The Application of Magnesium Carbonate in Flame Retardant Textiles

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate FR Background and Objectives

Magnesium carbonate has emerged as a promising flame retardant material in the textile industry, driven by the increasing demand for safer and more environmentally friendly fire protection solutions. The evolution of flame retardant technologies has been marked by a shift from halogenated compounds to more sustainable alternatives, with magnesium carbonate gaining attention due to its non-toxic nature and effectiveness in reducing fire hazards.

The development of flame retardant textiles using magnesium carbonate is rooted in the broader context of fire safety regulations and consumer awareness. As global standards for fire protection in textiles have become more stringent, manufacturers have been compelled to explore innovative materials that can meet these requirements without compromising on performance or environmental sustainability.

Magnesium carbonate's journey as a flame retardant agent in textiles began with its recognition as an inorganic compound capable of endothermic decomposition when exposed to high temperatures. This property allows it to absorb heat and release non-flammable gases, effectively suppressing the spread of flames. The material's abundance in nature and relatively low production costs have further contributed to its appeal as a viable flame retardant solution.

The primary objective of incorporating magnesium carbonate into flame retardant textiles is to enhance the fire resistance of fabrics while maintaining their original properties such as comfort, durability, and aesthetic appeal. Researchers and industry professionals aim to develop efficient methods for integrating magnesium carbonate into various textile structures, optimizing its flame retardant performance, and ensuring its compatibility with different fiber types and fabric compositions.

Another crucial goal in the application of magnesium carbonate as a flame retardant is to address the limitations of traditional flame retardant treatments. These include issues such as reduced fabric breathability, increased stiffness, and potential skin irritation. By leveraging the unique properties of magnesium carbonate, developers seek to create flame retardant textiles that offer superior comfort and wearability without compromising on safety.

The ongoing research in this field is focused on understanding the mechanisms by which magnesium carbonate imparts flame retardancy to textiles, exploring synergistic effects with other flame retardant additives, and developing novel application techniques to enhance its effectiveness. Additionally, efforts are being made to improve the durability of magnesium carbonate treatments, ensuring that the flame retardant properties persist throughout the lifecycle of the textile product.

The development of flame retardant textiles using magnesium carbonate is rooted in the broader context of fire safety regulations and consumer awareness. As global standards for fire protection in textiles have become more stringent, manufacturers have been compelled to explore innovative materials that can meet these requirements without compromising on performance or environmental sustainability.

Magnesium carbonate's journey as a flame retardant agent in textiles began with its recognition as an inorganic compound capable of endothermic decomposition when exposed to high temperatures. This property allows it to absorb heat and release non-flammable gases, effectively suppressing the spread of flames. The material's abundance in nature and relatively low production costs have further contributed to its appeal as a viable flame retardant solution.

The primary objective of incorporating magnesium carbonate into flame retardant textiles is to enhance the fire resistance of fabrics while maintaining their original properties such as comfort, durability, and aesthetic appeal. Researchers and industry professionals aim to develop efficient methods for integrating magnesium carbonate into various textile structures, optimizing its flame retardant performance, and ensuring its compatibility with different fiber types and fabric compositions.

Another crucial goal in the application of magnesium carbonate as a flame retardant is to address the limitations of traditional flame retardant treatments. These include issues such as reduced fabric breathability, increased stiffness, and potential skin irritation. By leveraging the unique properties of magnesium carbonate, developers seek to create flame retardant textiles that offer superior comfort and wearability without compromising on safety.

The ongoing research in this field is focused on understanding the mechanisms by which magnesium carbonate imparts flame retardancy to textiles, exploring synergistic effects with other flame retardant additives, and developing novel application techniques to enhance its effectiveness. Additionally, efforts are being made to improve the durability of magnesium carbonate treatments, ensuring that the flame retardant properties persist throughout the lifecycle of the textile product.

Market Analysis for FR Textiles

The flame retardant (FR) textile market has been experiencing significant growth in recent years, driven by increasing safety regulations and growing awareness of fire hazards across various industries. The global FR textile market was valued at approximately $5.3 billion in 2020 and is projected to reach $8.2 billion by 2026, growing at a CAGR of 7.5% during the forecast period.

