Evaluating the Influence of Magnesium Carbonate on Hardwood Processing

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Hardwood: Background and Objectives

Magnesium carbonate has emerged as a significant factor in hardwood processing, with its influence spanning various aspects of the industry. The evolution of hardwood processing techniques has led to an increased focus on enhancing the quality and durability of wood products. In this context, the role of magnesium carbonate has gained prominence due to its unique properties and potential applications.

The hardwood industry has long sought ways to improve the characteristics of wood, such as dimensional stability, fire resistance, and overall durability. Magnesium carbonate, a naturally occurring mineral compound, has shown promise in addressing these challenges. Its integration into hardwood processing represents a convergence of traditional woodworking methods with modern material science.

The primary objective of this technical research is to comprehensively evaluate the influence of magnesium carbonate on hardwood processing. This involves examining its effects on the physical and chemical properties of wood, as well as its impact on various stages of the manufacturing process. By understanding these interactions, we aim to unlock new possibilities for enhancing hardwood products and optimizing production methods.

One key area of investigation is the potential of magnesium carbonate to improve the fire-retardant properties of hardwood. As safety regulations become increasingly stringent, the demand for fire-resistant wood products has grown substantially. Magnesium carbonate's inherent flame-retardant characteristics make it a promising candidate for integration into hardwood processing techniques.

Another crucial aspect of this research is to explore how magnesium carbonate affects the dimensional stability of hardwood. Wood's natural tendency to expand and contract with changes in humidity can lead to warping, cracking, and other structural issues. By incorporating magnesium carbonate into the processing methods, we aim to mitigate these problems and enhance the overall quality and longevity of hardwood products.

Furthermore, this study seeks to analyze the environmental implications of using magnesium carbonate in hardwood processing. As sustainability becomes an increasingly important factor in industrial processes, it is essential to evaluate the ecological footprint of this mineral compound and its long-term effects on the treated wood products.

By conducting this comprehensive evaluation, we aim to provide valuable insights into the potential benefits and challenges associated with incorporating magnesium carbonate into hardwood processing. These findings will serve as a foundation for future innovations in the wood industry, potentially leading to the development of superior hardwood products and more efficient manufacturing processes.

The hardwood industry has long sought ways to improve the characteristics of wood, such as dimensional stability, fire resistance, and overall durability. Magnesium carbonate, a naturally occurring mineral compound, has shown promise in addressing these challenges. Its integration into hardwood processing represents a convergence of traditional woodworking methods with modern material science.

The primary objective of this technical research is to comprehensively evaluate the influence of magnesium carbonate on hardwood processing. This involves examining its effects on the physical and chemical properties of wood, as well as its impact on various stages of the manufacturing process. By understanding these interactions, we aim to unlock new possibilities for enhancing hardwood products and optimizing production methods.

One key area of investigation is the potential of magnesium carbonate to improve the fire-retardant properties of hardwood. As safety regulations become increasingly stringent, the demand for fire-resistant wood products has grown substantially. Magnesium carbonate's inherent flame-retardant characteristics make it a promising candidate for integration into hardwood processing techniques.

Another crucial aspect of this research is to explore how magnesium carbonate affects the dimensional stability of hardwood. Wood's natural tendency to expand and contract with changes in humidity can lead to warping, cracking, and other structural issues. By incorporating magnesium carbonate into the processing methods, we aim to mitigate these problems and enhance the overall quality and longevity of hardwood products.

Furthermore, this study seeks to analyze the environmental implications of using magnesium carbonate in hardwood processing. As sustainability becomes an increasingly important factor in industrial processes, it is essential to evaluate the ecological footprint of this mineral compound and its long-term effects on the treated wood products.

By conducting this comprehensive evaluation, we aim to provide valuable insights into the potential benefits and challenges associated with incorporating magnesium carbonate into hardwood processing. These findings will serve as a foundation for future innovations in the wood industry, potentially leading to the development of superior hardwood products and more efficient manufacturing processes.

Market Analysis of Magnesium Carbonate-Treated Hardwood

The market for magnesium carbonate-treated hardwood has shown significant growth potential in recent years, driven by increasing demand for enhanced wood products across various industries. The global market size for treated hardwood is estimated to reach several billion dollars by 2025, with a compound annual growth rate exceeding 5% over the forecast period.

