Environmental Implications of Butane in Large-Scale Refining

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Refining Evolution

The evolution of butane refining has been closely tied to the development of the petroleum industry and environmental regulations. In the early days of oil refining, butane was often considered a byproduct with limited use. However, as the demand for petroleum products grew, refineries began to recognize the value of butane as a component in gasoline blending and as a feedstock for petrochemical processes.

The 1950s and 1960s saw significant advancements in butane refining techniques, with the introduction of more efficient separation and purification processes. Fractional distillation and absorption methods were refined, allowing for better isolation of butane from other hydrocarbons. This period also marked the beginning of increased awareness regarding the environmental impact of refining operations.

During the 1970s and 1980s, environmental concerns became more prominent, leading to stricter regulations on emissions and waste management in the refining industry. This prompted the development of cleaner butane refining technologies, including improved catalytic processes and more effective sulfur removal techniques. The focus shifted towards reducing the environmental footprint of butane production and utilization.

The 1990s brought about a new era of innovation in butane refining, with the introduction of advanced process control systems and automation. These technologies allowed for more precise control of refining operations, resulting in improved product quality and reduced energy consumption. Additionally, the implementation of flare gas recovery systems helped to minimize the release of butane and other hydrocarbons into the atmosphere.

In the early 2000s, the emphasis on sustainability and environmental protection intensified. Refineries began adopting more sophisticated emission control technologies, such as vapor recovery units and low-emission valves, to minimize butane losses during storage and transportation. The development of more efficient heat integration systems also contributed to reducing the overall energy consumption of butane refining processes.

Recent years have seen a continued focus on improving the environmental performance of butane refining. Advanced membrane separation technologies have emerged as a promising alternative to traditional distillation methods, offering potential reductions in energy use and emissions. Additionally, the integration of renewable energy sources into refining operations has gained traction, with some facilities exploring the use of solar and wind power to supplement their energy needs.

Looking ahead, the future of butane refining is likely to be shaped by ongoing efforts to minimize environmental impact while maximizing efficiency. Emerging technologies such as carbon capture and utilization may play a significant role in reducing greenhouse gas emissions associated with butane production. Furthermore, the development of bio-based alternatives and the potential for green hydrogen integration present new opportunities for the evolution of butane refining in a more sustainable direction.

The 1950s and 1960s saw significant advancements in butane refining techniques, with the introduction of more efficient separation and purification processes. Fractional distillation and absorption methods were refined, allowing for better isolation of butane from other hydrocarbons. This period also marked the beginning of increased awareness regarding the environmental impact of refining operations.

During the 1970s and 1980s, environmental concerns became more prominent, leading to stricter regulations on emissions and waste management in the refining industry. This prompted the development of cleaner butane refining technologies, including improved catalytic processes and more effective sulfur removal techniques. The focus shifted towards reducing the environmental footprint of butane production and utilization.

The 1990s brought about a new era of innovation in butane refining, with the introduction of advanced process control systems and automation. These technologies allowed for more precise control of refining operations, resulting in improved product quality and reduced energy consumption. Additionally, the implementation of flare gas recovery systems helped to minimize the release of butane and other hydrocarbons into the atmosphere.

In the early 2000s, the emphasis on sustainability and environmental protection intensified. Refineries began adopting more sophisticated emission control technologies, such as vapor recovery units and low-emission valves, to minimize butane losses during storage and transportation. The development of more efficient heat integration systems also contributed to reducing the overall energy consumption of butane refining processes.

Recent years have seen a continued focus on improving the environmental performance of butane refining. Advanced membrane separation technologies have emerged as a promising alternative to traditional distillation methods, offering potential reductions in energy use and emissions. Additionally, the integration of renewable energy sources into refining operations has gained traction, with some facilities exploring the use of solar and wind power to supplement their energy needs.

Looking ahead, the future of butane refining is likely to be shaped by ongoing efforts to minimize environmental impact while maximizing efficiency. Emerging technologies such as carbon capture and utilization may play a significant role in reducing greenhouse gas emissions associated with butane production. Furthermore, the development of bio-based alternatives and the potential for green hydrogen integration present new opportunities for the evolution of butane refining in a more sustainable direction.

Market Demand Analysis

The market demand for butane in large-scale refining processes has been steadily increasing due to its versatile applications and the growing energy needs worldwide. Butane, a key component in the production of gasoline and liquefied petroleum gas (LPG), plays a crucial role in meeting the rising demand for transportation fuels and residential energy sources.