The demand for FR textiles is particularly strong in sectors such as construction, automotive, aerospace, and industrial workwear. In the construction industry, stringent building codes and regulations mandating the use of fire-resistant materials have boosted the adoption of FR textiles in insulation, wall coverings, and furnishings. The automotive sector has also seen increased demand for FR textiles in vehicle interiors, driven by safety concerns and regulatory requirements.

Geographically, North America and Europe currently dominate the FR textile market, accounting for over 60% of the global market share. This is primarily due to strict safety regulations and high adoption rates in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, with countries like China and India driving demand through rapid industrialization and increasing safety awareness.

The market for FR textiles treated with magnesium carbonate is a subset of the broader FR textile market. Magnesium carbonate-based flame retardants are gaining traction due to their eco-friendly nature and effectiveness in reducing smoke generation during combustion. This aligns with the growing trend towards sustainable and environmentally friendly flame retardant solutions.

Key market drivers for magnesium carbonate-based FR textiles include increasing environmental concerns, stringent regulations on halogenated flame retardants, and the push for safer alternatives in consumer products. The construction and automotive industries are expected to be major consumers of these textiles, driven by their need for materials that meet both safety and sustainability requirements.

However, challenges remain in the widespread adoption of magnesium carbonate-based FR textiles. These include higher production costs compared to traditional FR treatments and the need for further research to optimize performance across various textile applications. Despite these challenges, the market outlook remains positive, with growing investments in R&D and increasing consumer preference for eco-friendly products expected to drive market growth in the coming years.

The demand for FR textiles is particularly strong in sectors such as construction, automotive, aerospace, and industrial workwear. In the construction industry, stringent building codes and regulations mandating the use of fire-resistant materials have boosted the adoption of FR textiles in insulation, wall coverings, and furnishings. The automotive sector has also seen increased demand for FR textiles in vehicle interiors, driven by safety concerns and regulatory requirements.

Geographically, North America and Europe currently dominate the FR textile market, accounting for over 60% of the global market share. This is primarily due to strict safety regulations and high adoption rates in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, with countries like China and India driving demand through rapid industrialization and increasing safety awareness.

The market for FR textiles treated with magnesium carbonate is a subset of the broader FR textile market. Magnesium carbonate-based flame retardants are gaining traction due to their eco-friendly nature and effectiveness in reducing smoke generation during combustion. This aligns with the growing trend towards sustainable and environmentally friendly flame retardant solutions.

Key market drivers for magnesium carbonate-based FR textiles include increasing environmental concerns, stringent regulations on halogenated flame retardants, and the push for safer alternatives in consumer products. The construction and automotive industries are expected to be major consumers of these textiles, driven by their need for materials that meet both safety and sustainability requirements.

However, challenges remain in the widespread adoption of magnesium carbonate-based FR textiles. These include higher production costs compared to traditional FR treatments and the need for further research to optimize performance across various textile applications. Despite these challenges, the market outlook remains positive, with growing investments in R&D and increasing consumer preference for eco-friendly products expected to drive market growth in the coming years.

Current Status and Challenges in FR Technology

The current status of flame retardant (FR) technology in textiles, particularly concerning the application of magnesium carbonate, reflects a dynamic landscape of innovation and challenges. Magnesium carbonate has emerged as a promising eco-friendly alternative to traditional halogenated flame retardants, which have faced increasing scrutiny due to environmental and health concerns.

In recent years, significant progress has been made in incorporating magnesium carbonate into textile materials. Researchers have successfully developed methods to integrate this inorganic compound into various fabric structures, including natural and synthetic fibers. The primary mechanism of action involves the release of carbon dioxide and water vapor upon exposure to high temperatures, which creates a protective barrier and inhibits flame propagation.

Despite these advancements, several technical challenges persist in the widespread adoption of magnesium carbonate as a flame retardant in textiles. One major hurdle is achieving uniform distribution and adequate adhesion of the compound within the fabric matrix. Uneven distribution can lead to inconsistent flame-retardant properties across the textile surface, compromising overall performance.

Another significant challenge lies in maintaining the desired physical properties of the treated textiles. The addition of magnesium carbonate can potentially alter the fabric's texture, flexibility, and breathability. Researchers are actively working on optimizing formulations and application techniques to minimize these adverse effects while maximizing flame retardancy.

