ESD Moisture and Thermal Management in MicroLED Reliability Studies

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED Reliability Background and Objectives

MicroLED technology has emerged as a promising next-generation display technology over the past decade, offering advantages such as high brightness, excellent color gamut, perfect black levels, and potential for ultra-high resolution displays. The evolution of this technology can be traced back to the early 2000s when the first micro-scale LED devices were demonstrated in research laboratories. Since then, significant advancements have been made in manufacturing processes, materials science, and integration techniques.

The reliability of MicroLED displays represents a critical challenge that must be addressed before widespread commercial adoption can occur. Unlike traditional LED or OLED technologies, MicroLED involves extremely small LED chips (typically less than 50 micrometers) that are transferred and integrated onto display backplanes. This miniaturization introduces unique reliability concerns, particularly regarding electrostatic discharge (ESD), moisture ingress, and thermal management.

ESD events can cause catastrophic failure in MicroLED devices due to their small size and delicate structure. Even minor electrostatic discharges that would be inconsequential for larger components can permanently damage MicroLED pixels, resulting in dead spots on displays. This vulnerability necessitates robust protection mechanisms throughout the manufacturing, assembly, and operational lifecycle of MicroLED products.

Moisture represents another significant threat to MicroLED reliability. Water molecules can penetrate encapsulation layers and cause degradation of both the LED materials and the electrical connections. This degradation manifests as decreased luminous efficiency, color shift, and eventually complete pixel failure. The industry has been working toward developing advanced encapsulation technologies and moisture barriers to mitigate these effects.

Thermal management presents perhaps the most complex challenge for MicroLED technology. Despite their high efficiency compared to other display technologies, MicroLEDs still generate significant heat during operation, especially when driven at high brightness levels. This heat must be effectively dissipated to prevent thermal runaway conditions that accelerate device degradation and reduce operational lifetime.

The primary technical objective in MicroLED reliability studies is to develop comprehensive understanding and solutions for these three interrelated challenges. Researchers aim to establish standardized testing protocols that can accurately predict device lifetime under various environmental conditions and usage scenarios. Additionally, there is a push toward developing novel materials and structural designs that inherently improve resistance to ESD, moisture, and thermal stress.

Industry projections suggest that solving these reliability challenges could enable MicroLED displays to achieve operational lifetimes exceeding 100,000 hours while maintaining consistent performance parameters. This would position the technology as a viable option for applications ranging from consumer electronics to automotive displays and large-format digital signage.

The reliability of MicroLED displays represents a critical challenge that must be addressed before widespread commercial adoption can occur. Unlike traditional LED or OLED technologies, MicroLED involves extremely small LED chips (typically less than 50 micrometers) that are transferred and integrated onto display backplanes. This miniaturization introduces unique reliability concerns, particularly regarding electrostatic discharge (ESD), moisture ingress, and thermal management.

ESD events can cause catastrophic failure in MicroLED devices due to their small size and delicate structure. Even minor electrostatic discharges that would be inconsequential for larger components can permanently damage MicroLED pixels, resulting in dead spots on displays. This vulnerability necessitates robust protection mechanisms throughout the manufacturing, assembly, and operational lifecycle of MicroLED products.

Moisture represents another significant threat to MicroLED reliability. Water molecules can penetrate encapsulation layers and cause degradation of both the LED materials and the electrical connections. This degradation manifests as decreased luminous efficiency, color shift, and eventually complete pixel failure. The industry has been working toward developing advanced encapsulation technologies and moisture barriers to mitigate these effects.

Thermal management presents perhaps the most complex challenge for MicroLED technology. Despite their high efficiency compared to other display technologies, MicroLEDs still generate significant heat during operation, especially when driven at high brightness levels. This heat must be effectively dissipated to prevent thermal runaway conditions that accelerate device degradation and reduce operational lifetime.

The primary technical objective in MicroLED reliability studies is to develop comprehensive understanding and solutions for these three interrelated challenges. Researchers aim to establish standardized testing protocols that can accurately predict device lifetime under various environmental conditions and usage scenarios. Additionally, there is a push toward developing novel materials and structural designs that inherently improve resistance to ESD, moisture, and thermal stress.

Industry projections suggest that solving these reliability challenges could enable MicroLED displays to achieve operational lifetimes exceeding 100,000 hours while maintaining consistent performance parameters. This would position the technology as a viable option for applications ranging from consumer electronics to automotive displays and large-format digital signage.

