Laser Induced Forward Transfer Mechanisms for MicroLED Mass Transfer

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED LIFT Technology Background and Objectives

Laser Induced Forward Transfer (LIFT) technology has emerged as a promising solution for the mass transfer of MicroLEDs, addressing critical challenges in next-generation display manufacturing. The evolution of this technology can be traced back to the early 2000s when researchers began exploring laser-based transfer methods for delicate electronic components. Over the past decade, LIFT has gained significant momentum as display technologies have shifted toward higher resolution, energy efficiency, and form factor flexibility.

The fundamental principle of LIFT involves using precisely controlled laser pulses to transfer microscopic LED elements from a donor substrate to a receiver substrate. This non-contact transfer method offers advantages over traditional pick-and-place techniques, particularly when handling the increasingly miniaturized MicroLEDs required for high-resolution displays.

Technical evolution in this field has followed several distinct phases: initial proof-of-concept demonstrations, optimization of laser parameters for different material systems, development of specialized donor structures, and most recently, scaling efforts for industrial implementation. Each phase has contributed to overcoming specific challenges related to transfer precision, yield rates, and throughput capacity.

Current technical trends in MicroLED LIFT technology focus on several key areas: multi-beam parallel processing to increase throughput, wavelength optimization to enhance transfer efficiency, pulse shaping techniques to minimize damage to sensitive components, and integration with automated inspection systems for real-time quality control.

The primary technical objectives for MicroLED LIFT technology development include achieving sub-micron placement accuracy, transfer yields exceeding 99.999% (essential for large displays with millions of pixels), process speeds compatible with mass production requirements, and compatibility with various MicroLED sizes and material compositions.

Additionally, researchers aim to develop comprehensive models of the transfer mechanisms, including thermal, mechanical, and photochemical processes that occur during the laser-material interaction. Understanding these fundamental mechanisms is crucial for optimizing process parameters and predicting outcomes across different material systems and device architectures.

Looking forward, the technology roadmap for MicroLED LIFT includes integration with complementary technologies such as in-situ testing and repair strategies, development of specialized donor substrates with release layers optimized for specific device types, and adaptation for flexible and conformable display manufacturing processes.

The fundamental principle of LIFT involves using precisely controlled laser pulses to transfer microscopic LED elements from a donor substrate to a receiver substrate. This non-contact transfer method offers advantages over traditional pick-and-place techniques, particularly when handling the increasingly miniaturized MicroLEDs required for high-resolution displays.

Technical evolution in this field has followed several distinct phases: initial proof-of-concept demonstrations, optimization of laser parameters for different material systems, development of specialized donor structures, and most recently, scaling efforts for industrial implementation. Each phase has contributed to overcoming specific challenges related to transfer precision, yield rates, and throughput capacity.

Current technical trends in MicroLED LIFT technology focus on several key areas: multi-beam parallel processing to increase throughput, wavelength optimization to enhance transfer efficiency, pulse shaping techniques to minimize damage to sensitive components, and integration with automated inspection systems for real-time quality control.

The primary technical objectives for MicroLED LIFT technology development include achieving sub-micron placement accuracy, transfer yields exceeding 99.999% (essential for large displays with millions of pixels), process speeds compatible with mass production requirements, and compatibility with various MicroLED sizes and material compositions.

Additionally, researchers aim to develop comprehensive models of the transfer mechanisms, including thermal, mechanical, and photochemical processes that occur during the laser-material interaction. Understanding these fundamental mechanisms is crucial for optimizing process parameters and predicting outcomes across different material systems and device architectures.

Looking forward, the technology roadmap for MicroLED LIFT includes integration with complementary technologies such as in-situ testing and repair strategies, development of specialized donor substrates with release layers optimized for specific device types, and adaptation for flexible and conformable display manufacturing processes.

Market Analysis for MicroLED Display Applications

The MicroLED display market is experiencing rapid growth, driven by increasing demand for high-performance displays across multiple sectors. Current market projections indicate that the global MicroLED display market will reach approximately $10.7 billion by 2025, with a compound annual growth rate (CAGR) of 89.3% from 2020 to 2025. This exceptional growth rate positions MicroLED technology as one of the fastest-growing segments within the display industry.

Consumer electronics represents the largest application segment, with smartphones, smartwatches, and AR/VR headsets driving significant demand. Apple's interest in MicroLED technology for future Apple Watch models has particularly catalyzed market attention. The automotive sector follows as the second-largest application area, where MicroLED displays offer superior brightness, contrast, and durability for dashboard displays and infotainment systems.

