The Impact of Magnesium Carbonate in Reducing Food Processing Energies

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Food Processing: Background and Objectives

Magnesium carbonate has emerged as a promising compound in the food processing industry, offering potential benefits in reducing energy consumption during various stages of production. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternative methods to enhance food processing efficiency. As global energy concerns grew, the focus shifted towards identifying substances that could significantly impact energy reduction in food manufacturing.

The primary objective of utilizing magnesium carbonate in food processing is to decrease the overall energy requirements while maintaining or improving product quality. This aligns with the broader industry goals of sustainability and cost-effectiveness. By incorporating magnesium carbonate into food processing techniques, manufacturers aim to optimize thermal processes, reduce drying times, and enhance the overall efficiency of production lines.

The technological progression in this field has been marked by several key milestones. Initial studies focused on the basic properties of magnesium carbonate and its interactions with food components. As research advanced, scientists discovered its potential in modifying food textures and improving heat transfer during processing. This led to the development of novel applications in areas such as baking, dairy processing, and fruit preservation.

Recent trends indicate a growing interest in combining magnesium carbonate with other food-grade additives to create synergistic effects in energy reduction. The integration of this compound into existing food processing systems has prompted innovations in equipment design and process optimization. Researchers are now exploring nanotechnology applications of magnesium carbonate to further enhance its energy-saving properties.

The market demand for energy-efficient food processing solutions has been a significant driver in the advancement of magnesium carbonate technology. With increasing consumer awareness of environmental issues and stricter regulations on energy consumption, food manufacturers are actively seeking ways to reduce their carbon footprint. This has created a fertile ground for the development and adoption of magnesium carbonate-based solutions.

As we look towards the future, the objectives for magnesium carbonate in food processing are becoming more ambitious. There is a push towards achieving even greater energy reductions, expanding its applicability across a wider range of food products, and ensuring its compatibility with clean label trends. The ultimate goal is to establish magnesium carbonate as a standard component in energy-efficient food processing, contributing to a more sustainable and economically viable food industry.

The primary objective of utilizing magnesium carbonate in food processing is to decrease the overall energy requirements while maintaining or improving product quality. This aligns with the broader industry goals of sustainability and cost-effectiveness. By incorporating magnesium carbonate into food processing techniques, manufacturers aim to optimize thermal processes, reduce drying times, and enhance the overall efficiency of production lines.

The technological progression in this field has been marked by several key milestones. Initial studies focused on the basic properties of magnesium carbonate and its interactions with food components. As research advanced, scientists discovered its potential in modifying food textures and improving heat transfer during processing. This led to the development of novel applications in areas such as baking, dairy processing, and fruit preservation.

Recent trends indicate a growing interest in combining magnesium carbonate with other food-grade additives to create synergistic effects in energy reduction. The integration of this compound into existing food processing systems has prompted innovations in equipment design and process optimization. Researchers are now exploring nanotechnology applications of magnesium carbonate to further enhance its energy-saving properties.

The market demand for energy-efficient food processing solutions has been a significant driver in the advancement of magnesium carbonate technology. With increasing consumer awareness of environmental issues and stricter regulations on energy consumption, food manufacturers are actively seeking ways to reduce their carbon footprint. This has created a fertile ground for the development and adoption of magnesium carbonate-based solutions.

As we look towards the future, the objectives for magnesium carbonate in food processing are becoming more ambitious. There is a push towards achieving even greater energy reductions, expanding its applicability across a wider range of food products, and ensuring its compatibility with clean label trends. The ultimate goal is to establish magnesium carbonate as a standard component in energy-efficient food processing, contributing to a more sustainable and economically viable food industry.

Market Analysis for Energy-Efficient Food Processing

The food processing industry is experiencing a significant shift towards energy-efficient technologies and practices, driven by increasing energy costs, environmental concerns, and regulatory pressures. The market for energy-efficient food processing solutions is rapidly expanding, with a compound annual growth rate (CAGR) projected to exceed 7% over the next five years. This growth is fueled by the dual benefits of cost savings and reduced environmental impact that these technologies offer.

