Quantum Dots and Phosphors for MicroLED Color Conversion

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dots and Phosphors Technology Background and Objectives

Quantum dots (QDs) and phosphors represent two of the most promising color conversion technologies for MicroLED displays, which have emerged as next-generation display technology offering superior brightness, energy efficiency, and longevity compared to traditional LCD and OLED displays. The evolution of these color conversion materials traces back to the early 2000s when quantum dots were first commercialized for display applications, while phosphors have a longer history dating back to their use in cathode ray tubes and fluorescent lighting.

The technological trajectory of quantum dots has seen significant advancements in material composition, from early cadmium-based QDs to more environmentally friendly indium phosphide and perovskite quantum dots. Similarly, phosphor technology has evolved from rare-earth doped YAG (Yttrium Aluminum Garnet) materials to more sophisticated compositions offering enhanced color gamut and stability. These developments have been driven by the increasing demand for higher color purity, wider color gamut, and greater energy efficiency in display technologies.

Current research in quantum dots focuses on improving quantum yield, enhancing stability against heat and light exposure, and developing manufacturing processes suitable for mass production. For phosphors, research efforts concentrate on reducing particle size to nanometer scale, improving conversion efficiency, and enhancing thermal quenching resistance. Both technologies aim to address the unique challenges posed by MicroLED integration, including the high energy density of blue MicroLED light sources and the miniaturization requirements for high-resolution displays.

The primary technical objectives in this field include developing color conversion materials with narrow emission spectra (FWHM <30nm) to achieve wide color gamut (>90% Rec.2020), high quantum efficiency (>90%), excellent thermal stability (minimal efficiency drop at operating temperatures of 80-100°C), and long operational lifetime (>30,000 hours). Additionally, researchers aim to develop deposition and patterning techniques compatible with existing semiconductor manufacturing processes.

Market trends indicate a growing preference for quantum dots in premium display applications due to their superior color performance, while phosphors maintain advantages in cost-effectiveness and established manufacturing infrastructure. The convergence of these technologies with MicroLED represents a critical juncture in display evolution, potentially enabling unprecedented display performance in terms of brightness, color accuracy, and energy efficiency.

The ultimate goal of research in this domain is to establish a robust, scalable, and cost-effective color conversion solution that can facilitate the mass adoption of MicroLED displays across various applications, from smartphones and televisions to augmented reality devices and automotive displays.

The technological trajectory of quantum dots has seen significant advancements in material composition, from early cadmium-based QDs to more environmentally friendly indium phosphide and perovskite quantum dots. Similarly, phosphor technology has evolved from rare-earth doped YAG (Yttrium Aluminum Garnet) materials to more sophisticated compositions offering enhanced color gamut and stability. These developments have been driven by the increasing demand for higher color purity, wider color gamut, and greater energy efficiency in display technologies.

Current research in quantum dots focuses on improving quantum yield, enhancing stability against heat and light exposure, and developing manufacturing processes suitable for mass production. For phosphors, research efforts concentrate on reducing particle size to nanometer scale, improving conversion efficiency, and enhancing thermal quenching resistance. Both technologies aim to address the unique challenges posed by MicroLED integration, including the high energy density of blue MicroLED light sources and the miniaturization requirements for high-resolution displays.

The primary technical objectives in this field include developing color conversion materials with narrow emission spectra (FWHM <30nm) to achieve wide color gamut (>90% Rec.2020), high quantum efficiency (>90%), excellent thermal stability (minimal efficiency drop at operating temperatures of 80-100°C), and long operational lifetime (>30,000 hours). Additionally, researchers aim to develop deposition and patterning techniques compatible with existing semiconductor manufacturing processes.

Market trends indicate a growing preference for quantum dots in premium display applications due to their superior color performance, while phosphors maintain advantages in cost-effectiveness and established manufacturing infrastructure. The convergence of these technologies with MicroLED represents a critical juncture in display evolution, potentially enabling unprecedented display performance in terms of brightness, color accuracy, and energy efficiency.

The ultimate goal of research in this domain is to establish a robust, scalable, and cost-effective color conversion solution that can facilitate the mass adoption of MicroLED displays across various applications, from smartphones and televisions to augmented reality devices and automotive displays.

