How Magnesium Carbonate Reduces Scalability in Heat Exchangers

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MgCO3 Scale Formation Background and Objectives

Magnesium carbonate (MgCO3) scale formation in heat exchangers has been a persistent challenge in various industries, particularly in cooling systems and geothermal power plants. This issue has gained significant attention over the past few decades due to its detrimental effects on heat transfer efficiency and equipment longevity. The formation of MgCO3 scale is a complex process influenced by multiple factors, including water chemistry, temperature, pressure, and flow conditions.

The historical context of this problem dates back to the early days of industrial heat exchanger applications. As industries expanded and the demand for efficient heat transfer systems grew, the negative impacts of scale formation became increasingly apparent. Early research in the 1950s and 1960s focused primarily on calcium carbonate scale, but as understanding of water chemistry evolved, the role of magnesium carbonate in scale formation came to the forefront.

The evolution of this technical challenge has been marked by several key milestones. In the 1970s and 1980s, researchers began to develop more sophisticated models to predict scale formation, incorporating factors such as supersaturation, nucleation, and crystal growth kinetics. The 1990s saw a shift towards understanding the molecular-level interactions between scale-forming species and heat exchanger surfaces, leading to the development of novel surface treatments and coatings.

Current research trends in MgCO3 scale mitigation focus on several key areas. These include the development of advanced anti-scaling chemicals, innovative heat exchanger designs that minimize scale accumulation, and the use of real-time monitoring and predictive maintenance techniques. Additionally, there is growing interest in leveraging nanotechnology and smart materials to create self-cleaning surfaces that actively resist scale formation.

The primary objective of ongoing research and development efforts is to significantly reduce or eliminate MgCO3 scale formation in heat exchangers. This goal encompasses several specific aims: enhancing heat transfer efficiency, extending equipment lifespan, reducing maintenance costs, and improving overall system reliability. Researchers are also striving to develop environmentally friendly solutions that align with increasingly stringent regulations on chemical usage and water treatment.

Looking ahead, the field is moving towards more holistic and sustainable approaches to scale management. This includes integrating scale mitigation strategies with overall water and energy management practices, as well as exploring the potential of circular economy principles in industrial cooling systems. The ultimate aim is to achieve a balance between operational efficiency, economic viability, and environmental sustainability in heat exchanger applications affected by MgCO3 scale formation.

The historical context of this problem dates back to the early days of industrial heat exchanger applications. As industries expanded and the demand for efficient heat transfer systems grew, the negative impacts of scale formation became increasingly apparent. Early research in the 1950s and 1960s focused primarily on calcium carbonate scale, but as understanding of water chemistry evolved, the role of magnesium carbonate in scale formation came to the forefront.

The evolution of this technical challenge has been marked by several key milestones. In the 1970s and 1980s, researchers began to develop more sophisticated models to predict scale formation, incorporating factors such as supersaturation, nucleation, and crystal growth kinetics. The 1990s saw a shift towards understanding the molecular-level interactions between scale-forming species and heat exchanger surfaces, leading to the development of novel surface treatments and coatings.

Current research trends in MgCO3 scale mitigation focus on several key areas. These include the development of advanced anti-scaling chemicals, innovative heat exchanger designs that minimize scale accumulation, and the use of real-time monitoring and predictive maintenance techniques. Additionally, there is growing interest in leveraging nanotechnology and smart materials to create self-cleaning surfaces that actively resist scale formation.

The primary objective of ongoing research and development efforts is to significantly reduce or eliminate MgCO3 scale formation in heat exchangers. This goal encompasses several specific aims: enhancing heat transfer efficiency, extending equipment lifespan, reducing maintenance costs, and improving overall system reliability. Researchers are also striving to develop environmentally friendly solutions that align with increasingly stringent regulations on chemical usage and water treatment.

Looking ahead, the field is moving towards more holistic and sustainable approaches to scale management. This includes integrating scale mitigation strategies with overall water and energy management practices, as well as exploring the potential of circular economy principles in industrial cooling systems. The ultimate aim is to achieve a balance between operational efficiency, economic viability, and environmental sustainability in heat exchanger applications affected by MgCO3 scale formation.