Market Analysis for MicroLED Display Technologies

The MicroLED display market is experiencing significant growth, driven by the technology's superior performance characteristics compared to traditional display technologies. Current market projections indicate that the global MicroLED market is expected to reach $19.4 billion by 2026, growing at a CAGR of 89.3% from 2021. This explosive growth is fueled by increasing demand for brighter, more energy-efficient displays with higher resolution and contrast ratios.

Consumer electronics represents the largest application segment for MicroLED technology, with smartphones, smartwatches, and AR/VR headsets leading adoption. Apple's acquisition of LuxVue and subsequent patents signal strong interest from major industry players. The automotive sector is emerging as another significant market, with premium vehicle manufacturers integrating MicroLED displays for instrument clusters and infotainment systems due to their durability and performance in varying lighting conditions.

Regionally, Asia-Pacific dominates MicroLED manufacturing, with South Korea, Taiwan, and China housing major production facilities. North America leads in research and development, while Europe shows growing adoption in automotive and luxury consumer electronics segments. The market structure remains highly concentrated, with Samsung, Sony, Apple, and LG making substantial investments in MicroLED technology development.

Reliability concerns, particularly related to ESD (Electrostatic Discharge), moisture sensitivity, and thermal management, represent significant market barriers. These factors directly impact product longevity and performance stability, affecting consumer confidence and adoption rates. Market research indicates that addressing these reliability issues could accelerate market penetration by 15-20% in consumer electronics segments.

Price sensitivity remains a critical market factor, with current MicroLED displays commanding premium pricing. Production costs are approximately 3-5 times higher than comparable OLED displays, primarily due to complex manufacturing processes and lower yields. Industry analysts predict that economies of scale and manufacturing innovations could reduce this cost differential to 1.5-2 times by 2025, significantly expanding market opportunities.

The competitive landscape is evolving rapidly, with traditional display manufacturers competing against specialized MicroLED startups. Companies focusing on solving reliability challenges, particularly in ESD protection and thermal management, are gaining competitive advantages and securing strategic partnerships with device manufacturers. Market consolidation through acquisitions and licensing agreements is expected to accelerate as the technology matures.

Consumer electronics represents the largest application segment for MicroLED technology, with smartphones, smartwatches, and AR/VR headsets leading adoption. Apple's acquisition of LuxVue and subsequent patents signal strong interest from major industry players. The automotive sector is emerging as another significant market, with premium vehicle manufacturers integrating MicroLED displays for instrument clusters and infotainment systems due to their durability and performance in varying lighting conditions.

Regionally, Asia-Pacific dominates MicroLED manufacturing, with South Korea, Taiwan, and China housing major production facilities. North America leads in research and development, while Europe shows growing adoption in automotive and luxury consumer electronics segments. The market structure remains highly concentrated, with Samsung, Sony, Apple, and LG making substantial investments in MicroLED technology development.

Reliability concerns, particularly related to ESD (Electrostatic Discharge), moisture sensitivity, and thermal management, represent significant market barriers. These factors directly impact product longevity and performance stability, affecting consumer confidence and adoption rates. Market research indicates that addressing these reliability issues could accelerate market penetration by 15-20% in consumer electronics segments.

Price sensitivity remains a critical market factor, with current MicroLED displays commanding premium pricing. Production costs are approximately 3-5 times higher than comparable OLED displays, primarily due to complex manufacturing processes and lower yields. Industry analysts predict that economies of scale and manufacturing innovations could reduce this cost differential to 1.5-2 times by 2025, significantly expanding market opportunities.

The competitive landscape is evolving rapidly, with traditional display manufacturers competing against specialized MicroLED startups. Companies focusing on solving reliability challenges, particularly in ESD protection and thermal management, are gaining competitive advantages and securing strategic partnerships with device manufacturers. Market consolidation through acquisitions and licensing agreements is expected to accelerate as the technology matures.

ESD, Moisture and Thermal Challenges in MicroLED

MicroLED technology faces significant reliability challenges related to electrostatic discharge (ESD), moisture ingress, and thermal management. These three factors represent critical barriers to widespread commercialization and long-term stability of MicroLED displays and lighting solutions.

ESD vulnerability in MicroLED devices stems from their microscopic dimensions and semiconductor composition. With individual LED sizes ranging from 3-10 μm, these structures are highly susceptible to damage from even minor electrostatic events. Testing has shown that voltage discharges as low as 100V can cause catastrophic failure in unprotected MicroLED arrays, significantly lower than conventional LED tolerance thresholds of 2000-3000V. This vulnerability necessitates specialized handling protocols throughout manufacturing and integration processes.