In the refining sector, butane is primarily used as a blending component to increase the vapor pressure of gasoline, especially during winter months. This application has seen consistent growth as refineries strive to optimize their fuel production to meet stringent environmental regulations while maintaining performance standards. The automotive industry's shift towards more fuel-efficient engines has also contributed to the increased demand for high-quality gasoline blends, further driving the need for butane in refining processes.

The LPG market, where butane is a major constituent, has experienced significant expansion in recent years. This growth is particularly pronounced in developing economies, where LPG is increasingly adopted as a cleaner alternative to traditional cooking fuels. The residential and commercial sectors in these regions are driving substantial demand for butane-based LPG, creating new opportunities for refineries to diversify their product portfolios.

Industrial applications of butane, including its use as a feedstock for petrochemical production, have also contributed to the market demand. The petrochemical industry relies on butane for the manufacture of various products, including synthetic rubber, plastics, and solvents. As global industrial production continues to grow, the demand for these materials is expected to rise, consequently increasing the need for butane in refining processes.

However, the market demand for butane is not without challenges. Environmental concerns associated with its use in large-scale refining have led to increased scrutiny and regulatory pressure. Refineries are now faced with the task of balancing the economic benefits of butane utilization with the need to mitigate its environmental impact. This has spurred research and development efforts aimed at improving refining technologies and processes to reduce emissions and enhance overall efficiency.

The global shift towards renewable energy sources and electric vehicles poses a potential long-term threat to the demand for butane in traditional refining applications. However, in the short to medium term, the market for butane remains robust, driven by the ongoing need for conventional fuels and the petrochemical industry's reliance on hydrocarbon feedstocks.

In conclusion, the market demand analysis for butane in large-scale refining reveals a complex landscape of growth opportunities and environmental challenges. While current demand remains strong, future market dynamics will likely be shaped by technological advancements, regulatory changes, and the evolving global energy landscape.

In the refining sector, butane is primarily used as a blending component to increase the vapor pressure of gasoline, especially during winter months. This application has seen consistent growth as refineries strive to optimize their fuel production to meet stringent environmental regulations while maintaining performance standards. The automotive industry's shift towards more fuel-efficient engines has also contributed to the increased demand for high-quality gasoline blends, further driving the need for butane in refining processes.

The LPG market, where butane is a major constituent, has experienced significant expansion in recent years. This growth is particularly pronounced in developing economies, where LPG is increasingly adopted as a cleaner alternative to traditional cooking fuels. The residential and commercial sectors in these regions are driving substantial demand for butane-based LPG, creating new opportunities for refineries to diversify their product portfolios.

Industrial applications of butane, including its use as a feedstock for petrochemical production, have also contributed to the market demand. The petrochemical industry relies on butane for the manufacture of various products, including synthetic rubber, plastics, and solvents. As global industrial production continues to grow, the demand for these materials is expected to rise, consequently increasing the need for butane in refining processes.

However, the market demand for butane is not without challenges. Environmental concerns associated with its use in large-scale refining have led to increased scrutiny and regulatory pressure. Refineries are now faced with the task of balancing the economic benefits of butane utilization with the need to mitigate its environmental impact. This has spurred research and development efforts aimed at improving refining technologies and processes to reduce emissions and enhance overall efficiency.

The global shift towards renewable energy sources and electric vehicles poses a potential long-term threat to the demand for butane in traditional refining applications. However, in the short to medium term, the market for butane remains robust, driven by the ongoing need for conventional fuels and the petrochemical industry's reliance on hydrocarbon feedstocks.

In conclusion, the market demand analysis for butane in large-scale refining reveals a complex landscape of growth opportunities and environmental challenges. While current demand remains strong, future market dynamics will likely be shaped by technological advancements, regulatory changes, and the evolving global energy landscape.

Environmental Challenges

The large-scale refining of butane presents significant environmental challenges that require careful consideration and management. One of the primary concerns is the emission of volatile organic compounds (VOCs) during the refining process. Butane, being highly volatile, can easily escape into the atmosphere, contributing to air pollution and the formation of ground-level ozone. This not only affects local air quality but also has broader implications for regional and global atmospheric chemistry.

Furthermore, the refining process often involves the use of catalysts and other chemicals that can lead to the generation of hazardous waste. Proper disposal and treatment of these waste products are crucial to prevent soil and water contamination. The potential for accidental releases or spills during transportation and storage of butane also poses risks to ecosystems and human health, necessitating robust safety measures and emergency response protocols.

