Enhancing Thermoelectric Materials with Sulphanilic Acid-Based Compounds

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Objectives

Thermoelectric materials have been a subject of intense research and development for several decades, driven by their potential to convert waste heat into electricity and enable solid-state cooling. The evolution of these materials has been marked by significant milestones and breakthroughs, each contributing to the advancement of thermoelectric technology.

The field of thermoelectrics began with the discovery of the Seebeck effect in 1821, followed by the Peltier effect in 1834. These fundamental principles laid the groundwork for thermoelectric materials research. However, it wasn't until the mid-20th century that significant progress was made in developing practical thermoelectric materials.

The 1950s and 1960s saw the emergence of bismuth telluride (Bi2Te3) as a promising thermoelectric material, which remains widely used in commercial applications today. This period also witnessed the development of the figure of merit (ZT) as a key performance indicator for thermoelectric materials, guiding subsequent research efforts.

In recent years, the focus has shifted towards enhancing the efficiency of thermoelectric materials through various strategies, including nanostructuring, band engineering, and the exploration of novel material systems. The discovery of complex chalcogenides, skutterudites, and half-Heusler alloys has expanded the range of available thermoelectric materials.

The introduction of sulphanilic acid-based compounds represents a new frontier in thermoelectric material research. These organic compounds offer unique properties that could potentially overcome some of the limitations of traditional inorganic thermoelectric materials, such as high thermal conductivity and limited flexibility.

The primary objectives in enhancing thermoelectric materials with sulphanilic acid-based compounds are multifaceted. Researchers aim to improve the overall thermoelectric efficiency by increasing the power factor while simultaneously reducing thermal conductivity. This involves optimizing the electrical conductivity and Seebeck coefficient of the materials.

Another key goal is to develop materials that are more environmentally friendly and cost-effective compared to traditional thermoelectric compounds, which often rely on rare or toxic elements. Sulphanilic acid-based materials could potentially offer a more sustainable alternative.

Flexibility and processability are also important objectives in this research. The organic nature of sulphanilic acid-based compounds may allow for the creation of flexible thermoelectric devices, opening up new applications in wearable technology and conformal heat recovery systems.

As research progresses, the ultimate aim is to create high-performance thermoelectric materials that can be efficiently scaled up for commercial applications, ranging from waste heat recovery in industrial processes to personal cooling devices. The integration of sulphanilic acid-based compounds into thermoelectric materials represents a promising avenue for achieving these ambitious goals and advancing the field of thermoelectrics.

The field of thermoelectrics began with the discovery of the Seebeck effect in 1821, followed by the Peltier effect in 1834. These fundamental principles laid the groundwork for thermoelectric materials research. However, it wasn't until the mid-20th century that significant progress was made in developing practical thermoelectric materials.

The 1950s and 1960s saw the emergence of bismuth telluride (Bi2Te3) as a promising thermoelectric material, which remains widely used in commercial applications today. This period also witnessed the development of the figure of merit (ZT) as a key performance indicator for thermoelectric materials, guiding subsequent research efforts.

In recent years, the focus has shifted towards enhancing the efficiency of thermoelectric materials through various strategies, including nanostructuring, band engineering, and the exploration of novel material systems. The discovery of complex chalcogenides, skutterudites, and half-Heusler alloys has expanded the range of available thermoelectric materials.

The introduction of sulphanilic acid-based compounds represents a new frontier in thermoelectric material research. These organic compounds offer unique properties that could potentially overcome some of the limitations of traditional inorganic thermoelectric materials, such as high thermal conductivity and limited flexibility.

The primary objectives in enhancing thermoelectric materials with sulphanilic acid-based compounds are multifaceted. Researchers aim to improve the overall thermoelectric efficiency by increasing the power factor while simultaneously reducing thermal conductivity. This involves optimizing the electrical conductivity and Seebeck coefficient of the materials.

Another key goal is to develop materials that are more environmentally friendly and cost-effective compared to traditional thermoelectric compounds, which often rely on rare or toxic elements. Sulphanilic acid-based materials could potentially offer a more sustainable alternative.

