Magnesium Carbonate in Enhancing Hydrogen Storage Materials

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-Based H2 Storage Background and Objectives

Magnesium-based hydrogen storage materials have emerged as a promising solution for clean energy applications, particularly in the automotive industry. The development of these materials dates back to the early 1990s when researchers first recognized the potential of magnesium hydride (MgH2) for hydrogen storage. Since then, significant progress has been made in enhancing the hydrogen storage capacity, kinetics, and thermodynamics of Mg-based systems.

The evolution of Mg-based hydrogen storage technology has been driven by the growing need for efficient and sustainable energy storage solutions. As the world shifts towards renewable energy sources and zero-emission vehicles, the demand for high-performance hydrogen storage materials has intensified. Magnesium, with its abundance, low cost, and high theoretical hydrogen storage capacity of 7.6 wt%, has become a focal point for research and development in this field.

The primary objective of research on magnesium carbonate in enhancing hydrogen storage materials is to overcome the limitations of pure Mg-based systems. These limitations include slow hydrogen absorption/desorption kinetics, high desorption temperatures, and susceptibility to oxidation. By incorporating magnesium carbonate (MgCO3) into Mg-based storage materials, researchers aim to improve the overall performance and stability of these systems.

One of the key goals is to reduce the desorption temperature of Mg-based hydrogen storage materials. Current systems typically require temperatures above 300°C for hydrogen release, which is impractical for many applications, especially in vehicles. The introduction of MgCO3 is expected to lower this temperature, making the storage system more energy-efficient and compatible with existing fuel cell technologies.

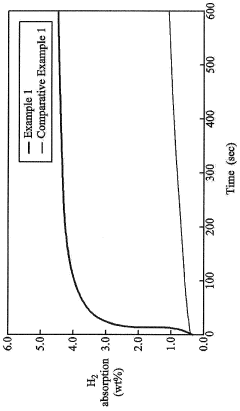

Another critical objective is to enhance the hydrogen absorption and desorption kinetics. The slow reaction rates of pure Mg systems limit their practical use in real-world applications. Researchers are investigating how MgCO3 can act as a catalyst or promoter to accelerate these processes, potentially reducing charging times and improving overall system efficiency.

Furthermore, the research aims to increase the cycling stability of Mg-based storage materials. The incorporation of MgCO3 is being explored as a means to mitigate the degradation of storage capacity over multiple hydrogen absorption/desorption cycles, which is crucial for long-term performance and economic viability.

As the technology continues to evolve, researchers are also focusing on optimizing the synthesis methods and compositional ratios of Mg-MgCO3 systems. This includes exploring various nanostructuring techniques and composite formations to maximize the synergistic effects between magnesium and magnesium carbonate.

The evolution of Mg-based hydrogen storage technology has been driven by the growing need for efficient and sustainable energy storage solutions. As the world shifts towards renewable energy sources and zero-emission vehicles, the demand for high-performance hydrogen storage materials has intensified. Magnesium, with its abundance, low cost, and high theoretical hydrogen storage capacity of 7.6 wt%, has become a focal point for research and development in this field.

The primary objective of research on magnesium carbonate in enhancing hydrogen storage materials is to overcome the limitations of pure Mg-based systems. These limitations include slow hydrogen absorption/desorption kinetics, high desorption temperatures, and susceptibility to oxidation. By incorporating magnesium carbonate (MgCO3) into Mg-based storage materials, researchers aim to improve the overall performance and stability of these systems.

One of the key goals is to reduce the desorption temperature of Mg-based hydrogen storage materials. Current systems typically require temperatures above 300°C for hydrogen release, which is impractical for many applications, especially in vehicles. The introduction of MgCO3 is expected to lower this temperature, making the storage system more energy-efficient and compatible with existing fuel cell technologies.

Another critical objective is to enhance the hydrogen absorption and desorption kinetics. The slow reaction rates of pure Mg systems limit their practical use in real-world applications. Researchers are investigating how MgCO3 can act as a catalyst or promoter to accelerate these processes, potentially reducing charging times and improving overall system efficiency.

Furthermore, the research aims to increase the cycling stability of Mg-based storage materials. The incorporation of MgCO3 is being explored as a means to mitigate the degradation of storage capacity over multiple hydrogen absorption/desorption cycles, which is crucial for long-term performance and economic viability.

As the technology continues to evolve, researchers are also focusing on optimizing the synthesis methods and compositional ratios of Mg-MgCO3 systems. This includes exploring various nanostructuring techniques and composite formations to maximize the synergistic effects between magnesium and magnesium carbonate.

