Engineering Conductive Inks Using Sulphanilic Acid

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Ink Evolution

Conductive inks have undergone significant evolution since their inception, driven by the growing demand for flexible and printed electronics. The journey began with traditional metal-based inks, primarily silver and copper, which offered high conductivity but were limited by cost and processing constraints. As the field progressed, researchers explored alternative materials and formulations to address these limitations.

The early 2000s saw the emergence of carbon-based conductive inks, including graphene and carbon nanotubes. These materials promised lower costs and improved flexibility compared to metal-based counterparts. However, challenges in dispersion and stability hindered widespread adoption. Parallel to this, organic conductive polymers gained traction, offering unique properties such as transparency and stretchability.

A pivotal shift occurred with the development of hybrid inks, combining metallic nanoparticles with organic binders. This approach aimed to leverage the high conductivity of metals while improving processability and adhesion. The introduction of silver nanoparticle inks marked a significant milestone, enabling low-temperature sintering and enhanced performance on flexible substrates.

Recent years have witnessed a focus on environmentally friendly and cost-effective alternatives. Water-based formulations have gained prominence, addressing concerns over volatile organic compounds in traditional solvent-based inks. Additionally, the exploration of abundant materials like copper and aluminum has intensified, aiming to reduce reliance on precious metals.

The integration of functional additives has expanded the capabilities of conductive inks. Researchers have incorporated materials to enhance specific properties, such as self-healing capabilities, electromagnetic shielding, and thermal management. This trend towards multifunctional inks has opened new avenues for application in smart textiles, wearable electronics, and Internet of Things (IoT) devices.

The latest frontier in conductive ink evolution involves the use of novel compounds like sulphanilic acid. This approach represents a shift towards molecular engineering of conductive materials, potentially offering unprecedented control over ink properties. By manipulating the molecular structure and interactions, researchers aim to achieve optimal conductivity, stability, and processability.

As the field continues to advance, the focus remains on developing inks that combine high performance with ease of manufacturing and environmental sustainability. The evolution of conductive inks reflects a broader trend in materials science towards tailored solutions that meet the complex demands of emerging technologies.

The early 2000s saw the emergence of carbon-based conductive inks, including graphene and carbon nanotubes. These materials promised lower costs and improved flexibility compared to metal-based counterparts. However, challenges in dispersion and stability hindered widespread adoption. Parallel to this, organic conductive polymers gained traction, offering unique properties such as transparency and stretchability.

A pivotal shift occurred with the development of hybrid inks, combining metallic nanoparticles with organic binders. This approach aimed to leverage the high conductivity of metals while improving processability and adhesion. The introduction of silver nanoparticle inks marked a significant milestone, enabling low-temperature sintering and enhanced performance on flexible substrates.

Recent years have witnessed a focus on environmentally friendly and cost-effective alternatives. Water-based formulations have gained prominence, addressing concerns over volatile organic compounds in traditional solvent-based inks. Additionally, the exploration of abundant materials like copper and aluminum has intensified, aiming to reduce reliance on precious metals.

The integration of functional additives has expanded the capabilities of conductive inks. Researchers have incorporated materials to enhance specific properties, such as self-healing capabilities, electromagnetic shielding, and thermal management. This trend towards multifunctional inks has opened new avenues for application in smart textiles, wearable electronics, and Internet of Things (IoT) devices.

The latest frontier in conductive ink evolution involves the use of novel compounds like sulphanilic acid. This approach represents a shift towards molecular engineering of conductive materials, potentially offering unprecedented control over ink properties. By manipulating the molecular structure and interactions, researchers aim to achieve optimal conductivity, stability, and processability.

As the field continues to advance, the focus remains on developing inks that combine high performance with ease of manufacturing and environmental sustainability. The evolution of conductive inks reflects a broader trend in materials science towards tailored solutions that meet the complex demands of emerging technologies.

Market Demand Analysis

The market demand for conductive inks using sulphanilic acid is experiencing significant growth, driven by the expanding applications in printed electronics, flexible circuits, and smart packaging industries. This innovative approach to engineering conductive inks addresses several key market needs, particularly in terms of improved conductivity, flexibility, and environmental sustainability.

In the printed electronics sector, there is a growing demand for conductive inks that can maintain high conductivity while offering enhanced flexibility. Sulphanilic acid-based conductive inks show promise in meeting these requirements, potentially opening up new opportunities in wearable technology, flexible displays, and smart textiles. The global printed electronics market is projected to reach substantial growth in the coming years, with conductive inks playing a crucial role in this expansion.