Market Demand for Scale-Resistant Heat Exchangers

The market demand for scale-resistant heat exchangers has been steadily increasing across various industries due to the growing awareness of the detrimental effects of scale formation on equipment efficiency and operational costs. Heat exchangers are critical components in numerous industrial processes, including power generation, chemical manufacturing, food processing, and HVAC systems. As these industries strive for improved energy efficiency and reduced maintenance costs, the need for heat exchangers that can resist scale buildup has become paramount.

In the power generation sector, scale-resistant heat exchangers are particularly sought after in cooling towers and condensers. The formation of scale in these systems can lead to reduced heat transfer efficiency, increased energy consumption, and more frequent maintenance shutdowns. According to industry reports, power plants equipped with scale-resistant heat exchangers have reported up to 15% improvement in overall plant efficiency and significant reductions in maintenance costs.

The chemical manufacturing industry has also shown a strong demand for scale-resistant heat exchangers. In processes involving high-temperature reactions or the handling of mineral-rich fluids, scale formation can severely impact production rates and product quality. Companies in this sector are increasingly investing in advanced heat exchanger technologies that can withstand harsh operating conditions while minimizing scale buildup.

In the food and beverage industry, where hygiene and product quality are of utmost importance, scale-resistant heat exchangers have gained traction. These systems help maintain consistent product quality by preventing contamination from scale particles and reducing the need for frequent cleaning cycles. This has led to increased production efficiency and compliance with stringent food safety regulations.

The HVAC industry has seen a surge in demand for scale-resistant heat exchangers in both residential and commercial applications. As energy efficiency standards become more stringent, building owners and facility managers are recognizing the long-term benefits of installing heat exchangers that can maintain their performance over extended periods without frequent descaling treatments.

Market analysts project that the global scale-resistant heat exchanger market will experience substantial growth in the coming years. Factors driving this growth include increasing industrialization in developing countries, stricter environmental regulations, and the push for energy-efficient technologies. Additionally, the rising costs associated with equipment downtime and maintenance have made scale-resistant heat exchangers an attractive investment for many businesses.

As the demand for scale-resistant heat exchangers continues to rise, manufacturers are investing in research and development to create more effective and cost-efficient solutions. This includes exploring new materials, surface treatments, and design innovations that can further enhance the scale-resistant properties of heat exchangers while maintaining or improving their heat transfer capabilities.

In the power generation sector, scale-resistant heat exchangers are particularly sought after in cooling towers and condensers. The formation of scale in these systems can lead to reduced heat transfer efficiency, increased energy consumption, and more frequent maintenance shutdowns. According to industry reports, power plants equipped with scale-resistant heat exchangers have reported up to 15% improvement in overall plant efficiency and significant reductions in maintenance costs.

The chemical manufacturing industry has also shown a strong demand for scale-resistant heat exchangers. In processes involving high-temperature reactions or the handling of mineral-rich fluids, scale formation can severely impact production rates and product quality. Companies in this sector are increasingly investing in advanced heat exchanger technologies that can withstand harsh operating conditions while minimizing scale buildup.

In the food and beverage industry, where hygiene and product quality are of utmost importance, scale-resistant heat exchangers have gained traction. These systems help maintain consistent product quality by preventing contamination from scale particles and reducing the need for frequent cleaning cycles. This has led to increased production efficiency and compliance with stringent food safety regulations.

The HVAC industry has seen a surge in demand for scale-resistant heat exchangers in both residential and commercial applications. As energy efficiency standards become more stringent, building owners and facility managers are recognizing the long-term benefits of installing heat exchangers that can maintain their performance over extended periods without frequent descaling treatments.

Market analysts project that the global scale-resistant heat exchanger market will experience substantial growth in the coming years. Factors driving this growth include increasing industrialization in developing countries, stricter environmental regulations, and the push for energy-efficient technologies. Additionally, the rising costs associated with equipment downtime and maintenance have made scale-resistant heat exchangers an attractive investment for many businesses.