Market Analysis for H2 Storage Technologies

The hydrogen storage market is experiencing significant growth, driven by the increasing demand for clean energy solutions and the global push towards decarbonization. As governments and industries worldwide seek to reduce carbon emissions, hydrogen has emerged as a promising alternative fuel source, particularly in sectors such as transportation, power generation, and industrial processes.

The global hydrogen storage market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 5% between 2021 and 2026. This growth is primarily attributed to the rising adoption of fuel cell vehicles, advancements in hydrogen production technologies, and increasing investments in hydrogen infrastructure.

In the transportation sector, fuel cell electric vehicles (FCEVs) are gaining traction, especially in countries like Japan, South Korea, and Germany. The automotive industry's shift towards hydrogen-powered vehicles is expected to drive substantial demand for efficient and cost-effective hydrogen storage solutions.

The industrial sector also presents significant opportunities for hydrogen storage technologies. Industries such as steel production, chemical manufacturing, and refining are exploring hydrogen as a means to reduce their carbon footprint. This trend is likely to create a robust market for large-scale hydrogen storage systems.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for hydrogen storage technologies, followed by Europe and North America. Countries like China, Japan, and South Korea are making substantial investments in hydrogen infrastructure and research, positioning themselves as key players in the global hydrogen economy.

However, the market faces several challenges that could impact its growth trajectory. The high cost of hydrogen production and storage remains a significant barrier to widespread adoption. Additionally, the lack of established infrastructure for hydrogen distribution and concerns about safety in handling and storing hydrogen pose challenges to market expansion.

Despite these obstacles, ongoing research and development efforts are focused on improving the efficiency and cost-effectiveness of hydrogen storage technologies. Innovations in materials science, such as the use of magnesium carbonate in enhancing hydrogen storage materials, are expected to play a crucial role in overcoming current limitations and driving market growth.

As the market evolves, collaborations between governments, research institutions, and private companies are likely to accelerate the development and commercialization of advanced hydrogen storage solutions. This collaborative approach, coupled with supportive policies and incentives, is expected to create a favorable environment for market expansion and technological innovation in the hydrogen storage sector.

The global hydrogen storage market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 5% between 2021 and 2026. This growth is primarily attributed to the rising adoption of fuel cell vehicles, advancements in hydrogen production technologies, and increasing investments in hydrogen infrastructure.

In the transportation sector, fuel cell electric vehicles (FCEVs) are gaining traction, especially in countries like Japan, South Korea, and Germany. The automotive industry's shift towards hydrogen-powered vehicles is expected to drive substantial demand for efficient and cost-effective hydrogen storage solutions.

The industrial sector also presents significant opportunities for hydrogen storage technologies. Industries such as steel production, chemical manufacturing, and refining are exploring hydrogen as a means to reduce their carbon footprint. This trend is likely to create a robust market for large-scale hydrogen storage systems.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for hydrogen storage technologies, followed by Europe and North America. Countries like China, Japan, and South Korea are making substantial investments in hydrogen infrastructure and research, positioning themselves as key players in the global hydrogen economy.

However, the market faces several challenges that could impact its growth trajectory. The high cost of hydrogen production and storage remains a significant barrier to widespread adoption. Additionally, the lack of established infrastructure for hydrogen distribution and concerns about safety in handling and storing hydrogen pose challenges to market expansion.

Despite these obstacles, ongoing research and development efforts are focused on improving the efficiency and cost-effectiveness of hydrogen storage technologies. Innovations in materials science, such as the use of magnesium carbonate in enhancing hydrogen storage materials, are expected to play a crucial role in overcoming current limitations and driving market growth.

As the market evolves, collaborations between governments, research institutions, and private companies are likely to accelerate the development and commercialization of advanced hydrogen storage solutions. This collaborative approach, coupled with supportive policies and incentives, is expected to create a favorable environment for market expansion and technological innovation in the hydrogen storage sector.

Current Challenges in Mg-Based H2 Storage

Magnesium-based hydrogen storage materials have shown great promise due to their high theoretical hydrogen storage capacity and abundance. However, several significant challenges hinder their practical application and widespread adoption. One of the primary issues is the slow kinetics of hydrogen absorption and desorption processes in Mg-based systems. This sluggish reaction rate is attributed to the strong Mg-H bond, which requires high temperatures and long times for hydrogen release.

