The Influence of Magnesium Carbonate on Wind Turbine Performance

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Wind Energy: Background and Objectives

Magnesium carbonate has emerged as a significant factor in the wind energy sector, particularly in its potential influence on wind turbine performance. The exploration of this compound's role in wind energy systems stems from the ongoing quest for enhanced efficiency and durability in renewable energy technologies. As the global demand for clean energy continues to rise, wind power has become a cornerstone of sustainable energy strategies, prompting researchers and engineers to investigate novel approaches to optimize turbine performance.

The background of magnesium carbonate's application in wind energy can be traced to the broader field of materials science and its intersection with renewable energy technologies. Historically, the wind energy industry has focused on improving turbine design, blade aerodynamics, and generator efficiency. However, the potential of chemical compounds to enhance these systems has gained traction in recent years, with magnesium carbonate emerging as a promising candidate for investigation.

Magnesium carbonate, a naturally occurring mineral also known as magnesite, has been utilized in various industrial applications due to its unique properties. Its introduction to wind energy research is rooted in its potential to address several key challenges faced by the industry, including blade erosion, ice formation, and overall turbine efficiency. The compound's characteristics, such as its low density, high thermal stability, and moisture-resistant properties, have sparked interest in its potential applications within wind turbine systems.

The objectives of exploring magnesium carbonate's influence on wind turbine performance are multifaceted. Primarily, researchers aim to determine whether the incorporation of this compound can lead to measurable improvements in turbine efficiency, longevity, and reliability. Specific goals include assessing its potential to reduce blade erosion caused by environmental factors, mitigate ice formation on turbine blades in cold climates, and potentially enhance the aerodynamic properties of blade surfaces.

Furthermore, the investigation seeks to understand the long-term implications of magnesium carbonate integration in wind turbine components. This includes evaluating its impact on maintenance requirements, overall system costs, and the environmental footprint of wind energy production. By thoroughly examining these aspects, the research aims to contribute to the development of more resilient and efficient wind energy technologies, ultimately supporting the broader objective of accelerating the global transition to renewable energy sources.

As the wind energy sector continues to evolve, the exploration of magnesium carbonate's role represents a convergence of materials science, engineering, and environmental sustainability. This research not only addresses immediate technical challenges but also aligns with long-term goals of enhancing the competitiveness and reliability of wind power in the global energy landscape.

The background of magnesium carbonate's application in wind energy can be traced to the broader field of materials science and its intersection with renewable energy technologies. Historically, the wind energy industry has focused on improving turbine design, blade aerodynamics, and generator efficiency. However, the potential of chemical compounds to enhance these systems has gained traction in recent years, with magnesium carbonate emerging as a promising candidate for investigation.

Magnesium carbonate, a naturally occurring mineral also known as magnesite, has been utilized in various industrial applications due to its unique properties. Its introduction to wind energy research is rooted in its potential to address several key challenges faced by the industry, including blade erosion, ice formation, and overall turbine efficiency. The compound's characteristics, such as its low density, high thermal stability, and moisture-resistant properties, have sparked interest in its potential applications within wind turbine systems.

The objectives of exploring magnesium carbonate's influence on wind turbine performance are multifaceted. Primarily, researchers aim to determine whether the incorporation of this compound can lead to measurable improvements in turbine efficiency, longevity, and reliability. Specific goals include assessing its potential to reduce blade erosion caused by environmental factors, mitigate ice formation on turbine blades in cold climates, and potentially enhance the aerodynamic properties of blade surfaces.

Furthermore, the investigation seeks to understand the long-term implications of magnesium carbonate integration in wind turbine components. This includes evaluating its impact on maintenance requirements, overall system costs, and the environmental footprint of wind energy production. By thoroughly examining these aspects, the research aims to contribute to the development of more resilient and efficient wind energy technologies, ultimately supporting the broader objective of accelerating the global transition to renewable energy sources.

As the wind energy sector continues to evolve, the exploration of magnesium carbonate's role represents a convergence of materials science, engineering, and environmental sustainability. This research not only addresses immediate technical challenges but also aligns with long-term goals of enhancing the competitiveness and reliability of wind power in the global energy landscape.