The flexible circuits industry is another major driver for the demand of advanced conductive inks. As electronic devices become increasingly compact and versatile, there is a rising need for conductive materials that can withstand bending and stretching without compromising electrical performance. Sulphanilic acid-engineered inks could offer a solution to this challenge, potentially capturing a significant share of the flexible circuits market.

Smart packaging represents an emerging market with considerable potential for conductive ink applications. The ability to integrate electronic components directly into packaging materials opens up possibilities for enhanced product tracking, anti-counterfeiting measures, and interactive consumer experiences. Conductive inks using sulphanilic acid could provide the necessary conductivity and durability required for these applications, driving demand in this sector.

Environmental concerns are also shaping market demand for conductive inks. Traditional silver-based inks, while highly conductive, pose environmental challenges due to their metal content. Sulphanilic acid-based alternatives offer a more sustainable option, aligning with the growing trend towards eco-friendly materials in electronics manufacturing. This shift in consumer and regulatory preferences is likely to boost demand for these innovative conductive inks.

The automotive industry presents another significant market opportunity for sulphanilic acid-engineered conductive inks. With the increasing integration of electronic systems in vehicles, there is a growing need for conductive materials that can withstand harsh environmental conditions while maintaining reliability. These specialized inks could find applications in various automotive components, from dashboard displays to sensor systems.

As the Internet of Things (IoT) continues to expand, the demand for cost-effective and reliable conductive materials for sensor networks and smart devices is expected to surge. Sulphanilic acid-based conductive inks could play a crucial role in enabling the widespread deployment of IoT devices across various sectors, including smart homes, industrial automation, and healthcare monitoring systems.

In the printed electronics sector, there is a growing demand for conductive inks that can maintain high conductivity while offering enhanced flexibility. Sulphanilic acid-based conductive inks show promise in meeting these requirements, potentially opening up new opportunities in wearable technology, flexible displays, and smart textiles. The global printed electronics market is projected to reach substantial growth in the coming years, with conductive inks playing a crucial role in this expansion.

The flexible circuits industry is another major driver for the demand of advanced conductive inks. As electronic devices become increasingly compact and versatile, there is a rising need for conductive materials that can withstand bending and stretching without compromising electrical performance. Sulphanilic acid-engineered inks could offer a solution to this challenge, potentially capturing a significant share of the flexible circuits market.

Smart packaging represents an emerging market with considerable potential for conductive ink applications. The ability to integrate electronic components directly into packaging materials opens up possibilities for enhanced product tracking, anti-counterfeiting measures, and interactive consumer experiences. Conductive inks using sulphanilic acid could provide the necessary conductivity and durability required for these applications, driving demand in this sector.

Environmental concerns are also shaping market demand for conductive inks. Traditional silver-based inks, while highly conductive, pose environmental challenges due to their metal content. Sulphanilic acid-based alternatives offer a more sustainable option, aligning with the growing trend towards eco-friendly materials in electronics manufacturing. This shift in consumer and regulatory preferences is likely to boost demand for these innovative conductive inks.

The automotive industry presents another significant market opportunity for sulphanilic acid-engineered conductive inks. With the increasing integration of electronic systems in vehicles, there is a growing need for conductive materials that can withstand harsh environmental conditions while maintaining reliability. These specialized inks could find applications in various automotive components, from dashboard displays to sensor systems.

As the Internet of Things (IoT) continues to expand, the demand for cost-effective and reliable conductive materials for sensor networks and smart devices is expected to surge. Sulphanilic acid-based conductive inks could play a crucial role in enabling the widespread deployment of IoT devices across various sectors, including smart homes, industrial automation, and healthcare monitoring systems.

Technical Challenges

The development of conductive inks using sulphanilic acid faces several significant technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal conductivity while maintaining the ink's stability and printability. Sulphanilic acid, while promising for its potential to enhance conductivity, presents difficulties in terms of solubility and dispersion within the ink matrix.

Researchers are grappling with the issue of uniform dispersion of sulphanilic acid particles throughout the ink formulation. Agglomeration of particles can lead to inconsistent conductivity and poor print quality. This challenge is compounded by the need to maintain the ink's viscosity within a range suitable for various printing techniques, such as inkjet or screen printing.

Another critical hurdle is the ink's adhesion to different substrate materials. The incorporation of sulphanilic acid can affect the ink's ability to bond effectively with surfaces, potentially leading to delamination or poor durability of the printed circuits. Engineers must develop formulations that balance conductivity enhancement with strong adhesive properties across a wide range of substrates, including flexible and non-porous materials.