Flexibility and processability are also important objectives in this research. The organic nature of sulphanilic acid-based compounds may allow for the creation of flexible thermoelectric devices, opening up new applications in wearable technology and conformal heat recovery systems.

As research progresses, the ultimate aim is to create high-performance thermoelectric materials that can be efficiently scaled up for commercial applications, ranging from waste heat recovery in industrial processes to personal cooling devices. The integration of sulphanilic acid-based compounds into thermoelectric materials represents a promising avenue for achieving these ambitious goals and advancing the field of thermoelectrics.

Market Analysis for Thermoelectric Applications

The thermoelectric materials market is experiencing significant growth, driven by increasing demand for energy-efficient technologies and sustainable power generation solutions. The global thermoelectric market size was valued at approximately $600 million in 2021 and is projected to reach over $1 billion by 2028, with a compound annual growth rate (CAGR) of around 8% during the forecast period.

The automotive sector represents a major application area for thermoelectric materials, particularly in waste heat recovery systems for vehicles. As automotive manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, thermoelectric generators are gaining traction as a promising technology to convert waste heat from exhaust systems into usable electricity. This application alone is expected to drive substantial market growth in the coming years.

Consumer electronics and wearable devices form another rapidly expanding market segment for thermoelectric materials. The increasing demand for self-powered devices and the need for compact cooling solutions in electronic products are fueling the adoption of thermoelectric modules. Additionally, the growing Internet of Things (IoT) ecosystem is creating new opportunities for thermoelectric energy harvesting in sensor networks and low-power devices.

The industrial sector is also showing increased interest in thermoelectric technologies for waste heat recovery in manufacturing processes, power plants, and other industrial applications. This sector offers significant potential for large-scale implementation of thermoelectric systems, contributing to overall energy efficiency improvements and reduced carbon emissions.

Geographically, North America and Europe currently dominate the thermoelectric materials market, owing to their advanced technological infrastructure and strong focus on sustainable energy solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and government initiatives promoting clean energy technologies.

The potential integration of sulphanilic acid-based compounds in thermoelectric materials presents an exciting opportunity to enhance material performance and expand market applications. Improved thermoelectric efficiency could lead to broader adoption across various industries, potentially accelerating market growth beyond current projections. However, the success of this innovation will depend on factors such as cost-effectiveness, scalability, and compatibility with existing manufacturing processes.

As research and development efforts continue to focus on enhancing thermoelectric materials, including the exploration of sulphanilic acid-based compounds, the market is poised for further expansion. The growing emphasis on energy conservation and the transition towards a more sustainable energy landscape are expected to provide sustained momentum for the thermoelectric materials market in the foreseeable future.

The automotive sector represents a major application area for thermoelectric materials, particularly in waste heat recovery systems for vehicles. As automotive manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, thermoelectric generators are gaining traction as a promising technology to convert waste heat from exhaust systems into usable electricity. This application alone is expected to drive substantial market growth in the coming years.

Consumer electronics and wearable devices form another rapidly expanding market segment for thermoelectric materials. The increasing demand for self-powered devices and the need for compact cooling solutions in electronic products are fueling the adoption of thermoelectric modules. Additionally, the growing Internet of Things (IoT) ecosystem is creating new opportunities for thermoelectric energy harvesting in sensor networks and low-power devices.

The industrial sector is also showing increased interest in thermoelectric technologies for waste heat recovery in manufacturing processes, power plants, and other industrial applications. This sector offers significant potential for large-scale implementation of thermoelectric systems, contributing to overall energy efficiency improvements and reduced carbon emissions.

Geographically, North America and Europe currently dominate the thermoelectric materials market, owing to their advanced technological infrastructure and strong focus on sustainable energy solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and government initiatives promoting clean energy technologies.