Market Analysis for MicroLED Color Conversion Solutions

The MicroLED display market is experiencing significant growth, with a projected CAGR of 80.5% from 2022 to 2027, potentially reaching a market value of $21.5 billion by 2027. This remarkable expansion is driven by the inherent advantages of MicroLED technology, including superior brightness, energy efficiency, and longevity compared to traditional display technologies. However, the color conversion aspect remains a critical challenge in MicroLED commercialization.

Color conversion solutions for MicroLED displays primarily utilize quantum dots (QDs) and phosphors to transform the blue or UV light emitted by MicroLEDs into full-color displays. The market for these solutions is currently dominated by phosphor-based approaches due to their established manufacturing processes and lower costs. Nevertheless, quantum dot solutions are gaining traction rapidly due to their superior color purity and narrower emission spectra.

The market segmentation for MicroLED color conversion technologies can be divided into three main categories: phosphor-based solutions (approximately 65% market share), quantum dot solutions (approximately 30% market share), and emerging hybrid approaches (approximately 5% market share). This distribution is expected to shift significantly toward quantum dot solutions over the next five years as manufacturing costs decrease and performance improves.

Consumer electronics represents the largest application segment for MicroLED color conversion technologies, accounting for approximately 45% of the market. This is followed by automotive displays (25%), augmented/virtual reality devices (15%), and large-format displays (10%), with other applications comprising the remaining 5%. The automotive sector is expected to show the fastest growth due to increasing demand for advanced dashboard displays and infotainment systems.

Regionally, East Asia dominates the market with approximately 70% of global production capacity for color conversion materials, particularly in South Korea, Japan, and Taiwan. North America follows with approximately 20% market share, primarily driven by research and development activities, while Europe accounts for approximately 10% of the market.

Key market drivers include increasing demand for higher resolution displays, growing adoption of AR/VR technologies, and the push for more energy-efficient display solutions. However, market challenges persist, including high production costs, yield issues in manufacturing processes, and technical limitations such as efficiency droop and thermal stability of conversion materials.

The competitive landscape features established materials companies like Nanosys, QD Vision, and Nanoco competing with display manufacturers who are developing proprietary color conversion solutions. Strategic partnerships between material developers and display manufacturers are becoming increasingly common as the industry seeks to overcome technical challenges and reduce production costs.

Color conversion solutions for MicroLED displays primarily utilize quantum dots (QDs) and phosphors to transform the blue or UV light emitted by MicroLEDs into full-color displays. The market for these solutions is currently dominated by phosphor-based approaches due to their established manufacturing processes and lower costs. Nevertheless, quantum dot solutions are gaining traction rapidly due to their superior color purity and narrower emission spectra.

The market segmentation for MicroLED color conversion technologies can be divided into three main categories: phosphor-based solutions (approximately 65% market share), quantum dot solutions (approximately 30% market share), and emerging hybrid approaches (approximately 5% market share). This distribution is expected to shift significantly toward quantum dot solutions over the next five years as manufacturing costs decrease and performance improves.

Consumer electronics represents the largest application segment for MicroLED color conversion technologies, accounting for approximately 45% of the market. This is followed by automotive displays (25%), augmented/virtual reality devices (15%), and large-format displays (10%), with other applications comprising the remaining 5%. The automotive sector is expected to show the fastest growth due to increasing demand for advanced dashboard displays and infotainment systems.

Regionally, East Asia dominates the market with approximately 70% of global production capacity for color conversion materials, particularly in South Korea, Japan, and Taiwan. North America follows with approximately 20% market share, primarily driven by research and development activities, while Europe accounts for approximately 10% of the market.

Key market drivers include increasing demand for higher resolution displays, growing adoption of AR/VR technologies, and the push for more energy-efficient display solutions. However, market challenges persist, including high production costs, yield issues in manufacturing processes, and technical limitations such as efficiency droop and thermal stability of conversion materials.

The competitive landscape features established materials companies like Nanosys, QD Vision, and Nanoco competing with display manufacturers who are developing proprietary color conversion solutions. Strategic partnerships between material developers and display manufacturers are becoming increasingly common as the industry seeks to overcome technical challenges and reduce production costs.