The long-term stability of sulphanilic acid-based conductive inks is also a concern. Oxidation and degradation over time can compromise the ink's performance, necessitating the development of effective stabilization techniques. This includes finding compatible additives that can prevent particle sedimentation and maintain the ink's conductive properties during storage and after printing.

Environmental and health considerations pose additional challenges. Sulphanilic acid and some of its derivatives may have potential toxicity concerns, requiring careful handling and disposal procedures. Researchers must explore eco-friendly alternatives or develop encapsulation methods to mitigate any environmental risks associated with the use of these inks.

The scalability of production processes for sulphanilic acid-based conductive inks presents another significant challenge. Moving from laboratory-scale synthesis to industrial-scale manufacturing while maintaining consistent quality and performance is a complex task. This involves optimizing reaction conditions, developing efficient purification methods, and ensuring batch-to-batch consistency in large-scale production.

Furthermore, the integration of these inks into existing manufacturing processes and equipment poses technical difficulties. Compatibility with current printing technologies and curing methods must be addressed to facilitate widespread adoption in the electronics industry. This may require modifications to existing machinery or the development of new specialized equipment for optimal deposition and curing of sulphanilic acid-based inks.

Lastly, the cost-effectiveness of using sulphanilic acid in conductive inks remains a challenge. While it may offer improved conductivity, the overall production costs must be competitive with existing alternatives to justify its adoption in commercial applications. This necessitates ongoing research into more efficient synthesis methods and exploration of potential synergies with other conductive materials to optimize performance while minimizing costs.

Researchers are grappling with the issue of uniform dispersion of sulphanilic acid particles throughout the ink formulation. Agglomeration of particles can lead to inconsistent conductivity and poor print quality. This challenge is compounded by the need to maintain the ink's viscosity within a range suitable for various printing techniques, such as inkjet or screen printing.

Another critical hurdle is the ink's adhesion to different substrate materials. The incorporation of sulphanilic acid can affect the ink's ability to bond effectively with surfaces, potentially leading to delamination or poor durability of the printed circuits. Engineers must develop formulations that balance conductivity enhancement with strong adhesive properties across a wide range of substrates, including flexible and non-porous materials.

The long-term stability of sulphanilic acid-based conductive inks is also a concern. Oxidation and degradation over time can compromise the ink's performance, necessitating the development of effective stabilization techniques. This includes finding compatible additives that can prevent particle sedimentation and maintain the ink's conductive properties during storage and after printing.

Environmental and health considerations pose additional challenges. Sulphanilic acid and some of its derivatives may have potential toxicity concerns, requiring careful handling and disposal procedures. Researchers must explore eco-friendly alternatives or develop encapsulation methods to mitigate any environmental risks associated with the use of these inks.

The scalability of production processes for sulphanilic acid-based conductive inks presents another significant challenge. Moving from laboratory-scale synthesis to industrial-scale manufacturing while maintaining consistent quality and performance is a complex task. This involves optimizing reaction conditions, developing efficient purification methods, and ensuring batch-to-batch consistency in large-scale production.

Furthermore, the integration of these inks into existing manufacturing processes and equipment poses technical difficulties. Compatibility with current printing technologies and curing methods must be addressed to facilitate widespread adoption in the electronics industry. This may require modifications to existing machinery or the development of new specialized equipment for optimal deposition and curing of sulphanilic acid-based inks.

Lastly, the cost-effectiveness of using sulphanilic acid in conductive inks remains a challenge. While it may offer improved conductivity, the overall production costs must be competitive with existing alternatives to justify its adoption in commercial applications. This necessitates ongoing research into more efficient synthesis methods and exploration of potential synergies with other conductive materials to optimize performance while minimizing costs.

Current Ink Solutions

01 Metal nanoparticle-based conductive inks

Conductive inks formulated with metal nanoparticles, particularly silver, gold, or copper, offer high conductivity. These inks can be sintered at lower temperatures, making them suitable for flexible substrates. The size and shape of nanoparticles, as well as their dispersion in the ink, significantly influence the final conductivity of the printed patterns.- Metal nanoparticle-based conductive inks: Conductive inks formulated with metal nanoparticles, particularly silver, gold, or copper, offer high conductivity. These inks can be sintered at lower temperatures, making them suitable for flexible substrates. The size and distribution of nanoparticles significantly affect the ink's conductivity.