Consumer demand for sustainably produced food products is a key driver in this market. A recent survey indicates that over 60% of consumers are willing to pay a premium for food items produced using energy-efficient methods. This consumer preference is pushing food manufacturers to adopt more sustainable processing techniques, creating a ripple effect throughout the supply chain.

The global market for energy-efficient food processing equipment is diverse, with applications spanning various sectors including dairy, meat, bakery, and beverage industries. Among these, the dairy and meat processing sectors are showing the highest adoption rates of energy-efficient technologies, accounting for nearly 40% of the market share.

Geographically, North America and Europe are leading the market, owing to stringent energy regulations and higher awareness of sustainability issues. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization and increasing food safety concerns.

Key technologies in this market include advanced heat exchangers, energy-efficient drying systems, and innovative refrigeration solutions. The use of magnesium carbonate in food processing is gaining attention as a potential energy-saving technique, particularly in drying processes. Early adopters of this technology report energy savings of up to 15% in specific applications.

Market challenges include high initial investment costs for energy-efficient equipment and the need for specialized training for operators. However, the long-term cost savings and environmental benefits are increasingly outweighing these initial barriers.

Government initiatives and regulations promoting energy efficiency in industrial processes are playing a crucial role in market growth. For instance, the European Union's Energy Efficiency Directive has set targets for reducing energy consumption in industrial processes, including food manufacturing.

As the market matures, we anticipate a trend towards integrated energy management systems in food processing facilities. These systems will combine various energy-efficient technologies with smart monitoring and control mechanisms, offering holistic solutions for energy optimization across the entire production process.

Consumer demand for sustainably produced food products is a key driver in this market. A recent survey indicates that over 60% of consumers are willing to pay a premium for food items produced using energy-efficient methods. This consumer preference is pushing food manufacturers to adopt more sustainable processing techniques, creating a ripple effect throughout the supply chain.

The global market for energy-efficient food processing equipment is diverse, with applications spanning various sectors including dairy, meat, bakery, and beverage industries. Among these, the dairy and meat processing sectors are showing the highest adoption rates of energy-efficient technologies, accounting for nearly 40% of the market share.

Geographically, North America and Europe are leading the market, owing to stringent energy regulations and higher awareness of sustainability issues. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization and increasing food safety concerns.

Key technologies in this market include advanced heat exchangers, energy-efficient drying systems, and innovative refrigeration solutions. The use of magnesium carbonate in food processing is gaining attention as a potential energy-saving technique, particularly in drying processes. Early adopters of this technology report energy savings of up to 15% in specific applications.

Market challenges include high initial investment costs for energy-efficient equipment and the need for specialized training for operators. However, the long-term cost savings and environmental benefits are increasingly outweighing these initial barriers.

Government initiatives and regulations promoting energy efficiency in industrial processes are playing a crucial role in market growth. For instance, the European Union's Energy Efficiency Directive has set targets for reducing energy consumption in industrial processes, including food manufacturing.

As the market matures, we anticipate a trend towards integrated energy management systems in food processing facilities. These systems will combine various energy-efficient technologies with smart monitoring and control mechanisms, offering holistic solutions for energy optimization across the entire production process.

Current Challenges in Food Processing Energy Consumption

The food processing industry faces significant challenges in energy consumption, which have become increasingly critical in recent years. One of the primary concerns is the high energy intensity of various food processing operations, particularly in thermal processes such as cooking, drying, and sterilization. These processes often require substantial amounts of heat energy, leading to elevated operational costs and environmental impacts.

Another major challenge is the inefficiency of current processing equipment and systems. Many food processing facilities still rely on outdated machinery that consumes excessive energy and lacks modern energy-saving features. This inefficiency not only increases energy consumption but also affects product quality and production rates, creating a complex problem that impacts both sustainability and profitability.

The variability in food products and processing requirements further complicates energy management. Different food types and desired end products necessitate diverse processing conditions, making it difficult to implement standardized energy-saving solutions across the industry. This variability often results in suboptimal energy use as processors struggle to balance energy efficiency with product quality and safety requirements.

Additionally, the food processing industry faces challenges in energy recovery and waste heat utilization. A significant amount of thermal energy is often lost during processing, particularly in the form of waste heat from cooking and cooling operations. The inability to effectively capture and reuse this energy represents a substantial loss of resources and contributes to the overall energy inefficiency of food processing operations.

