Evaluating the Durability of Self-Powered Sensors in Harsh Environments

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past two decades, transitioning from laboratory curiosities to practical industrial applications. The fundamental concept behind these sensors involves harvesting ambient energy from the surrounding environment—such as vibration, temperature gradients, light, or RF signals—to power sensing, processing, and communication functions without requiring external power sources or battery replacements. This technological approach emerged from the convergence of energy harvesting techniques, low-power electronics, and advanced sensing materials.

The evolution trajectory shows three distinct phases: early experimental systems (2000-2010) focused primarily on proof-of-concept demonstrations; intermediate development (2010-2018) that achieved practical energy densities and improved reliability; and current advanced integration (2018-present) featuring sophisticated power management and multi-source harvesting capabilities. Each phase has progressively addressed key limitations in energy conversion efficiency, power management, and system integration.

Market drivers for self-powered sensor technology include the explosive growth of IoT applications, industrial automation requirements, and the need for monitoring in remote or hazardous locations where conventional power sources are impractical. The technology has gained particular traction in industrial monitoring, structural health assessment, environmental sensing, and medical applications.

The specific challenge of durability in harsh environments represents a critical frontier for this technology. Harsh environments—characterized by extreme temperatures, corrosive chemicals, high radiation, intense mechanical stress, or combinations thereof—present unique challenges that conventional sensor technologies struggle to address. Self-powered sensors offer theoretical advantages in these settings due to their maintenance-free operation and potential for hermetic sealing.

Current technical objectives in this domain focus on several key areas: enhancing energy harvesting efficiency under extreme conditions; developing robust packaging solutions that maintain functionality while protecting sensitive components; improving power management circuits that can operate reliably across wide temperature ranges; and creating sensing elements resistant to degradation in corrosive or high-radiation environments.

The long-term vision for self-powered sensors in harsh environments encompasses truly "deploy and forget" capabilities, where sensors can operate autonomously for years or decades without maintenance, even under the most challenging conditions. This would enable transformative applications in deep-sea exploration, nuclear facilities, aerospace, geothermal wells, and chemical processing plants, where current monitoring solutions require frequent replacement or are simply infeasible.

The evolution trajectory shows three distinct phases: early experimental systems (2000-2010) focused primarily on proof-of-concept demonstrations; intermediate development (2010-2018) that achieved practical energy densities and improved reliability; and current advanced integration (2018-present) featuring sophisticated power management and multi-source harvesting capabilities. Each phase has progressively addressed key limitations in energy conversion efficiency, power management, and system integration.

Market drivers for self-powered sensor technology include the explosive growth of IoT applications, industrial automation requirements, and the need for monitoring in remote or hazardous locations where conventional power sources are impractical. The technology has gained particular traction in industrial monitoring, structural health assessment, environmental sensing, and medical applications.

The specific challenge of durability in harsh environments represents a critical frontier for this technology. Harsh environments—characterized by extreme temperatures, corrosive chemicals, high radiation, intense mechanical stress, or combinations thereof—present unique challenges that conventional sensor technologies struggle to address. Self-powered sensors offer theoretical advantages in these settings due to their maintenance-free operation and potential for hermetic sealing.

Current technical objectives in this domain focus on several key areas: enhancing energy harvesting efficiency under extreme conditions; developing robust packaging solutions that maintain functionality while protecting sensitive components; improving power management circuits that can operate reliably across wide temperature ranges; and creating sensing elements resistant to degradation in corrosive or high-radiation environments.

The long-term vision for self-powered sensors in harsh environments encompasses truly "deploy and forget" capabilities, where sensors can operate autonomously for years or decades without maintenance, even under the most challenging conditions. This would enable transformative applications in deep-sea exploration, nuclear facilities, aerospace, geothermal wells, and chemical processing plants, where current monitoring solutions require frequent replacement or are simply infeasible.

Market Demand Analysis for Harsh Environment Sensors

The global market for harsh environment sensors is experiencing robust growth, driven by increasing industrial automation, expansion of IoT applications, and growing demand for reliable monitoring systems in extreme conditions. The self-powered sensor segment represents a particularly promising area, with a compound annual growth rate projected to exceed the broader sensor market due to their unique value proposition in remote and challenging deployments.

Industries including oil and gas, mining, aerospace, defense, and automotive manufacturing demonstrate the strongest demand for durable self-powered sensors. These sectors operate in environments characterized by extreme temperatures, high pressure, corrosive substances, intense vibration, and electromagnetic interference—conditions that conventional sensors struggle to withstand. The elimination of external power requirements and wiring infrastructure presents significant cost advantages for installations in remote locations or hazardous areas.

Market research indicates that end-users are willing to pay premium prices for sensors that can deliver extended operational lifespans in harsh environments. The total cost of ownership calculation increasingly favors self-powered solutions when factoring in reduced maintenance requirements, decreased downtime, and elimination of battery replacement logistics. This economic reality is shifting procurement strategies toward higher initial investment in more durable sensing technologies.