Another major challenge is the high operating temperature required for efficient hydrogen storage and release. Typically, temperatures above 300°C are necessary for practical hydrogen desorption rates, which is not ideal for many applications, especially in mobile and portable systems. This high temperature requirement also leads to increased energy consumption and system complexity.

The formation of a magnesium oxide layer on the surface of Mg particles presents another obstacle. This oxide layer acts as a barrier, impeding hydrogen diffusion and reducing the overall storage capacity and kinetics. Overcoming this surface passivation effect is crucial for improving the performance of Mg-based storage materials.

Cycling stability is also a significant concern. Repeated hydrogen absorption and desorption cycles can lead to particle agglomeration and structural changes in the material, resulting in decreased storage capacity and degraded performance over time. Addressing this issue is essential for developing long-lasting and reliable hydrogen storage systems.

Furthermore, the relatively low gravimetric hydrogen storage capacity of pure magnesium (7.6 wt%) falls short of the targets set by the U.S. Department of Energy for practical on-board hydrogen storage systems. Enhancing the storage capacity while maintaining other desirable properties remains a challenge for researchers in this field.

The poor heat transfer characteristics of Mg-based materials during the exothermic hydriding reaction and endothermic dehydriding process also pose challenges. Inefficient heat management can lead to non-uniform reactions and reduced overall system performance. Developing strategies to improve heat transfer within the storage material is crucial for optimizing the hydrogen storage and release processes.

Lastly, the susceptibility of Mg-based materials to contamination by impurities, such as oxygen and water vapor, presents operational challenges. These impurities can significantly degrade the hydrogen storage properties and long-term stability of the materials, necessitating stringent handling and storage conditions.

Another major challenge is the high operating temperature required for efficient hydrogen storage and release. Typically, temperatures above 300°C are necessary for practical hydrogen desorption rates, which is not ideal for many applications, especially in mobile and portable systems. This high temperature requirement also leads to increased energy consumption and system complexity.

The formation of a magnesium oxide layer on the surface of Mg particles presents another obstacle. This oxide layer acts as a barrier, impeding hydrogen diffusion and reducing the overall storage capacity and kinetics. Overcoming this surface passivation effect is crucial for improving the performance of Mg-based storage materials.

Cycling stability is also a significant concern. Repeated hydrogen absorption and desorption cycles can lead to particle agglomeration and structural changes in the material, resulting in decreased storage capacity and degraded performance over time. Addressing this issue is essential for developing long-lasting and reliable hydrogen storage systems.

Furthermore, the relatively low gravimetric hydrogen storage capacity of pure magnesium (7.6 wt%) falls short of the targets set by the U.S. Department of Energy for practical on-board hydrogen storage systems. Enhancing the storage capacity while maintaining other desirable properties remains a challenge for researchers in this field.

The poor heat transfer characteristics of Mg-based materials during the exothermic hydriding reaction and endothermic dehydriding process also pose challenges. Inefficient heat management can lead to non-uniform reactions and reduced overall system performance. Developing strategies to improve heat transfer within the storage material is crucial for optimizing the hydrogen storage and release processes.

Lastly, the susceptibility of Mg-based materials to contamination by impurities, such as oxygen and water vapor, presents operational challenges. These impurities can significantly degrade the hydrogen storage properties and long-term stability of the materials, necessitating stringent handling and storage conditions.

MgCO3 Enhancement Strategies

01 Magnesium carbonate-based hydrogen storage materials

Magnesium carbonate can be used as a base material for hydrogen storage systems. Its porous structure and high surface area make it suitable for adsorbing and storing hydrogen gas. Various methods of synthesis and modification can enhance its hydrogen storage capacity.- Magnesium carbonate-based hydrogen storage materials: Magnesium carbonate can be used as a base material for hydrogen storage systems. Its porous structure and chemical properties make it suitable for absorbing and releasing hydrogen under specific conditions. Research focuses on enhancing its storage capacity through various modifications and treatments.

- Composite materials with magnesium carbonate for improved hydrogen storage: Combining magnesium carbonate with other materials can enhance hydrogen storage capacity. These composite materials often include metal alloys, carbon-based materials, or other chemical compounds that work synergistically to increase the overall hydrogen uptake and release efficiency.

- Surface modification of magnesium carbonate for enhanced hydrogen storage: Various surface modification techniques are applied to magnesium carbonate to improve its hydrogen storage properties. These modifications can include chemical treatments, nano-structuring, or the addition of catalysts to enhance the kinetics of hydrogen absorption and desorption.