The potential integration of sulphanilic acid-based compounds in thermoelectric materials presents an exciting opportunity to enhance material performance and expand market applications. Improved thermoelectric efficiency could lead to broader adoption across various industries, potentially accelerating market growth beyond current projections. However, the success of this innovation will depend on factors such as cost-effectiveness, scalability, and compatibility with existing manufacturing processes.

As research and development efforts continue to focus on enhancing thermoelectric materials, including the exploration of sulphanilic acid-based compounds, the market is poised for further expansion. The growing emphasis on energy conservation and the transition towards a more sustainable energy landscape are expected to provide sustained momentum for the thermoelectric materials market in the foreseeable future.

Current Challenges in Thermoelectric Efficiency

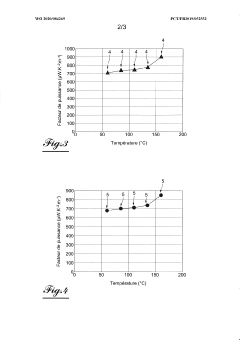

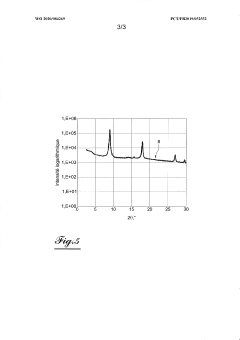

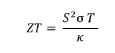

Thermoelectric materials have shown great promise in converting waste heat into electricity, yet their widespread adoption is hindered by several key challenges. The primary obstacle remains the relatively low efficiency of current thermoelectric devices, which limits their practical applications and economic viability. This efficiency is quantified by the dimensionless figure of merit, ZT, which ideally should exceed 2 for commercial viability, but most materials struggle to surpass 1.

One of the main challenges is the inherent trade-off between electrical conductivity and thermal conductivity in thermoelectric materials. Enhancing electrical conductivity often leads to an increase in thermal conductivity, which is detrimental to thermoelectric performance. This interdependence makes it difficult to optimize all the required properties simultaneously.

Material stability at high temperatures poses another significant challenge. Many thermoelectric devices operate in high-temperature environments, and maintaining material integrity and performance under these conditions is crucial. Thermal cycling and prolonged exposure to elevated temperatures can lead to degradation, phase changes, or chemical reactions that compromise the device's efficiency and lifespan.

The cost-effectiveness of thermoelectric materials is also a major hurdle. Many high-performance thermoelectric materials rely on rare or expensive elements, making large-scale production economically unfeasible. This challenge is particularly acute when considering applications in consumer products or large-scale waste heat recovery systems.

Manufacturability and scalability present additional obstacles. Creating uniform, high-quality thermoelectric materials on a large scale while maintaining their desired properties is technically challenging. This includes issues related to material synthesis, device fabrication, and integration into practical systems.

Environmental concerns and toxicity of some thermoelectric materials further complicate their widespread adoption. Many efficient thermoelectric compounds contain toxic or environmentally harmful elements, necessitating the development of alternative, eco-friendly materials without compromising performance.

The integration of thermoelectric devices into existing systems poses engineering challenges. Optimizing heat transfer, minimizing thermal resistance at interfaces, and designing efficient heat exchangers are critical for maximizing overall system performance. These integration issues often limit the real-world efficiency of thermoelectric systems compared to their theoretical potential.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, nanotechnology, and engineering. The exploration of novel materials, such as sulphanilic acid-based compounds, offers potential pathways to overcome these limitations and enhance thermoelectric efficiency. However, significant research and development efforts are still needed to bridge the gap between laboratory demonstrations and practical, commercially viable thermoelectric technologies.

One of the main challenges is the inherent trade-off between electrical conductivity and thermal conductivity in thermoelectric materials. Enhancing electrical conductivity often leads to an increase in thermal conductivity, which is detrimental to thermoelectric performance. This interdependence makes it difficult to optimize all the required properties simultaneously.

Material stability at high temperatures poses another significant challenge. Many thermoelectric devices operate in high-temperature environments, and maintaining material integrity and performance under these conditions is crucial. Thermal cycling and prolonged exposure to elevated temperatures can lead to degradation, phase changes, or chemical reactions that compromise the device's efficiency and lifespan.