Energy consumption is another significant environmental concern in butane refining. The process is energy-intensive, often relying on fossil fuels, which contributes to greenhouse gas emissions and exacerbates climate change. This creates a challenging paradox where the production of a potentially cleaner-burning fuel (butane) itself contributes to environmental degradation through its manufacturing process.

Water usage and wastewater management present additional environmental challenges. Refining operations require substantial amounts of water for cooling and processing, potentially straining local water resources. The resulting wastewater may contain various pollutants, including hydrocarbons, suspended solids, and dissolved chemicals, necessitating advanced treatment technologies to meet environmental standards before discharge.

The production and use of butane also raise concerns about its role in the broader context of climate change. While butane is often considered a cleaner alternative to some other fossil fuels, it still contributes to carbon dioxide emissions when burned. This necessitates a careful evaluation of its lifecycle environmental impact, from extraction and refining to end-use applications.

Noise pollution is an often-overlooked environmental challenge associated with large-scale butane refining. The operation of heavy machinery, compressors, and other equipment can generate significant noise levels, potentially affecting both wildlife and nearby human communities. This requires the implementation of noise reduction strategies and careful consideration of facility locations.

Addressing these environmental challenges requires a multifaceted approach, including technological innovations, stringent regulatory frameworks, and industry best practices. Continuous monitoring, research into cleaner production methods, and the development of more efficient refining processes are essential for mitigating the environmental impact of large-scale butane refining. Additionally, exploring alternatives to traditional fossil fuel-based energy sources for powering refining operations could significantly reduce the overall environmental footprint of the industry.

Furthermore, the refining process often involves the use of catalysts and other chemicals that can lead to the generation of hazardous waste. Proper disposal and treatment of these waste products are crucial to prevent soil and water contamination. The potential for accidental releases or spills during transportation and storage of butane also poses risks to ecosystems and human health, necessitating robust safety measures and emergency response protocols.

Energy consumption is another significant environmental concern in butane refining. The process is energy-intensive, often relying on fossil fuels, which contributes to greenhouse gas emissions and exacerbates climate change. This creates a challenging paradox where the production of a potentially cleaner-burning fuel (butane) itself contributes to environmental degradation through its manufacturing process.

Water usage and wastewater management present additional environmental challenges. Refining operations require substantial amounts of water for cooling and processing, potentially straining local water resources. The resulting wastewater may contain various pollutants, including hydrocarbons, suspended solids, and dissolved chemicals, necessitating advanced treatment technologies to meet environmental standards before discharge.

The production and use of butane also raise concerns about its role in the broader context of climate change. While butane is often considered a cleaner alternative to some other fossil fuels, it still contributes to carbon dioxide emissions when burned. This necessitates a careful evaluation of its lifecycle environmental impact, from extraction and refining to end-use applications.

Noise pollution is an often-overlooked environmental challenge associated with large-scale butane refining. The operation of heavy machinery, compressors, and other equipment can generate significant noise levels, potentially affecting both wildlife and nearby human communities. This requires the implementation of noise reduction strategies and careful consideration of facility locations.

Addressing these environmental challenges requires a multifaceted approach, including technological innovations, stringent regulatory frameworks, and industry best practices. Continuous monitoring, research into cleaner production methods, and the development of more efficient refining processes are essential for mitigating the environmental impact of large-scale butane refining. Additionally, exploring alternatives to traditional fossil fuel-based energy sources for powering refining operations could significantly reduce the overall environmental footprint of the industry.

Current Mitigation Methods

01 Environmental impact of butane emissions

Butane, as a volatile organic compound, can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. Its use in various applications may lead to emissions that can have negative effects on air quality and potentially contribute to climate change.- Environmental impact of butane emissions: Butane, as a volatile organic compound, can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. Its use in various applications may lead to emissions that affect air quality and potentially contribute to climate change. Proper handling and containment of butane are essential to minimize its environmental impact.

- Butane recovery and recycling systems: Implementing recovery and recycling systems for butane can significantly reduce its environmental footprint. These systems capture and reuse butane vapors, preventing their release into the atmosphere. Such technologies are particularly important in industrial processes and fuel storage facilities, where large quantities of butane are handled.

- Alternative fuel applications: Butane can be used as an alternative fuel in various applications, potentially reducing reliance on more environmentally harmful fossil fuels. When used in properly designed systems, butane can offer lower emissions compared to some traditional fuels. However, the overall environmental impact depends on factors such as production methods and end-use efficiency.