Moisture presents another substantial challenge for MicroLED reliability. The gallium nitride (GaN) semiconductor material commonly used in MicroLEDs can undergo accelerated degradation when exposed to moisture, particularly at junction points and metal contacts. Humidity penetration can lead to oxidation of metal interconnects, delamination of protective layers, and ultimately result in decreased luminous efficiency or complete pixel failure. Industry data indicates that unprotected MicroLED structures exposed to 85% relative humidity at 85°C can show significant performance degradation within 1000 hours.

Thermal management represents perhaps the most complex reliability challenge. Despite their improved efficiency compared to conventional LEDs, MicroLEDs still convert approximately 40-60% of input energy to heat. The ultra-high density of MicroLED arrays (often exceeding 10^6 pixels per square inch) creates concentrated heat zones that can lead to thermal runaway if not properly managed. Temperature increases of just 10°C above optimal operating conditions can reduce device lifespan by 30-50%.

The interconnected nature of these challenges compounds their effects. Thermal cycling can create microfractures that accelerate moisture ingress, while moisture can compromise ESD protection structures. This creates a complex reliability matrix that must be addressed holistically rather than as isolated issues.

Current industry approaches include advanced encapsulation techniques using atomic layer deposition (ALD), integrated temperature sensors and thermal spreading layers, and sophisticated ESD protection circuits. However, these solutions often add complexity, cost, and manufacturing challenges that limit MicroLED market penetration.

The reliability triad of ESD, moisture, and thermal management represents a critical frontier in MicroLED development, requiring interdisciplinary solutions spanning materials science, electrical engineering, and thermal physics to enable the technology's full potential.

ESD vulnerability in MicroLED devices stems from their microscopic dimensions and semiconductor composition. With individual LED sizes ranging from 3-10 μm, these structures are highly susceptible to damage from even minor electrostatic events. Testing has shown that voltage discharges as low as 100V can cause catastrophic failure in unprotected MicroLED arrays, significantly lower than conventional LED tolerance thresholds of 2000-3000V. This vulnerability necessitates specialized handling protocols throughout manufacturing and integration processes.

Moisture presents another substantial challenge for MicroLED reliability. The gallium nitride (GaN) semiconductor material commonly used in MicroLEDs can undergo accelerated degradation when exposed to moisture, particularly at junction points and metal contacts. Humidity penetration can lead to oxidation of metal interconnects, delamination of protective layers, and ultimately result in decreased luminous efficiency or complete pixel failure. Industry data indicates that unprotected MicroLED structures exposed to 85% relative humidity at 85°C can show significant performance degradation within 1000 hours.

Thermal management represents perhaps the most complex reliability challenge. Despite their improved efficiency compared to conventional LEDs, MicroLEDs still convert approximately 40-60% of input energy to heat. The ultra-high density of MicroLED arrays (often exceeding 10^6 pixels per square inch) creates concentrated heat zones that can lead to thermal runaway if not properly managed. Temperature increases of just 10°C above optimal operating conditions can reduce device lifespan by 30-50%.

The interconnected nature of these challenges compounds their effects. Thermal cycling can create microfractures that accelerate moisture ingress, while moisture can compromise ESD protection structures. This creates a complex reliability matrix that must be addressed holistically rather than as isolated issues.

Current industry approaches include advanced encapsulation techniques using atomic layer deposition (ALD), integrated temperature sensors and thermal spreading layers, and sophisticated ESD protection circuits. However, these solutions often add complexity, cost, and manufacturing challenges that limit MicroLED market penetration.

The reliability triad of ESD, moisture, and thermal management represents a critical frontier in MicroLED development, requiring interdisciplinary solutions spanning materials science, electrical engineering, and thermal physics to enable the technology's full potential.