The increasing demand for processed foods, coupled with stricter food safety regulations, has led to more energy-intensive processing methods. Advanced preservation techniques and extended shelf-life requirements often necessitate additional processing steps, each consuming more energy. This trend towards more complex processing further exacerbates the energy consumption challenges faced by the industry.

Lastly, the integration of renewable energy sources and sustainable practices into food processing operations remains a significant challenge. While there is growing pressure to reduce carbon footprints and adopt greener technologies, the high initial costs and technical complexities of implementing renewable energy systems in food processing facilities often hinder widespread adoption. This creates a tension between the need for sustainability and the economic realities of the industry.

Another major challenge is the inefficiency of current processing equipment and systems. Many food processing facilities still rely on outdated machinery that consumes excessive energy and lacks modern energy-saving features. This inefficiency not only increases energy consumption but also affects product quality and production rates, creating a complex problem that impacts both sustainability and profitability.

The variability in food products and processing requirements further complicates energy management. Different food types and desired end products necessitate diverse processing conditions, making it difficult to implement standardized energy-saving solutions across the industry. This variability often results in suboptimal energy use as processors struggle to balance energy efficiency with product quality and safety requirements.

Additionally, the food processing industry faces challenges in energy recovery and waste heat utilization. A significant amount of thermal energy is often lost during processing, particularly in the form of waste heat from cooking and cooling operations. The inability to effectively capture and reuse this energy represents a substantial loss of resources and contributes to the overall energy inefficiency of food processing operations.

The increasing demand for processed foods, coupled with stricter food safety regulations, has led to more energy-intensive processing methods. Advanced preservation techniques and extended shelf-life requirements often necessitate additional processing steps, each consuming more energy. This trend towards more complex processing further exacerbates the energy consumption challenges faced by the industry.

Lastly, the integration of renewable energy sources and sustainable practices into food processing operations remains a significant challenge. While there is growing pressure to reduce carbon footprints and adopt greener technologies, the high initial costs and technical complexities of implementing renewable energy systems in food processing facilities often hinder widespread adoption. This creates a tension between the need for sustainability and the economic realities of the industry.

Existing Applications of Magnesium Carbonate in Food Processing

01 Use of magnesium carbonate in food processing

Magnesium carbonate is utilized in various food processing applications due to its properties as an anti-caking agent, pH regulator, and mineral supplement. It can improve the texture and stability of food products while providing nutritional benefits.- Use of magnesium carbonate in food processing: Magnesium carbonate is utilized in various food processing applications due to its properties as an anti-caking agent, pH regulator, and mineral supplement. It can improve the texture and stability of food products while providing nutritional benefits.

- Energy efficiency in magnesium carbonate production: Innovative methods are being developed to enhance energy efficiency in the production of magnesium carbonate for food applications. These techniques aim to reduce energy consumption and environmental impact while maintaining product quality.

- Magnesium carbonate in beverage processing: Magnesium carbonate is employed in beverage processing to adjust pH levels, improve mineral content, and enhance the overall stability of drinks. It can also contribute to the development of functional beverages with added health benefits.

- Magnesium carbonate as a processing aid in baking: In baking applications, magnesium carbonate serves as a processing aid to improve dough handling, texture, and shelf life of baked goods. It can also act as a leavening agent and contribute to the nutritional profile of the final product.

- Sustainable sourcing of magnesium carbonate for food processing: Research is being conducted on sustainable methods for sourcing and producing magnesium carbonate for food processing applications. This includes exploring alternative raw materials and eco-friendly extraction processes to meet the growing demand in the food industry.