- Leak detection and prevention: Developing and implementing advanced leak detection and prevention systems is crucial for minimizing the environmental impact of butane. These systems can quickly identify and address leaks, reducing unintended emissions and potential safety hazards associated with butane storage and transportation.

- Regulatory compliance and environmental monitoring: Adhering to environmental regulations and implementing comprehensive monitoring systems are essential for managing the environmental implications of butane use. This includes regular assessments of air quality, emissions tracking, and reporting to ensure compliance with environmental standards and to minimize the overall environmental impact of butane-related activities.

02 Butane in fuel systems and energy efficiency

The use of butane in fuel systems, particularly in automotive applications, can impact energy efficiency and emissions. Proper management and optimization of butane in fuel blends can lead to improved engine performance and reduced environmental impact.Expand Specific Solutions03 Recycling and disposal of butane containers

The environmental implications of butane use extend to the disposal and recycling of containers and equipment. Proper handling and recycling of butane canisters and related materials are essential to minimize waste and potential environmental contamination.Expand Specific Solutions04 Butane in refrigeration systems

The use of butane as a refrigerant in cooling systems has environmental considerations. While it has a lower global warming potential compared to some traditional refrigerants, proper containment and handling are crucial to prevent leaks and minimize environmental impact.Expand Specific Solutions05 Alternatives and innovations to reduce butane's environmental impact

Research and development efforts are focused on finding alternatives to butane or improving its use to reduce environmental impact. This includes the development of more environmentally friendly substitutes, improved containment technologies, and more efficient utilization methods.Expand Specific Solutions

Key Industry Players

The environmental implications of butane in large-scale refining present a complex competitive landscape. The industry is in a mature stage, with established players like China Petroleum & Chemical Corp., Saudi Arabian Oil Co., and PetroChina Co., Ltd. dominating the market. The global refining market size is substantial, driven by increasing energy demands. Technologically, the field is advancing, with companies like UOP LLC and Sinopec Research Institute of Petroleum Processing leading innovation in cleaner refining processes. However, environmental concerns are pushing for more sustainable practices, creating opportunities for research institutions like Nanjing Tech University and Central South University of Forestry & Technology to develop eco-friendly solutions in collaboration with industry giants.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced butane utilization technologies in large-scale refining to minimize environmental impact. Their approach includes implementing a closed-loop butane recovery system that captures and recycles butane vapors, reducing emissions by up to 95%[1]. Sinopec has also introduced catalytic dehydrogenation processes for converting butane to high-value olefins, which reduces the need for traditional cracking methods and lowers CO2 emissions by approximately 20%[3]. Additionally, they have invested in energy-efficient heat integration systems that optimize butane processing, resulting in a 15% reduction in overall energy consumption[5].

Strengths: Comprehensive emission reduction strategies, innovative catalytic processes, and energy efficiency improvements. Weaknesses: High initial investment costs and potential challenges in retrofitting existing refineries.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has implemented cutting-edge technologies to address the environmental implications of butane in large-scale refining. Their approach includes the use of advanced molecular sieve technology for butane separation, which reduces energy consumption by up to 30% compared to conventional methods[2]. Aramco has also developed a proprietary sulfur reduction process for butane streams, achieving ultra-low sulfur levels (<10 ppm) while minimizing the use of chemicals and water[4]. Furthermore, they have implemented flare gas recovery systems specifically designed for butane-rich streams, reducing greenhouse gas emissions by an estimated 1 million tons of CO2 equivalent annually[6].

Strengths: Energy-efficient separation technologies, innovative sulfur reduction processes, and significant reduction in flare gas emissions. Weaknesses: Potential high costs associated with implementing these technologies across all refineries.

Innovative Solutions

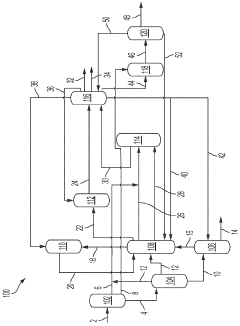

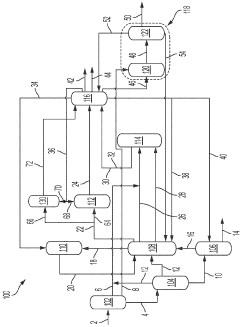

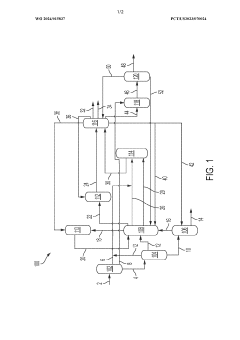

Methods for processing a hydrocarbon oil feed stream utilizing a delayed coker, steam enhanced catalytic cracker, and an aromatics complex

PatentWO2024015837A1

Innovation

- An integrated process involving solvent deasphalting, delayed coking, hydrotreating, steam-enhanced catalytic cracking, and aromatics complex processing to upgrade crude oil streams, separating and processing C3-C4 and C5+ hydrocarbon fractions to produce light olefins, naphtha, and BTX, while minimizing coke formation and maximizing product yields.