Current ESD and Thermal Management Solutions

01 Thermal management solutions for MicroLED reliability

Effective thermal management is crucial for ensuring the reliability of MicroLED displays. Heat dissipation techniques and thermal interface materials help prevent performance degradation and extend device lifespan. Solutions include specialized heat sinks, thermal conductive materials, and optimized device architectures that efficiently transfer heat away from the LED junctions. These approaches maintain stable operating temperatures, reducing thermal stress that can lead to premature failure and color shift in MicroLED displays.- Thermal management solutions for MicroLED reliability: Effective thermal management is crucial for ensuring the reliability of MicroLED displays. Heat dissipation techniques and materials help prevent thermal degradation of MicroLED components, extending their operational lifetime. Solutions include specialized heat sinks, thermal interface materials, and cooling structures integrated into the display architecture. These thermal management approaches help maintain consistent performance and prevent premature failure of MicroLED devices under various operating conditions.

- Encapsulation and protection technologies: Advanced encapsulation methods protect MicroLED devices from environmental factors that can compromise reliability. These technologies include moisture-resistant barriers, hermetic sealing techniques, and protective coatings that shield sensitive components from oxygen, humidity, and contaminants. Proper encapsulation prevents oxidation of materials, electrical shorts, and mechanical damage, significantly improving the long-term stability and reliability of MicroLED displays in various applications and environments.

- Defect detection and repair mechanisms: Sophisticated defect detection and repair systems are essential for maintaining MicroLED reliability. These include automated optical inspection technologies, electrical testing methods, and self-healing mechanisms that can identify and address potential failure points. By implementing comprehensive quality control during manufacturing and incorporating repair capabilities, manufacturers can significantly reduce defect rates and improve the overall reliability and yield of MicroLED displays.

- Stress-resistant structural designs: Innovative structural designs enhance the mechanical reliability of MicroLED displays. These include flexible substrates, stress-relief features, and reinforced bonding techniques that help MicroLED components withstand physical stresses during operation. By incorporating these design elements, manufacturers can create displays that maintain performance integrity despite mechanical vibration, thermal cycling, and other physical stresses, resulting in more durable and reliable MicroLED products.

- Driving circuit optimization for longevity: Optimized driving circuits play a critical role in extending MicroLED lifespan and reliability. Advanced current control mechanisms, voltage regulation systems, and intelligent power management prevent electrical overstress and ensure uniform current distribution across all pixels. These circuit designs minimize performance degradation over time by protecting MicroLED elements from electrical damage while maintaining consistent brightness and color accuracy throughout the display's operational life.

02 Encapsulation and protection technologies

Advanced encapsulation technologies protect MicroLED devices from environmental factors that affect reliability. Hermetic sealing methods, moisture-resistant barriers, and specialized packaging materials shield sensitive components from oxygen, moisture, and contaminants. These protection systems prevent oxidation of metal contacts and degradation of organic materials within the device structure, significantly improving long-term stability and operational lifetime of MicroLED displays under various environmental conditions.Expand Specific Solutions03 Defect detection and repair mechanisms

Sophisticated defect detection and repair systems are implemented to enhance MicroLED reliability. These include automated optical inspection techniques, electrical testing methodologies, and redundancy architectures that identify and address potential failure points. Self-healing circuits and bypass mechanisms allow displays to maintain functionality even when individual pixels fail. These approaches significantly improve yield rates during manufacturing and ensure consistent performance throughout the device lifetime.Expand Specific Solutions04 Material innovations for enhanced durability

Novel materials are being developed to improve the inherent reliability of MicroLED components. These include advanced semiconductor compounds with higher stability, improved electrode materials resistant to electromigration, and specialized phosphors with enhanced thermal and photo stability. Quantum dot materials and nanostructured surfaces optimize light extraction while maintaining long-term performance. These material innovations address fundamental degradation mechanisms and extend the operational lifetime of MicroLED displays.Expand Specific Solutions05 Driving circuit and power management optimization

Optimized driving circuits and power management systems significantly impact MicroLED reliability. Constant current drivers, pulse width modulation techniques, and intelligent power distribution systems prevent current crowding and electrical overstress. Advanced compensation algorithms adjust for pixel aging and maintain uniform brightness over time. These electrical engineering approaches minimize junction temperature fluctuations and electrical stress, which are primary factors affecting the long-term reliability of MicroLED displays.Expand Specific Solutions