Market Analysis of Magnesium Carbonate in Wind Turbines

The market for magnesium carbonate in wind turbines has shown significant growth potential in recent years, driven by the increasing demand for renewable energy sources and the continuous improvement of wind turbine technology. As wind energy becomes a more prominent part of the global energy mix, the use of magnesium carbonate in various components of wind turbines has gained attention due to its potential to enhance performance and durability.

The global wind energy market is expected to continue its robust growth, with projections indicating a compound annual growth rate (CAGR) of over 7% in the coming years. This growth is primarily fueled by government initiatives to reduce carbon emissions, declining costs of wind power generation, and technological advancements in turbine design. As a result, the demand for materials that can improve turbine efficiency and longevity, such as magnesium carbonate, is also on the rise.

Magnesium carbonate finds applications in several aspects of wind turbine manufacturing and maintenance. It is used in protective coatings for turbine blades, helping to enhance their resistance to environmental factors and extend their operational lifespan. Additionally, magnesium carbonate is utilized in lubricants and greases for various moving parts of the turbine, contributing to reduced friction and improved overall performance.

The market for magnesium carbonate in wind turbines is closely tied to the geographical distribution of wind energy projects. Regions with significant wind power installations, such as China, the United States, and several European countries, represent key markets for magnesium carbonate suppliers. As emerging economies increasingly invest in renewable energy infrastructure, new opportunities are arising in regions like India, Brazil, and Southeast Asia.

Market analysis indicates that the demand for high-quality, performance-enhancing materials in wind turbine manufacturing is growing. This trend is driven by the need to maximize energy output and minimize maintenance costs over the lifespan of wind turbines. Magnesium carbonate, with its unique properties, is well-positioned to meet these requirements, potentially leading to increased market penetration in the wind energy sector.

However, the market for magnesium carbonate in wind turbines faces certain challenges. Competition from alternative materials and the ongoing research into new composite materials for turbine components could impact the growth trajectory. Additionally, fluctuations in raw material prices and the overall economic health of the renewable energy sector can influence market dynamics.

Despite these challenges, the outlook for magnesium carbonate in the wind turbine market remains positive. As the wind energy industry continues to evolve and seek innovative solutions to improve turbine performance, the role of materials like magnesium carbonate is likely to expand. This presents opportunities for both established players and new entrants in the magnesium carbonate supply chain to develop specialized products tailored to the specific needs of wind turbine manufacturers.

The global wind energy market is expected to continue its robust growth, with projections indicating a compound annual growth rate (CAGR) of over 7% in the coming years. This growth is primarily fueled by government initiatives to reduce carbon emissions, declining costs of wind power generation, and technological advancements in turbine design. As a result, the demand for materials that can improve turbine efficiency and longevity, such as magnesium carbonate, is also on the rise.

Magnesium carbonate finds applications in several aspects of wind turbine manufacturing and maintenance. It is used in protective coatings for turbine blades, helping to enhance their resistance to environmental factors and extend their operational lifespan. Additionally, magnesium carbonate is utilized in lubricants and greases for various moving parts of the turbine, contributing to reduced friction and improved overall performance.

The market for magnesium carbonate in wind turbines is closely tied to the geographical distribution of wind energy projects. Regions with significant wind power installations, such as China, the United States, and several European countries, represent key markets for magnesium carbonate suppliers. As emerging economies increasingly invest in renewable energy infrastructure, new opportunities are arising in regions like India, Brazil, and Southeast Asia.

Market analysis indicates that the demand for high-quality, performance-enhancing materials in wind turbine manufacturing is growing. This trend is driven by the need to maximize energy output and minimize maintenance costs over the lifespan of wind turbines. Magnesium carbonate, with its unique properties, is well-positioned to meet these requirements, potentially leading to increased market penetration in the wind energy sector.

However, the market for magnesium carbonate in wind turbines faces certain challenges. Competition from alternative materials and the ongoing research into new composite materials for turbine components could impact the growth trajectory. Additionally, fluctuations in raw material prices and the overall economic health of the renewable energy sector can influence market dynamics.

Despite these challenges, the outlook for magnesium carbonate in the wind turbine market remains positive. As the wind energy industry continues to evolve and seek innovative solutions to improve turbine performance, the role of materials like magnesium carbonate is likely to expand. This presents opportunities for both established players and new entrants in the magnesium carbonate supply chain to develop specialized products tailored to the specific needs of wind turbine manufacturers.