Regional analysis reveals that North America and Europe currently lead market adoption, primarily due to stringent regulatory requirements for industrial safety and environmental monitoring. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate as countries like China and India accelerate industrial modernization efforts and implement more sophisticated infrastructure monitoring systems.

Customer requirements are evolving toward comprehensive sensing solutions rather than standalone devices. End-users increasingly demand sensors that combine self-powering capabilities with wireless communication, edge computing functionality, and integration with existing industrial control systems. This trend is driving the development of more sophisticated sensor ecosystems designed specifically for harsh environment applications.

The market demonstrates particular interest in self-powered sensors for predictive maintenance applications, where continuous monitoring can prevent catastrophic equipment failures and optimize maintenance schedules. Environmental monitoring represents another high-growth application area, with increasing regulatory pressure driving demand for reliable long-term monitoring solutions in challenging outdoor conditions.

Supply chain considerations are becoming increasingly important in the harsh environment sensor market, with customers placing greater emphasis on secure sourcing, component traceability, and resilience against disruptions. This trend favors manufacturers with diversified supply chains and vertical integration capabilities.

Industries including oil and gas, mining, aerospace, defense, and automotive manufacturing demonstrate the strongest demand for durable self-powered sensors. These sectors operate in environments characterized by extreme temperatures, high pressure, corrosive substances, intense vibration, and electromagnetic interference—conditions that conventional sensors struggle to withstand. The elimination of external power requirements and wiring infrastructure presents significant cost advantages for installations in remote locations or hazardous areas.

Market research indicates that end-users are willing to pay premium prices for sensors that can deliver extended operational lifespans in harsh environments. The total cost of ownership calculation increasingly favors self-powered solutions when factoring in reduced maintenance requirements, decreased downtime, and elimination of battery replacement logistics. This economic reality is shifting procurement strategies toward higher initial investment in more durable sensing technologies.

Regional analysis reveals that North America and Europe currently lead market adoption, primarily due to stringent regulatory requirements for industrial safety and environmental monitoring. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate as countries like China and India accelerate industrial modernization efforts and implement more sophisticated infrastructure monitoring systems.

Customer requirements are evolving toward comprehensive sensing solutions rather than standalone devices. End-users increasingly demand sensors that combine self-powering capabilities with wireless communication, edge computing functionality, and integration with existing industrial control systems. This trend is driving the development of more sophisticated sensor ecosystems designed specifically for harsh environment applications.

The market demonstrates particular interest in self-powered sensors for predictive maintenance applications, where continuous monitoring can prevent catastrophic equipment failures and optimize maintenance schedules. Environmental monitoring represents another high-growth application area, with increasing regulatory pressure driving demand for reliable long-term monitoring solutions in challenging outdoor conditions.

Supply chain considerations are becoming increasingly important in the harsh environment sensor market, with customers placing greater emphasis on secure sourcing, component traceability, and resilience against disruptions. This trend favors manufacturers with diversified supply chains and vertical integration capabilities.

Current Challenges in Harsh Environment Sensing

The deployment of self-powered sensors in harsh environments presents significant technical challenges that must be addressed to ensure reliable operation. These environments, characterized by extreme temperatures, high pressure, corrosive substances, intense radiation, or mechanical stress, impose severe constraints on sensor durability and functionality. Traditional sensing technologies often fail prematurely when exposed to such conditions, leading to system failures and increased maintenance costs.

Temperature extremes represent one of the most formidable challenges. In industrial settings like steel mills or deep-sea oil drilling operations, sensors must withstand temperatures ranging from -40°C to over 1000°C. These thermal stresses accelerate material degradation, affect electronic component performance, and compromise power harvesting efficiency in self-powered systems. Current energy harvesting mechanisms, particularly those based on thermoelectric or piezoelectric principles, show significant performance degradation at temperature extremes.

Chemical corrosion poses another critical challenge, especially in environments containing acids, bases, or reactive gases. The corrosive agents can rapidly degrade sensor housings, electronic components, and energy harvesting elements. While protective coatings offer some defense, they often deteriorate over time, particularly when subjected to temperature cycling or mechanical stress. The development of cost-effective, long-lasting protective solutions remains an ongoing challenge.

Mechanical stress, including vibration, shock, and abrasion, represents a significant threat to sensor integrity. In applications such as aerospace, mining, or heavy machinery monitoring, sensors experience continuous mechanical forces that can lead to structural fatigue, connection failures, and calibration drift. Self-powered sensors face the additional challenge of maintaining stable energy harvesting under these dynamic conditions.

Radiation exposure in nuclear facilities, space applications, or certain medical environments can cause semiconductor degradation, alter material properties, and induce electronic malfunctions. Current radiation-hardening techniques often result in bulkier designs or reduced performance, creating a difficult trade-off between durability and functionality.

Power management presents perhaps the most fundamental challenge for self-powered sensors in harsh environments. Energy harvesting mechanisms must not only survive harsh conditions but maintain sufficient output to power sensing, processing, and communication functions. Current energy storage solutions, including specialized batteries and supercapacitors, show limited lifespans in extreme conditions, often becoming the weakest link in otherwise robust systems.