Current Technical Challenges in Quantum Dots and Phosphors

Quantum dots (QDs) and phosphors face significant technical challenges in their application for MicroLED color conversion. The stability of quantum dots remains a primary concern, particularly their susceptibility to degradation under high-intensity blue light from MicroLEDs. This photo-oxidation effect substantially reduces quantum yield and shifts emission wavelengths over time, compromising display longevity. Environmental factors such as heat, moisture, and oxygen accelerate this degradation, making robust encapsulation technologies essential yet currently insufficient.

Efficiency losses during energy transfer represent another critical challenge. The conversion efficiency from blue light to red/green emissions typically ranges from 30-70%, with significant energy lost as heat. This inefficiency impacts both power consumption and device thermal management, particularly problematic in portable applications where battery life is paramount.

The narrow emission spectrum of quantum dots, while beneficial for color purity, creates manufacturing difficulties in achieving precise wavelength control. Current production methods struggle to maintain consistent particle size distributions across large-scale manufacturing, resulting in batch-to-batch variations that affect color accuracy and uniformity across displays.

For phosphors, the primary challenge lies in their relatively broad emission spectra compared to quantum dots, limiting the color gamut achievable in displays. While more stable than quantum dots, phosphors suffer from lower efficiency in red emission regions, creating an imbalance in the RGB color system that requires compensation through software or additional hardware components.

Integration challenges persist for both technologies. The deposition of quantum dots or phosphors onto MicroLED arrays demands precise patterning techniques to prevent color mixing between adjacent pixels. Current methods like photolithography, inkjet printing, and transfer printing each present trade-offs between resolution, scalability, and manufacturing cost that have yet to be optimally resolved.

Material compatibility issues further complicate integration, as the solvents used in quantum dot processing can damage underlying MicroLED structures. Similarly, the high temperatures often required for phosphor integration can negatively impact the performance of temperature-sensitive components in the display stack.

Cadmium-based quantum dots, despite their superior performance, face regulatory restrictions due to environmental concerns, while cadmium-free alternatives currently exhibit lower efficiency and stability. This regulatory landscape creates uncertainty for manufacturers and necessitates continued research into environmentally friendly alternatives that maintain performance standards.

Efficiency losses during energy transfer represent another critical challenge. The conversion efficiency from blue light to red/green emissions typically ranges from 30-70%, with significant energy lost as heat. This inefficiency impacts both power consumption and device thermal management, particularly problematic in portable applications where battery life is paramount.

The narrow emission spectrum of quantum dots, while beneficial for color purity, creates manufacturing difficulties in achieving precise wavelength control. Current production methods struggle to maintain consistent particle size distributions across large-scale manufacturing, resulting in batch-to-batch variations that affect color accuracy and uniformity across displays.

For phosphors, the primary challenge lies in their relatively broad emission spectra compared to quantum dots, limiting the color gamut achievable in displays. While more stable than quantum dots, phosphors suffer from lower efficiency in red emission regions, creating an imbalance in the RGB color system that requires compensation through software or additional hardware components.

Integration challenges persist for both technologies. The deposition of quantum dots or phosphors onto MicroLED arrays demands precise patterning techniques to prevent color mixing between adjacent pixels. Current methods like photolithography, inkjet printing, and transfer printing each present trade-offs between resolution, scalability, and manufacturing cost that have yet to be optimally resolved.

Material compatibility issues further complicate integration, as the solvents used in quantum dot processing can damage underlying MicroLED structures. Similarly, the high temperatures often required for phosphor integration can negatively impact the performance of temperature-sensitive components in the display stack.

Cadmium-based quantum dots, despite their superior performance, face regulatory restrictions due to environmental concerns, while cadmium-free alternatives currently exhibit lower efficiency and stability. This regulatory landscape creates uncertainty for manufacturers and necessitates continued research into environmentally friendly alternatives that maintain performance standards.