Premium television manufacturers are increasingly investing in MicroLED technology, with Samsung, LG, and Sony already showcasing commercial products. The large-format display market segment, including digital signage and cinema screens, is expected to grow at the highest CAGR due to MicroLED's seamless tiling capabilities and superior outdoor visibility.

Regionally, Asia-Pacific dominates the MicroLED market, accounting for approximately 65% of global production capacity, with South Korea, Taiwan, and China leading manufacturing efforts. North America follows with significant research activities and intellectual property development, while Europe contributes through specialized applications in automotive and industrial sectors.

Market adoption faces several challenges, with production costs being the most significant barrier. Current MicroLED displays cost 5-10 times more than comparable OLED displays, primarily due to inefficient mass transfer processes. The yield rates for Laser Induced Forward Transfer (LIFT) mechanisms currently range between 95-98%, but industry experts suggest that 99.9999% yield is necessary for cost-effective mass production.

Consumer awareness represents another challenge, with only 12% of surveyed consumers familiar with MicroLED technology and its advantages over OLED and LCD. Market education will be crucial for driving adoption beyond early technology enthusiasts.

The competitive landscape is evolving rapidly, with established display manufacturers competing against specialized MicroLED startups. Strategic partnerships between display manufacturers and mass transfer technology providers are becoming increasingly common, highlighting the critical role of efficient transfer mechanisms in market development.

Consumer electronics represents the largest application segment, with smartphones, smartwatches, and AR/VR headsets driving significant demand. Apple's interest in MicroLED technology for future Apple Watch models has particularly catalyzed market attention. The automotive sector follows as the second-largest application area, where MicroLED displays offer superior brightness, contrast, and durability for dashboard displays and infotainment systems.

Premium television manufacturers are increasingly investing in MicroLED technology, with Samsung, LG, and Sony already showcasing commercial products. The large-format display market segment, including digital signage and cinema screens, is expected to grow at the highest CAGR due to MicroLED's seamless tiling capabilities and superior outdoor visibility.

Regionally, Asia-Pacific dominates the MicroLED market, accounting for approximately 65% of global production capacity, with South Korea, Taiwan, and China leading manufacturing efforts. North America follows with significant research activities and intellectual property development, while Europe contributes through specialized applications in automotive and industrial sectors.

Market adoption faces several challenges, with production costs being the most significant barrier. Current MicroLED displays cost 5-10 times more than comparable OLED displays, primarily due to inefficient mass transfer processes. The yield rates for Laser Induced Forward Transfer (LIFT) mechanisms currently range between 95-98%, but industry experts suggest that 99.9999% yield is necessary for cost-effective mass production.

Consumer awareness represents another challenge, with only 12% of surveyed consumers familiar with MicroLED technology and its advantages over OLED and LCD. Market education will be crucial for driving adoption beyond early technology enthusiasts.

The competitive landscape is evolving rapidly, with established display manufacturers competing against specialized MicroLED startups. Strategic partnerships between display manufacturers and mass transfer technology providers are becoming increasingly common, highlighting the critical role of efficient transfer mechanisms in market development.

Current LIFT Mechanisms and Technical Challenges

Laser Induced Forward Transfer (LIFT) technology has emerged as a promising solution for microLED mass transfer, addressing the critical challenge of efficiently transferring microscale LED devices from donor substrates to receiver substrates. Currently, several LIFT mechanisms are being employed in the industry, each with distinct operational principles and technical considerations.

The dominant LIFT mechanism involves a dynamic release layer (DRL) that absorbs laser energy and converts it to thermal energy, creating localized vaporization. This rapid phase change generates a propulsive force that transfers the microLED pixel to the receiving substrate. The DRL typically consists of materials with high optical absorption coefficients at the laser wavelength, such as metals (titanium, aluminum) or polymers doped with absorbing compounds.