- Carbon-based conductive inks: Conductive inks incorporating carbon materials such as graphene, carbon nanotubes, or carbon black provide good conductivity and flexibility. These inks are often more cost-effective than metal-based alternatives and can be used in various printing processes, including inkjet and screen printing.

- Polymer-based conductive inks: Conductive polymers, such as PEDOT:PSS, can be used to create flexible and stretchable conductive inks. These inks offer good conductivity while maintaining mechanical flexibility, making them suitable for wearable electronics and flexible displays.

- Additives for enhancing conductivity: Various additives can be incorporated into conductive inks to improve their conductivity. These may include conductive fillers, surfactants, or binders that help to optimize particle dispersion and film formation, resulting in better electrical performance of the printed patterns.

- Post-processing techniques for conductivity improvement: Post-processing methods such as thermal sintering, photonic sintering, or plasma treatment can significantly enhance the conductivity of printed conductive inks. These techniques help to remove organic components and promote particle coalescence, resulting in improved electrical pathways and higher conductivity.

02 Carbon-based conductive inks

Conductive inks incorporating carbon materials such as graphene, carbon nanotubes, or carbon black provide a balance between conductivity and cost-effectiveness. These inks often exhibit good flexibility and adhesion to various substrates. The conductivity can be enhanced by optimizing the carbon material concentration and improving dispersion techniques.Expand Specific Solutions03 Polymer-based conductive inks

Conductive polymers, such as PEDOT:PSS, can be used to formulate inks with moderate conductivity. These inks offer advantages in terms of flexibility, transparency, and ease of processing. The conductivity can be improved by incorporating additives or by post-treatment methods like solvent annealing.Expand Specific Solutions04 Hybrid conductive inks

Hybrid inks combining different conductive materials, such as metal nanoparticles with carbon materials or conductive polymers, can achieve synergistic effects. These formulations aim to balance conductivity, cost, and processability. The ratio of different components and their interactions play crucial roles in determining the final conductivity.Expand Specific Solutions05 Post-processing techniques for conductivity enhancement

Various post-processing methods can significantly improve the conductivity of printed patterns. These include thermal sintering, photonic sintering, plasma treatment, and chemical reduction. The choice of post-processing technique depends on the ink composition and substrate properties, aiming to optimize the connectivity between conductive particles without damaging the substrate.Expand Specific Solutions

Industry Leaders

The engineering of conductive inks using sulphanilic acid is in an early development stage, with a growing market driven by increasing demand for printed electronics. The technology is still evolving, with varying levels of maturity among key players. Companies like Henkel, LG Chem, and Ricoh are leading in research and development, leveraging their expertise in chemical engineering and materials science. Universities such as Tsinghua and Wuhan are contributing to fundamental research. Smaller specialized firms like InkTec and artience are focusing on niche applications. The competitive landscape is diverse, with both established chemical companies and innovative startups vying for market share in this emerging field.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a novel approach to engineering conductive inks using sulphanilic acid as a key component. Their method involves synthesizing sulphanilic acid-based conductive polymers and incorporating them into a specialized ink formulation. This formulation includes carefully selected solvents and additives to optimize conductivity and printability. The ink is designed for use in printed electronics applications, offering improved conductivity and stability compared to traditional silver-based inks[1]. Henkel's process involves precise control of sulphanilic acid polymerization, resulting in uniform particle size distribution and enhanced dispersion in the ink matrix[3]. The company has also developed proprietary surface modification techniques to improve adhesion to various substrates, including flexible plastics and textiles[5].

Strengths: Cost-effective alternative to silver-based inks, improved flexibility for wearable electronics, and enhanced environmental stability. Weaknesses: May have lower conductivity compared to metal-based inks, and potential limitations in high-temperature applications.

Xerox Holdings Corp.

Technical Solution: Xerox has pioneered a unique approach to conductive ink engineering using sulphanilic acid derivatives. Their technology involves the synthesis of sulphanilic acid-based conductive polymers with tailored side chains to enhance solubility and processability. The company's proprietary ink formulation incorporates these polymers along with nano-sized conductive fillers, creating a hybrid organic-inorganic system[2]. This approach allows for lower curing temperatures, making it suitable for heat-sensitive substrates. Xerox's ink demonstrates excellent adhesion to a wide range of materials, including paper and plastic films[4]. The company has also developed specialized printing techniques to optimize the deposition and patterning of these inks, enabling high-resolution conductive traces for flexible electronics and smart packaging applications[6].