02 Energy efficiency in magnesium carbonate production

Innovative methods are being developed to enhance energy efficiency in the production of magnesium carbonate for food processing applications. These techniques aim to reduce energy consumption and environmental impact while maintaining product quality.Expand Specific Solutions03 Magnesium carbonate as a functional ingredient

Research focuses on incorporating magnesium carbonate as a functional ingredient in food products to enhance nutritional value and improve product characteristics. This includes its use in fortified foods and beverages to address magnesium deficiencies.Expand Specific Solutions04 Sustainable production of magnesium carbonate

Efforts are being made to develop sustainable production methods for magnesium carbonate used in food processing. These methods aim to reduce carbon footprint and utilize renewable energy sources in the manufacturing process.Expand Specific Solutions05 Magnesium carbonate in food packaging and preservation

Innovative applications of magnesium carbonate in food packaging and preservation are being explored. These applications aim to extend shelf life, maintain food quality, and reduce energy consumption in storage and transportation.Expand Specific Solutions

Key Players in Food Processing and Additive Manufacturing

The impact of magnesium carbonate in reducing food processing energies is an emerging field with growing interest from both industry and academia. The market is in its early stages of development, with potential for significant growth as energy efficiency becomes increasingly important in food processing. The technology's maturity is still evolving, with various players at different stages of research and implementation. Companies like Calix Ltd. and Timab Magnesium SAS are leading the way in developing magnesium-based solutions, while academic institutions such as Hebei University of Science & Technology and Zhejiang University are contributing to fundamental research. Major industrial players like thyssenkrupp AG and BASF Corp. are also exploring applications, indicating the technology's potential for widespread adoption in the food processing sector.

Calix Ltd.

Technical Solution: Calix Ltd. has developed a proprietary technology called "Calix Flash Calcination" which can be applied to the production of magnesium carbonate. This process involves rapid heating of magnesium carbonate in a specialized reactor, resulting in a highly reactive product with increased surface area. In the context of food processing, this reactive magnesium carbonate can be used as an efficient pH regulator and anti-caking agent, potentially reducing the energy required in various food processing steps[1]. The company has also explored the use of their technology in creating advanced materials for energy-efficient building products, which could indirectly contribute to reducing energy consumption in food storage and processing facilities[2].

Strengths: Innovative calcination technology, potential for energy reduction in multiple industries. Weaknesses: May require significant initial investment for implementation in food processing facilities.

Timab Magnesium SAS

Technical Solution: Timab Magnesium SAS, a subsidiary of Groupe Roullier, specializes in the production and application of magnesium-based products, including magnesium carbonate for food processing. The company has developed a range of high-purity magnesium carbonate products under their "Timab Food" line, specifically designed for use in food and nutraceutical applications. These products are used as anti-caking agents and acidity regulators, potentially improving the efficiency of food processing operations and reducing energy consumption[9]. Timab has also invested in research on the use of magnesium carbonate in functional food formulations, which could lead to the development of energy-efficient, nutrient-dense food products[10].

Strengths: Specialized focus on magnesium products, expertise in food applications. Weaknesses: Limited scope compared to larger, diversified chemical companies.

Innovative Uses of Magnesium Carbonate for Energy Reduction

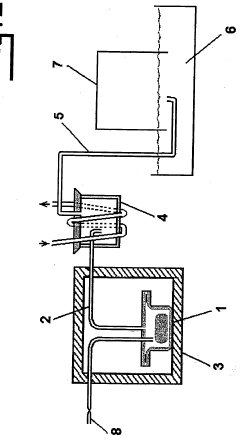

Process for production of magnesium carbonate

PatentInactiveGB595284A

Innovation

- A process involving controlled carbonation of a slurry containing magnesium oxide or hydroxide, with controlled carbonate concentration and agitation, to produce large-sized crystals of neutral magnesium carbonate, which can be separated from impurities, and further treated to achieve high purity magnesium compounds.

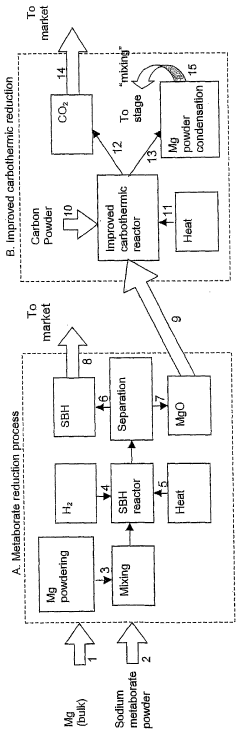

Elemental magnesium production by carbothermic reduction for use in the regeneration of hydrogen storage compounds

PatentWO2008053460A1

Innovation

- Incorporating a catalyst or supported catalyst for the disproportionation of carbon monoxide in the carbothermic reduction of magnesium oxide, which enhances kinetics and yield by continuously removing carbon, driving the reaction to produce elemental magnesium and carbon dioxide, and integrating this process with metaborate reduction to efficiently recycle magnesium.