As the demand for scale-resistant heat exchangers continues to rise, manufacturers are investing in research and development to create more effective and cost-efficient solutions. This includes exploring new materials, surface treatments, and design innovations that can further enhance the scale-resistant properties of heat exchangers while maintaining or improving their heat transfer capabilities.

Current Challenges in MgCO3 Scale Mitigation

The mitigation of magnesium carbonate (MgCO3) scale in heat exchangers presents several significant challenges that continue to plague industrial processes. One of the primary obstacles is the rapid formation and accumulation of MgCO3 deposits on heat transfer surfaces, which drastically reduces the efficiency of heat exchange systems. This scaling process is particularly problematic in industries such as desalination plants, power generation facilities, and chemical processing plants, where high temperatures and mineral-rich water are common.

The complex chemistry of MgCO3 scale formation poses another major challenge. Unlike some other types of scale, MgCO3 precipitation is highly dependent on temperature, pH, and the presence of other ions in the system. This complexity makes it difficult to predict and control scale formation accurately, leading to unexpected maintenance issues and system downtime.

Furthermore, the tenacious nature of MgCO3 scale presents significant removal difficulties. Traditional descaling methods, such as acid cleaning or mechanical scraping, often prove inadequate or potentially damaging to the heat exchanger surfaces. This necessitates the development of more sophisticated and less invasive removal techniques, which can be both costly and time-consuming to implement.

Another critical challenge lies in the development of effective scale inhibitors specifically tailored for MgCO3. While various chemical treatments exist for other types of scale, finding a solution that effectively prevents or slows MgCO3 formation without negatively impacting the overall system performance or environmental safety remains an ongoing struggle for researchers and engineers.

The environmental impact of scale mitigation strategies also presents a significant challenge. Many traditional anti-scaling chemicals are harmful to aquatic ecosystems when discharged, leading to increased regulatory scrutiny and the need for more environmentally friendly alternatives. This environmental concern adds another layer of complexity to the already challenging task of MgCO3 scale management.

Lastly, the economic implications of MgCO3 scaling are substantial. The reduced heat transfer efficiency leads to increased energy consumption, while frequent maintenance and cleaning operations result in higher operational costs and production losses. Developing cost-effective solutions that balance performance, environmental safety, and economic viability remains a key challenge in the field of MgCO3 scale mitigation.

The complex chemistry of MgCO3 scale formation poses another major challenge. Unlike some other types of scale, MgCO3 precipitation is highly dependent on temperature, pH, and the presence of other ions in the system. This complexity makes it difficult to predict and control scale formation accurately, leading to unexpected maintenance issues and system downtime.

Furthermore, the tenacious nature of MgCO3 scale presents significant removal difficulties. Traditional descaling methods, such as acid cleaning or mechanical scraping, often prove inadequate or potentially damaging to the heat exchanger surfaces. This necessitates the development of more sophisticated and less invasive removal techniques, which can be both costly and time-consuming to implement.

Another critical challenge lies in the development of effective scale inhibitors specifically tailored for MgCO3. While various chemical treatments exist for other types of scale, finding a solution that effectively prevents or slows MgCO3 formation without negatively impacting the overall system performance or environmental safety remains an ongoing struggle for researchers and engineers.

The environmental impact of scale mitigation strategies also presents a significant challenge. Many traditional anti-scaling chemicals are harmful to aquatic ecosystems when discharged, leading to increased regulatory scrutiny and the need for more environmentally friendly alternatives. This environmental concern adds another layer of complexity to the already challenging task of MgCO3 scale management.

Lastly, the economic implications of MgCO3 scaling are substantial. The reduced heat transfer efficiency leads to increased energy consumption, while frequent maintenance and cleaning operations result in higher operational costs and production losses. Developing cost-effective solutions that balance performance, environmental safety, and economic viability remains a key challenge in the field of MgCO3 scale mitigation.