Strengths: Low-temperature processing, compatibility with various substrates, and potential for high-resolution printing. Weaknesses: May have lower conductivity than metal-based inks and potential long-term stability issues in harsh environments.

Key Innovations

Use of sulphonic and phosphonic acids as dopants of conductive polyaniline films and conductive composite materials based on polyaniline

PatentWO2001004910A1

Innovation

- The use of sulfonic and phosphonic acids as dopants that act as both protonating agents and plasticizers, improving the conductivity of polyaniline films to 200-300 S/cm and enhancing mechanical properties, including flexibility, by forming solutions with specific organic solvents and insulating polymers.

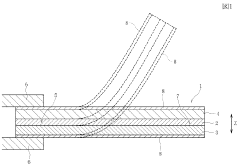

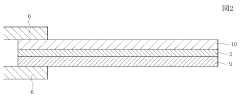

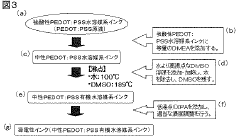

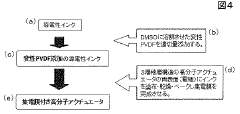

Conductive ink, electroconductive film, polymer actuator element, method for manufacturing the conductive ink, and method for manufacturing polymer actuator element

PatentInactiveJP2011201933A

Innovation

- A neutral conductive ink is produced by neutralizing PEDOT:PSS with a tertiary amine and dispersing it in an organic solvent with a higher boiling point, such as dimethylsulfoxide, to form a conductive film that suppresses chemical decomposition and enhances electrical conductivity.

Environmental Impact

The environmental impact of engineering conductive inks using sulphanilic acid is a crucial aspect to consider in the development and application of this technology. Sulphanilic acid, a key component in these conductive inks, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of using sulphanilic acid in conductive inks is its potential to reduce the reliance on more toxic and environmentally harmful materials traditionally used in electronic components. Sulphanilic acid-based inks can potentially replace heavy metal-based conductive materials, which often pose significant environmental risks during production, use, and disposal.

However, the production and use of sulphanilic acid itself are not without environmental concerns. The synthesis of sulphanilic acid typically involves the sulfonation of aniline, a process that can generate hazardous by-products and require significant energy inputs. This raises questions about the overall environmental footprint of the production process and the need for careful waste management strategies.

The disposal and end-of-life management of products containing sulphanilic acid-based conductive inks also warrant attention. While these inks may offer improved recyclability compared to some traditional electronic materials, proper recycling infrastructure and processes need to be developed to fully realize this potential benefit.

Water pollution is another environmental factor to consider. Sulphanilic acid and its derivatives can be water-soluble, potentially leading to contamination of water sources if not properly managed during production or disposal. This necessitates the implementation of robust wastewater treatment systems in manufacturing facilities using this technology.

On the positive side, the use of sulphanilic acid in conductive inks may contribute to the development of more energy-efficient electronic devices. The improved conductivity and performance of these inks could lead to reduced power consumption in various applications, indirectly contributing to lower energy demand and associated environmental impacts.

The potential for biodegradability is another area of interest. While sulphanilic acid itself is not readily biodegradable, research into incorporating it into more environmentally friendly polymer matrices could lead to conductive inks with improved end-of-life characteristics.

In conclusion, the environmental impact of engineering conductive inks using sulphanilic acid is multifaceted. While it offers potential benefits in terms of reduced toxicity and improved energy efficiency, challenges remain in terms of production processes, waste management, and water pollution. Ongoing research and development efforts should focus on optimizing the environmental performance of these inks throughout their lifecycle, from production to disposal or recycling.

One of the primary environmental benefits of using sulphanilic acid in conductive inks is its potential to reduce the reliance on more toxic and environmentally harmful materials traditionally used in electronic components. Sulphanilic acid-based inks can potentially replace heavy metal-based conductive materials, which often pose significant environmental risks during production, use, and disposal.

However, the production and use of sulphanilic acid itself are not without environmental concerns. The synthesis of sulphanilic acid typically involves the sulfonation of aniline, a process that can generate hazardous by-products and require significant energy inputs. This raises questions about the overall environmental footprint of the production process and the need for careful waste management strategies.

The disposal and end-of-life management of products containing sulphanilic acid-based conductive inks also warrant attention. While these inks may offer improved recyclability compared to some traditional electronic materials, proper recycling infrastructure and processes need to be developed to fully realize this potential benefit.

Water pollution is another environmental factor to consider. Sulphanilic acid and its derivatives can be water-soluble, potentially leading to contamination of water sources if not properly managed during production or disposal. This necessitates the implementation of robust wastewater treatment systems in manufacturing facilities using this technology.