Reliability validation methodologies represent another significant challenge. Accelerated life testing protocols for harsh environments are often inadequate, failing to accurately predict real-world performance. This leads to uncertainty in lifetime estimates and makes it difficult to compare competing technologies objectively.

Temperature extremes represent one of the most formidable challenges. In industrial settings like steel mills or deep-sea oil drilling operations, sensors must withstand temperatures ranging from -40°C to over 1000°C. These thermal stresses accelerate material degradation, affect electronic component performance, and compromise power harvesting efficiency in self-powered systems. Current energy harvesting mechanisms, particularly those based on thermoelectric or piezoelectric principles, show significant performance degradation at temperature extremes.

Chemical corrosion poses another critical challenge, especially in environments containing acids, bases, or reactive gases. The corrosive agents can rapidly degrade sensor housings, electronic components, and energy harvesting elements. While protective coatings offer some defense, they often deteriorate over time, particularly when subjected to temperature cycling or mechanical stress. The development of cost-effective, long-lasting protective solutions remains an ongoing challenge.

Mechanical stress, including vibration, shock, and abrasion, represents a significant threat to sensor integrity. In applications such as aerospace, mining, or heavy machinery monitoring, sensors experience continuous mechanical forces that can lead to structural fatigue, connection failures, and calibration drift. Self-powered sensors face the additional challenge of maintaining stable energy harvesting under these dynamic conditions.

Radiation exposure in nuclear facilities, space applications, or certain medical environments can cause semiconductor degradation, alter material properties, and induce electronic malfunctions. Current radiation-hardening techniques often result in bulkier designs or reduced performance, creating a difficult trade-off between durability and functionality.

Power management presents perhaps the most fundamental challenge for self-powered sensors in harsh environments. Energy harvesting mechanisms must not only survive harsh conditions but maintain sufficient output to power sensing, processing, and communication functions. Current energy storage solutions, including specialized batteries and supercapacitors, show limited lifespans in extreme conditions, often becoming the weakest link in otherwise robust systems.

Reliability validation methodologies represent another significant challenge. Accelerated life testing protocols for harsh environments are often inadequate, failing to accurately predict real-world performance. This leads to uncertainty in lifetime estimates and makes it difficult to compare competing technologies objectively.

Current Durability Solutions for Self-Powered Sensors

01 Energy harvesting mechanisms for self-powered sensors

Various energy harvesting mechanisms can be employed to power sensors autonomously, enhancing their durability by eliminating the need for battery replacement. These mechanisms include piezoelectric generators, solar cells, thermoelectric generators, and electromagnetic harvesters that convert ambient energy from the environment into electrical power. The integration of these energy harvesting technologies enables sensors to operate continuously in remote or inaccessible locations, significantly extending their operational lifespan.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be integrated into self-powered sensors to enhance their durability and operational lifespan. These mechanisms include piezoelectric, thermoelectric, and photovoltaic systems that convert ambient energy into electrical power. By incorporating efficient energy harvesting technologies, sensors can operate autonomously for extended periods without requiring battery replacement, significantly improving their durability in field applications.

- Protective encapsulation and packaging techniques: Advanced encapsulation and packaging methods play a crucial role in enhancing the durability of self-powered sensors. These techniques include hermetic sealing, conformal coating, and specialized polymer encapsulation that protect sensitive electronic components from environmental factors such as moisture, dust, and chemical exposure. Proper encapsulation extends sensor lifespan by preventing degradation of both the sensing elements and energy harvesting components.

- Materials selection for harsh environment operation: The selection of durable materials is essential for self-powered sensors deployed in harsh environments. Advanced materials such as corrosion-resistant alloys, high-temperature ceramics, and specialized polymers can significantly enhance sensor durability. These materials protect against extreme temperatures, chemical exposure, mechanical stress, and radiation, ensuring reliable long-term operation of both sensing elements and power generation components.

- Power management and consumption optimization: Efficient power management systems are critical for extending the operational life of self-powered sensors. These include ultra-low-power microcontrollers, adaptive sampling rates, and intelligent sleep modes that minimize energy consumption. Advanced power conditioning circuits ensure optimal utilization of harvested energy, while energy storage solutions such as supercapacitors and thin-film batteries provide reliable power during periods of insufficient energy harvesting.

- Redundancy and self-healing capabilities: Incorporating redundancy and self-healing capabilities significantly enhances the durability of self-powered sensors. These features include redundant sensing elements, fault-tolerant architectures, and self-diagnostic algorithms that can detect and compensate for component degradation. Some advanced sensors incorporate self-repair mechanisms such as reconfigurable circuits and adaptive algorithms that maintain functionality even when individual components fail, thereby extending overall system lifespan.