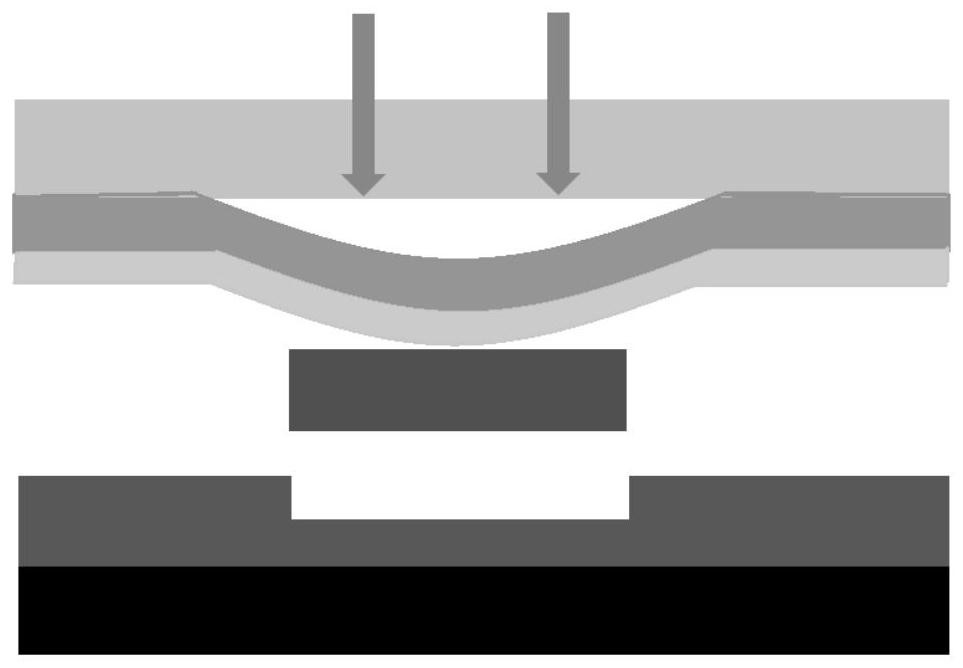

Another prevalent mechanism is the blister-actuated LIFT, which utilizes a transparent elastic layer between the donor substrate and the transfer material. When irradiated by a laser pulse, the elastic layer deforms to create a blister that mechanically pushes the microLED pixel forward without significant thermal effects on the device itself, potentially reducing thermal damage.

Photochemical LIFT represents a third approach, where laser energy triggers chemical bond breaking in specifically designed molecular structures, facilitating the release of microLED pixels. This mechanism operates at lower energy thresholds and produces less thermal stress compared to conventional thermal LIFT processes.

Despite these advancements, significant technical challenges persist in LIFT technology for microLED mass transfer. Laser energy distribution uniformity remains problematic, as even minor variations can lead to inconsistent transfer results across large arrays. Engineers struggle to maintain precise control over the laser pulse characteristics, including energy density, pulse duration, and beam profile, which directly impact transfer success rates.

Thermal management presents another critical challenge, as excessive heat can damage the delicate microLED structures, affecting their electrical and optical properties. The industry is actively researching advanced cooling strategies and optimized laser parameters to mitigate thermal damage while maintaining transfer efficiency.

Placement accuracy and yield represent persistent hurdles, with current technologies struggling to achieve the sub-micron placement precision required for high-resolution displays while maintaining acceptable yields above 99.99%. This challenge intensifies as pixel sizes decrease below 10 microns, where even nanometer-scale misalignments become problematic.

Material compatibility issues further complicate implementation, as the LIFT process must accommodate various material combinations in the microLED stack without compromising device performance. Additionally, scaling LIFT technology for high-volume manufacturing remains challenging, with current throughput rates insufficient for cost-effective mass production of large microLED displays.

The dominant LIFT mechanism involves a dynamic release layer (DRL) that absorbs laser energy and converts it to thermal energy, creating localized vaporization. This rapid phase change generates a propulsive force that transfers the microLED pixel to the receiving substrate. The DRL typically consists of materials with high optical absorption coefficients at the laser wavelength, such as metals (titanium, aluminum) or polymers doped with absorbing compounds.

Another prevalent mechanism is the blister-actuated LIFT, which utilizes a transparent elastic layer between the donor substrate and the transfer material. When irradiated by a laser pulse, the elastic layer deforms to create a blister that mechanically pushes the microLED pixel forward without significant thermal effects on the device itself, potentially reducing thermal damage.

Photochemical LIFT represents a third approach, where laser energy triggers chemical bond breaking in specifically designed molecular structures, facilitating the release of microLED pixels. This mechanism operates at lower energy thresholds and produces less thermal stress compared to conventional thermal LIFT processes.

Despite these advancements, significant technical challenges persist in LIFT technology for microLED mass transfer. Laser energy distribution uniformity remains problematic, as even minor variations can lead to inconsistent transfer results across large arrays. Engineers struggle to maintain precise control over the laser pulse characteristics, including energy density, pulse duration, and beam profile, which directly impact transfer success rates.