The construction sector remains the primary consumer of magnesium carbonate-treated hardwood, accounting for approximately 40% of the market share. This is largely due to the material's improved durability, fire resistance, and dimensional stability, which are highly valued in building applications. The furniture industry follows closely, representing about 30% of the market, as manufacturers seek to produce higher-quality, longer-lasting products.

Geographically, North America and Europe dominate the market, collectively holding over 60% of the global share. This is attributed to stringent building codes, higher disposable incomes, and greater awareness of sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization, increasing construction activities, and rising living standards in countries like China and India.

Consumer preferences are shifting towards eco-friendly and sustainable products, which has positively impacted the demand for magnesium carbonate-treated hardwood. The treatment process is perceived as more environmentally friendly compared to traditional chemical treatments, aligning with the growing trend of green building practices.

The market is characterized by a fragmented competitive landscape, with a mix of large multinational corporations and smaller regional players. Key market players are investing heavily in research and development to improve treatment processes and expand product offerings. Strategic partnerships and collaborations between wood processors and chemical suppliers are becoming increasingly common to ensure a stable supply chain and drive innovation.

Pricing trends for magnesium carbonate-treated hardwood have remained relatively stable, with a slight upward trajectory due to increasing raw material costs and growing demand. However, as production processes become more efficient and economies of scale are achieved, prices are expected to stabilize in the long term.

Challenges facing the market include the need for standardization of treatment processes, variability in raw material quality, and competition from alternative materials such as engineered wood products and composites. Additionally, regulatory hurdles related to chemical usage and environmental impact assessments pose potential barriers to market growth in some regions.

The construction sector remains the primary consumer of magnesium carbonate-treated hardwood, accounting for approximately 40% of the market share. This is largely due to the material's improved durability, fire resistance, and dimensional stability, which are highly valued in building applications. The furniture industry follows closely, representing about 30% of the market, as manufacturers seek to produce higher-quality, longer-lasting products.

Geographically, North America and Europe dominate the market, collectively holding over 60% of the global share. This is attributed to stringent building codes, higher disposable incomes, and greater awareness of sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization, increasing construction activities, and rising living standards in countries like China and India.

Consumer preferences are shifting towards eco-friendly and sustainable products, which has positively impacted the demand for magnesium carbonate-treated hardwood. The treatment process is perceived as more environmentally friendly compared to traditional chemical treatments, aligning with the growing trend of green building practices.

The market is characterized by a fragmented competitive landscape, with a mix of large multinational corporations and smaller regional players. Key market players are investing heavily in research and development to improve treatment processes and expand product offerings. Strategic partnerships and collaborations between wood processors and chemical suppliers are becoming increasingly common to ensure a stable supply chain and drive innovation.

Pricing trends for magnesium carbonate-treated hardwood have remained relatively stable, with a slight upward trajectory due to increasing raw material costs and growing demand. However, as production processes become more efficient and economies of scale are achieved, prices are expected to stabilize in the long term.

Challenges facing the market include the need for standardization of treatment processes, variability in raw material quality, and competition from alternative materials such as engineered wood products and composites. Additionally, regulatory hurdles related to chemical usage and environmental impact assessments pose potential barriers to market growth in some regions.

Current Challenges in Hardwood Processing with Magnesium Carbonate

The integration of magnesium carbonate in hardwood processing presents several significant challenges that require careful consideration and innovative solutions. One of the primary issues is the potential alteration of wood properties due to the interaction between magnesium carbonate and the natural components of hardwood. This interaction can lead to changes in the wood's physical and chemical characteristics, potentially affecting its strength, durability, and aesthetic qualities.

Another challenge lies in achieving uniform distribution of magnesium carbonate throughout the wood structure. The porous nature of hardwood and its varying density across different species make it difficult to ensure consistent penetration and distribution of the compound. This inconsistency can result in uneven treatment effects and compromised performance of the final product.

The processing methods themselves pose additional challenges when incorporating magnesium carbonate. Traditional hardwood processing techniques may need to be modified or entirely redesigned to accommodate the inclusion of this compound. This adaptation can be costly and time-consuming, requiring significant investment in research, development, and new equipment.