02 Protective encapsulation and packaging techniques

Advanced encapsulation and packaging methods are crucial for enhancing the durability of self-powered sensors. These techniques include hermetic sealing, conformal coating, and specialized polymer encapsulation that protect sensitive electronic components from environmental factors such as moisture, dust, and chemical exposure. Robust packaging designs also incorporate shock-absorbing materials and reinforced structures to withstand mechanical stress and vibration, thereby extending the operational lifetime of self-powered sensing systems in harsh environments.Expand Specific Solutions03 Low-power consumption circuit designs

Innovative low-power circuit designs are essential for maximizing the durability of self-powered sensors. These designs incorporate ultra-low-power microcontrollers, sleep modes, and efficient power management systems that minimize energy consumption during operation. Advanced circuit architectures also include adaptive sampling rates and intelligent power distribution networks that optimize energy usage based on environmental conditions and sensing requirements, ensuring sustained operation even with limited energy harvesting capabilities.Expand Specific Solutions04 Environmental adaptation and resilience features

Self-powered sensors with enhanced durability incorporate environmental adaptation and resilience features that allow them to function reliably under varying conditions. These features include temperature compensation circuits, humidity-resistant components, and anti-corrosion materials that maintain sensor performance despite environmental fluctuations. Some designs also implement self-healing mechanisms and redundant systems that can recover from damage or component failure, ensuring continuous operation in challenging environments such as industrial settings, outdoor installations, or extreme weather conditions.Expand Specific Solutions05 Integrated power storage and management systems

Advanced self-powered sensors incorporate integrated power storage and management systems to enhance durability and reliability. These systems include high-efficiency energy storage components such as supercapacitors or solid-state batteries combined with intelligent power management algorithms. The integration enables effective energy buffering during periods of abundant energy harvesting and controlled distribution during low-energy periods. Additionally, these systems often feature health monitoring capabilities that track power system performance over time, allowing for predictive maintenance and extending the overall operational lifespan of the sensing device.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The self-powered sensor durability market in harsh environments is in a growth phase, with increasing demand driven by IoT applications and industrial automation. The market is projected to reach significant scale as industries seek maintenance-free monitoring solutions. Technologically, academic institutions like Chongqing University, Shandong University, and California Institute of Technology are advancing fundamental research, while commercial players demonstrate varying maturity levels. EnOcean leads in energy harvesting sensors, with major corporations like Lockheed Martin, State Grid, and Boeing developing specialized applications. Chinese institutions collaborate closely with State Grid Corporation, creating a competitive ecosystem where partnerships between academia and industry are accelerating innovation and practical deployment capabilities.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced self-powered sensor systems for extreme military and aerospace environments. Their HUMS (Health and Usage Monitoring Systems) incorporate piezoelectric energy harvesters that convert vibration energy from aircraft engines and structures into electrical power for wireless sensors[1]. These systems can withstand extreme temperature fluctuations (-55°C to +125°C), high-G forces (up to 20G continuous), and electromagnetic interference common in military applications. Lockheed's proprietary sensor encapsulation technology utilizes ceramic-metal composites and specialized conformal coatings that provide protection against chemical exposure, salt fog, and radiation[2]. Their sensors employ redundant power harvesting mechanisms, combining vibration energy with thermoelectric generators that leverage temperature differentials in aircraft engines to ensure continuous operation even when one energy source is compromised[3]. The company has also pioneered self-healing sensor networks that can reconfigure communication pathways when individual nodes are damaged in hostile environments.

Strengths: Military-grade durability with proven performance in combat environments; sophisticated power management algorithms that maximize sensor lifetime; advanced encryption and security features protecting transmitted data. Weaknesses: Extremely high cost limiting commercial applications; significant weight compared to commercial alternatives; proprietary protocols requiring specialized integration with existing systems.

EnOcean GmbH

Technical Solution: EnOcean has pioneered self-powered wireless sensor technology specifically designed for harsh environments. Their patented energy harvesting technology combines multiple sources (solar, thermal, kinetic, RF) to power sensors without batteries. Their Dolphin platform integrates ultra-low power electronics with efficient energy harvesting modules capable of operating in temperature ranges from -40°C to +85°C[1]. EnOcean's sensors incorporate specialized encapsulation techniques using industrial-grade polymers that provide IP67-rated protection against dust and water immersion[2]. Their self-powered sensors utilize proprietary wireless protocols operating in sub-GHz bands (868MHz in Europe, 902MHz in North America) that offer superior penetration through walls and obstacles compared to 2.4GHz alternatives, making them ideal for industrial environments with significant interference[3].

Strengths: Industry-leading energy harvesting efficiency (converting as little as 50μW into usable power); maintenance-free operation with 20+ year lifespan; interoperability with major building automation protocols. Weaknesses: Higher initial cost compared to battery-powered alternatives; limited data transmission rates (typically 125 kbps); requires minimum ambient energy levels to function reliably.