Existing MgCO3 Scale Reduction Solutions

01 Production methods for magnesium carbonate

Various methods for producing magnesium carbonate at scale have been developed. These include precipitation reactions, carbonation processes, and the use of different magnesium sources. The scalability of these methods depends on factors such as raw material availability, reaction conditions, and equipment design.- Production methods for magnesium carbonate: Various methods for producing magnesium carbonate at scale have been developed. These include precipitation reactions, carbonation processes, and the use of different magnesium sources. The scalability of these methods depends on factors such as raw material availability, reaction conditions, and equipment design.

- Particle size control and morphology optimization: Techniques for controlling the particle size and morphology of magnesium carbonate during production have been developed to enhance its properties and scalability. These methods involve adjusting reaction parameters, using additives, and employing specialized equipment to achieve desired particle characteristics.

- Continuous production processes: Continuous production processes for magnesium carbonate have been designed to improve scalability and efficiency. These processes involve the use of specialized reactors, continuous flow systems, and automated control mechanisms to enable large-scale production with consistent quality.

- Purification and quality control methods: Various purification and quality control methods have been developed to ensure the production of high-quality magnesium carbonate at scale. These include filtration techniques, washing processes, and advanced analytical methods to monitor and control product purity and consistency.

- Sustainable and eco-friendly production: Sustainable and eco-friendly production methods for magnesium carbonate have been explored to improve scalability while reducing environmental impact. These approaches include the use of waste materials as raw sources, energy-efficient processes, and the development of closed-loop systems for resource recovery.

02 Particle size control and morphology optimization

Techniques for controlling the particle size and morphology of magnesium carbonate during production have been developed to enhance its properties for various applications. These methods involve adjusting reaction parameters, using additives, or employing specific processing techniques to achieve desired characteristics at scale.Expand Specific Solutions03 Purification and quality control processes

Scalable purification and quality control processes have been implemented to ensure the production of high-quality magnesium carbonate. These processes may include filtration, washing, drying, and analytical techniques to maintain consistent product quality in large-scale manufacturing.Expand Specific Solutions04 Equipment and process design for large-scale production

Specialized equipment and process designs have been developed to facilitate the large-scale production of magnesium carbonate. These innovations focus on improving efficiency, reducing energy consumption, and optimizing material handling in industrial settings.Expand Specific Solutions05 Applications and market demand driving scalability

The increasing demand for magnesium carbonate in various industries, such as pharmaceuticals, construction, and environmental applications, has driven the development of scalable production methods. Research has focused on meeting specific application requirements while ensuring cost-effective and sustainable large-scale manufacturing processes.Expand Specific Solutions

Key Players in Heat Exchanger Industry

The competition landscape for magnesium carbonate's impact on heat exchanger scalability is in a mature phase, with established players and ongoing research. The global heat exchanger market, valued at over $15 billion, is expected to grow steadily due to increasing industrial applications. Technologically, companies like ExxonMobil Technology & Engineering Co., Sanden Corp., and Johnson Controls-Hitachi Air Conditioning are at the forefront, developing advanced solutions to mitigate scaling issues. Academic institutions such as China University of Mining & Technology and the Technical University of Berlin contribute to fundamental research, while industrial giants like Siemens AG and Mitsubishi Electric Corp. focus on practical applications and system integration to address this challenge in various sectors.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced heat exchanger designs that mitigate magnesium carbonate scaling. Their approach involves using specialized coatings and surface treatments on heat exchanger surfaces to reduce scale adhesion. The company has also implemented innovative flow patterns and geometries that minimize areas prone to scale formation. Additionally, ExxonMobil has developed smart monitoring systems that detect early signs of scaling, allowing for timely maintenance interventions[1][3].

Strengths: Comprehensive approach combining material science and design innovations. Weaknesses: May require frequent maintenance and potential high initial costs for implementation.

Siemens AG

Technical Solution: Siemens has developed a multi-pronged strategy to address magnesium carbonate scaling in heat exchangers. Their approach includes the use of advanced materials with low surface energy to reduce scale adhesion, coupled with intelligent flow distribution systems that minimize stagnant zones where scaling is more likely to occur. Siemens has also implemented ultrasonic technology for continuous scale prevention and removal. Furthermore, they have developed AI-driven predictive maintenance algorithms that can forecast scaling issues before they become critical[2][5].