Thermal management presents another critical challenge, as excessive heat can damage the delicate microLED structures, affecting their electrical and optical properties. The industry is actively researching advanced cooling strategies and optimized laser parameters to mitigate thermal damage while maintaining transfer efficiency.

Placement accuracy and yield represent persistent hurdles, with current technologies struggling to achieve the sub-micron placement precision required for high-resolution displays while maintaining acceptable yields above 99.99%. This challenge intensifies as pixel sizes decrease below 10 microns, where even nanometer-scale misalignments become problematic.

Material compatibility issues further complicate implementation, as the LIFT process must accommodate various material combinations in the microLED stack without compromising device performance. Additionally, scaling LIFT technology for high-volume manufacturing remains challenging, with current throughput rates insufficient for cost-effective mass production of large microLED displays.

State-of-the-Art LIFT Implementation Approaches

01 Basic LIFT mechanisms for material transfer

Laser Induced Forward Transfer (LIFT) is a direct-write technique that uses laser energy to transfer materials from a donor substrate to a receiver substrate. The process involves focusing a laser pulse onto a thin film of material, causing localized heating and vaporization, which creates pressure that propels the material forward. This mechanism enables precise deposition of various materials including metals, ceramics, and biomaterials with high spatial resolution and controlled thickness.- Basic LIFT mechanism principles: Laser Induced Forward Transfer (LIFT) is a direct-write technique that uses laser energy to transfer material from a donor substrate to a receiver substrate. The process involves focusing a laser pulse onto a thin film of material (donor), causing localized heating and vaporization, which creates pressure that propels the material forward onto a receiving substrate. This non-contact transfer method allows precise deposition of various materials including metals, ceramics, and biomaterials with high spatial resolution.

- Advanced LIFT techniques for biological materials: Specialized LIFT techniques have been developed for transferring sensitive biological materials such as cells, proteins, and DNA. These techniques often employ an absorbing sacrificial layer that converts laser energy to mechanical energy, protecting the biomaterial from direct laser exposure. Temperature control mechanisms and biocompatible transfer matrices are incorporated to maintain cell viability during transfer. These modifications enable applications in tissue engineering, biosensor fabrication, and bioprinting of complex structures.

- LIFT for electronic and semiconductor applications: LIFT mechanisms have been adapted for precise deposition of electronic materials and components in semiconductor manufacturing. These systems utilize ultrafast lasers with precise energy control to transfer conductive inks, metal nanoparticles, and semiconductor materials. The technology enables fabrication of flexible electronics, printed circuit boards, and microelectronic components with high resolution. Advanced control systems ensure accurate positioning and uniform material transfer for consistent electronic performance.

- Multi-material LIFT systems and transfer optimization: Advanced LIFT systems incorporate mechanisms for transferring multiple materials in sequence or simultaneously. These systems feature automated material selection, precise laser parameter control, and substrate alignment capabilities. Transfer optimization involves controlling laser fluence, pulse duration, donor film thickness, and donor-receiver gap distance. Computational models and real-time monitoring systems help predict and control the transfer process dynamics, improving reproducibility and transfer quality across different material types.