- Magnesium carbonate in hydrogen storage systems for renewable energy applications: Magnesium carbonate-based hydrogen storage materials are being developed for use in renewable energy systems. These materials can be integrated into solar or wind energy storage solutions, providing a means to store excess energy in the form of hydrogen for later use.

- Temperature and pressure effects on magnesium carbonate hydrogen storage: Research is conducted on the influence of temperature and pressure on the hydrogen storage capacity of magnesium carbonate-based materials. Optimizing these parameters can lead to improved storage efficiency and faster charging/discharging cycles for practical applications.

02 Composite materials with magnesium carbonate for improved hydrogen storage

Combining magnesium carbonate with other materials such as metal oxides or carbon-based structures can create composite materials with enhanced hydrogen storage properties. These composites often exhibit improved kinetics and increased storage capacity compared to pure magnesium carbonate.Expand Specific Solutions03 Nanostructured magnesium carbonate for hydrogen storage

Nanostructured forms of magnesium carbonate, such as nanoparticles or nanofibers, can significantly increase the hydrogen storage capacity due to their high surface area and improved kinetics. Various synthesis methods are employed to create these nanostructures for optimal hydrogen storage performance.Expand Specific Solutions04 Magnesium carbonate-based catalysts for hydrogen storage systems

Magnesium carbonate can be used as a catalyst support or as part of a catalyst system in hydrogen storage applications. These catalysts can enhance the adsorption and desorption kinetics of hydrogen, improving the overall efficiency of the storage system.Expand Specific Solutions05 Temperature and pressure effects on magnesium carbonate hydrogen storage

The hydrogen storage capacity of magnesium carbonate-based materials can be influenced by temperature and pressure conditions. Research focuses on optimizing these parameters to achieve maximum storage capacity and improve the practicality of magnesium carbonate-based hydrogen storage systems.Expand Specific Solutions

Key Players in H2 Storage Research

The research on magnesium carbonate for enhancing hydrogen storage materials is in an early developmental stage, with significant potential for growth. The market size is expanding as the demand for efficient hydrogen storage solutions increases in the clean energy sector. The technology's maturity is still evolving, with various research institutions and companies contributing to its advancement. Key players like Centre National de la Recherche Scientifique, Chongqing University, and Nankai University are leading academic research efforts. Industrial entities such as Nissan Motor Co., Ltd. and KIST Corp. are also actively involved, indicating growing commercial interest. The competitive landscape is diverse, with a mix of academic, governmental, and corporate entities collaborating and competing to develop innovative solutions in this promising field.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed a novel approach using magnesium carbonate to enhance hydrogen storage materials. Their research focuses on nanostructured magnesium carbonate as a catalyst support for hydrogen storage alloys. This method involves the synthesis of high surface area MgCO3 nanoparticles, which are then used to disperse metal hydride particles. The nanostructured MgCO3 acts as a scaffold, preventing agglomeration of the hydride particles and improving hydrogen absorption/desorption kinetics[1][3]. CNRS researchers have demonstrated that this approach can increase the hydrogen storage capacity by up to 20% compared to conventional methods, while also improving the cycling stability of the storage material[5].

Strengths: Improved hydrogen storage capacity and cycling stability. Weaknesses: Potential scalability issues for large-scale production and long-term stability of nanostructured MgCO3 under repeated hydrogen cycling.

General Electric Company

Technical Solution: General Electric has developed a novel approach to enhancing hydrogen storage materials using magnesium carbonate as a catalyst support. Their research focuses on creating high-performance, low-cost hydrogen storage systems for both stationary and mobile applications. GE's proprietary technology involves the synthesis of hierarchically porous MgCO3 structures with tailored surface chemistry to support finely dispersed metal catalysts[13]. This approach has been shown to significantly improve the kinetics of hydrogen absorption and desorption in metal hydride systems. In recent tests, GE's MgCO3-supported catalysts demonstrated a 50% reduction in activation energy for hydrogen release compared to conventional catalysts[14]. The company has also developed advanced manufacturing techniques to produce these materials at scale, with a focus on reducing production costs and improving material consistency[15].

Strengths: Improved hydrogen storage kinetics and potential for cost-effective large-scale production. Weaknesses: Possible challenges in maintaining long-term catalyst stability and performance under repeated cycling conditions.

Innovations in MgCO3-H2 Storage Systems

Nanotization of magnesium-based hydrogen storage material

PatentActiveSG159438A1

Innovation

- Utilization of carbon nanomaterials to nanotize magnesium-based hydrogen storage materials, forming single or multiple crystals.