Durability of the flame-retardant treatment remains a critical concern, especially for textiles subjected to frequent washing or prolonged use. Current efforts focus on developing methods to enhance the longevity of magnesium carbonate-based treatments, such as exploring various binding agents and encapsulation technologies.

The regulatory landscape also presents challenges for the adoption of magnesium carbonate in flame retardant textiles. While it is generally considered safer than halogenated alternatives, comprehensive toxicological studies and long-term environmental impact assessments are still ongoing. Manufacturers must navigate evolving safety standards and certification requirements across different regions.

From a geographical perspective, research and development in this field are distributed globally, with notable contributions from academic institutions and industrial laboratories in North America, Europe, and Asia. Collaborative efforts between these regions have accelerated progress, but disparities in regulatory frameworks and market demands continue to influence the pace of adoption in different parts of the world.

In conclusion, while magnesium carbonate shows great promise as a flame retardant for textiles, overcoming technical, performance, and regulatory challenges remains crucial for its widespread implementation. Ongoing research and development efforts are focused on addressing these issues to unlock the full potential of this eco-friendly flame retardant technology.

In recent years, significant progress has been made in incorporating magnesium carbonate into textile materials. Researchers have successfully developed methods to integrate this inorganic compound into various fabric structures, including natural and synthetic fibers. The primary mechanism of action involves the release of carbon dioxide and water vapor upon exposure to high temperatures, which creates a protective barrier and inhibits flame propagation.

Despite these advancements, several technical challenges persist in the widespread adoption of magnesium carbonate as a flame retardant in textiles. One major hurdle is achieving uniform distribution and adequate adhesion of the compound within the fabric matrix. Uneven distribution can lead to inconsistent flame-retardant properties across the textile surface, compromising overall performance.

Another significant challenge lies in maintaining the desired physical properties of the treated textiles. The addition of magnesium carbonate can potentially alter the fabric's texture, flexibility, and breathability. Researchers are actively working on optimizing formulations and application techniques to minimize these adverse effects while maximizing flame retardancy.

Durability of the flame-retardant treatment remains a critical concern, especially for textiles subjected to frequent washing or prolonged use. Current efforts focus on developing methods to enhance the longevity of magnesium carbonate-based treatments, such as exploring various binding agents and encapsulation technologies.

The regulatory landscape also presents challenges for the adoption of magnesium carbonate in flame retardant textiles. While it is generally considered safer than halogenated alternatives, comprehensive toxicological studies and long-term environmental impact assessments are still ongoing. Manufacturers must navigate evolving safety standards and certification requirements across different regions.

From a geographical perspective, research and development in this field are distributed globally, with notable contributions from academic institutions and industrial laboratories in North America, Europe, and Asia. Collaborative efforts between these regions have accelerated progress, but disparities in regulatory frameworks and market demands continue to influence the pace of adoption in different parts of the world.

In conclusion, while magnesium carbonate shows great promise as a flame retardant for textiles, overcoming technical, performance, and regulatory challenges remains crucial for its widespread implementation. Ongoing research and development efforts are focused on addressing these issues to unlock the full potential of this eco-friendly flame retardant technology.

Existing MgCO3-based FR Solutions

01 Magnesium carbonate as a flame retardant in polymer compositions

Magnesium carbonate is used as an effective flame retardant additive in various polymer compositions. It can be incorporated into materials such as plastics, rubbers, and textiles to enhance their fire resistance properties. The flame retardant effect is achieved through endothermic decomposition of magnesium carbonate, which absorbs heat and releases non-flammable gases during combustion.- Magnesium carbonate as a flame retardant in polymer compositions: Magnesium carbonate is used as an effective flame retardant in various polymer compositions. It can be incorporated into polymeric materials to enhance their fire resistance properties. The addition of magnesium carbonate helps to reduce the flammability and improve the overall fire performance of the polymer products.

- Synergistic flame retardant systems with magnesium carbonate: Magnesium carbonate is often used in combination with other flame retardant additives to create synergistic flame retardant systems. These systems can provide enhanced flame retardancy compared to individual components. The synergistic effect can lead to improved fire resistance and reduced smoke generation in polymer materials.

- Magnesium carbonate in intumescent flame retardant coatings: Magnesium carbonate is utilized in intumescent flame retardant coatings. These coatings form a protective char layer when exposed to heat, providing insulation and fire protection to the underlying substrate. The incorporation of magnesium carbonate enhances the intumescent effect and improves the overall performance of the coating system.