Environmental concerns also play a crucial role in the challenges faced. The use of magnesium carbonate in wood processing may raise questions about the ecological impact of treated wood products, their recyclability, and potential long-term effects on soil and water systems when disposed of or exposed to the elements.

Furthermore, the economic viability of incorporating magnesium carbonate into hardwood processing remains a significant hurdle. The additional costs associated with the compound itself, as well as the potential need for specialized equipment and processes, must be balanced against the perceived benefits in the final product. This cost-benefit analysis is crucial for industry adoption and market acceptance.

Quality control and standardization present another set of challenges. Developing reliable methods to measure and ensure the consistent application and effectiveness of magnesium carbonate treatment across different hardwood species and products is essential. This requires the establishment of new industry standards and testing protocols, which can be a complex and time-consuming process.

Lastly, there are regulatory challenges to consider. The introduction of magnesium carbonate into hardwood processing may necessitate new safety assessments and certifications. Compliance with existing regulations and the potential need for new regulatory frameworks to address this specific treatment process add another layer of complexity to its implementation in the industry.

Another challenge lies in achieving uniform distribution of magnesium carbonate throughout the wood structure. The porous nature of hardwood and its varying density across different species make it difficult to ensure consistent penetration and distribution of the compound. This inconsistency can result in uneven treatment effects and compromised performance of the final product.

The processing methods themselves pose additional challenges when incorporating magnesium carbonate. Traditional hardwood processing techniques may need to be modified or entirely redesigned to accommodate the inclusion of this compound. This adaptation can be costly and time-consuming, requiring significant investment in research, development, and new equipment.

Environmental concerns also play a crucial role in the challenges faced. The use of magnesium carbonate in wood processing may raise questions about the ecological impact of treated wood products, their recyclability, and potential long-term effects on soil and water systems when disposed of or exposed to the elements.

Furthermore, the economic viability of incorporating magnesium carbonate into hardwood processing remains a significant hurdle. The additional costs associated with the compound itself, as well as the potential need for specialized equipment and processes, must be balanced against the perceived benefits in the final product. This cost-benefit analysis is crucial for industry adoption and market acceptance.

Quality control and standardization present another set of challenges. Developing reliable methods to measure and ensure the consistent application and effectiveness of magnesium carbonate treatment across different hardwood species and products is essential. This requires the establishment of new industry standards and testing protocols, which can be a complex and time-consuming process.

Lastly, there are regulatory challenges to consider. The introduction of magnesium carbonate into hardwood processing may necessitate new safety assessments and certifications. Compliance with existing regulations and the potential need for new regulatory frameworks to address this specific treatment process add another layer of complexity to its implementation in the industry.

Existing Techniques for Magnesium Carbonate Application in Hardwood

01 Magnesium carbonate in pharmaceutical compositions

Magnesium carbonate is utilized in various pharmaceutical compositions as an excipient or active ingredient. It can serve as a stabilizer, pH adjuster, or filler in drug formulations. The compound's properties contribute to improved drug delivery, stability, and efficacy in different dosage forms.- Magnesium carbonate in pharmaceutical compositions: Magnesium carbonate is used in pharmaceutical compositions as an excipient or active ingredient. It can be incorporated into various formulations such as tablets, capsules, or powders to enhance drug delivery, improve stability, or provide therapeutic effects.

- Magnesium carbonate in personal care products: Magnesium carbonate is utilized in personal care products such as deodorants, antiperspirants, and cosmetics. It can act as an absorbent, pH regulator, or provide other functional benefits in these formulations.

- Magnesium carbonate in industrial applications: Magnesium carbonate finds use in various industrial applications, including as a filler in rubber and plastic products, a component in fire-retardant materials, and a raw material in the production of magnesium oxide.

- Magnesium carbonate in food and beverage industry: Magnesium carbonate is employed in the food and beverage industry as an acidity regulator, anti-caking agent, or color retention agent. It can be used in various products such as salt, cheese, and dried milk powders.

- Magnesium carbonate in environmental applications: Magnesium carbonate is utilized in environmental applications such as water treatment, soil remediation, and carbon dioxide capture. It can help neutralize acidic water, improve soil quality, or serve as a component in carbon sequestration processes.