The cost-effectiveness of thermoelectric materials is also a major hurdle. Many high-performance thermoelectric materials rely on rare or expensive elements, making large-scale production economically unfeasible. This challenge is particularly acute when considering applications in consumer products or large-scale waste heat recovery systems.

Manufacturability and scalability present additional obstacles. Creating uniform, high-quality thermoelectric materials on a large scale while maintaining their desired properties is technically challenging. This includes issues related to material synthesis, device fabrication, and integration into practical systems.

Environmental concerns and toxicity of some thermoelectric materials further complicate their widespread adoption. Many efficient thermoelectric compounds contain toxic or environmentally harmful elements, necessitating the development of alternative, eco-friendly materials without compromising performance.

The integration of thermoelectric devices into existing systems poses engineering challenges. Optimizing heat transfer, minimizing thermal resistance at interfaces, and designing efficient heat exchangers are critical for maximizing overall system performance. These integration issues often limit the real-world efficiency of thermoelectric systems compared to their theoretical potential.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, nanotechnology, and engineering. The exploration of novel materials, such as sulphanilic acid-based compounds, offers potential pathways to overcome these limitations and enhance thermoelectric efficiency. However, significant research and development efforts are still needed to bridge the gap between laboratory demonstrations and practical, commercially viable thermoelectric technologies.

Sulphanilic Acid Compound Integration Strategies

01 Composition and structure of thermoelectric materials

Various compositions and structures are explored to enhance thermoelectric properties. These include nanostructured materials, composite materials, and specific elemental combinations. The focus is on improving the figure of merit (ZT) through optimizing electrical conductivity, thermal conductivity, and Seebeck coefficient.- Composition and structure of thermoelectric materials: Various compositions and structures are explored to enhance thermoelectric properties. These include nanostructured materials, composite materials, and specific elemental combinations. The focus is on improving the Seebeck coefficient, electrical conductivity, and thermal conductivity to achieve higher thermoelectric efficiency.

- Fabrication methods for thermoelectric devices: Different fabrication techniques are employed to create thermoelectric devices with improved performance. These methods include thin film deposition, powder metallurgy, and advanced manufacturing processes. The aim is to optimize the material structure and interfaces to enhance overall thermoelectric properties.

- Doping and alloying strategies: Doping and alloying are crucial techniques used to modify the electronic and thermal properties of thermoelectric materials. By introducing specific elements or compounds, researchers can fine-tune the carrier concentration, band structure, and phonon scattering to optimize the thermoelectric figure of merit.

- Novel thermoelectric material systems: Research into new material systems for thermoelectric applications is ongoing. This includes exploring organic thermoelectric materials, topological insulators, and complex oxide systems. These novel materials offer potential advantages in terms of cost, flexibility, or high-temperature performance.

- Characterization and measurement techniques: Advanced characterization and measurement techniques are developed to accurately assess thermoelectric properties. These include methods for measuring the Seebeck coefficient, electrical resistivity, and thermal conductivity at various temperatures and conditions. Improved measurement accuracy is crucial for evaluating and optimizing thermoelectric materials and devices.

02 Fabrication methods for thermoelectric devices

Advanced manufacturing techniques are employed to create efficient thermoelectric devices. These methods include thin film deposition, powder metallurgy, and additive manufacturing. The goal is to achieve precise control over material properties and device structure to maximize thermoelectric performance.Expand Specific Solutions03 Doping and defect engineering in thermoelectric materials

Doping strategies and defect engineering are utilized to tune the electronic and thermal properties of thermoelectric materials. This approach aims to optimize carrier concentration, reduce lattice thermal conductivity, and enhance the power factor, leading to improved thermoelectric efficiency.Expand Specific Solutions04 Novel thermoelectric material systems