Current Color Conversion Implementation Approaches

01 Quantum dot and phosphor compositions for color conversion

Various compositions combining quantum dots and phosphors are used for color conversion applications. These compositions can include different types of quantum dots (such as cadmium-based or cadmium-free) and phosphors (like rare earth phosphors) arranged in specific configurations to achieve desired color outputs. The materials are often embedded in polymer matrices or other binding materials to create stable conversion layers that can transform light from one wavelength to another with high efficiency.- Quantum dot and phosphor compositions for color conversion: Various compositions combining quantum dots and phosphors are used for color conversion applications. These compositions can include specific materials like perovskite quantum dots, rare earth phosphors, or hybrid structures designed to optimize light emission properties. The compositions are engineered to achieve specific color outputs, enhanced stability, and improved quantum efficiency for display and lighting applications.

- Display device applications using quantum dot and phosphor color converters: Quantum dots and phosphors are integrated into various display technologies to enhance color gamut and visual performance. These color conversion materials are incorporated into LCD, OLED, and microLED displays to achieve wider color gamut, higher brightness, and improved energy efficiency. The integration methods include film-based approaches, on-chip configurations, and pixel-level color conversion strategies.

- Manufacturing methods for quantum dot and phosphor color conversion layers: Various manufacturing techniques are employed to produce quantum dot and phosphor color conversion layers. These methods include solution processing, inkjet printing, photolithography, and encapsulation techniques to create stable and efficient color conversion films. The manufacturing processes focus on achieving uniform distribution of quantum dots and phosphors, preventing degradation, and optimizing optical properties for specific applications.

- Energy transfer mechanisms between quantum dots and phosphors: The energy transfer mechanisms between quantum dots and phosphors enable efficient color conversion. These mechanisms include Förster resonance energy transfer (FRET), photon reabsorption, and direct energy coupling. By understanding and optimizing these energy transfer pathways, enhanced luminescence efficiency, reduced energy loss, and improved color purity can be achieved in hybrid quantum dot-phosphor systems.

- Stability and encapsulation techniques for quantum dot and phosphor materials: Various encapsulation and stability enhancement techniques are developed to protect quantum dots and phosphors from environmental degradation. These include polymer encapsulation, inorganic shell formation, surface modification, and composite structures that shield the color conversion materials from oxygen, moisture, and heat. The encapsulation methods aim to extend device lifetime, maintain color quality, and preserve quantum efficiency under operating conditions.

02 Display applications of quantum dot and phosphor color converters

Quantum dots and phosphors are integrated into various display technologies to enhance color gamut and brightness. These color conversion materials are applied in LCD displays, OLED displays, and microLED displays to convert blue or UV light into specific wavelengths needed for full-color displays. The technology enables wider color gamut, improved color accuracy, and higher energy efficiency compared to traditional display technologies, resulting in more vibrant and power-efficient screens.Expand Specific Solutions03 Lighting applications using quantum dot and phosphor conversion

Quantum dots and phosphors are utilized in lighting applications to convert LED light into specific spectral outputs. These materials can be incorporated into LED packages or remote conversion components to create white light with tunable color temperatures or specialized spectral distributions. The technology enables the creation of lighting solutions with high color rendering index (CRI), reduced blue light hazard, and customizable spectral output for applications ranging from general illumination to specialized lighting for horticulture, healthcare, and architectural purposes.Expand Specific Solutions04 Solar energy applications of quantum dot and phosphor converters

Quantum dots and phosphors are employed in solar energy applications to enhance the efficiency of photovoltaic systems. These materials can be used as spectral converters that transform portions of the solar spectrum that are typically poorly utilized by solar cells into wavelengths that can be more efficiently converted to electricity. The technology includes down-conversion of high-energy photons and up-conversion of low-energy photons, potentially increasing the overall efficiency of solar cells beyond traditional limits.Expand Specific Solutions05 Manufacturing and encapsulation techniques for quantum dot and phosphor converters

Various manufacturing and encapsulation methods are developed to create stable and efficient quantum dot and phosphor color conversion components. These techniques include embedding the materials in polymers, glasses, or ceramic matrices, applying protective coatings, and developing specialized deposition methods. The encapsulation provides protection against environmental factors such as oxygen, moisture, and heat, which can degrade the performance of quantum dots and phosphors over time. Advanced manufacturing techniques enable precise control over the distribution and orientation of the conversion materials to optimize optical performance.Expand Specific Solutions