On the positive side, the use of sulphanilic acid in conductive inks may contribute to the development of more energy-efficient electronic devices. The improved conductivity and performance of these inks could lead to reduced power consumption in various applications, indirectly contributing to lower energy demand and associated environmental impacts.

The potential for biodegradability is another area of interest. While sulphanilic acid itself is not readily biodegradable, research into incorporating it into more environmentally friendly polymer matrices could lead to conductive inks with improved end-of-life characteristics.

In conclusion, the environmental impact of engineering conductive inks using sulphanilic acid is multifaceted. While it offers potential benefits in terms of reduced toxicity and improved energy efficiency, challenges remain in terms of production processes, waste management, and water pollution. Ongoing research and development efforts should focus on optimizing the environmental performance of these inks throughout their lifecycle, from production to disposal or recycling.

Regulatory Compliance

The regulatory landscape for conductive inks using sulphanilic acid is complex and multifaceted, requiring careful consideration of various aspects to ensure compliance. Environmental regulations play a significant role, as sulphanilic acid and its derivatives may pose potential risks to ecosystems if not properly managed. Manufacturers must adhere to strict guidelines set by environmental protection agencies regarding the production, handling, and disposal of these materials.

Workplace safety regulations are another critical area of compliance. The use of sulphanilic acid in conductive ink formulations necessitates robust safety protocols to protect workers from potential exposure. This includes implementing proper ventilation systems, providing appropriate personal protective equipment (PPE), and establishing emergency response procedures in case of accidental spills or releases.

Product safety regulations are equally important, particularly for conductive inks intended for use in consumer electronics or medical devices. Regulatory bodies such as the FDA in the United States or the European Chemicals Agency (ECHA) may require extensive testing and documentation to demonstrate the safety and biocompatibility of these materials. This often involves conducting toxicological studies and assessing potential long-term health effects.

Transportation and storage of sulphanilic acid and related compounds are subject to specific regulations due to their potential hazards. Compliance with international shipping standards, such as those set by the International Maritime Dangerous Goods (IMDG) Code, is essential for global distribution of these materials. Proper labeling, packaging, and documentation are crucial to meet these requirements.

Intellectual property considerations also factor into regulatory compliance for conductive inks using sulphanilic acid. Manufacturers must ensure that their formulations and production processes do not infringe on existing patents or violate trade secrets. This may involve conducting thorough patent searches and potentially seeking legal counsel to navigate the complex landscape of intellectual property rights in the field of conductive materials.

As the technology evolves, staying abreast of changing regulations is crucial. Emerging concerns about nanomaterials and their potential environmental and health impacts may lead to new regulatory requirements for conductive inks containing nanoparticles. Proactive engagement with regulatory bodies and industry associations can help manufacturers anticipate and adapt to these evolving standards, ensuring long-term compliance and market viability for their products.

Workplace safety regulations are another critical area of compliance. The use of sulphanilic acid in conductive ink formulations necessitates robust safety protocols to protect workers from potential exposure. This includes implementing proper ventilation systems, providing appropriate personal protective equipment (PPE), and establishing emergency response procedures in case of accidental spills or releases.

Product safety regulations are equally important, particularly for conductive inks intended for use in consumer electronics or medical devices. Regulatory bodies such as the FDA in the United States or the European Chemicals Agency (ECHA) may require extensive testing and documentation to demonstrate the safety and biocompatibility of these materials. This often involves conducting toxicological studies and assessing potential long-term health effects.

Transportation and storage of sulphanilic acid and related compounds are subject to specific regulations due to their potential hazards. Compliance with international shipping standards, such as those set by the International Maritime Dangerous Goods (IMDG) Code, is essential for global distribution of these materials. Proper labeling, packaging, and documentation are crucial to meet these requirements.

Intellectual property considerations also factor into regulatory compliance for conductive inks using sulphanilic acid. Manufacturers must ensure that their formulations and production processes do not infringe on existing patents or violate trade secrets. This may involve conducting thorough patent searches and potentially seeking legal counsel to navigate the complex landscape of intellectual property rights in the field of conductive materials.

As the technology evolves, staying abreast of changing regulations is crucial. Emerging concerns about nanomaterials and their potential environmental and health impacts may lead to new regulatory requirements for conductive inks containing nanoparticles. Proactive engagement with regulatory bodies and industry associations can help manufacturers anticipate and adapt to these evolving standards, ensuring long-term compliance and market viability for their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!