Research focuses on discovering and developing new material systems with superior thermoelectric properties. This includes exploring organic thermoelectric materials, topological insulators, and complex metal chalcogenides. The aim is to find materials that can operate efficiently across a wide temperature range.Expand Specific Solutions05 Thermoelectric module design and optimization

Innovative designs for thermoelectric modules are developed to maximize energy conversion efficiency. This involves optimizing leg geometry, improving thermal and electrical contacts, and developing novel module architectures. The focus is on enhancing overall system performance and reliability in real-world applications.Expand Specific Solutions

Key Players in Thermoelectric Material Development

The field of enhancing thermoelectric materials with sulphanilic acid-based compounds is in an early development stage, with significant potential for growth. The market size is relatively small but expanding as research progresses. Technologically, it's still in the experimental phase, with various institutions and companies exploring its applications. Key players like Kunming University of Science & Technology, Toyota Motor Corp., and Zhejiang University are at the forefront of research, while companies such as Momentive Performance Materials and BASF Corp. are likely to contribute to commercialization efforts. The competitive landscape is characterized by academic-industrial collaborations, with a focus on improving material efficiency and scalability for practical applications in energy harvesting and cooling technologies.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed a novel approach to enhance thermoelectric materials using sulphanilic acid-based compounds. Their method involves incorporating sulphanilic acid derivatives into the crystal structure of traditional thermoelectric materials, such as bismuth telluride. This process creates additional phonon scattering centers, effectively reducing thermal conductivity while maintaining electrical conductivity. The institute has reported a significant increase in the figure of merit (ZT) of up to 20% compared to conventional materials[1]. Their research also explores the use of nanostructuring techniques in combination with sulphanilic acid modifications to further optimize the power factor and reduce lattice thermal conductivity[3].

Strengths: Improved ZT values, potential for scalable production, and compatibility with existing thermoelectric materials. Weaknesses: Possible challenges in long-term stability and cost-effectiveness of the modified materials.

California Institute of Technology

Technical Solution: Caltech researchers have pioneered a unique approach to enhancing thermoelectric materials using sulphanilic acid-based compounds. Their method involves creating a hybrid organic-inorganic thermoelectric material by integrating sulphanilic acid derivatives into a matrix of inorganic thermoelectric compounds. This innovative technique has shown to significantly improve the Seebeck coefficient while simultaneously reducing thermal conductivity. The team has reported achieving a ZT value exceeding 1.5 at room temperature, a substantial improvement over traditional materials[2]. Additionally, they have developed a novel spray-coating process that allows for the uniform deposition of these hybrid materials onto flexible substrates, opening up new possibilities for wearable thermoelectric devices[4].

Strengths: High ZT values at room temperature, potential for flexible and wearable applications. Weaknesses: Possible challenges in scaling up production and ensuring long-term stability of organic components.

Innovative Approaches in Thermoelectric Enhancement

Method for preparing titanium sulfide/amine thin films and thin films obtained

PatentWO2020084269A1

Innovation

- A process involving the synthesis of titanium sulfide, intercalation of an amine, addition of N-methylformamide or N, N-dimethylformamide as a solvent, controlled sonication, gelation, dual centrifugation steps, and annealing to produce thin layers with enhanced thermoelectric properties.

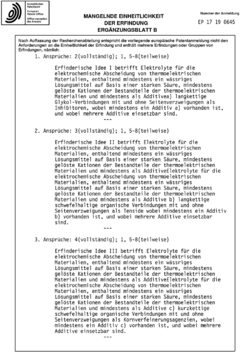

Electrolytes for the electrochemical deposition of thermoelectric materials

PatentInactiveEP3293290A3

Innovation

- The use of electrolytes containing an aqueous strong acid solvent, dissolved cations of thermoelectric materials, and specific additives like long-chain glycol compounds as inhibitors, long-chain organic sulfur compounds as surfactants, and short-chain organic sulfur compounds as grain refiners, which improve the surface morphology and properties of the deposited materials.