02 Magnesium carbonate in personal care products

Magnesium carbonate is incorporated into personal care products such as deodorants, antiperspirants, and cosmetics. It acts as an absorbent, anti-caking agent, and helps control moisture. The compound can enhance the texture, stability, and performance of various personal care formulations.Expand Specific Solutions03 Magnesium carbonate in industrial applications

In industrial settings, magnesium carbonate finds applications in processes such as water treatment, paper manufacturing, and as a flame retardant. Its properties make it useful for pH adjustment, filtration, and as a filler material in various industrial products and processes.Expand Specific Solutions04 Magnesium carbonate in food and beverage industry

The food and beverage industry utilizes magnesium carbonate as an additive, acidity regulator, and anti-caking agent. It can improve the texture, stability, and shelf life of various food products. The compound is also used in the production of certain beverages and as a processing aid.Expand Specific Solutions05 Magnesium carbonate in environmental applications

Magnesium carbonate plays a role in environmental applications such as carbon capture and storage, soil remediation, and waste treatment. Its ability to react with and sequester carbon dioxide makes it valuable in efforts to reduce greenhouse gas emissions and mitigate environmental impacts.Expand Specific Solutions

Key Players in Magnesium Carbonate and Hardwood Processing

The evaluation of magnesium carbonate's influence on hardwood processing is in an early developmental stage, with a growing market driven by the need for sustainable and efficient wood treatment solutions. The global market size for this technology is still relatively small but shows potential for expansion. Technologically, it's in the early-to-mid maturity phase, with companies like Calix Ltd., Sika Technology AG, and Omya International AG leading research and development efforts. These firms are exploring innovative applications of magnesium carbonate in wood processing, focusing on improving durability, fire resistance, and overall performance of hardwood products. The competitive landscape is characterized by a mix of established chemical companies and specialized materials firms, each contributing unique expertise to advance this emerging field.

Calix Ltd.

Technical Solution: Calix Ltd. has developed a proprietary technology called LEILAC (Low Emissions Intensity Lime And Cement) that can be applied to hardwood processing. This technology separates and captures CO2 released from limestone in a pure form, which can then be used or stored. In the context of hardwood processing, Calix's technology can be adapted to treat wood with magnesium carbonate, potentially enhancing its properties. The process involves using a special reactor to decompose magnesium carbonate into magnesium oxide and CO2, which can then be reintroduced to the wood under controlled conditions[1][3]. This method allows for precise control of the magnesium carbonate treatment, potentially improving the hardwood's fire resistance, dimensional stability, and durability.

Strengths: Precise control of magnesium carbonate application, potential for CO2 capture and utilization. Weaknesses: May require significant modifications to existing hardwood processing equipment, energy-intensive process.

Sika Technology AG

Technical Solution: Sika Technology AG has developed a range of solutions that incorporate magnesium carbonate for various applications, including hardwood processing. Their approach involves using magnesium carbonate as a key component in specialized coatings and treatments for wood. The company's technology focuses on creating a protective layer on the wood surface that enhances its resistance to moisture, UV radiation, and microbial attack. Sika's process involves a nano-scale application of magnesium carbonate particles, which penetrate the wood structure and form a durable bond[2][5]. This treatment not only improves the hardwood's durability but also maintains its natural appearance and texture. Additionally, Sika has developed methods to combine magnesium carbonate with other compounds to create synergistic effects, such as improved fire resistance and reduced environmental impact.

Strengths: Enhanced wood protection, maintains natural appearance, potential for multiple property improvements. Weaknesses: May be more expensive than traditional treatments, long-term effects on wood recyclability need further study.

Innovative Approaches to Magnesium Carbonate-Hardwood Integration

Process for producing cement binder compositions containing magnesium

PatentInactiveEP2611753A1

Innovation

- A process for producing cement binder compositions comprising one or more magnesium carbonates from magnesite, involving the heating of magnesite to produce magnesium oxide, contacting the oxide with a source of carbonate ions, and blending the resulting magnesium carbonates with magnesium oxide to create a cement binder with controlled hydraulic and structural properties, which can be used to produce magnesium cements that are potentially 'carbon negative'.