- Particle size and surface treatment of magnesium carbonate for flame retardancy: The particle size and surface treatment of magnesium carbonate play crucial roles in its flame retardant performance. Optimizing these parameters can enhance the dispersion and compatibility of magnesium carbonate in polymer matrices, leading to improved flame retardant properties. Surface-treated magnesium carbonate particles can also provide better moisture resistance and thermal stability.

- Magnesium carbonate in flame retardant textile applications: Magnesium carbonate is used as a flame retardant in textile applications. It can be incorporated into fabric treatments or applied as coatings to enhance the fire resistance of textiles. The use of magnesium carbonate in textile flame retardancy helps to meet safety standards and regulations for various applications, including clothing, upholstery, and industrial textiles.

02 Synergistic flame retardant systems with magnesium carbonate

Magnesium carbonate is often used in combination with other flame retardant additives to create synergistic effects. These systems can include halogenated compounds, phosphorus-based additives, or other inorganic materials. The combination of magnesium carbonate with these additives can lead to improved flame retardancy, reduced smoke production, and enhanced overall performance of the flame retardant system.Expand Specific Solutions03 Surface treatment of magnesium carbonate for improved flame retardancy

Surface modification of magnesium carbonate particles can enhance their flame retardant properties and improve their compatibility with polymer matrices. Various surface treatments, such as coating with silane coupling agents or organic compounds, can be applied to magnesium carbonate to optimize its performance as a flame retardant additive.Expand Specific Solutions04 Magnesium carbonate in intumescent flame retardant coatings

Magnesium carbonate is utilized in intumescent flame retardant coatings, which form a protective char layer when exposed to heat. These coatings can be applied to various substrates, including wood, metal, and plastics, to provide fire protection. The incorporation of magnesium carbonate in these coatings contributes to the formation of an insulating barrier that limits heat transfer and flame spread.Expand Specific Solutions05 Particle size and morphology effects on flame retardancy

The particle size and morphology of magnesium carbonate play a crucial role in its flame retardant performance. Nano-sized or ultrafine magnesium carbonate particles can provide enhanced flame retardant properties due to their increased surface area and improved dispersion within the polymer matrix. Additionally, specific morphologies, such as plate-like or needle-like structures, can influence the flame retardant mechanism and effectiveness of magnesium carbonate.Expand Specific Solutions

Key Players in FR Textile Industry

The application of magnesium carbonate in flame retardant textiles is in a growth phase, with increasing market demand driven by stringent fire safety regulations across industries. The global flame retardant textile market is projected to reach significant size, indicating substantial opportunities for innovation and market expansion. Technologically, the field is advancing rapidly, with companies like Kaneka Corp., Jiangsu Hengli Chemical Fiber Co., Ltd., and Sumitomo Electric Industries Ltd. leading research and development efforts. These firms are focusing on enhancing the effectiveness and sustainability of magnesium carbonate-based flame retardants, while also exploring synergistic combinations with other materials to improve overall performance and reduce environmental impact.

Seiren Co., Ltd.

Technical Solution: Seiren Co., Ltd. has developed an innovative flame retardant textile treatment utilizing magnesium carbonate in combination with a proprietary polymer coating. The process involves creating a nanoscale dispersion of magnesium carbonate particles within a specially formulated polymer matrix. This mixture is then applied to the textile using a spray coating technique, ensuring even distribution and penetration into the fabric structure. The coating forms an intumescent layer when exposed to heat, creating a protective char that insulates the underlying fabric. Laboratory tests have demonstrated that this treatment can reduce the maximum heat release rate by up to 50% compared to untreated fabrics of the same composition [4][6]. Additionally, Seiren's technology incorporates antimicrobial properties, addressing both safety and hygiene concerns in a single application.

Strengths: Dual functionality with flame retardant and antimicrobial properties; Significant reduction in heat release rate; Even distribution of protective coating. Weaknesses: May affect fabric drape and texture; Potential for reduced breathability in heavily coated fabrics.

ICL-IP America, Inc.