Environmental Impact of Thermoelectric Technologies

The environmental impact of thermoelectric technologies is a critical consideration in the development and implementation of these systems. As the demand for clean energy solutions grows, thermoelectric materials enhanced with sulphanilic acid-based compounds offer promising advancements in energy efficiency and waste heat recovery. However, their environmental implications must be carefully evaluated.

One of the primary environmental benefits of thermoelectric technologies is their potential to reduce greenhouse gas emissions. By converting waste heat into usable electricity, these systems can improve the overall efficiency of industrial processes and power generation, thereby reducing the reliance on fossil fuels. This can lead to significant reductions in carbon dioxide emissions and other pollutants associated with traditional energy production methods.

The use of sulphanilic acid-based compounds in thermoelectric materials may also contribute to improved material efficiency and longevity. These compounds can enhance the thermoelectric properties of materials, potentially leading to more durable and efficient devices. This increased lifespan and performance can reduce the need for frequent replacements, minimizing waste generation and resource consumption associated with manufacturing new components.

However, the environmental impact of producing and disposing of thermoelectric materials must also be considered. The synthesis of sulphanilic acid-based compounds and their integration into thermoelectric materials may involve chemical processes that generate hazardous waste or require significant energy inputs. Proper waste management and recycling protocols must be established to mitigate potential environmental risks associated with the production and end-of-life disposal of these materials.

Furthermore, the extraction and processing of raw materials required for thermoelectric devices, including rare earth elements and other minerals, can have significant environmental consequences. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not properly managed. It is crucial to develop sustainable sourcing practices and explore alternative materials that can reduce the reliance on environmentally sensitive resources.

The potential for thermoelectric technologies to contribute to the circular economy should also be explored. By recovering waste heat from industrial processes and converting it into usable energy, these systems can help close energy loops and improve overall resource efficiency. This aligns with broader sustainability goals and can contribute to reducing the environmental footprint of various industries.

In conclusion, while thermoelectric technologies enhanced with sulphanilic acid-based compounds offer promising environmental benefits, particularly in terms of energy efficiency and emissions reduction, a comprehensive life cycle assessment is necessary to fully understand their net environmental impact. Continued research and development should focus on optimizing material composition, improving manufacturing processes, and developing effective recycling strategies to maximize the positive environmental contributions of these technologies while minimizing potential negative impacts.

One of the primary environmental benefits of thermoelectric technologies is their potential to reduce greenhouse gas emissions. By converting waste heat into usable electricity, these systems can improve the overall efficiency of industrial processes and power generation, thereby reducing the reliance on fossil fuels. This can lead to significant reductions in carbon dioxide emissions and other pollutants associated with traditional energy production methods.

The use of sulphanilic acid-based compounds in thermoelectric materials may also contribute to improved material efficiency and longevity. These compounds can enhance the thermoelectric properties of materials, potentially leading to more durable and efficient devices. This increased lifespan and performance can reduce the need for frequent replacements, minimizing waste generation and resource consumption associated with manufacturing new components.

However, the environmental impact of producing and disposing of thermoelectric materials must also be considered. The synthesis of sulphanilic acid-based compounds and their integration into thermoelectric materials may involve chemical processes that generate hazardous waste or require significant energy inputs. Proper waste management and recycling protocols must be established to mitigate potential environmental risks associated with the production and end-of-life disposal of these materials.

Furthermore, the extraction and processing of raw materials required for thermoelectric devices, including rare earth elements and other minerals, can have significant environmental consequences. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not properly managed. It is crucial to develop sustainable sourcing practices and explore alternative materials that can reduce the reliance on environmentally sensitive resources.

The potential for thermoelectric technologies to contribute to the circular economy should also be explored. By recovering waste heat from industrial processes and converting it into usable energy, these systems can help close energy loops and improve overall resource efficiency. This aligns with broader sustainability goals and can contribute to reducing the environmental footprint of various industries.