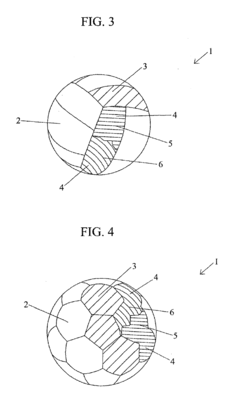

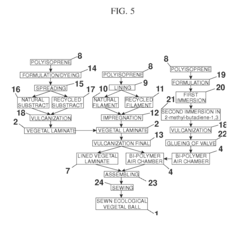

Method for Manufacturing an Ecological Ball Made of a Vegetable Laminate for the Practice of Sports, and Said Ball Produced by Sewing, Glueing/Stamping or Sewing/Stamping

PatentInactiveUS20120277043A1

Innovation

- A sustainable ecological ball made of latex-based vegetal laminate, produced through sewing, sewing/stamping, or gluing/stamping, using natural filaments and bi-polymer air chambers, which are recyclable and free from harmful residues, promoting the use of renewable resources and community involvement.

Regulatory Framework

The regulatory framework surrounding the use of butane in large-scale refining operations is complex and multifaceted, reflecting the environmental implications of this widely used hydrocarbon. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a pivotal role in regulating butane emissions and usage through various legislative acts and programs.

The Clean Air Act (CAA) serves as the primary regulatory mechanism for controlling air pollutants associated with butane refining. Under the CAA, the EPA has established National Ambient Air Quality Standards (NAAQS) for criteria pollutants, including volatile organic compounds (VOCs) of which butane is a significant contributor. Refineries must adhere to these standards and implement control technologies to minimize butane emissions.

The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically target petroleum refineries, mandating stringent emission controls for various processes involving butane. These regulations require refineries to implement leak detection and repair (LDAR) programs, install vapor recovery systems, and utilize best available control technologies (BACT) to mitigate butane releases.

Furthermore, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste generated during refining processes, including those involving butane. Refineries must comply with strict guidelines for the storage, handling, and disposal of butane-containing waste streams to prevent environmental contamination.

At the state level, regulatory bodies often impose additional requirements that may exceed federal standards. For instance, California's Air Resources Board (CARB) has implemented more stringent regulations on refinery emissions, including those related to butane, as part of its efforts to improve air quality in the state.

Internationally, the regulatory landscape varies significantly. The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation imposes strict controls on the use and handling of butane in industrial processes, including refining. Many other countries have adopted similar regulatory frameworks, often modeled after U.S. or EU standards, to address the environmental implications of butane in refining operations.

Compliance with these regulations requires refineries to invest in advanced monitoring systems, emission control technologies, and comprehensive environmental management programs. The regulatory framework continues to evolve, with increasing emphasis on reducing greenhouse gas emissions and promoting cleaner production processes in the refining industry.

The Clean Air Act (CAA) serves as the primary regulatory mechanism for controlling air pollutants associated with butane refining. Under the CAA, the EPA has established National Ambient Air Quality Standards (NAAQS) for criteria pollutants, including volatile organic compounds (VOCs) of which butane is a significant contributor. Refineries must adhere to these standards and implement control technologies to minimize butane emissions.

The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically target petroleum refineries, mandating stringent emission controls for various processes involving butane. These regulations require refineries to implement leak detection and repair (LDAR) programs, install vapor recovery systems, and utilize best available control technologies (BACT) to mitigate butane releases.

Furthermore, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste generated during refining processes, including those involving butane. Refineries must comply with strict guidelines for the storage, handling, and disposal of butane-containing waste streams to prevent environmental contamination.

At the state level, regulatory bodies often impose additional requirements that may exceed federal standards. For instance, California's Air Resources Board (CARB) has implemented more stringent regulations on refinery emissions, including those related to butane, as part of its efforts to improve air quality in the state.