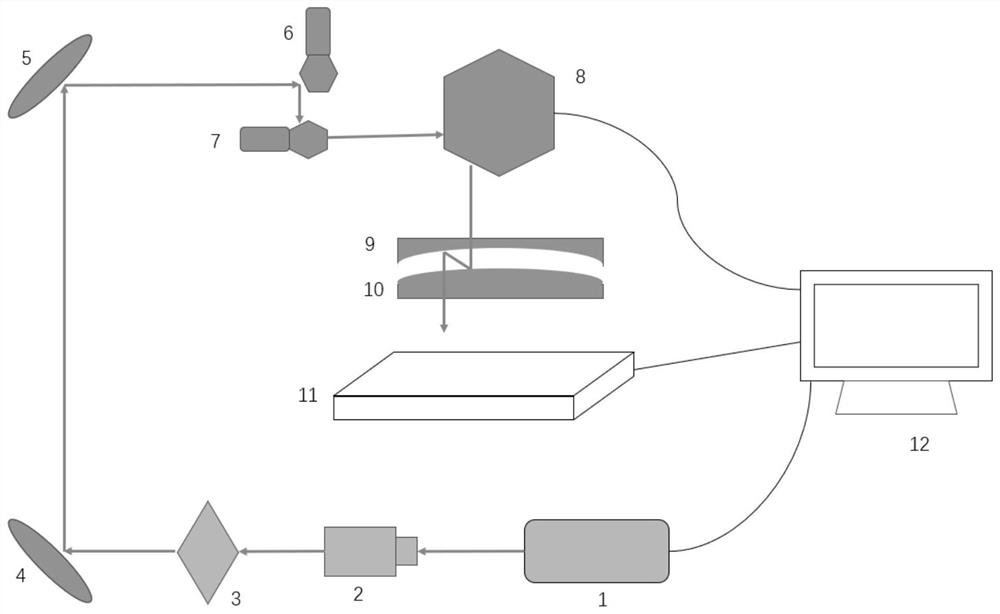

- Novel LIFT apparatus designs and control systems: Innovative LIFT apparatus designs incorporate advanced optical systems, precise motion control, and specialized environmental chambers. These systems feature beam shaping optics to control energy distribution, high-precision positioning stages for accurate donor-receiver alignment, and environmental controls for temperature and atmosphere regulation. Integrated monitoring systems using high-speed cameras and spectroscopic techniques provide real-time feedback on transfer quality. Automated control systems adjust process parameters dynamically to maintain consistent transfer results across large areas or complex patterns.

02 Advanced LIFT techniques for biological applications

Specialized LIFT mechanisms have been developed for transferring biological materials and living cells. These techniques employ gentler laser parameters and often include absorption layers or hydrogels to protect sensitive biomaterials during transfer. The mechanisms focus on maintaining cell viability and functionality by controlling thermal effects and mechanical stress during the transfer process, enabling applications in tissue engineering, biosensors, and cell patterning.Expand Specific Solutions03 Multi-material LIFT systems and apparatus

Advanced LIFT systems incorporate mechanisms for transferring multiple materials in sequence or simultaneously. These systems feature automated donor substrate positioning, precise laser beam control, and specialized receiver substrate handling. The mechanisms often include real-time monitoring and feedback control to ensure accurate material deposition and pattern formation, enabling complex multi-layer structures and functional devices to be fabricated in a single process.Expand Specific Solutions04 Laser parameter optimization for controlled mass transfer

The mass transfer mechanisms in LIFT are highly dependent on laser parameters including pulse duration, energy density, wavelength, and beam profile. Optimization of these parameters controls the material ejection process, affecting transfer efficiency, resolution, and quality. Short pulse durations minimize thermal effects, while specific energy thresholds determine whether material transfer occurs through solid-phase transfer, melting, or vaporization-driven processes, allowing precise control over the transferred material's properties.Expand Specific Solutions05 Novel donor substrate configurations for enhanced transfer

Innovative donor substrate designs significantly influence LIFT mass transfer mechanisms. Multi-layer donor substrates incorporating dynamic release layers, sacrificial layers, or nanostructured surfaces can enhance transfer efficiency and quality. These specialized configurations control the energy absorption, pressure generation, and material release dynamics during the LIFT process, enabling transfer of materials that were previously challenging to process and improving the precision of deposition for advanced manufacturing applications.Expand Specific Solutions

Leading Companies in MicroLED Mass Transfer Solutions

The Laser Induced Forward Transfer (LIFT) mechanism for MicroLED mass transfer is currently in an early growth phase, with the market expanding rapidly due to increasing demand for high-performance displays. The global competitive landscape features both established electronics giants like Samsung Display and BOE Technology, alongside specialized players such as eLux and Kaistar Lighting. While the technology shows promising applications in next-generation displays, technical maturity varies significantly among competitors. Research institutions including Tsinghua University, Xiamen University, and Naval Research Laboratory are advancing fundamental aspects, while companies like Samsung and Coherent LaserSystems are developing commercial-scale solutions, though challenges in yield and precision remain significant barriers to widespread adoption.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an advanced Laser Induced Forward Transfer (LIFT) technology for microLED mass transfer that utilizes a pulsed laser system with precise energy control. Their approach employs a donor substrate with a sacrificial layer that absorbs laser energy and creates a controlled microexplosion to propel microLED pixels onto a receiving substrate. Samsung has implemented a multi-beam parallel processing system that can transfer thousands of microLED pixels simultaneously, significantly improving throughput. Their process incorporates real-time optical monitoring and feedback control to ensure accurate placement with positioning precision below 1μm. Samsung has also developed specialized release layer materials that optimize energy transfer while minimizing thermal damage to the microLED devices. The company has integrated this LIFT technology into their manufacturing lines with automated handling systems and post-transfer testing capabilities.