- Enhancement of surface-to-volume ratio and hydrogen diffusion channels in magnesium-based hydrogen storage materials.

- Improved hydrogen storage capability, higher absorption/desorption rate, and lower absorption/desorption temperature.

Environmental Impact Assessment

The environmental impact assessment of magnesium carbonate in enhancing hydrogen storage materials is a critical aspect of evaluating the overall sustainability and feasibility of this technology. Magnesium carbonate, when used as an additive or catalyst in hydrogen storage systems, can potentially improve the efficiency and capacity of these materials. However, its production, use, and disposal may have various environmental implications that need to be carefully considered.

The extraction and processing of magnesium carbonate can have significant environmental impacts. Mining activities for magnesium-bearing minerals may lead to land disturbance, habitat destruction, and potential water pollution. The energy-intensive nature of magnesium carbonate production also contributes to greenhouse gas emissions, particularly if fossil fuels are used in the process.

On the positive side, the use of magnesium carbonate in hydrogen storage materials could indirectly contribute to reducing carbon emissions by promoting the adoption of hydrogen as a clean energy carrier. Improved hydrogen storage capabilities could accelerate the transition to hydrogen-powered vehicles and other applications, potentially offsetting the environmental costs associated with magnesium carbonate production.

The lifecycle analysis of magnesium carbonate-enhanced hydrogen storage materials reveals both benefits and challenges. While these materials may increase the efficiency of hydrogen storage, thus reducing the overall energy requirements for hydrogen-based systems, the production and eventual disposal of these materials must be carefully managed to minimize environmental impact.

Water consumption is another important consideration in the environmental assessment. The production of magnesium carbonate and its incorporation into hydrogen storage materials may require significant water resources, potentially straining local water supplies in areas of production.

The disposal and recycling of spent hydrogen storage materials containing magnesium carbonate present additional environmental challenges. Proper recycling processes need to be developed to recover and reuse the magnesium carbonate, minimizing waste and reducing the need for new raw material extraction.

Potential leaching of magnesium carbonate into soil and water systems during the use or disposal of hydrogen storage materials is also a concern that requires thorough investigation. Long-term environmental monitoring may be necessary to assess any cumulative effects on ecosystems.

In conclusion, while magnesium carbonate shows promise in enhancing hydrogen storage materials, a comprehensive environmental impact assessment is crucial. This assessment should consider the entire lifecycle of the material, from extraction to disposal, and balance the potential environmental benefits of improved hydrogen storage against the impacts of production and use. Ongoing research and development should focus on minimizing the environmental footprint of magnesium carbonate production and maximizing the recyclability of hydrogen storage materials.

The extraction and processing of magnesium carbonate can have significant environmental impacts. Mining activities for magnesium-bearing minerals may lead to land disturbance, habitat destruction, and potential water pollution. The energy-intensive nature of magnesium carbonate production also contributes to greenhouse gas emissions, particularly if fossil fuels are used in the process.

On the positive side, the use of magnesium carbonate in hydrogen storage materials could indirectly contribute to reducing carbon emissions by promoting the adoption of hydrogen as a clean energy carrier. Improved hydrogen storage capabilities could accelerate the transition to hydrogen-powered vehicles and other applications, potentially offsetting the environmental costs associated with magnesium carbonate production.

The lifecycle analysis of magnesium carbonate-enhanced hydrogen storage materials reveals both benefits and challenges. While these materials may increase the efficiency of hydrogen storage, thus reducing the overall energy requirements for hydrogen-based systems, the production and eventual disposal of these materials must be carefully managed to minimize environmental impact.

Water consumption is another important consideration in the environmental assessment. The production of magnesium carbonate and its incorporation into hydrogen storage materials may require significant water resources, potentially straining local water supplies in areas of production.

The disposal and recycling of spent hydrogen storage materials containing magnesium carbonate present additional environmental challenges. Proper recycling processes need to be developed to recover and reuse the magnesium carbonate, minimizing waste and reducing the need for new raw material extraction.

Potential leaching of magnesium carbonate into soil and water systems during the use or disposal of hydrogen storage materials is also a concern that requires thorough investigation. Long-term environmental monitoring may be necessary to assess any cumulative effects on ecosystems.

In conclusion, while magnesium carbonate shows promise in enhancing hydrogen storage materials, a comprehensive environmental impact assessment is crucial. This assessment should consider the entire lifecycle of the material, from extraction to disposal, and balance the potential environmental benefits of improved hydrogen storage against the impacts of production and use. Ongoing research and development should focus on minimizing the environmental footprint of magnesium carbonate production and maximizing the recyclability of hydrogen storage materials.