Strengths: Holistic approach combining material science, fluid dynamics, and AI. Weaknesses: High complexity may lead to increased costs and potential integration challenges in existing systems.

Core Innovations in Anti-Scaling Technologies

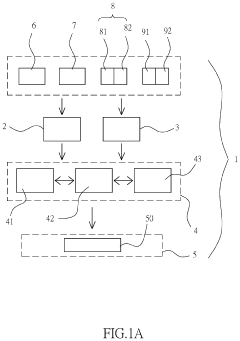

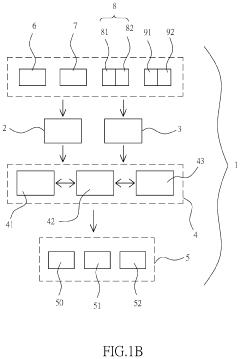

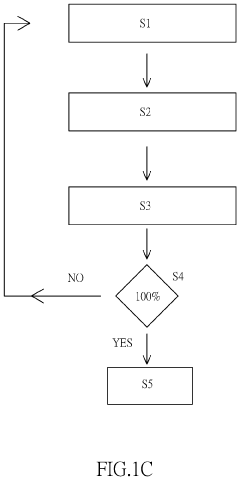

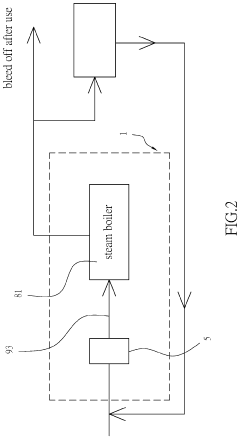

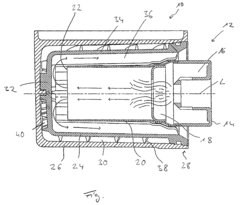

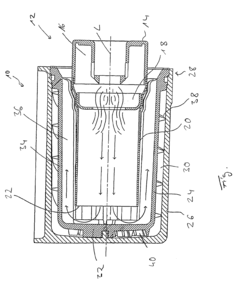

Heat exchange system having desired Anti-scaling performance and an Anti-scaling method thereof

PatentPendingUS20230392885A1

Innovation

- A heat exchange system with an integrated load control unit, temperature and pressure detection unit, and anti-scaling treatment unit that simulates field-like water quality to condition calcium ions and carbonate ions, preventing scaling formation through a fast anti-scaling performance testing method, ensuring 100% scale inhibition and enhancing operational efficiency.

Heat exchanger for a heater

PatentInactiveEP1541935A2

Innovation

- The use of a magnesium or magnesium-containing material for the outer heat exchanger housing, which has a lower thermal conductivity coefficient than aluminum, reduces heat transfer to the environment and enhances heat retention within the medium, while the inner heat exchanger housing, often made of aluminum, efficiently transfers heat from combustion exhaust gases to the medium.

Environmental Impact of Scale Inhibitors

The use of scale inhibitors, including magnesium carbonate, in heat exchangers has significant environmental implications that warrant careful consideration. While these inhibitors effectively reduce scale formation and improve heat transfer efficiency, their environmental impact extends beyond the immediate industrial setting.

One of the primary environmental concerns associated with scale inhibitors is their potential to contaminate water systems. When heat exchangers are flushed or cleaned, residual inhibitors can be released into wastewater streams. If not properly treated, these chemicals may find their way into natural water bodies, potentially affecting aquatic ecosystems. Magnesium carbonate, although less toxic than some other scale inhibitors, can still contribute to increased mineral content in water, potentially altering pH levels and affecting sensitive aquatic organisms.

The production and disposal of scale inhibitors also contribute to their environmental footprint. Manufacturing processes for these chemicals often involve energy-intensive operations and may result in greenhouse gas emissions. Additionally, the packaging and transportation of these products add to their overall carbon footprint. When considering the lifecycle of scale inhibitors, it's crucial to account for these indirect environmental impacts.