Key Industry Players in Quantum Dots and MicroLED Ecosystem

The quantum dots and phosphors for MicroLED color conversion market is currently in a growth phase, with increasing adoption across display technologies. The market size is expanding rapidly due to rising demand for high-quality displays in consumer electronics, automotive, and AR/VR applications. Technologically, the field shows varying maturity levels among key players. Companies like Nanosys and Nanoco lead in quantum dot development, while Samsung, Apple, and BOE are advancing integration into commercial products. Traditional display manufacturers including TCL China Star, Sony, and OSRAM are investing heavily in this technology. Academic institutions such as MIT, Xiamen University, and Hong Kong University of Science & Technology are contributing fundamental research, creating a competitive ecosystem balancing established corporations and specialized technology providers.

Merck Patent GmbH

Technical Solution: Merck has developed a comprehensive portfolio of quantum dot and phosphor materials specifically engineered for MicroLED color conversion applications. Their liviSQD® quantum dot technology features a unique core-multi-shell architecture that provides enhanced stability under high-energy blue light excitation. The company's quantum dots achieve quantum yields exceeding 85% while maintaining narrow emission linewidths (FWHM <30nm) across the visible spectrum[6]. Merck has pioneered hybrid inorganic-organic encapsulation methods that significantly improve resistance to photo-oxidation and thermal degradation, extending operational lifetime in display applications. Their phosphor technology includes specialized silicate and garnet-based materials with optimized particle morphology for efficient light conversion and reduced scattering effects. Merck has developed proprietary surface functionalization techniques that enable quantum dots and phosphors to be incorporated into photoresist materials, facilitating direct patterning using conventional photolithography processes compatible with MicroLED manufacturing[7]. Their materials are engineered to maintain performance stability at the high current densities typical in MicroLED operation.

Strengths: Extensive materials science expertise and established supply chain for high-volume production. Comprehensive portfolio covering both quantum dots and phosphors for flexible implementation options. Weaknesses: Less vertical integration in display manufacturing compared to device manufacturers. Requires partnerships for complete solution implementation.

Koninklijke Philips NV

Technical Solution: Philips has developed a sophisticated phosphor-based color conversion technology for MicroLED displays, leveraging their extensive experience in LED lighting phosphors. Their approach utilizes advanced narrow-band phosphor materials including europium-doped nitrides for red emission and beta-sialon materials for green emission, achieving color gamut coverage exceeding 90% of Rec.2020 standards. Philips' proprietary phosphor synthesis methods produce particles with optimized morphology (typically 0.5-2μm) and surface treatments that minimize scattering effects critical for maintaining the high-resolution capabilities of MicroLED displays[8]. The company has developed specialized deposition and patterning techniques including electrophoretic deposition and laser-induced forward transfer (LIFT) that enable precise phosphor placement at the pixel level. Their phosphor materials feature exceptional thermal stability (maintaining >90% efficiency at operating temperatures up to 150°C) and resistance to high-energy blue light exposure, resulting in projected operational lifetimes exceeding 100,000 hours in typical display applications[9]. Recent developments include hybrid phosphor systems that combine multiple emitter types to achieve optimized spectral output.

Strengths: Exceptional thermal and photo stability compared to quantum dot alternatives. Established manufacturing infrastructure and supply chain for reliable high-volume production. Weaknesses: Broader emission spectra compared to quantum dots, resulting in slightly reduced color purity. Larger particle size creates challenges for ultra-high-resolution displays.

Critical Patents and Innovations in Quantum Dots Technology

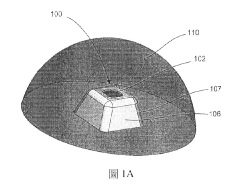

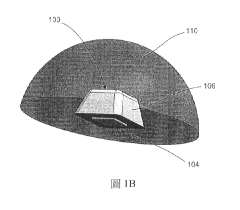

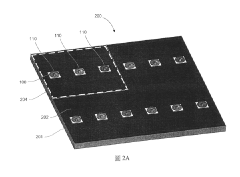

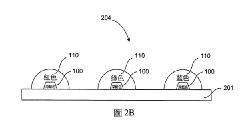

Micro LED with wavelength conversion layer

PatentActiveTW201507212A

Innovation

- The integration of micro LED devices with a wavelength conversion layer containing phosphor particles, such as quantum dots, surrounded by a light distribution layer and optionally a color filter, allows for precise control of color emission spectra and improved color gamut through spatial separation of phosphor particles.