Key Industry Players in MicroLED Development

The MicroLED reliability market is in an early growth phase, characterized by increasing investments but still evolving technical standards. The global market is projected to expand significantly as MicroLED technology advances toward commercial viability, driven by applications in AR/VR, automotive displays, and consumer electronics. Key players like Samsung Electronics and 3M are leading innovation in ESD protection and thermal management solutions, while companies such as Jade Bird Display and Innolux are developing specialized MicroLED display technologies. Emerging players including Applied Materials and Lumileds Singapore are advancing manufacturing processes to address moisture sensitivity and thermal challenges. The technology remains in mid-maturity, with significant R&D efforts focused on improving reliability, yield rates, and cost-effectiveness before widespread adoption.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed comprehensive MicroLED reliability solutions focusing on multi-layered ESD protection schemes specifically designed for MicroLED displays. Their approach includes specialized thin-film encapsulation (TFE) technology that creates hermetic sealing against moisture ingress while maintaining optical transparency. For thermal management, Samsung employs advanced heat dissipation structures with micro-channel cooling integrated directly into the display substrate, allowing for efficient heat transfer away from individual LED pixels. Their proprietary "pixel isolation technology" creates thermal barriers between adjacent pixels to prevent thermal crosstalk while maintaining display uniformity. Samsung has also implemented automated in-line ESD monitoring during manufacturing processes, with specialized test protocols that can detect potential reliability issues before final assembly[1][3]. Recent developments include implementation of graphene-based heat spreaders that improve thermal conductivity by up to 40% compared to conventional materials.

Strengths: Industry-leading encapsulation technology provides superior moisture protection while maintaining optical performance; integrated thermal management solutions address heat at both pixel and system levels. Weaknesses: Complex multi-layer protection schemes increase manufacturing costs and production complexity; some thermal management solutions require additional space that may impact overall device thickness.

Jade Bird Display (Shanghai) Ltd.

Technical Solution: Jade Bird Display has pioneered monolithic MicroLED solutions with built-in ESD protection circuits directly integrated into the display backplane. Their approach focuses on a proprietary "distributed ESD network" that provides localized protection for pixel clusters rather than relying solely on perimeter protection. For moisture management, they've developed a multi-layer polymer encapsulation system specifically optimized for high-density MicroLED arrays, which maintains flexibility while providing effective moisture barrier properties. Their thermal management strategy employs a micro-structured heat dissipation layer with directional heat channeling that guides thermal energy away from sensitive components. This system incorporates thermally conductive particles suspended in a polymer matrix, creating pathways for heat dissipation while maintaining electrical isolation between components[2]. Jade Bird has also implemented automated reliability testing systems that simultaneously stress devices with thermal cycling, humidity exposure, and ESD events to identify potential failure modes under combined stressors.

Strengths: Highly integrated protection approach reduces component count and simplifies manufacturing; specialized testing protocols provide comprehensive reliability data under real-world conditions. Weaknesses: Distributed protection circuits consume valuable pixel area, potentially reducing maximum achievable resolution; polymer-based moisture barriers may have limited lifetime compared to inorganic alternatives.

Critical Patents in MicroLED Protection Technologies

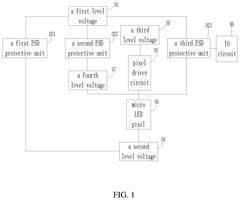

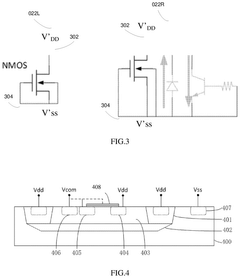

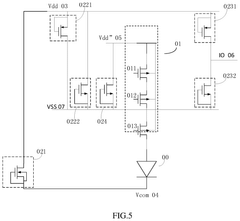

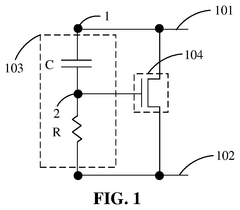

Electrostatic discharge protection system of micro device

PatentInactiveUS20250194262A1

Innovation

- An ESD protection system for micro devices, specifically designed for micro LED panels, comprising a pixel driver circuit and a first ESD protective unit connected to different voltage levels, effectively clamping ESD current energy to the ground bus and protecting the micro LED pixels.

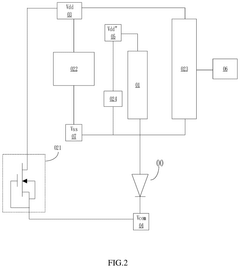

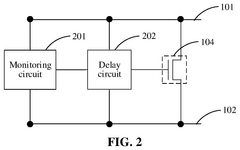

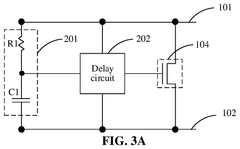

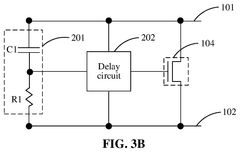

Electrostatic protection circuit

PatentActiveUS12132308B2

Innovation

- An electrostatic protection circuit is introduced, comprising a monitoring circuit to generate a trigger signal for a discharge transistor connected between a power supply pad and a ground pad, along with a delay circuit that adjusts the discharge time and turns off the transistor in a normal state to maintain voltage, reducing turn-on voltage and prolonging discharge time.