However, it's important to note that the use of scale inhibitors like magnesium carbonate can also have positive environmental effects. By improving the efficiency of heat exchangers, these inhibitors reduce energy consumption in industrial processes. This increased efficiency translates to lower fuel consumption and, consequently, reduced greenhouse gas emissions. In this context, the environmental benefits of using scale inhibitors may outweigh their potential negative impacts, especially when proper handling and disposal practices are implemented.

The long-term accumulation of scale inhibitors in the environment is another area of concern. While magnesium carbonate is generally considered less persistent than some synthetic inhibitors, its continuous use and release could lead to gradual buildup in sediments and soil. This accumulation may have unforeseen consequences on soil chemistry and microbial communities, potentially affecting terrestrial ecosystems in the vicinity of industrial sites.

To mitigate these environmental risks, industries are increasingly focusing on developing and implementing more environmentally friendly scale inhibition techniques. This includes exploring biodegradable alternatives, optimizing dosage to minimize excess chemical use, and improving wastewater treatment processes to remove residual inhibitors before discharge. Additionally, closed-loop systems that recycle and reuse treatment chemicals are being adopted to reduce the overall environmental impact of scale inhibition practices.

One of the primary environmental concerns associated with scale inhibitors is their potential to contaminate water systems. When heat exchangers are flushed or cleaned, residual inhibitors can be released into wastewater streams. If not properly treated, these chemicals may find their way into natural water bodies, potentially affecting aquatic ecosystems. Magnesium carbonate, although less toxic than some other scale inhibitors, can still contribute to increased mineral content in water, potentially altering pH levels and affecting sensitive aquatic organisms.

The production and disposal of scale inhibitors also contribute to their environmental footprint. Manufacturing processes for these chemicals often involve energy-intensive operations and may result in greenhouse gas emissions. Additionally, the packaging and transportation of these products add to their overall carbon footprint. When considering the lifecycle of scale inhibitors, it's crucial to account for these indirect environmental impacts.

However, it's important to note that the use of scale inhibitors like magnesium carbonate can also have positive environmental effects. By improving the efficiency of heat exchangers, these inhibitors reduce energy consumption in industrial processes. This increased efficiency translates to lower fuel consumption and, consequently, reduced greenhouse gas emissions. In this context, the environmental benefits of using scale inhibitors may outweigh their potential negative impacts, especially when proper handling and disposal practices are implemented.

The long-term accumulation of scale inhibitors in the environment is another area of concern. While magnesium carbonate is generally considered less persistent than some synthetic inhibitors, its continuous use and release could lead to gradual buildup in sediments and soil. This accumulation may have unforeseen consequences on soil chemistry and microbial communities, potentially affecting terrestrial ecosystems in the vicinity of industrial sites.

To mitigate these environmental risks, industries are increasingly focusing on developing and implementing more environmentally friendly scale inhibition techniques. This includes exploring biodegradable alternatives, optimizing dosage to minimize excess chemical use, and improving wastewater treatment processes to remove residual inhibitors before discharge. Additionally, closed-loop systems that recycle and reuse treatment chemicals are being adopted to reduce the overall environmental impact of scale inhibition practices.

Economic Analysis of Scaling Prevention Methods

The economic analysis of scaling prevention methods in heat exchangers is crucial for industries seeking to optimize their operational efficiency and reduce maintenance costs. When considering the use of magnesium carbonate as a scaling prevention method, several economic factors come into play.

Firstly, the initial investment in implementing magnesium carbonate treatment systems must be evaluated against the long-term benefits. This includes the cost of equipment, installation, and integration into existing heat exchanger systems. While the upfront costs may be significant, the potential savings in maintenance and energy efficiency can offset these expenses over time.

Operational costs associated with magnesium carbonate treatment are generally lower compared to other scaling prevention methods. The chemical itself is relatively inexpensive and readily available, which contributes to reduced ongoing expenses. Additionally, the dosing requirements are typically modest, further minimizing the recurring costs of treatment.