Red-green-blue monolithic integrated high purity micro-light emitting diode display device

PatentWO2022090693A1

Innovation

- A vertically integrated color conversion resonator system with partially reflective regions and cavities that convert input light into distinct red, green, and blue wavelengths, achieving narrow FWHM spectra and improved directionality without the need for collimators, enabling high-resolution microLED arrays with enhanced color gamut.

Material Stability and Lifetime Enhancement Strategies

Material stability remains a critical challenge for quantum dots (QDs) and phosphors in MicroLED applications. These color conversion materials often suffer from degradation under high-energy blue light exposure, elevated temperatures, and environmental factors such as oxygen and moisture. This degradation manifests as decreased quantum yield, color shift, and ultimately reduced display lifetime.

For quantum dots, core-shell structures have emerged as a primary stability enhancement strategy. By encapsulating the semiconductor core with wider bandgap materials, these structures provide physical barriers against oxidation while simultaneously confining excitons to improve quantum efficiency. Recent advancements include gradient alloy shells that minimize lattice mismatch and reduce interfacial defects, significantly extending operational lifetimes.

Surface ligand engineering represents another crucial approach for QD stability. Traditional organic ligands are being replaced by more robust alternatives such as inorganic ligands or hybrid organic-inorganic compounds. These advanced ligand systems maintain colloidal stability while offering superior resistance to photo-oxidation processes that typically lead to luminescence quenching.

For phosphor materials, ceramic encapsulation techniques have demonstrated remarkable improvements in thermal stability. High-temperature sintering processes create dense ceramic matrices that protect phosphor particles from environmental degradation while enhancing thermal conductivity. This approach has shown particular promise for garnet-based phosphors used in high-brightness MicroLED applications.

Compositional optimization through elemental doping has yielded significant stability improvements for both material classes. For instance, incorporating specific rare earth elements into phosphor lattices can reduce thermal quenching effects, while halide ion doping in perovskite QDs has been shown to enhance moisture resistance without compromising optical properties.

Advanced encapsulation technologies represent a system-level approach to stability enhancement. Atomic layer deposition (ALD) techniques enable conformal oxide coatings at the nanoscale, providing hermetic barriers against oxygen and moisture penetration. Similarly, specialized polymer matrices incorporating oxygen scavengers and UV absorbers create protective microenvironments for color conversion materials.

Industry-academic collaborations have accelerated the development of accelerated testing protocols that more accurately predict real-world degradation mechanisms. These standardized methodologies enable rapid screening of stability enhancement strategies and facilitate meaningful comparisons between different material systems, ultimately accelerating the path to commercialization for stable color conversion solutions in MicroLED displays.

For quantum dots, core-shell structures have emerged as a primary stability enhancement strategy. By encapsulating the semiconductor core with wider bandgap materials, these structures provide physical barriers against oxidation while simultaneously confining excitons to improve quantum efficiency. Recent advancements include gradient alloy shells that minimize lattice mismatch and reduce interfacial defects, significantly extending operational lifetimes.

Surface ligand engineering represents another crucial approach for QD stability. Traditional organic ligands are being replaced by more robust alternatives such as inorganic ligands or hybrid organic-inorganic compounds. These advanced ligand systems maintain colloidal stability while offering superior resistance to photo-oxidation processes that typically lead to luminescence quenching.

For phosphor materials, ceramic encapsulation techniques have demonstrated remarkable improvements in thermal stability. High-temperature sintering processes create dense ceramic matrices that protect phosphor particles from environmental degradation while enhancing thermal conductivity. This approach has shown particular promise for garnet-based phosphors used in high-brightness MicroLED applications.

Compositional optimization through elemental doping has yielded significant stability improvements for both material classes. For instance, incorporating specific rare earth elements into phosphor lattices can reduce thermal quenching effects, while halide ion doping in perovskite QDs has been shown to enhance moisture resistance without compromising optical properties.