Strengths: High throughput capability with multi-beam parallel processing; exceptional placement accuracy (<1μm); integrated quality control systems; production-ready implementation. Weaknesses: High capital equipment costs; complex optical system requiring precise maintenance; potential yield challenges with very small (<10μm) microLEDs.

Coherent LaserSystems GmbH & Co. KG

Technical Solution: Coherent LaserSystems has developed a high-precision LIFT technology for microLED mass transfer that leverages their expertise in industrial laser systems. Their approach utilizes ultra-short pulse lasers (picosecond to femtosecond regime) that minimize thermal effects during the transfer process, preserving the electrical and optical properties of sensitive microLED devices. Coherent has implemented a proprietary beam homogenization technology that ensures uniform energy distribution across the transfer area, improving consistency and yield. Their system incorporates advanced galvanometric scanning with sub-micron positioning accuracy, enabling precise placement of microLEDs as small as 3μm. Coherent's technology features a modular design that can be configured for different production requirements, from R&D prototyping to high-volume manufacturing. They have also developed specialized process monitoring tools that provide real-time feedback on transfer quality, including high-speed imaging and spectroscopic analysis of the transfer plume dynamics to optimize process parameters.

Strengths: Superior laser beam quality and control; minimal thermal damage to devices; exceptional precision for very small microLEDs; flexible configuration options. Weaknesses: Lower throughput compared to parallel transfer systems; higher capital equipment costs; complex optical setup requiring expert maintenance; primarily focused on equipment rather than complete process integration.

Critical Patents and Research in LIFT MicroLED Transfer

Miniature LED mass transfer method and device based on high-speed scanning laser transfer printing

PatentActiveCN112768572A

Innovation

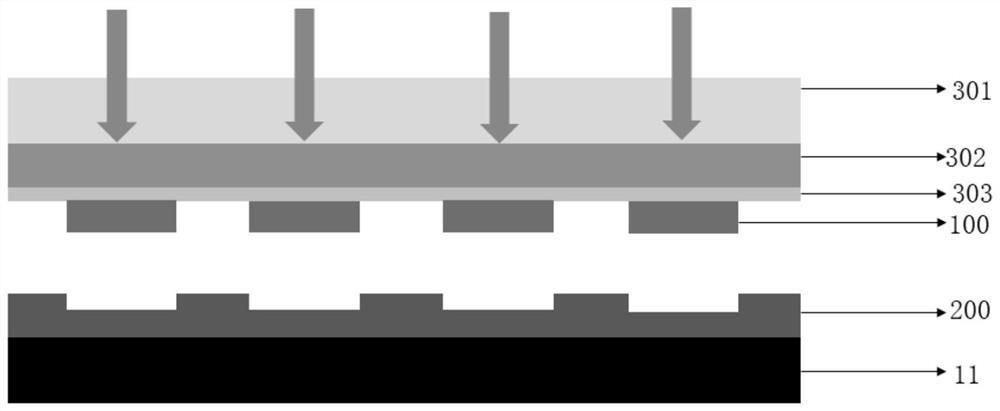

- Using a method based on high-speed scanning laser transfer, by focusing the femtosecond laser at the interface between the transparent substrate and the polyimide layer, the polyimide layer is ablated to generate a hot air cavity, which squeezes the micro LED chip and makes it fall into the receiving substrate , to achieve efficient transfer.

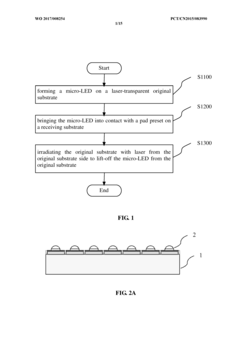

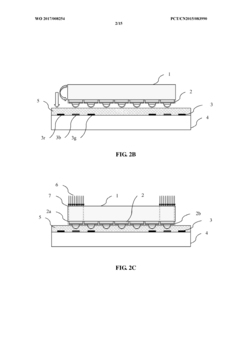

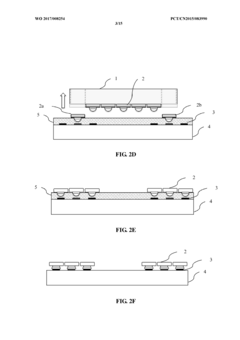

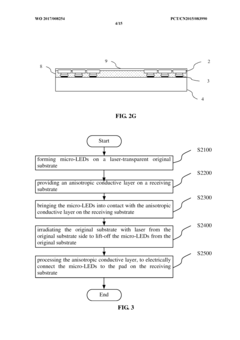

Transferring method, manufacturing method, device and electronic apparatus of micro-led

PatentWO2017008254A1

Innovation

- Direct contact between micro-LED electrodes and receiving substrate pads before laser lift-off, enabling more stable transfer process.