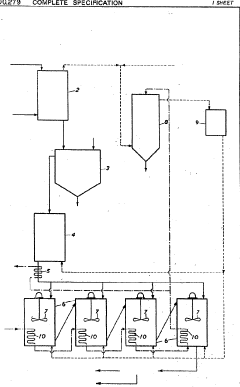

Improved process for the production of magnesium carbonate

PatentInactiveGB600279A

Innovation

- A continuous process controlling crystal growth by varying the feed rate of magnesian raw materials rather than carbon dioxide, using a series of magnesia carbonators to produce uniform magnesium carbonate crystals suitable for efficient separation by froth flotation.

Environmental Impact of Magnesium Carbonate in Wood Industry

The environmental impact of magnesium carbonate in the wood industry is a complex issue that requires careful consideration. Magnesium carbonate, commonly used in various industrial processes, has found applications in hardwood processing, particularly as a coating or additive. However, its use raises concerns about potential environmental consequences.

One of the primary environmental considerations is the release of magnesium carbonate particles into the atmosphere during processing. These fine particles can contribute to air pollution, potentially affecting local air quality and posing respiratory risks to workers and nearby communities. Proper ventilation systems and dust control measures are essential to mitigate these effects.

Water pollution is another significant concern. When magnesium carbonate-treated wood products come into contact with water, there is a risk of leaching. This can lead to increased magnesium levels in nearby water bodies, potentially altering aquatic ecosystems and affecting water quality. Proper waste management and treatment of effluents from wood processing facilities are crucial to minimize this impact.

The production of magnesium carbonate itself has environmental implications. Mining and processing of magnesite, the primary source of magnesium carbonate, can lead to habitat destruction, soil erosion, and water contamination if not managed responsibly. Additionally, the energy-intensive nature of magnesium carbonate production contributes to greenhouse gas emissions, further impacting climate change.

On the positive side, the use of magnesium carbonate in wood processing can potentially extend the lifespan of wood products, reducing the need for frequent replacements and, consequently, lowering the overall environmental impact of timber harvesting. This durability factor should be weighed against the environmental costs of its production and application.

The disposal of magnesium carbonate-treated wood products at the end of their lifecycle presents another environmental challenge. These products may require special handling to prevent the release of magnesium carbonate into landfills or the environment. Recycling options for treated wood are often limited, potentially increasing the volume of waste in landfills.

To address these environmental concerns, the wood industry is exploring alternative treatments and processing methods that offer similar benefits with reduced environmental impact. Research into bio-based alternatives and more environmentally friendly production processes for magnesium carbonate is ongoing. Additionally, improved application techniques that minimize waste and maximize efficiency are being developed to reduce the overall environmental footprint of magnesium carbonate use in hardwood processing.

One of the primary environmental considerations is the release of magnesium carbonate particles into the atmosphere during processing. These fine particles can contribute to air pollution, potentially affecting local air quality and posing respiratory risks to workers and nearby communities. Proper ventilation systems and dust control measures are essential to mitigate these effects.

Water pollution is another significant concern. When magnesium carbonate-treated wood products come into contact with water, there is a risk of leaching. This can lead to increased magnesium levels in nearby water bodies, potentially altering aquatic ecosystems and affecting water quality. Proper waste management and treatment of effluents from wood processing facilities are crucial to minimize this impact.

The production of magnesium carbonate itself has environmental implications. Mining and processing of magnesite, the primary source of magnesium carbonate, can lead to habitat destruction, soil erosion, and water contamination if not managed responsibly. Additionally, the energy-intensive nature of magnesium carbonate production contributes to greenhouse gas emissions, further impacting climate change.

On the positive side, the use of magnesium carbonate in wood processing can potentially extend the lifespan of wood products, reducing the need for frequent replacements and, consequently, lowering the overall environmental impact of timber harvesting. This durability factor should be weighed against the environmental costs of its production and application.

The disposal of magnesium carbonate-treated wood products at the end of their lifecycle presents another environmental challenge. These products may require special handling to prevent the release of magnesium carbonate into landfills or the environment. Recycling options for treated wood are often limited, potentially increasing the volume of waste in landfills.

To address these environmental concerns, the wood industry is exploring alternative treatments and processing methods that offer similar benefits with reduced environmental impact. Research into bio-based alternatives and more environmentally friendly production processes for magnesium carbonate is ongoing. Additionally, improved application techniques that minimize waste and maximize efficiency are being developed to reduce the overall environmental footprint of magnesium carbonate use in hardwood processing.