Material Science Advancements for MicroLED Protection

Recent advancements in material science have significantly contributed to enhancing MicroLED protection against environmental and operational stressors. Novel encapsulation materials with superior barrier properties have emerged, offering unprecedented protection against moisture ingress. These materials, including advanced atomic layer deposition (ALD) films and hybrid organic-inorganic composites, demonstrate water vapor transmission rates below 10^-6 g/m²/day, representing a hundredfold improvement over previous generation materials.

Thermal management materials have similarly evolved, with the development of specialized thermal interface materials (TIMs) that maintain performance integrity under the high-density heat loads characteristic of MicroLED displays. Diamond-based composites and graphene-enhanced polymers have shown thermal conductivity values exceeding 2000 W/m·K, enabling more efficient heat dissipation while maintaining dimensional stability under thermal cycling.

Electrostatic discharge protection has benefited from the integration of nano-engineered materials that can rapidly dissipate charge without compromising optical performance. These materials incorporate conductive nanoparticles within transparent matrices, achieving surface resistivity values between 10^6 and 10^9 ohms/square—optimal for ESD protection while maintaining over 95% optical transparency across the visible spectrum.

Self-healing polymers represent another breakthrough, with materials capable of autonomously repairing microcracks induced by thermal or mechanical stress. These polymers incorporate dynamic covalent bonds that reform after rupture, extending device lifetime by up to 40% in accelerated aging tests compared to conventional encapsulants.

Anti-corrosion coatings specifically engineered for MicroLED materials have demonstrated exceptional chemical stability against ionic contaminants. These coatings form conformal layers as thin as 5-10 nm while providing effective barriers against chloride, sulfate, and other corrosive species commonly encountered in consumer electronics environments.

Multifunctional materials that simultaneously address multiple protection requirements have emerged as particularly promising. These include nanocomposites that combine moisture barrier properties with thermal conductivity and ESD protection in single-layer solutions, simplifying manufacturing processes while enhancing overall reliability.

The integration of these advanced materials into MicroLED fabrication processes presents challenges in terms of compatibility with existing manufacturing equipment and techniques. However, recent developments in low-temperature deposition methods and selective area protection strategies have shown promising results in maintaining the integrity of temperature-sensitive MicroLED components while applying these protective materials.

Thermal management materials have similarly evolved, with the development of specialized thermal interface materials (TIMs) that maintain performance integrity under the high-density heat loads characteristic of MicroLED displays. Diamond-based composites and graphene-enhanced polymers have shown thermal conductivity values exceeding 2000 W/m·K, enabling more efficient heat dissipation while maintaining dimensional stability under thermal cycling.

Electrostatic discharge protection has benefited from the integration of nano-engineered materials that can rapidly dissipate charge without compromising optical performance. These materials incorporate conductive nanoparticles within transparent matrices, achieving surface resistivity values between 10^6 and 10^9 ohms/square—optimal for ESD protection while maintaining over 95% optical transparency across the visible spectrum.

Self-healing polymers represent another breakthrough, with materials capable of autonomously repairing microcracks induced by thermal or mechanical stress. These polymers incorporate dynamic covalent bonds that reform after rupture, extending device lifetime by up to 40% in accelerated aging tests compared to conventional encapsulants.

Anti-corrosion coatings specifically engineered for MicroLED materials have demonstrated exceptional chemical stability against ionic contaminants. These coatings form conformal layers as thin as 5-10 nm while providing effective barriers against chloride, sulfate, and other corrosive species commonly encountered in consumer electronics environments.

Multifunctional materials that simultaneously address multiple protection requirements have emerged as particularly promising. These include nanocomposites that combine moisture barrier properties with thermal conductivity and ESD protection in single-layer solutions, simplifying manufacturing processes while enhancing overall reliability.

The integration of these advanced materials into MicroLED fabrication processes presents challenges in terms of compatibility with existing manufacturing equipment and techniques. However, recent developments in low-temperature deposition methods and selective area protection strategies have shown promising results in maintaining the integrity of temperature-sensitive MicroLED components while applying these protective materials.