Internationally, the regulatory landscape varies significantly. The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation imposes strict controls on the use and handling of butane in industrial processes, including refining. Many other countries have adopted similar regulatory frameworks, often modeled after U.S. or EU standards, to address the environmental implications of butane in refining operations.

Compliance with these regulations requires refineries to invest in advanced monitoring systems, emission control technologies, and comprehensive environmental management programs. The regulatory framework continues to evolve, with increasing emphasis on reducing greenhouse gas emissions and promoting cleaner production processes in the refining industry.

Sustainability Strategies

Sustainability strategies in the context of butane usage in large-scale refining operations are crucial for mitigating environmental impacts and ensuring long-term viability. These strategies focus on reducing emissions, improving energy efficiency, and minimizing waste throughout the refining process.

One key approach is the implementation of advanced process control systems. These systems optimize butane utilization, reducing unnecessary consumption and associated emissions. By fine-tuning operational parameters, refineries can achieve significant reductions in energy usage and greenhouse gas emissions without compromising product quality or output.

Carbon capture and storage (CCS) technologies represent another important sustainability strategy. When applied to butane-related processes, CCS can significantly reduce carbon dioxide emissions. This technology captures CO2 emissions from refinery operations and stores them underground, preventing their release into the atmosphere.

Circular economy principles are increasingly being adopted in refining operations. This involves recovering and reusing butane and other hydrocarbons that would otherwise be lost or flared. By implementing efficient recovery systems, refineries can reduce both waste and the need for fresh butane inputs, thereby lowering their environmental footprint.

Energy integration and heat recovery systems play a vital role in sustainability efforts. By capturing and reusing waste heat from butane-related processes, refineries can substantially reduce their overall energy consumption. This not only decreases operational costs but also significantly lowers carbon emissions associated with energy production.

Water management strategies are also critical, particularly in water-stressed regions. Advanced water treatment and recycling systems can minimize freshwater consumption in butane-related refining processes. This reduces the environmental impact on local water resources and enhances the refinery's resilience to water scarcity.

Leak detection and repair (LDAR) programs are essential for preventing fugitive emissions of butane and other volatile organic compounds. Regular monitoring and maintenance of equipment can significantly reduce unintended releases, improving air quality and worker safety while conserving valuable resources.

Investing in renewable energy sources for powering refinery operations is another key sustainability strategy. By integrating solar, wind, or other clean energy technologies, refineries can reduce their reliance on fossil fuels for energy needs, further decreasing their carbon footprint.

Research and development efforts focused on catalysts and process innovations are ongoing. These aim to enhance the efficiency of butane-related processes, potentially leading to breakthroughs that could dramatically reduce environmental impacts while maintaining or improving product quality.

One key approach is the implementation of advanced process control systems. These systems optimize butane utilization, reducing unnecessary consumption and associated emissions. By fine-tuning operational parameters, refineries can achieve significant reductions in energy usage and greenhouse gas emissions without compromising product quality or output.

Carbon capture and storage (CCS) technologies represent another important sustainability strategy. When applied to butane-related processes, CCS can significantly reduce carbon dioxide emissions. This technology captures CO2 emissions from refinery operations and stores them underground, preventing their release into the atmosphere.

Circular economy principles are increasingly being adopted in refining operations. This involves recovering and reusing butane and other hydrocarbons that would otherwise be lost or flared. By implementing efficient recovery systems, refineries can reduce both waste and the need for fresh butane inputs, thereby lowering their environmental footprint.

Energy integration and heat recovery systems play a vital role in sustainability efforts. By capturing and reusing waste heat from butane-related processes, refineries can substantially reduce their overall energy consumption. This not only decreases operational costs but also significantly lowers carbon emissions associated with energy production.

Water management strategies are also critical, particularly in water-stressed regions. Advanced water treatment and recycling systems can minimize freshwater consumption in butane-related refining processes. This reduces the environmental impact on local water resources and enhances the refinery's resilience to water scarcity.

Leak detection and repair (LDAR) programs are essential for preventing fugitive emissions of butane and other volatile organic compounds. Regular monitoring and maintenance of equipment can significantly reduce unintended releases, improving air quality and worker safety while conserving valuable resources.

Investing in renewable energy sources for powering refinery operations is another key sustainability strategy. By integrating solar, wind, or other clean energy technologies, refineries can reduce their reliance on fossil fuels for energy needs, further decreasing their carbon footprint.

Research and development efforts focused on catalysts and process innovations are ongoing. These aim to enhance the efficiency of butane-related processes, potentially leading to breakthroughs that could dramatically reduce environmental impacts while maintaining or improving product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!