Critical Technologies for Environmental Resilience

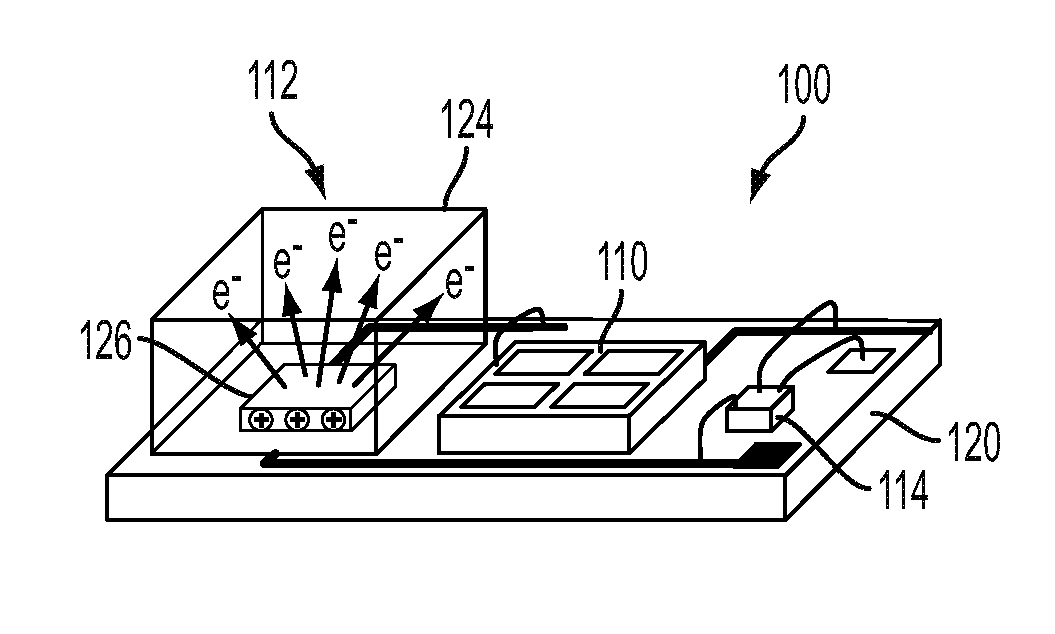

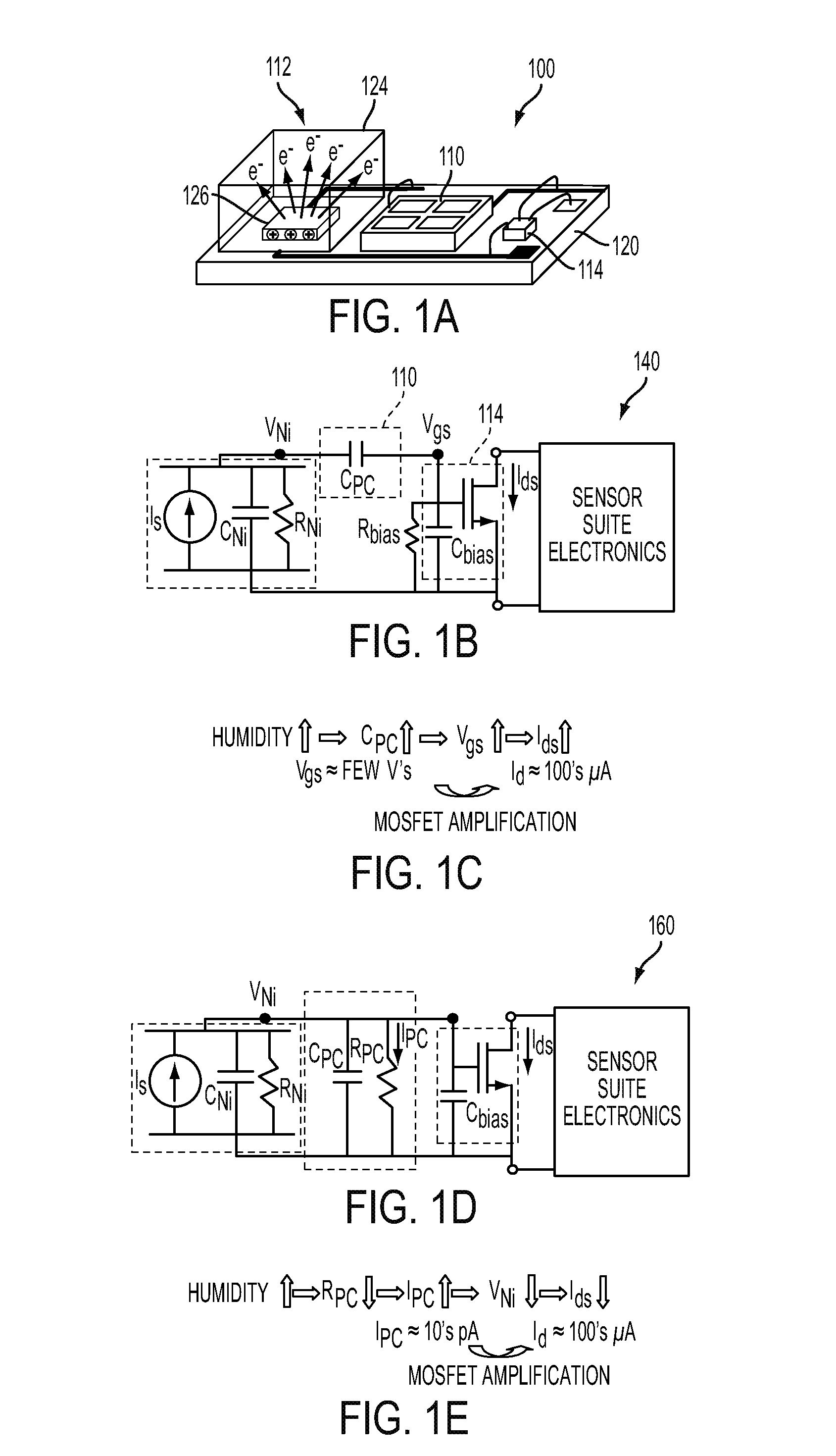

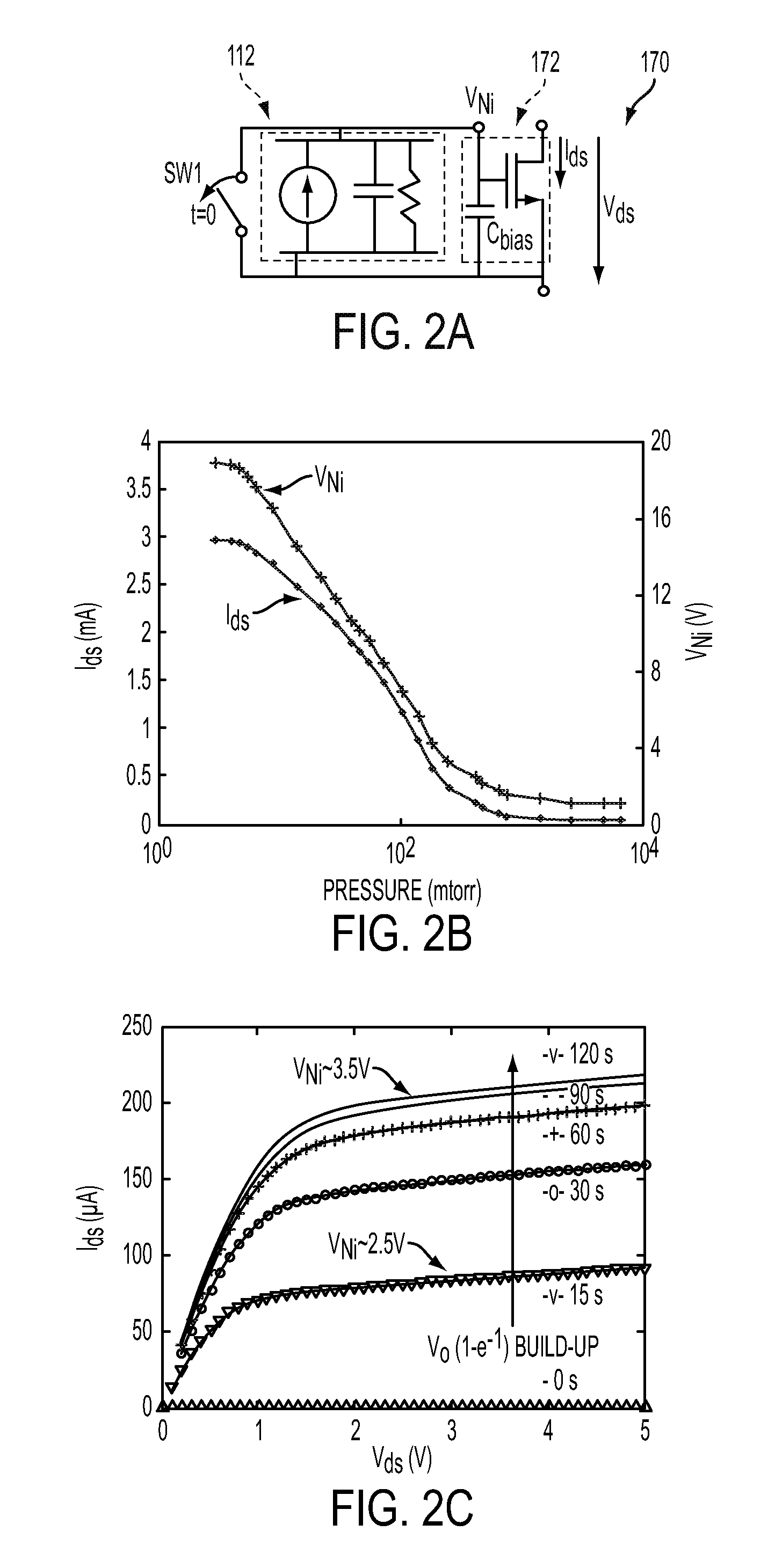

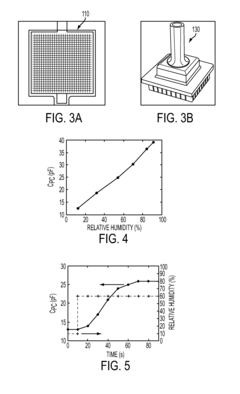

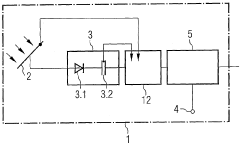

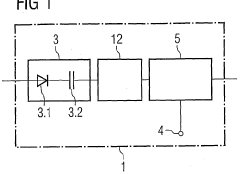

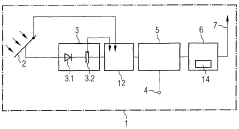

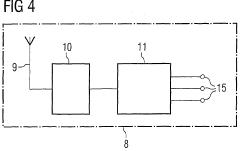

Self-powered environmental sensor with wake-up circuitry

PatentInactiveUS8309942B2

Innovation

- The development of zero-power sensors using radioisotope-powered humidity and temperature sensors with self-powered capacitors and mechanical amplifiers, employing Nickel-63 as a safe radioisotope source, which modulates conductance in MOSFETs for energy-efficient operation and high sensitivity detection.

Sensor

PatentWO2004065908A2

Innovation

- A self-sufficient sensor system utilizing a photovoltaic element to generate electrical voltage from ambient light, coupled with a storage element and timer circuit to manage energy use, allowing intermittent operation and wireless transmission of data, eliminating the need for batteries and reducing energy consumption.

Material Science Advancements for Sensor Protection

Recent advancements in material science have revolutionized the protection mechanisms for self-powered sensors operating in harsh environments. Traditional protective materials have been significantly enhanced through the development of composite structures that combine multiple functional layers. These next-generation materials exhibit superior resistance to extreme temperatures, chemical exposure, and mechanical stress while maintaining the operational efficiency of the underlying sensors.