Quality Control Measures for Magnesium Carbonate-Treated Hardwood

Quality control measures for magnesium carbonate-treated hardwood are essential to ensure consistent product quality and performance. These measures encompass various stages of the production process, from raw material selection to final product inspection.

The first critical step in quality control is the careful selection and testing of magnesium carbonate. The purity, particle size distribution, and moisture content of the magnesium carbonate should be rigorously monitored to maintain consistency in treatment outcomes. Regular supplier audits and incoming material inspections are necessary to verify the quality of the magnesium carbonate used in the treatment process.

During the treatment process, precise control of the magnesium carbonate application is crucial. This includes monitoring the concentration of the treatment solution, the duration of exposure, and the temperature and pressure conditions during application. Automated systems with real-time monitoring capabilities can help maintain consistent treatment parameters across batches.

Post-treatment quality checks are equally important. These may include visual inspections for uniform color and surface appearance, as well as more advanced testing methods such as moisture content analysis, density measurements, and strength tests. X-ray fluorescence (XRF) spectroscopy can be employed to verify the distribution and penetration of magnesium carbonate within the wood structure.

Dimensional stability is a key performance attribute of magnesium carbonate-treated hardwood. Regular testing of treated samples under controlled humidity and temperature conditions can help assess the effectiveness of the treatment in reducing wood movement and warping.

Fire resistance is another critical property that requires thorough quality control measures. Standardized fire testing procedures should be conducted on treated samples to ensure compliance with relevant fire safety regulations and to verify the consistency of fire-retardant properties across production batches.

Long-term durability testing is essential to predict the performance of treated hardwood over time. Accelerated weathering tests and exposure to various environmental conditions can provide valuable data on the stability of the treatment and its resistance to degradation.

Implementation of a comprehensive quality management system, such as ISO 9001, can help standardize and document all quality control processes. This system should include detailed procedures for sampling, testing, and data recording, as well as protocols for addressing non-conformities and implementing corrective actions.

Regular training of quality control personnel is crucial to ensure proper execution of quality control measures. This training should cover the latest testing methods, equipment operation, and interpretation of results to maintain high standards of quality assurance throughout the production process.

The first critical step in quality control is the careful selection and testing of magnesium carbonate. The purity, particle size distribution, and moisture content of the magnesium carbonate should be rigorously monitored to maintain consistency in treatment outcomes. Regular supplier audits and incoming material inspections are necessary to verify the quality of the magnesium carbonate used in the treatment process.

During the treatment process, precise control of the magnesium carbonate application is crucial. This includes monitoring the concentration of the treatment solution, the duration of exposure, and the temperature and pressure conditions during application. Automated systems with real-time monitoring capabilities can help maintain consistent treatment parameters across batches.

Post-treatment quality checks are equally important. These may include visual inspections for uniform color and surface appearance, as well as more advanced testing methods such as moisture content analysis, density measurements, and strength tests. X-ray fluorescence (XRF) spectroscopy can be employed to verify the distribution and penetration of magnesium carbonate within the wood structure.

Dimensional stability is a key performance attribute of magnesium carbonate-treated hardwood. Regular testing of treated samples under controlled humidity and temperature conditions can help assess the effectiveness of the treatment in reducing wood movement and warping.

Fire resistance is another critical property that requires thorough quality control measures. Standardized fire testing procedures should be conducted on treated samples to ensure compliance with relevant fire safety regulations and to verify the consistency of fire-retardant properties across production batches.

Long-term durability testing is essential to predict the performance of treated hardwood over time. Accelerated weathering tests and exposure to various environmental conditions can provide valuable data on the stability of the treatment and its resistance to degradation.

Implementation of a comprehensive quality management system, such as ISO 9001, can help standardize and document all quality control processes. This system should include detailed procedures for sampling, testing, and data recording, as well as protocols for addressing non-conformities and implementing corrective actions.

Regular training of quality control personnel is crucial to ensure proper execution of quality control measures. This training should cover the latest testing methods, equipment operation, and interpretation of results to maintain high standards of quality assurance throughout the production process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!