, and environmental variables can significantly impact yield metrics. Accounting for these variables in a standardized benchmarking process is a complex task that the industry has yet to fully address.

Furthermore, the rapid pace of technological advancements in engine design and manufacturing processes makes it difficult to establish long-term benchmarking standards. As new technologies are introduced, existing yield metrics may become less relevant or require significant adjustments to remain meaningful.

The industry also grapples with balancing yield improvements against other critical factors such as cost, quality, and production speed. Optimizing yield metrics in isolation may lead to unintended consequences in other areas of production, necessitating a holistic approach to benchmarking and improvement.

Lastly, there is a challenge in effectively communicating and acting upon yield metrics across different levels of an organization. Translating complex yield data into actionable insights for both management and shop floor personnel requires sophisticated reporting systems and a culture of data-driven decision-making, which many companies are still in the process of developing.

One of the primary challenges is the lack of standardized measurement methodologies across different manufacturers and production facilities. This inconsistency makes it difficult to compare yield metrics between companies or even between different plants within the same organization. Without a unified approach, benchmarking becomes a complex and often unreliable process, hindering industry-wide improvements and best practice sharing.

Another major hurdle is the complexity of modern engine block production processes. With the integration of advanced materials, intricate designs, and sophisticated manufacturing techniques, isolating the factors affecting yield becomes increasingly challenging. This complexity makes it difficult to identify the root causes of yield losses and implement targeted improvements.

Data collection and analysis present another significant challenge. Many production lines still rely on manual data entry or outdated systems, leading to potential inaccuracies and delays in reporting. Real-time monitoring and analysis of yield metrics are often lacking, preventing timely interventions and continuous improvement initiatives.

The variability in production environments also poses a challenge to consistent yield benchmarking. Factors such as equipment conditions, raw material quality, and environmental variables can significantly impact yield metrics. Accounting for these variables in a standardized benchmarking process is a complex task that the industry has yet to fully address.

Furthermore, the rapid pace of technological advancements in engine design and manufacturing processes makes it difficult to establish long-term benchmarking standards. As new technologies are introduced, existing yield metrics may become less relevant or require significant adjustments to remain meaningful.

The industry also grapples with balancing yield improvements against other critical factors such as cost, quality, and production speed. Optimizing yield metrics in isolation may lead to unintended consequences in other areas of production, necessitating a holistic approach to benchmarking and improvement.

Lastly, there is a challenge in effectively communicating and acting upon yield metrics across different levels of an organization. Translating complex yield data into actionable insights for both management and shop floor personnel requires sophisticated reporting systems and a culture of data-driven decision-making, which many companies are still in the process of developing.

Existing Benchmarking Methods

01 Improved casting techniques for engine blocks

Advanced casting methods are employed to enhance the production yield of engine blocks. These techniques may include optimized mold designs, precise temperature control during casting, and improved cooling processes. Such methods can reduce defects and increase the overall quality of the engine blocks produced.- Improved casting techniques for engine blocks: Advanced casting methods are employed to enhance the production yield of engine blocks. These techniques may include optimized mold designs, precise temperature control during casting, and improved cooling processes. Such methods aim to reduce defects and increase the overall quality of the cast engine blocks.

- Automated production and quality control systems: Implementation of automated systems in engine block production lines to increase efficiency and reduce human error. This includes robotic assembly, automated inspection processes, and real-time monitoring of production parameters. These systems help maintain consistent quality and improve overall production yield.

- Advanced materials and alloy compositions: Utilization of innovative materials and alloy compositions in engine block manufacturing to enhance durability, reduce weight, and improve overall performance. This may include the use of high-strength aluminum alloys or composite materials that offer better casting properties and reduced defect rates.

- Optimized machining processes: Development of improved machining techniques for engine blocks to increase precision and reduce waste. This may involve advanced CNC machining, high-speed cutting tools, and optimized toolpaths. These processes aim to minimize material removal while maintaining tight tolerances, thereby improving production yield.

- Enhanced cooling and thermal management: Implementation of innovative cooling systems and thermal management techniques in engine block design and production. This includes optimized coolant passages, improved heat dissipation methods, and advanced thermal barrier coatings. These enhancements aim to reduce thermal stress and improve overall engine block performance and longevity.