Ceramic-polymer hybrid coatings represent a breakthrough in sensor protection technology. These materials leverage the thermal stability of ceramics and the flexibility of polymers to create protective layers that can withstand temperatures ranging from -60°C to 300°C. Research conducted at MIT and Stanford University has demonstrated that incorporating nanoparticles of silicon carbide and aluminum oxide into fluoropolymer matrices can enhance thermal conductivity while maintaining excellent electrical insulation properties.

Graphene-based protective films have emerged as another promising solution for sensor protection. With a thickness of just a few nanometers, these films provide exceptional barrier properties against corrosive gases and liquids while allowing the transmission of mechanical forces necessary for energy harvesting in self-powered sensors. Recent studies have shown that functionalized graphene oxide layers can self-heal minor damages through reversible hydrogen bonding mechanisms, extending the operational lifetime of sensors by up to 300%.

Biomimetic approaches have inspired a new class of adaptive protective materials. These smart coatings can respond to environmental changes by altering their physical or chemical properties. For instance, materials inspired by the lotus leaf demonstrate superhydrophobic characteristics that prevent water and contaminant accumulation on sensor surfaces. Similarly, materials modeled after the skin of certain deep-sea creatures can withstand extreme pressures while maintaining flexibility.

Metal-organic frameworks (MOFs) have been engineered specifically for sensor protection in chemically aggressive environments. These crystalline materials feature customizable pore sizes that can selectively filter harmful molecules while allowing smaller analytes to reach the sensing elements. Recent developments in MOF synthesis have produced variants stable in pH ranges from 1 to 14 and resistant to organic solvents commonly found in industrial settings.