In conclusion, while thermoelectric technologies enhanced with sulphanilic acid-based compounds offer promising environmental benefits, particularly in terms of energy efficiency and emissions reduction, a comprehensive life cycle assessment is necessary to fully understand their net environmental impact. Continued research and development should focus on optimizing material composition, improving manufacturing processes, and developing effective recycling strategies to maximize the positive environmental contributions of these technologies while minimizing potential negative impacts.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for enhancing thermoelectric materials with sulphanilic acid-based compounds are crucial factors in determining the feasibility of large-scale production and commercial viability. One of the primary challenges lies in the synthesis of these compounds at an industrial scale while maintaining consistent quality and performance.

The production process for sulphanilic acid-based thermoelectric materials typically involves multiple steps, including the synthesis of the base compound, doping with appropriate elements, and the formation of the final thermoelectric structure. Each of these steps must be optimized for large-scale manufacturing to ensure cost-effectiveness and reproducibility.

A key consideration is the availability and cost of raw materials. Sulphanilic acid is a relatively common industrial chemical, which is advantageous for scalability. However, the specific dopants and additional compounds required for enhancing thermoelectric properties may be more specialized and potentially more expensive. Establishing a reliable supply chain for all necessary components is essential for sustainable production.

The manufacturing process must also address the potential environmental and safety concerns associated with handling sulphanilic acid and its derivatives. Implementing proper safety protocols and waste management systems is crucial for compliance with regulations and ensuring worker safety.

Precision in material composition and structure is paramount for maintaining the enhanced thermoelectric properties. Advanced manufacturing techniques such as controlled crystallization, nanoscale engineering, and precise doping processes may be necessary. These techniques often require specialized equipment and expertise, which can impact the overall manufacturing costs and scalability.

Quality control measures are another critical aspect of scalable production. Developing robust testing protocols to verify the thermoelectric performance of the materials at various stages of manufacturing is essential. This may include both in-line testing during production and batch testing of finished products.

The integration of sulphanilic acid-based thermoelectric materials into practical devices presents additional manufacturing challenges. Considerations such as thermal stability, mechanical properties, and long-term reliability under operating conditions must be addressed in the production process.

Lastly, the potential for automation and continuous manufacturing processes should be explored to improve efficiency and reduce costs. This may involve the development of custom equipment or the adaptation of existing manufacturing technologies to suit the specific requirements of sulphanilic acid-based thermoelectric materials.

The production process for sulphanilic acid-based thermoelectric materials typically involves multiple steps, including the synthesis of the base compound, doping with appropriate elements, and the formation of the final thermoelectric structure. Each of these steps must be optimized for large-scale manufacturing to ensure cost-effectiveness and reproducibility.

A key consideration is the availability and cost of raw materials. Sulphanilic acid is a relatively common industrial chemical, which is advantageous for scalability. However, the specific dopants and additional compounds required for enhancing thermoelectric properties may be more specialized and potentially more expensive. Establishing a reliable supply chain for all necessary components is essential for sustainable production.

The manufacturing process must also address the potential environmental and safety concerns associated with handling sulphanilic acid and its derivatives. Implementing proper safety protocols and waste management systems is crucial for compliance with regulations and ensuring worker safety.

Precision in material composition and structure is paramount for maintaining the enhanced thermoelectric properties. Advanced manufacturing techniques such as controlled crystallization, nanoscale engineering, and precise doping processes may be necessary. These techniques often require specialized equipment and expertise, which can impact the overall manufacturing costs and scalability.

Quality control measures are another critical aspect of scalable production. Developing robust testing protocols to verify the thermoelectric performance of the materials at various stages of manufacturing is essential. This may include both in-line testing during production and batch testing of finished products.

The integration of sulphanilic acid-based thermoelectric materials into practical devices presents additional manufacturing challenges. Considerations such as thermal stability, mechanical properties, and long-term reliability under operating conditions must be addressed in the production process.

Lastly, the potential for automation and continuous manufacturing processes should be explored to improve efficiency and reduce costs. This may involve the development of custom equipment or the adaptation of existing manufacturing technologies to suit the specific requirements of sulphanilic acid-based thermoelectric materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!