02 Automated production and quality control systems

Implementation of automated production lines and advanced quality control systems can significantly improve engine block production yield. These systems may include robotic assembly, real-time monitoring of production parameters, and automated inspection processes to detect and address issues early in the manufacturing process.Expand Specific Solutions03 Material selection and optimization

Careful selection and optimization of materials used in engine block production can lead to improved yield. This may involve using high-quality alloys, developing new material compositions, or implementing advanced heat treatment processes to enhance the mechanical properties of the engine blocks.Expand Specific Solutions04 Innovative design and manufacturing processes

Novel design approaches and manufacturing processes can contribute to increased production yield of engine blocks. This may include the use of lightweight materials, modular designs, or additive manufacturing techniques to reduce complexity and improve manufacturability.Expand Specific Solutions05 Enhanced cooling and lubrication systems

Improving the cooling and lubrication systems within engine blocks can lead to better performance and increased production yield. This may involve optimizing coolant passages, implementing advanced oil circulation systems, or developing new coatings to reduce friction and wear.Expand Specific Solutions

Key Industry Players

The engine block production yield metrics benchmarking landscape is characterized by a mature market with established players and evolving technologies. The automotive and heavy machinery sectors drive demand, with a global market size estimated in billions. Key competitors like Cummins, Ford, Honda, and Caterpillar lead in technological advancements. These companies, along with others such as Siemens and Bosch, are investing in precision manufacturing, data analytics, and automation to improve yield metrics. The industry is transitioning towards more efficient and sustainable production methods, with a focus on reducing waste and improving quality control through advanced sensing and AI-driven process optimization.

Cummins, Inc.

Technical Solution: Cummins employs advanced statistical process control (SPC) and Six Sigma methodologies to benchmark engine block production yield metrics. They utilize real-time data collection systems integrated with their manufacturing execution system (MES) to monitor key performance indicators (KPIs) throughout the production process. Cummins has implemented a comprehensive defect tracking system that categorizes and analyzes defects at each stage of production, allowing for rapid identification and resolution of issues affecting yield[1]. The company also employs machine learning algorithms to predict potential quality issues before they occur, enabling proactive adjustments to manufacturing parameters[3]. Additionally, Cummins has developed a proprietary yield optimization software that combines historical data with current production metrics to continuously improve their benchmarking process and overall yield performance[5].

Strengths: Comprehensive data-driven approach, predictive analytics capabilities, and continuous improvement methodology. Weaknesses: High initial investment in technology and potential over-reliance on automated systems.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies has developed a sophisticated benchmarking system for engine block production yield metrics that incorporates both traditional and innovative approaches. They utilize a combination of in-line measurement technologies, including optical and laser-based systems, to capture dimensional data on engine blocks throughout the manufacturing process[2]. Ford's system includes advanced analytics platforms that process this data in real-time, allowing for immediate adjustments to machining parameters to maintain optimal yield. The company has also implemented a digital twin concept for their engine block production lines, enabling virtual simulations of process changes before implementation on the physical line[4]. Ford's benchmarking process includes a comprehensive supplier quality management system, ensuring that incoming materials meet strict specifications, thus contributing to overall yield improvement[6].

Strengths: Advanced in-line measurement technologies, digital twin capabilities for process optimization, and strong supplier quality management. Weaknesses: Complexity of the system may require specialized training and maintenance.

Core Yield Optimization Techniques

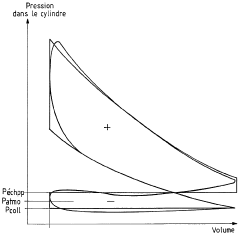

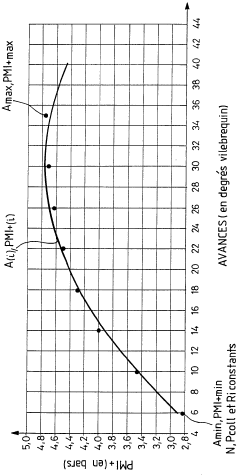

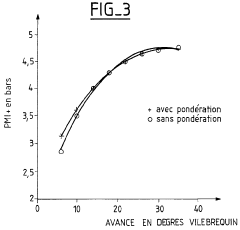

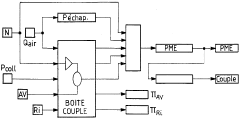

Method for computing an internal combustion engine indicated mean pressure

PatentWO1999046497A1

Innovation

- Calculating the indicated average pressure of the positive loop of the pressure cycle in the cylinder as a function of the volume, air flow, manifold pressure, operating speed, ignition advance, and combustion richness, using a weighted second-degree polynomial regression to model the evolution of indicated average pressure and advance yield, allowing for real-time engine control.