Advanced encapsulation technologies represent a system-level approach to stability enhancement. Atomic layer deposition (ALD) techniques enable conformal oxide coatings at the nanoscale, providing hermetic barriers against oxygen and moisture penetration. Similarly, specialized polymer matrices incorporating oxygen scavengers and UV absorbers create protective microenvironments for color conversion materials.

Industry-academic collaborations have accelerated the development of accelerated testing protocols that more accurately predict real-world degradation mechanisms. These standardized methodologies enable rapid screening of stability enhancement strategies and facilitate meaningful comparisons between different material systems, ultimately accelerating the path to commercialization for stable color conversion solutions in MicroLED displays.

Environmental Impact and Sustainability Considerations

The environmental impact of quantum dots and phosphors in MicroLED color conversion technology presents significant sustainability challenges that warrant careful consideration. Heavy metals such as cadmium, lead, and indium used in conventional quantum dot manufacturing pose serious environmental and health risks throughout their lifecycle. When improperly disposed of, these materials can leach into soil and water systems, potentially entering food chains and causing bioaccumulation in living organisms. This toxicity concern extends beyond disposal to manufacturing processes, where worker exposure and environmental contamination remain persistent issues.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive, have begun imposing stricter limitations on heavy metal content in electronic components. This regulatory landscape is driving research toward cadmium-free and heavy metal-free quantum dot alternatives, though these often face efficiency and stability trade-offs compared to their toxic counterparts. The environmental calculus must balance performance requirements against ecological impact.

Energy consumption represents another critical sustainability factor in quantum dot and phosphor production. Traditional manufacturing methods typically involve high-temperature processes requiring substantial energy inputs, contributing significantly to the carbon footprint of these materials. Emerging low-temperature synthesis routes and green chemistry approaches show promise for reducing energy demands while minimizing hazardous waste generation. Solution-based processing techniques, in particular, offer pathways to more environmentally benign manufacturing.

The recyclability of quantum dot and phosphor materials presents both challenges and opportunities. Current MicroLED displays incorporating these materials lack established recycling protocols, resulting in valuable rare earth elements and semiconductor materials being lost to landfills. Developing effective recovery methods for these materials could substantially reduce environmental impact while conserving critical resources facing supply constraints.

Life cycle assessment (LCA) studies comparing quantum dot and phosphor technologies reveal complex sustainability profiles. While phosphors generally contain fewer acutely toxic components than some quantum dot formulations, they often rely heavily on rare earth elements with environmentally destructive mining practices. Comprehensive cradle-to-grave analysis indicates that manufacturing impacts frequently outweigh operational benefits, highlighting the need for holistic design approaches that consider environmental factors throughout product development.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive, have begun imposing stricter limitations on heavy metal content in electronic components. This regulatory landscape is driving research toward cadmium-free and heavy metal-free quantum dot alternatives, though these often face efficiency and stability trade-offs compared to their toxic counterparts. The environmental calculus must balance performance requirements against ecological impact.

Energy consumption represents another critical sustainability factor in quantum dot and phosphor production. Traditional manufacturing methods typically involve high-temperature processes requiring substantial energy inputs, contributing significantly to the carbon footprint of these materials. Emerging low-temperature synthesis routes and green chemistry approaches show promise for reducing energy demands while minimizing hazardous waste generation. Solution-based processing techniques, in particular, offer pathways to more environmentally benign manufacturing.

The recyclability of quantum dot and phosphor materials presents both challenges and opportunities. Current MicroLED displays incorporating these materials lack established recycling protocols, resulting in valuable rare earth elements and semiconductor materials being lost to landfills. Developing effective recovery methods for these materials could substantially reduce environmental impact while conserving critical resources facing supply constraints.

Life cycle assessment (LCA) studies comparing quantum dot and phosphor technologies reveal complex sustainability profiles. While phosphors generally contain fewer acutely toxic components than some quantum dot formulations, they often rely heavily on rare earth elements with environmentally destructive mining practices. Comprehensive cradle-to-grave analysis indicates that manufacturing impacts frequently outweigh operational benefits, highlighting the need for holistic design approaches that consider environmental factors throughout product development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!