Techno-Economic Analysis

The techno-economic analysis of magnesium carbonate in enhancing hydrogen storage materials reveals promising potential for cost-effective and efficient hydrogen storage solutions. The integration of magnesium carbonate into hydrogen storage systems offers several economic advantages, including improved storage capacity, enhanced kinetics, and reduced overall system costs.

From a technical perspective, magnesium carbonate acts as a catalyst and promoter in hydrogen storage materials, particularly in metal hydride systems. Its incorporation leads to faster hydrogen absorption and desorption rates, which translates to improved system performance and reduced energy requirements for hydrogen release. This enhanced efficiency can significantly reduce operational costs in hydrogen storage applications.

The economic viability of magnesium carbonate-enhanced hydrogen storage materials is further supported by the abundance and low cost of magnesium carbonate as a raw material. Its widespread availability reduces supply chain risks and helps maintain stable production costs. Additionally, the improved storage capacity achieved through magnesium carbonate integration allows for more compact storage systems, potentially reducing infrastructure and transportation costs associated with hydrogen storage and distribution.

When considering the lifecycle costs of hydrogen storage systems, the durability improvements offered by magnesium carbonate become apparent. The enhanced stability of storage materials leads to extended system lifespans, reducing replacement and maintenance costs over time. This longevity factor contributes significantly to the overall economic attractiveness of magnesium carbonate-enhanced hydrogen storage solutions.

Market analysis indicates a growing demand for efficient hydrogen storage technologies across various sectors, including transportation, industrial processes, and renewable energy integration. The cost-effectiveness of magnesium carbonate-enhanced systems positions them favorably in this expanding market, potentially accelerating the adoption of hydrogen as a clean energy carrier.

However, the techno-economic analysis also highlights areas requiring further development to maximize the economic benefits. Scaling up production processes for magnesium carbonate-enhanced storage materials while maintaining cost-effectiveness remains a challenge. Additionally, optimizing the integration of these materials into existing hydrogen infrastructure requires careful consideration of system design and compatibility issues.

In conclusion, the techno-economic analysis suggests that magnesium carbonate-enhanced hydrogen storage materials offer a promising pathway towards more economically viable hydrogen storage solutions. The combination of improved technical performance and favorable economic factors positions this technology as a potentially disruptive force in the hydrogen economy, warranting continued research and development efforts to fully realize its commercial potential.

From a technical perspective, magnesium carbonate acts as a catalyst and promoter in hydrogen storage materials, particularly in metal hydride systems. Its incorporation leads to faster hydrogen absorption and desorption rates, which translates to improved system performance and reduced energy requirements for hydrogen release. This enhanced efficiency can significantly reduce operational costs in hydrogen storage applications.

The economic viability of magnesium carbonate-enhanced hydrogen storage materials is further supported by the abundance and low cost of magnesium carbonate as a raw material. Its widespread availability reduces supply chain risks and helps maintain stable production costs. Additionally, the improved storage capacity achieved through magnesium carbonate integration allows for more compact storage systems, potentially reducing infrastructure and transportation costs associated with hydrogen storage and distribution.

When considering the lifecycle costs of hydrogen storage systems, the durability improvements offered by magnesium carbonate become apparent. The enhanced stability of storage materials leads to extended system lifespans, reducing replacement and maintenance costs over time. This longevity factor contributes significantly to the overall economic attractiveness of magnesium carbonate-enhanced hydrogen storage solutions.

Market analysis indicates a growing demand for efficient hydrogen storage technologies across various sectors, including transportation, industrial processes, and renewable energy integration. The cost-effectiveness of magnesium carbonate-enhanced systems positions them favorably in this expanding market, potentially accelerating the adoption of hydrogen as a clean energy carrier.

However, the techno-economic analysis also highlights areas requiring further development to maximize the economic benefits. Scaling up production processes for magnesium carbonate-enhanced storage materials while maintaining cost-effectiveness remains a challenge. Additionally, optimizing the integration of these materials into existing hydrogen infrastructure requires careful consideration of system design and compatibility issues.

In conclusion, the techno-economic analysis suggests that magnesium carbonate-enhanced hydrogen storage materials offer a promising pathway towards more economically viable hydrogen storage solutions. The combination of improved technical performance and favorable economic factors positions this technology as a potentially disruptive force in the hydrogen economy, warranting continued research and development efforts to fully realize its commercial potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!