Testing Standards and Certification Requirements

The reliability testing of MicroLED devices requires adherence to rigorous standards and certification requirements, particularly for ESD, moisture, and thermal management aspects. Industry standards such as JEDEC JESD22-A114 and IEC 61000-4-2 provide comprehensive frameworks for ESD testing, with the former focusing on human body model (HBM) testing and the latter on equipment-level ESD immunity. These standards specify test methodologies, voltage levels, and pass/fail criteria essential for ensuring MicroLED devices can withstand electrostatic discharge events in real-world applications.

For moisture sensitivity assessment, the JEDEC J-STD-020 standard classifies electronic components into moisture sensitivity levels (MSLs) from 1 to 6, with MicroLED devices typically requiring classification at MSL 3 or higher due to their sensitivity to humidity. This standard mandates specific preconditioning procedures, including bake-out, moisture soak, and reflow simulation, followed by comprehensive electrical and optical performance verification.

Thermal reliability testing follows standards such as MIL-STD-883 Method 1010 for temperature cycling and JEDEC JESD22-A104 for thermal shock. These tests subject MicroLED devices to extreme temperature variations (typically -40°C to +125°C) to evaluate their resistance to thermally induced mechanical stresses. The number of cycles, dwell times, and transition rates are precisely defined to ensure reproducible results across different testing facilities.

The International Electrotechnical Commission (IEC) provides additional relevant standards, including IEC 60068-2-78 for steady-state humidity testing and IEC 60068-2-30 for cyclic humidity testing. These standards are particularly important for consumer electronics applications where MicroLED displays may be exposed to varying environmental conditions.

Certification requirements vary by region and application domain. In North America, UL certification often requires compliance with UL 8750 for LED equipment safety. European markets demand CE marking, which necessitates conformity with multiple directives including the RoHS Directive 2011/65/EU and the Electromagnetic Compatibility Directive 2014/30/EU. For automotive applications, the AEC-Q102 qualification specifically developed for optoelectronic components imposes additional reliability requirements.

Testing documentation must include detailed reports on test conditions, sample sizes, failure criteria, and statistical analysis of results. Many certification bodies require testing to be conducted by accredited third-party laboratories to ensure impartiality and adherence to standardized procedures. The emergence of MicroLED technology has prompted standards organizations to develop new test methodologies specifically addressing the unique failure mechanisms of these devices, including pixel-level ESD sensitivity and thermal management at microscale dimensions.

For moisture sensitivity assessment, the JEDEC J-STD-020 standard classifies electronic components into moisture sensitivity levels (MSLs) from 1 to 6, with MicroLED devices typically requiring classification at MSL 3 or higher due to their sensitivity to humidity. This standard mandates specific preconditioning procedures, including bake-out, moisture soak, and reflow simulation, followed by comprehensive electrical and optical performance verification.

Thermal reliability testing follows standards such as MIL-STD-883 Method 1010 for temperature cycling and JEDEC JESD22-A104 for thermal shock. These tests subject MicroLED devices to extreme temperature variations (typically -40°C to +125°C) to evaluate their resistance to thermally induced mechanical stresses. The number of cycles, dwell times, and transition rates are precisely defined to ensure reproducible results across different testing facilities.

The International Electrotechnical Commission (IEC) provides additional relevant standards, including IEC 60068-2-78 for steady-state humidity testing and IEC 60068-2-30 for cyclic humidity testing. These standards are particularly important for consumer electronics applications where MicroLED displays may be exposed to varying environmental conditions.

Certification requirements vary by region and application domain. In North America, UL certification often requires compliance with UL 8750 for LED equipment safety. European markets demand CE marking, which necessitates conformity with multiple directives including the RoHS Directive 2011/65/EU and the Electromagnetic Compatibility Directive 2014/30/EU. For automotive applications, the AEC-Q102 qualification specifically developed for optoelectronic components imposes additional reliability requirements.

Testing documentation must include detailed reports on test conditions, sample sizes, failure criteria, and statistical analysis of results. Many certification bodies require testing to be conducted by accredited third-party laboratories to ensure impartiality and adherence to standardized procedures. The emergence of MicroLED technology has prompted standards organizations to develop new test methodologies specifically addressing the unique failure mechanisms of these devices, including pixel-level ESD sensitivity and thermal management at microscale dimensions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!