Energy efficiency gains represent a significant economic advantage of using magnesium carbonate. By preventing scale formation, heat exchangers maintain their optimal thermal transfer capabilities, reducing energy consumption and associated costs. This improved efficiency can lead to substantial savings, especially in large-scale industrial applications where even small improvements in energy usage can translate to significant financial benefits.

Maintenance cost reduction is another key economic factor. Magnesium carbonate's ability to prevent scaling reduces the frequency and extent of cleaning and descaling operations. This translates to lower labor costs, decreased downtime, and extended equipment lifespan. The reduction in mechanical cleaning also minimizes the risk of damage to heat exchanger surfaces, potentially avoiding costly repairs or premature equipment replacement.

When comparing magnesium carbonate to alternative scaling prevention methods, such as chemical treatments or water softening systems, a comprehensive cost-benefit analysis is essential. While some alternatives may have lower initial costs, their long-term operational expenses and effectiveness should be carefully considered. Magnesium carbonate often proves more economical over the equipment's lifecycle due to its low ongoing costs and high efficacy.

Environmental considerations also factor into the economic analysis. Magnesium carbonate is an environmentally friendly option, which can lead to cost savings related to regulatory compliance and waste disposal. This aspect is particularly relevant in industries facing stringent environmental regulations or those prioritizing sustainable operations.

In conclusion, the economic analysis of magnesium carbonate as a scaling prevention method in heat exchangers reveals a favorable cost-benefit ratio for many applications. While initial implementation costs may be a consideration, the long-term savings in energy, maintenance, and operational efficiency often justify the investment. As industries continue to seek ways to optimize their processes and reduce costs, magnesium carbonate treatment stands out as an economically viable solution for managing scale in heat exchangers.

Firstly, the initial investment in implementing magnesium carbonate treatment systems must be evaluated against the long-term benefits. This includes the cost of equipment, installation, and integration into existing heat exchanger systems. While the upfront costs may be significant, the potential savings in maintenance and energy efficiency can offset these expenses over time.

Operational costs associated with magnesium carbonate treatment are generally lower compared to other scaling prevention methods. The chemical itself is relatively inexpensive and readily available, which contributes to reduced ongoing expenses. Additionally, the dosing requirements are typically modest, further minimizing the recurring costs of treatment.

Energy efficiency gains represent a significant economic advantage of using magnesium carbonate. By preventing scale formation, heat exchangers maintain their optimal thermal transfer capabilities, reducing energy consumption and associated costs. This improved efficiency can lead to substantial savings, especially in large-scale industrial applications where even small improvements in energy usage can translate to significant financial benefits.

Maintenance cost reduction is another key economic factor. Magnesium carbonate's ability to prevent scaling reduces the frequency and extent of cleaning and descaling operations. This translates to lower labor costs, decreased downtime, and extended equipment lifespan. The reduction in mechanical cleaning also minimizes the risk of damage to heat exchanger surfaces, potentially avoiding costly repairs or premature equipment replacement.

When comparing magnesium carbonate to alternative scaling prevention methods, such as chemical treatments or water softening systems, a comprehensive cost-benefit analysis is essential. While some alternatives may have lower initial costs, their long-term operational expenses and effectiveness should be carefully considered. Magnesium carbonate often proves more economical over the equipment's lifecycle due to its low ongoing costs and high efficacy.

Environmental considerations also factor into the economic analysis. Magnesium carbonate is an environmentally friendly option, which can lead to cost savings related to regulatory compliance and waste disposal. This aspect is particularly relevant in industries facing stringent environmental regulations or those prioritizing sustainable operations.

In conclusion, the economic analysis of magnesium carbonate as a scaling prevention method in heat exchangers reveals a favorable cost-benefit ratio for many applications. While initial implementation costs may be a consideration, the long-term savings in energy, maintenance, and operational efficiency often justify the investment. As industries continue to seek ways to optimize their processes and reduce costs, magnesium carbonate treatment stands out as an economically viable solution for managing scale in heat exchangers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!