- Simplified laser-induced transfer process that eliminates intermediate carrier layers, reducing manufacturing complexity and potential failure points.

- Integration of laser lift-off with direct bonding in a single step, improving manufacturing throughput and reliability.

Manufacturing Scalability and Yield Optimization

The scalability of Laser Induced Forward Transfer (LIFT) for MicroLED mass transfer presents both significant opportunities and challenges for industrial implementation. Current manufacturing processes demonstrate transfer yields ranging from 95% to 99%, depending on the specific LIFT technique employed and the target display specifications. However, achieving consistent yields above 99.5%, which is necessary for high-resolution consumer displays, remains a significant hurdle.

Key factors affecting manufacturing scalability include laser pulse uniformity across large substrate areas, thermal management during high-volume transfers, and precise alignment systems capable of maintaining sub-micron accuracy over increasingly larger panel sizes. Recent advancements in multi-beam LIFT systems have shown promise in addressing throughput limitations, with some experimental setups demonstrating transfer rates exceeding 50 million microLEDs per hour—a tenfold improvement over early-generation systems.

Yield optimization strategies have evolved significantly in recent years, focusing on three primary areas: donor substrate preparation, laser parameter optimization, and receiver substrate engineering. Advanced donor substrate preparation techniques, including specialized release layers with controlled adhesion properties, have reduced pixel damage during transfer by approximately 40% compared to conventional methods. Adaptive laser parameter control systems that adjust pulse energy based on real-time feedback have further improved consistency across large panel areas.

Statistical process control methods specifically developed for LIFT manufacturing have enabled more sophisticated yield prediction models. These models incorporate multiple variables including donor-receiver gap distance variations, laser beam profile consistency, and material property fluctuations. Implementation of these advanced monitoring systems has reduced yield variations by up to 30% in pilot production environments.

Cost considerations remain critical for commercial viability. Current estimates suggest that LIFT-based transfer costs need to decrease by approximately 65-70% to compete with established display manufacturing technologies. Economies of scale and equipment optimization are expected to drive significant cost reductions, with industry projections indicating potential for 40-50% cost reduction within the next three years as production volumes increase.

Integration with automated inspection and repair systems represents another frontier in yield optimization. Advanced optical inspection systems capable of identifying transfer defects at speeds compatible with high-volume manufacturing have been demonstrated, with defect detection accuracies exceeding 98%. These systems, when coupled with selective repair capabilities, have shown potential to increase effective yields by an additional 1-2 percentage points—a significant improvement when considering the millions of pixels in modern high-resolution displays.

Key factors affecting manufacturing scalability include laser pulse uniformity across large substrate areas, thermal management during high-volume transfers, and precise alignment systems capable of maintaining sub-micron accuracy over increasingly larger panel sizes. Recent advancements in multi-beam LIFT systems have shown promise in addressing throughput limitations, with some experimental setups demonstrating transfer rates exceeding 50 million microLEDs per hour—a tenfold improvement over early-generation systems.

Yield optimization strategies have evolved significantly in recent years, focusing on three primary areas: donor substrate preparation, laser parameter optimization, and receiver substrate engineering. Advanced donor substrate preparation techniques, including specialized release layers with controlled adhesion properties, have reduced pixel damage during transfer by approximately 40% compared to conventional methods. Adaptive laser parameter control systems that adjust pulse energy based on real-time feedback have further improved consistency across large panel areas.

Statistical process control methods specifically developed for LIFT manufacturing have enabled more sophisticated yield prediction models. These models incorporate multiple variables including donor-receiver gap distance variations, laser beam profile consistency, and material property fluctuations. Implementation of these advanced monitoring systems has reduced yield variations by up to 30% in pilot production environments.

Cost considerations remain critical for commercial viability. Current estimates suggest that LIFT-based transfer costs need to decrease by approximately 65-70% to compete with established display manufacturing technologies. Economies of scale and equipment optimization are expected to drive significant cost reductions, with industry projections indicating potential for 40-50% cost reduction within the next three years as production volumes increase.

Integration with automated inspection and repair systems represents another frontier in yield optimization. Advanced optical inspection systems capable of identifying transfer defects at speeds compatible with high-volume manufacturing have been demonstrated, with defect detection accuracies exceeding 98%. These systems, when coupled with selective repair capabilities, have shown potential to increase effective yields by an additional 1-2 percentage points—a significant improvement when considering the millions of pixels in modern high-resolution displays.