Radiation-hardened composites incorporating boron nitride nanotubes and lead-free perovskites have shown remarkable resistance to ionizing radiation, making them suitable for sensor protection in nuclear facilities and space applications. These materials maintain their structural integrity after exposure to radiation doses exceeding 1 MGy, significantly outperforming conventional radiation shields while adding minimal weight to sensor packages.

Ceramic-polymer hybrid coatings represent a breakthrough in sensor protection technology. These materials leverage the thermal stability of ceramics and the flexibility of polymers to create protective layers that can withstand temperatures ranging from -60°C to 300°C. Research conducted at MIT and Stanford University has demonstrated that incorporating nanoparticles of silicon carbide and aluminum oxide into fluoropolymer matrices can enhance thermal conductivity while maintaining excellent electrical insulation properties.

Graphene-based protective films have emerged as another promising solution for sensor protection. With a thickness of just a few nanometers, these films provide exceptional barrier properties against corrosive gases and liquids while allowing the transmission of mechanical forces necessary for energy harvesting in self-powered sensors. Recent studies have shown that functionalized graphene oxide layers can self-heal minor damages through reversible hydrogen bonding mechanisms, extending the operational lifetime of sensors by up to 300%.

Biomimetic approaches have inspired a new class of adaptive protective materials. These smart coatings can respond to environmental changes by altering their physical or chemical properties. For instance, materials inspired by the lotus leaf demonstrate superhydrophobic characteristics that prevent water and contaminant accumulation on sensor surfaces. Similarly, materials modeled after the skin of certain deep-sea creatures can withstand extreme pressures while maintaining flexibility.