Environmental Impact of Magnesium Carbonate in Food Industry

The environmental impact of magnesium carbonate in the food industry is a multifaceted issue that requires careful consideration. As a food processing aid, magnesium carbonate has shown promising results in reducing energy consumption during various stages of food production. This reduction in energy usage directly translates to a decrease in greenhouse gas emissions and overall carbon footprint of food manufacturing processes.

One of the primary environmental benefits of using magnesium carbonate is its ability to enhance heat transfer efficiency in food processing equipment. This improved thermal conductivity allows for faster heating and cooling cycles, reducing the overall energy required for temperature-controlled processes. Consequently, food manufacturers can achieve significant reductions in electricity and fuel consumption, leading to lower emissions of carbon dioxide and other pollutants associated with energy production.

Furthermore, magnesium carbonate's role in improving food texture and stability can lead to extended shelf life for certain products. This extended shelf life contributes to reduced food waste, which is a significant environmental concern in the global food supply chain. By minimizing spoilage and maintaining product quality for longer periods, the use of magnesium carbonate indirectly helps conserve resources and reduce the environmental impact associated with food production and disposal.

However, it is essential to consider the potential environmental drawbacks of increased magnesium carbonate usage in the food industry. The mining and processing of magnesium carbonate can have localized environmental impacts, including habitat disruption and energy consumption during extraction and refinement. Additionally, the disposal of food products containing magnesium carbonate may introduce elevated levels of magnesium into waste streams, potentially affecting aquatic ecosystems if not properly managed.

To fully assess the environmental impact, a life cycle analysis approach is necessary. This would involve evaluating the entire supply chain, from raw material extraction to end-of-life disposal, to determine the net environmental effect of magnesium carbonate use in food processing. Such an analysis would need to weigh the benefits of reduced energy consumption and food waste against the potential negative impacts of increased mineral extraction and disposal.

In conclusion, while magnesium carbonate shows promise in reducing the energy footprint of food processing, a comprehensive environmental assessment is crucial to ensure that its widespread adoption aligns with sustainable practices in the food industry. Future research and development efforts should focus on optimizing the use of magnesium carbonate to maximize its energy-saving potential while minimizing any adverse environmental effects throughout its lifecycle.

One of the primary environmental benefits of using magnesium carbonate is its ability to enhance heat transfer efficiency in food processing equipment. This improved thermal conductivity allows for faster heating and cooling cycles, reducing the overall energy required for temperature-controlled processes. Consequently, food manufacturers can achieve significant reductions in electricity and fuel consumption, leading to lower emissions of carbon dioxide and other pollutants associated with energy production.

Furthermore, magnesium carbonate's role in improving food texture and stability can lead to extended shelf life for certain products. This extended shelf life contributes to reduced food waste, which is a significant environmental concern in the global food supply chain. By minimizing spoilage and maintaining product quality for longer periods, the use of magnesium carbonate indirectly helps conserve resources and reduce the environmental impact associated with food production and disposal.

However, it is essential to consider the potential environmental drawbacks of increased magnesium carbonate usage in the food industry. The mining and processing of magnesium carbonate can have localized environmental impacts, including habitat disruption and energy consumption during extraction and refinement. Additionally, the disposal of food products containing magnesium carbonate may introduce elevated levels of magnesium into waste streams, potentially affecting aquatic ecosystems if not properly managed.

To fully assess the environmental impact, a life cycle analysis approach is necessary. This would involve evaluating the entire supply chain, from raw material extraction to end-of-life disposal, to determine the net environmental effect of magnesium carbonate use in food processing. Such an analysis would need to weigh the benefits of reduced energy consumption and food waste against the potential negative impacts of increased mineral extraction and disposal.

In conclusion, while magnesium carbonate shows promise in reducing the energy footprint of food processing, a comprehensive environmental assessment is crucial to ensure that its widespread adoption aligns with sustainable practices in the food industry. Future research and development efforts should focus on optimizing the use of magnesium carbonate to maximize its energy-saving potential while minimizing any adverse environmental effects throughout its lifecycle.