Diagnostic systems and methods using model predictive control

PatentActiveUS20150275806A1

Innovation

- A fuel control module transitions fueling from rich to lean, with a catalyst fault detection module diagnosing faults using oxygen sensor responses, and a prediction module generating operating parameters based on an engine model to determine optimal target values, while a cost module adjusts parameters for fault diagnosis and actuator control.

Industry Standards and Regulations

In the engine block production industry, adherence to stringent standards and regulations is crucial for ensuring product quality, safety, and environmental compliance. The Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) have established comprehensive guidelines for engine block manufacturing processes and quality control measures. These standards encompass material specifications, dimensional tolerances, and performance requirements that directly impact production yield metrics.

Key industry standards include SAE J1086, which outlines the recommended practices for cast iron engine blocks, and ISO 16949, which specifies quality management system requirements for automotive production. These standards provide a framework for benchmarking production yield metrics by defining acceptable ranges for various quality parameters such as porosity, surface finish, and dimensional accuracy.

Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards also play a significant role in shaping engine block production requirements. These regulations impose strict limits on engine emissions and fuel efficiency, indirectly influencing the design and manufacturing processes of engine blocks. Compliance with these regulations is essential for market access and can significantly impact production yield metrics.

The National Institute of Standards and Technology (NIST) provides guidelines for measurement and calibration techniques that are critical for accurately assessing engine block production yield metrics. Their recommendations on metrology and statistical process control methods help manufacturers establish reliable benchmarking systems.

Industry associations like the Automotive Industry Action Group (AIAG) offer additional resources and best practices for quality management and production efficiency. Their publications, such as the Production Part Approval Process (PPAP) manual, provide standardized methods for validating production processes and ensuring consistent quality outputs.

To effectively benchmark engine block production yield metrics, manufacturers must integrate these industry standards and regulatory requirements into their quality management systems. This involves implementing robust measurement and testing protocols, establishing clear acceptance criteria based on industry norms, and continuously monitoring production processes against these benchmarks. Regular audits and certifications from accredited bodies help ensure ongoing compliance and provide opportunities for comparative analysis within the industry.

Key industry standards include SAE J1086, which outlines the recommended practices for cast iron engine blocks, and ISO 16949, which specifies quality management system requirements for automotive production. These standards provide a framework for benchmarking production yield metrics by defining acceptable ranges for various quality parameters such as porosity, surface finish, and dimensional accuracy.

Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards also play a significant role in shaping engine block production requirements. These regulations impose strict limits on engine emissions and fuel efficiency, indirectly influencing the design and manufacturing processes of engine blocks. Compliance with these regulations is essential for market access and can significantly impact production yield metrics.

The National Institute of Standards and Technology (NIST) provides guidelines for measurement and calibration techniques that are critical for accurately assessing engine block production yield metrics. Their recommendations on metrology and statistical process control methods help manufacturers establish reliable benchmarking systems.

Industry associations like the Automotive Industry Action Group (AIAG) offer additional resources and best practices for quality management and production efficiency. Their publications, such as the Production Part Approval Process (PPAP) manual, provide standardized methods for validating production processes and ensuring consistent quality outputs.

To effectively benchmark engine block production yield metrics, manufacturers must integrate these industry standards and regulatory requirements into their quality management systems. This involves implementing robust measurement and testing protocols, establishing clear acceptance criteria based on industry norms, and continuously monitoring production processes against these benchmarks. Regular audits and certifications from accredited bodies help ensure ongoing compliance and provide opportunities for comparative analysis within the industry.

Environmental Impact Assessment

The environmental impact assessment of engine block production yield metrics benchmarking is a crucial aspect that must be considered in the automotive manufacturing industry. This assessment evaluates the potential environmental consequences of implementing various benchmarking methods and strategies to improve engine block production yield.