Metal-organic frameworks (MOFs) have been engineered specifically for sensor protection in chemically aggressive environments. These crystalline materials feature customizable pore sizes that can selectively filter harmful molecules while allowing smaller analytes to reach the sensing elements. Recent developments in MOF synthesis have produced variants stable in pH ranges from 1 to 14 and resistant to organic solvents commonly found in industrial settings.

Radiation-hardened composites incorporating boron nitride nanotubes and lead-free perovskites have shown remarkable resistance to ionizing radiation, making them suitable for sensor protection in nuclear facilities and space applications. These materials maintain their structural integrity after exposure to radiation doses exceeding 1 MGy, significantly outperforming conventional radiation shields while adding minimal weight to sensor packages.

Environmental Testing Standards and Certification

Environmental testing standards and certification play a crucial role in validating the durability claims of self-powered sensors designed for harsh environments. These standards provide structured methodologies to simulate extreme conditions and establish benchmarks for performance evaluation across different industries and applications.

The International Electrotechnical Commission (IEC) offers several relevant standards, including IEC 60068 for environmental testing of electronic equipment. This comprehensive standard covers temperature extremes, humidity, vibration, shock, and corrosion resistance—all critical factors for self-powered sensors deployed in challenging settings. Similarly, MIL-STD-810 from the U.S. Department of Defense provides rigorous testing protocols specifically designed for military equipment operating in severe conditions.

For sensors deployed in industrial environments, the IP (Ingress Protection) rating system defined by IEC 60529 has become the de facto standard. Ratings such as IP67 or IP68 indicate protection levels against dust and water ingress, essential characteristics for self-powered sensors exposed to particulates and moisture. The NEMA (National Electrical Manufacturers Association) ratings complement these standards, particularly for enclosures housing sensitive electronic components.

Industry-specific certifications further validate sensor durability in specialized applications. ATEX and IECEx certifications are mandatory for equipment operating in potentially explosive atmospheres, while maritime applications require compliance with standards from organizations like DNV GL or the American Bureau of Shipping. For automotive applications, the AEC-Q100 qualification provides standardized stress tests for integrated circuits.

Certification processes typically involve third-party testing laboratories that conduct standardized tests under controlled conditions. These tests include thermal cycling, salt fog exposure, mechanical shock, vibration analysis, and accelerated aging. The documentation resulting from these tests serves as objective evidence of a sensor's durability claims and often becomes a competitive differentiator in the marketplace.

Recent developments in testing standards have begun to address the unique challenges of energy harvesting components in self-powered sensors. Standards organizations are developing new protocols specifically for evaluating energy harvesting efficiency under variable environmental conditions, recognizing that power generation capability directly impacts the overall durability and reliability of self-powered sensing systems.

Compliance with these standards not only validates technical performance but also facilitates market access across different regions and industries. Many regulatory frameworks require certification to specific environmental standards before permitting deployment in critical infrastructure, industrial facilities, or consumer applications.

The International Electrotechnical Commission (IEC) offers several relevant standards, including IEC 60068 for environmental testing of electronic equipment. This comprehensive standard covers temperature extremes, humidity, vibration, shock, and corrosion resistance—all critical factors for self-powered sensors deployed in challenging settings. Similarly, MIL-STD-810 from the U.S. Department of Defense provides rigorous testing protocols specifically designed for military equipment operating in severe conditions.

For sensors deployed in industrial environments, the IP (Ingress Protection) rating system defined by IEC 60529 has become the de facto standard. Ratings such as IP67 or IP68 indicate protection levels against dust and water ingress, essential characteristics for self-powered sensors exposed to particulates and moisture. The NEMA (National Electrical Manufacturers Association) ratings complement these standards, particularly for enclosures housing sensitive electronic components.

Industry-specific certifications further validate sensor durability in specialized applications. ATEX and IECEx certifications are mandatory for equipment operating in potentially explosive atmospheres, while maritime applications require compliance with standards from organizations like DNV GL or the American Bureau of Shipping. For automotive applications, the AEC-Q100 qualification provides standardized stress tests for integrated circuits.

Certification processes typically involve third-party testing laboratories that conduct standardized tests under controlled conditions. These tests include thermal cycling, salt fog exposure, mechanical shock, vibration analysis, and accelerated aging. The documentation resulting from these tests serves as objective evidence of a sensor's durability claims and often becomes a competitive differentiator in the marketplace.

Recent developments in testing standards have begun to address the unique challenges of energy harvesting components in self-powered sensors. Standards organizations are developing new protocols specifically for evaluating energy harvesting efficiency under variable environmental conditions, recognizing that power generation capability directly impacts the overall durability and reliability of self-powered sensing systems.

Compliance with these standards not only validates technical performance but also facilitates market access across different regions and industries. Many regulatory frameworks require certification to specific environmental standards before permitting deployment in critical infrastructure, industrial facilities, or consumer applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!