Regulatory Framework for Food Additives and Processing Aids

The regulatory framework for food additives and processing aids plays a crucial role in ensuring the safety and efficacy of substances used in food processing, including magnesium carbonate. In the context of reducing food processing energies, understanding and navigating this framework is essential for the successful implementation of innovative technologies.

At the international level, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), sets global standards for food additives and processing aids. These standards serve as a reference point for national regulatory bodies and help facilitate international trade while ensuring consumer safety.

In the United States, the Food and Drug Administration (FDA) regulates food additives and processing aids under the Federal Food, Drug, and Cosmetic Act. Magnesium carbonate is classified as a Generally Recognized as Safe (GRAS) substance, which allows for its use in food processing without premarket approval, provided it meets certain criteria. However, manufacturers must ensure that its use complies with good manufacturing practices and does not adulterate the final food product.

The European Union (EU) has a comprehensive regulatory framework for food additives and processing aids, governed by Regulation (EC) No 1333/2008 and Regulation (EC) No 1332/2008, respectively. These regulations establish a Union list of approved substances and set conditions for their use. Magnesium carbonate (E504) is approved for use in various food categories, subject to specific limitations and requirements.

In Asia, regulatory approaches vary by country. Japan's Ministry of Health, Labour and Welfare regulates food additives through the Food Sanitation Act, while China's National Health Commission oversees the approval and management of food additives and processing aids. Both countries have specific regulations and positive lists for permitted substances.

When considering the use of magnesium carbonate to reduce food processing energies, manufacturers must navigate these regulatory frameworks to ensure compliance. This includes adhering to maximum usage levels, labeling requirements, and any specific conditions set by regulatory authorities. Additionally, they must consider potential differences in regulations across markets if the product is intended for international distribution.

As research continues to explore the energy-saving potential of magnesium carbonate in food processing, regulatory bodies may need to adapt their frameworks to accommodate new applications. This could involve reassessing existing approvals, conducting additional safety evaluations, or developing new guidelines for innovative uses of the substance.

Understanding and complying with these regulatory frameworks is essential for food manufacturers and technology developers seeking to leverage magnesium carbonate's properties in energy-efficient food processing. It ensures that innovations in this area can be successfully brought to market while maintaining the highest standards of food safety and quality.

At the international level, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), sets global standards for food additives and processing aids. These standards serve as a reference point for national regulatory bodies and help facilitate international trade while ensuring consumer safety.

In the United States, the Food and Drug Administration (FDA) regulates food additives and processing aids under the Federal Food, Drug, and Cosmetic Act. Magnesium carbonate is classified as a Generally Recognized as Safe (GRAS) substance, which allows for its use in food processing without premarket approval, provided it meets certain criteria. However, manufacturers must ensure that its use complies with good manufacturing practices and does not adulterate the final food product.

The European Union (EU) has a comprehensive regulatory framework for food additives and processing aids, governed by Regulation (EC) No 1333/2008 and Regulation (EC) No 1332/2008, respectively. These regulations establish a Union list of approved substances and set conditions for their use. Magnesium carbonate (E504) is approved for use in various food categories, subject to specific limitations and requirements.

In Asia, regulatory approaches vary by country. Japan's Ministry of Health, Labour and Welfare regulates food additives through the Food Sanitation Act, while China's National Health Commission oversees the approval and management of food additives and processing aids. Both countries have specific regulations and positive lists for permitted substances.

When considering the use of magnesium carbonate to reduce food processing energies, manufacturers must navigate these regulatory frameworks to ensure compliance. This includes adhering to maximum usage levels, labeling requirements, and any specific conditions set by regulatory authorities. Additionally, they must consider potential differences in regulations across markets if the product is intended for international distribution.

As research continues to explore the energy-saving potential of magnesium carbonate in food processing, regulatory bodies may need to adapt their frameworks to accommodate new applications. This could involve reassessing existing approvals, conducting additional safety evaluations, or developing new guidelines for innovative uses of the substance.

Understanding and complying with these regulatory frameworks is essential for food manufacturers and technology developers seeking to leverage magnesium carbonate's properties in energy-efficient food processing. It ensures that innovations in this area can be successfully brought to market while maintaining the highest standards of food safety and quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!