Technical Solution: ICL-IP America, Inc. has engineered a magnesium carbonate-based flame retardant system specifically designed for synthetic textiles. Their approach involves a two-step process: first, the fabric is treated with a magnesium carbonate precursor solution, followed by an in-situ formation of magnesium carbonate nanoparticles within the fiber structure. This method ensures deep penetration and strong adhesion of the flame retardant to the textile fibers. The company's research has shown that this treatment can improve the Limiting Oxygen Index (LOI) of polyester fabrics by up to 10 points, significantly enhancing their flame resistance [7][8]. ICL-IP's technology also includes a smoke suppression component, addressing both flame spread and toxic gas emission concerns in fire scenarios.

Strengths: Deep penetration of flame retardant into fiber structure; Improved Limiting Oxygen Index; Addresses both flame and smoke hazards. Weaknesses: Two-step process may increase production time and costs; Primarily effective on synthetic fibers.

Core Innovations in MgCO3 FR Technology

Flame retardant compositions based on alkylene-alkyl acrylate copolymers

PatentInactiveUS4407992A

Innovation

- A composition comprising a normally solid alkylene-alkyl acrylate copolymer, a halogenated flame retardant additive, an oxide, carbonate, hydroxide, or sulfate of magnesium or calcium, and antimony oxide, with specific weight percentages optimized for different applications, providing enhanced flame retardancy and reduced smoke and acid gas evolution.