One of the primary environmental concerns in engine block production is the energy consumption associated with manufacturing processes. Benchmarking yield metrics often involves optimizing production lines, which may lead to increased energy usage in the short term. However, improved efficiency can result in long-term energy savings and reduced carbon emissions. It is essential to conduct a comprehensive analysis of the energy balance to ensure that the environmental benefits outweigh the initial energy investment.

Material waste is another significant environmental factor to consider. Benchmarking yield metrics can help identify areas where material waste occurs and implement strategies to minimize it. This not only reduces the environmental impact of raw material extraction and processing but also decreases the amount of waste sent to landfills. Implementing recycling and reuse programs for scrap materials can further mitigate the environmental footprint of engine block production.

Water usage and wastewater management are critical environmental aspects in engine block manufacturing. Benchmarking yield metrics should include an assessment of water consumption and the potential for water conservation measures. Implementing closed-loop water systems and water treatment technologies can significantly reduce the environmental impact of production processes.

Air quality is also a concern in engine block production. Benchmarking efforts should evaluate the emissions of volatile organic compounds (VOCs) and other air pollutants associated with manufacturing processes. Implementing advanced filtration systems and low-emission technologies can help minimize the impact on local air quality and comply with environmental regulations.

The use of hazardous materials in engine block production must be carefully monitored and controlled. Benchmarking yield metrics should include an assessment of the types and quantities of hazardous substances used in the manufacturing process. Identifying opportunities to substitute these materials with more environmentally friendly alternatives can reduce the risk of environmental contamination and improve worker safety.

Transportation and logistics associated with engine block production also contribute to the overall environmental impact. Benchmarking efforts should consider optimizing supply chain routes and implementing more efficient transportation methods to reduce fuel consumption and greenhouse gas emissions.

In conclusion, a comprehensive environmental impact assessment of engine block production yield metrics benchmarking is essential for sustainable manufacturing practices. By considering factors such as energy consumption, material waste, water usage, air quality, hazardous materials, and transportation, manufacturers can implement benchmarking strategies that not only improve production efficiency but also minimize environmental impact and promote long-term sustainability in the automotive industry.

One of the primary environmental concerns in engine block production is the energy consumption associated with manufacturing processes. Benchmarking yield metrics often involves optimizing production lines, which may lead to increased energy usage in the short term. However, improved efficiency can result in long-term energy savings and reduced carbon emissions. It is essential to conduct a comprehensive analysis of the energy balance to ensure that the environmental benefits outweigh the initial energy investment.

Material waste is another significant environmental factor to consider. Benchmarking yield metrics can help identify areas where material waste occurs and implement strategies to minimize it. This not only reduces the environmental impact of raw material extraction and processing but also decreases the amount of waste sent to landfills. Implementing recycling and reuse programs for scrap materials can further mitigate the environmental footprint of engine block production.

Water usage and wastewater management are critical environmental aspects in engine block manufacturing. Benchmarking yield metrics should include an assessment of water consumption and the potential for water conservation measures. Implementing closed-loop water systems and water treatment technologies can significantly reduce the environmental impact of production processes.

Air quality is also a concern in engine block production. Benchmarking efforts should evaluate the emissions of volatile organic compounds (VOCs) and other air pollutants associated with manufacturing processes. Implementing advanced filtration systems and low-emission technologies can help minimize the impact on local air quality and comply with environmental regulations.

The use of hazardous materials in engine block production must be carefully monitored and controlled. Benchmarking yield metrics should include an assessment of the types and quantities of hazardous substances used in the manufacturing process. Identifying opportunities to substitute these materials with more environmentally friendly alternatives can reduce the risk of environmental contamination and improve worker safety.

Transportation and logistics associated with engine block production also contribute to the overall environmental impact. Benchmarking efforts should consider optimizing supply chain routes and implementing more efficient transportation methods to reduce fuel consumption and greenhouse gas emissions.

In conclusion, a comprehensive environmental impact assessment of engine block production yield metrics benchmarking is essential for sustainable manufacturing practices. By considering factors such as energy consumption, material waste, water usage, air quality, hazardous materials, and transportation, manufacturers can implement benchmarking strategies that not only improve production efficiency but also minimize environmental impact and promote long-term sustainability in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!