Environmental and Energy Efficiency Considerations

The environmental impact of microLED manufacturing processes has become increasingly significant as the industry scales toward mass production. Laser Induced Forward Transfer (LIFT) mechanisms for microLED mass transfer present several environmental advantages over traditional pick-and-place methods. The laser-based process eliminates the need for mechanical components that require frequent replacement, thereby reducing material waste and associated environmental footprint. Additionally, LIFT systems typically consume less energy per transferred pixel compared to robotic transfer systems, particularly when operating at high throughput rates.

Energy efficiency considerations are paramount in evaluating LIFT technologies for industrial implementation. Current LIFT systems demonstrate variable efficiency profiles depending on laser type, pulse characteristics, and donor/acceptor substrate configurations. Solid-state lasers commonly used in LIFT processes, such as Nd:YAG or fiber lasers, offer electrical-to-optical conversion efficiencies ranging from 20-30%, which represents a significant improvement over earlier generation lasers. The overall energy consumption of LIFT systems must be evaluated across the entire transfer process, including substrate preparation, laser operation, cooling systems, and post-transfer processing.

Thermal management presents both environmental and efficiency challenges in LIFT-based microLED transfer. The localized heating inherent to the process must be carefully controlled to prevent thermal damage to adjacent pixels while ensuring successful transfer. Advanced cooling systems and thermal management strategies can significantly reduce energy consumption while extending equipment lifespan. Recent innovations in pulse shaping and beam profile optimization have demonstrated up to 40% reduction in energy requirements for successful pixel transfer compared to first-generation LIFT systems.

Waste reduction represents another critical environmental consideration. LIFT processes generate minimal chemical waste compared to wet etching or other traditional semiconductor manufacturing steps. However, the donor substrates used in LIFT typically require specialized coatings that may contain rare or potentially hazardous materials. Industry research is increasingly focused on developing environmentally benign donor materials that maintain transfer efficiency while reducing environmental impact. Several research groups have demonstrated promising results with biodegradable polymers as dynamic release layers.

The scalability of LIFT technology also affects its environmental profile. As transfer speeds increase to meet mass production requirements, the energy efficiency per transferred pixel generally improves, creating a positive environmental scaling factor. However, this must be balanced against increased cooling requirements and potential material stress at higher operating speeds. Life cycle assessment studies suggest that LIFT-based manufacturing, when optimized for energy efficiency, can reduce the carbon footprint of microLED display production by 15-25% compared to conventional transfer methods.

Energy efficiency considerations are paramount in evaluating LIFT technologies for industrial implementation. Current LIFT systems demonstrate variable efficiency profiles depending on laser type, pulse characteristics, and donor/acceptor substrate configurations. Solid-state lasers commonly used in LIFT processes, such as Nd:YAG or fiber lasers, offer electrical-to-optical conversion efficiencies ranging from 20-30%, which represents a significant improvement over earlier generation lasers. The overall energy consumption of LIFT systems must be evaluated across the entire transfer process, including substrate preparation, laser operation, cooling systems, and post-transfer processing.

Thermal management presents both environmental and efficiency challenges in LIFT-based microLED transfer. The localized heating inherent to the process must be carefully controlled to prevent thermal damage to adjacent pixels while ensuring successful transfer. Advanced cooling systems and thermal management strategies can significantly reduce energy consumption while extending equipment lifespan. Recent innovations in pulse shaping and beam profile optimization have demonstrated up to 40% reduction in energy requirements for successful pixel transfer compared to first-generation LIFT systems.

Waste reduction represents another critical environmental consideration. LIFT processes generate minimal chemical waste compared to wet etching or other traditional semiconductor manufacturing steps. However, the donor substrates used in LIFT typically require specialized coatings that may contain rare or potentially hazardous materials. Industry research is increasingly focused on developing environmentally benign donor materials that maintain transfer efficiency while reducing environmental impact. Several research groups have demonstrated promising results with biodegradable polymers as dynamic release layers.

The scalability of LIFT technology also affects its environmental profile. As transfer speeds increase to meet mass production requirements, the energy efficiency per transferred pixel generally improves, creating a positive environmental scaling factor. However, this must be balanced against increased cooling requirements and potential material stress at higher operating speeds. Life cycle assessment studies suggest that LIFT-based manufacturing, when optimized for energy efficiency, can reduce the carbon footprint of microLED display production by 15-25% compared to conventional transfer methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!