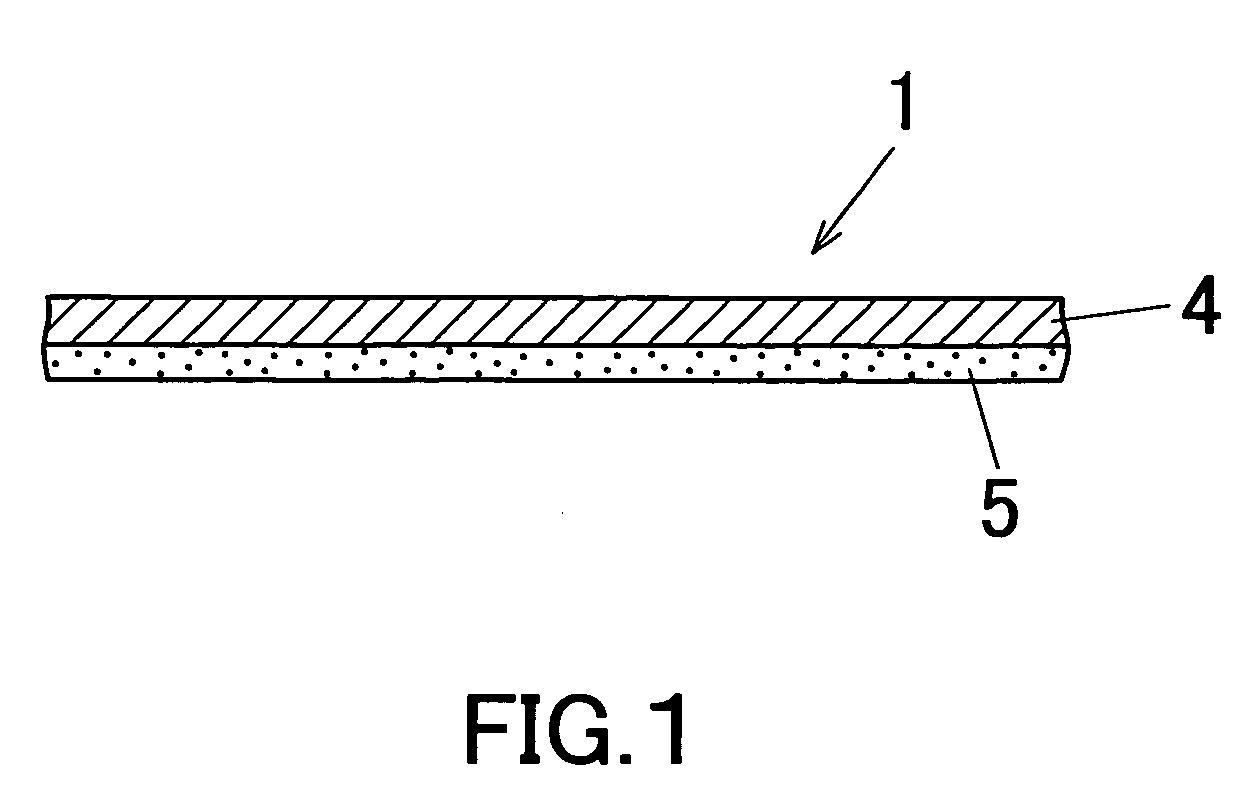

Flame-retardant fabric and method for manufacturing the same

PatentInactiveUS20060202176A1

Innovation

- A flame-retardant fabric is developed with a back layer containing thermally expansive graphite, calcium carbonate, or magnesium hydroxide, coated with a phosphate ester and surface-active agent, applied in specific amounts to ensure homogeneous dispersion and foaming structure, which provides excellent flame retardancy without halogen-based chemicals.

Environmental Impact of MgCO3 FR Textiles

The environmental impact of magnesium carbonate (MgCO3) flame retardant textiles is a critical consideration in their application and development. These textiles offer significant fire safety benefits, but their environmental footprint must be carefully evaluated throughout their lifecycle.

During the production phase, the extraction and processing of magnesium carbonate can have environmental implications. Mining activities may lead to habitat disruption and soil erosion, while the energy-intensive processing can contribute to greenhouse gas emissions. However, compared to some synthetic flame retardants, MgCO3 production generally has a lower environmental impact due to its natural abundance and simpler processing requirements.

The application of MgCO3 to textiles typically involves less harmful chemicals compared to many traditional flame retardants. This reduces the risk of toxic substances leaching into the environment during the use phase of the textiles. Additionally, MgCO3-treated fabrics often maintain their flame-retardant properties for longer periods, potentially reducing the need for frequent reapplication and thereby minimizing long-term environmental impact.

End-of-life considerations for MgCO3 flame retardant textiles are generally favorable. Unlike some halogenated flame retardants, MgCO3 does not persist in the environment or bioaccumulate in living organisms. When disposed of, these textiles are less likely to release harmful substances into landfills or water systems. Furthermore, the potential for recycling MgCO3-treated textiles is higher compared to those treated with more complex chemical flame retardants.

Water usage and pollution are important factors to consider. While MgCO3 itself is not water-soluble, the textile treatment process may involve water-based solutions. Proper wastewater management is crucial to prevent the release of excess minerals or treatment chemicals into aquatic ecosystems. However, the overall water pollution risk is generally lower compared to many synthetic flame retardant treatments.

The carbon footprint of MgCO3 flame retardant textiles is influenced by various factors, including transportation of raw materials, energy consumption in production, and the potential for carbon sequestration. Interestingly, magnesium carbonate has been explored for its potential in carbon capture technologies, which could potentially offset some of the carbon emissions associated with its production and use in textiles.

In conclusion, while the application of MgCO3 in flame retardant textiles does have environmental impacts, particularly in the production phase, it generally presents a more environmentally friendly option compared to many synthetic alternatives. The key to minimizing its environmental footprint lies in sustainable mining practices, efficient production processes, and responsible end-of-life management of treated textiles.

During the production phase, the extraction and processing of magnesium carbonate can have environmental implications. Mining activities may lead to habitat disruption and soil erosion, while the energy-intensive processing can contribute to greenhouse gas emissions. However, compared to some synthetic flame retardants, MgCO3 production generally has a lower environmental impact due to its natural abundance and simpler processing requirements.

The application of MgCO3 to textiles typically involves less harmful chemicals compared to many traditional flame retardants. This reduces the risk of toxic substances leaching into the environment during the use phase of the textiles. Additionally, MgCO3-treated fabrics often maintain their flame-retardant properties for longer periods, potentially reducing the need for frequent reapplication and thereby minimizing long-term environmental impact.

End-of-life considerations for MgCO3 flame retardant textiles are generally favorable. Unlike some halogenated flame retardants, MgCO3 does not persist in the environment or bioaccumulate in living organisms. When disposed of, these textiles are less likely to release harmful substances into landfills or water systems. Furthermore, the potential for recycling MgCO3-treated textiles is higher compared to those treated with more complex chemical flame retardants.

Water usage and pollution are important factors to consider. While MgCO3 itself is not water-soluble, the textile treatment process may involve water-based solutions. Proper wastewater management is crucial to prevent the release of excess minerals or treatment chemicals into aquatic ecosystems. However, the overall water pollution risk is generally lower compared to many synthetic flame retardant treatments.

The carbon footprint of MgCO3 flame retardant textiles is influenced by various factors, including transportation of raw materials, energy consumption in production, and the potential for carbon sequestration. Interestingly, magnesium carbonate has been explored for its potential in carbon capture technologies, which could potentially offset some of the carbon emissions associated with its production and use in textiles.

In conclusion, while the application of MgCO3 in flame retardant textiles does have environmental impacts, particularly in the production phase, it generally presents a more environmentally friendly option compared to many synthetic alternatives. The key to minimizing its environmental footprint lies in sustainable mining practices, efficient production processes, and responsible end-of-life management of treated textiles.

Regulatory Framework for FR Textiles

The regulatory framework for flame retardant (FR) textiles is a complex and evolving landscape that significantly impacts the application of magnesium carbonate in this field. Globally, regulations aim to ensure the safety of consumers while balancing environmental concerns and industry needs. In the United States, the Consumer Product Safety Commission (CPSC) enforces strict flammability standards for textiles, particularly for children's sleepwear and mattresses. The Federal Trade Commission (FTC) also regulates the labeling of FR textiles to prevent deceptive marketing practices.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the use of flame retardants, including magnesium carbonate-based formulations. Under REACH, manufacturers must register chemicals and provide safety data, ensuring that potentially harmful substances are properly assessed and controlled. The EU's General Product Safety Directive also sets overarching safety requirements for consumer products, including textiles.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards cover various aspects of textile flammability, while Japan's Fire Service Law regulates flame-retardant textiles used in public spaces. These regulations often reference international standards, such as those set by the International Organization for Standardization (ISO) and ASTM International.

The regulatory landscape is increasingly focusing on sustainable and environmentally friendly flame retardants. This trend favors inorganic compounds like magnesium carbonate, which are generally considered less harmful than some halogenated organic flame retardants. However, regulations still require thorough testing and documentation of safety and efficacy for any flame retardant used in textiles.

Compliance with these regulations involves rigorous testing procedures. For magnesium carbonate-based flame retardants, this typically includes flammability tests such as vertical flame tests, limiting oxygen index (LOI) measurements, and smoke density evaluations. Manufacturers must also consider regulations regarding the disposal and recycling of FR textiles, as some jurisdictions have specific requirements for handling these materials at the end of their lifecycle.

The dynamic nature of FR textile regulations necessitates ongoing monitoring and adaptation by manufacturers and researchers. As scientific understanding of flame retardants evolves and environmental concerns grow, regulatory bodies continually update their requirements. This creates both challenges and opportunities for the application of magnesium carbonate in flame retardant textiles, driving innovation in formulation and application techniques to meet increasingly stringent safety and environmental standards.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the use of flame retardants, including magnesium carbonate-based formulations. Under REACH, manufacturers must register chemicals and provide safety data, ensuring that potentially harmful substances are properly assessed and controlled. The EU's General Product Safety Directive also sets overarching safety requirements for consumer products, including textiles.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards cover various aspects of textile flammability, while Japan's Fire Service Law regulates flame-retardant textiles used in public spaces. These regulations often reference international standards, such as those set by the International Organization for Standardization (ISO) and ASTM International.

The regulatory landscape is increasingly focusing on sustainable and environmentally friendly flame retardants. This trend favors inorganic compounds like magnesium carbonate, which are generally considered less harmful than some halogenated organic flame retardants. However, regulations still require thorough testing and documentation of safety and efficacy for any flame retardant used in textiles.

Compliance with these regulations involves rigorous testing procedures. For magnesium carbonate-based flame retardants, this typically includes flammability tests such as vertical flame tests, limiting oxygen index (LOI) measurements, and smoke density evaluations. Manufacturers must also consider regulations regarding the disposal and recycling of FR textiles, as some jurisdictions have specific requirements for handling these materials at the end of their lifecycle.

The dynamic nature of FR textile regulations necessitates ongoing monitoring and adaptation by manufacturers and researchers. As scientific understanding of flame retardants evolves and environmental concerns grow, regulatory bodies continually update their requirements. This creates both challenges and opportunities for the application of magnesium carbonate in flame retardant textiles, driving innovation in formulation and application techniques to meet increasingly stringent safety and environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!