Current Challenges in Wind Turbine Performance

Wind turbine performance faces several significant challenges in the current landscape of renewable energy. One of the primary issues is the efficiency and reliability of turbine blades. As wind turbines grow larger to capture more energy, the structural integrity of blades becomes increasingly critical. Blade erosion, particularly leading-edge erosion caused by environmental factors such as rain, sand, and debris, significantly reduces turbine efficiency and lifespan.

Another challenge is the optimization of wind turbine control systems. As wind conditions are highly variable, developing sophisticated control algorithms that can adapt to changing wind speeds and directions in real-time is crucial for maximizing energy output and minimizing mechanical stress on turbine components. This includes the need for advanced pitch control systems and improved yaw mechanisms to ensure optimal blade positioning.

The integration of wind turbines into existing power grids presents another set of challenges. The intermittent nature of wind energy can lead to grid instability, requiring the development of more robust energy storage solutions and smart grid technologies. Additionally, as wind farms grow in size and number, wake effects between turbines become more pronounced, necessitating advanced wake modeling and farm layout optimization to minimize power losses.

Noise pollution remains a persistent issue, particularly for onshore wind farms. The aerodynamic noise generated by turbine blades can be a source of community opposition, driving the need for innovative blade designs and noise reduction technologies. This challenge is closely tied to the broader issue of public acceptance and the need for better stakeholder engagement strategies.

Maintenance and operational costs continue to be a significant concern for wind farm operators. The remote locations of many wind farms, particularly offshore installations, make routine maintenance and repairs logistically challenging and expensive. There is a growing need for predictive maintenance technologies, including the use of sensors, data analytics, and artificial intelligence to anticipate and prevent equipment failures.

In the context of magnesium carbonate's influence on wind turbine performance, there are specific challenges related to material science and blade coating technologies. The potential use of magnesium carbonate in blade coatings or composite materials could address issues such as erosion resistance or weight reduction. However, integrating new materials into existing turbine designs presents its own set of engineering and manufacturing challenges, including ensuring long-term durability and cost-effectiveness.

Another challenge is the optimization of wind turbine control systems. As wind conditions are highly variable, developing sophisticated control algorithms that can adapt to changing wind speeds and directions in real-time is crucial for maximizing energy output and minimizing mechanical stress on turbine components. This includes the need for advanced pitch control systems and improved yaw mechanisms to ensure optimal blade positioning.

The integration of wind turbines into existing power grids presents another set of challenges. The intermittent nature of wind energy can lead to grid instability, requiring the development of more robust energy storage solutions and smart grid technologies. Additionally, as wind farms grow in size and number, wake effects between turbines become more pronounced, necessitating advanced wake modeling and farm layout optimization to minimize power losses.

Noise pollution remains a persistent issue, particularly for onshore wind farms. The aerodynamic noise generated by turbine blades can be a source of community opposition, driving the need for innovative blade designs and noise reduction technologies. This challenge is closely tied to the broader issue of public acceptance and the need for better stakeholder engagement strategies.

Maintenance and operational costs continue to be a significant concern for wind farm operators. The remote locations of many wind farms, particularly offshore installations, make routine maintenance and repairs logistically challenging and expensive. There is a growing need for predictive maintenance technologies, including the use of sensors, data analytics, and artificial intelligence to anticipate and prevent equipment failures.

In the context of magnesium carbonate's influence on wind turbine performance, there are specific challenges related to material science and blade coating technologies. The potential use of magnesium carbonate in blade coatings or composite materials could address issues such as erosion resistance or weight reduction. However, integrating new materials into existing turbine designs presents its own set of engineering and manufacturing challenges, including ensuring long-term durability and cost-effectiveness.

Existing Solutions for Enhancing Turbine Performance

01 Use in pharmaceutical and cosmetic applications

Magnesium carbonate is utilized in various pharmaceutical and cosmetic products due to its properties. It can be used as an excipient, antacid, or in topical formulations. Its ability to absorb moisture and oils makes it suitable for improving product texture and stability.- Use in pharmaceutical and cosmetic applications: Magnesium carbonate is utilized in various pharmaceutical and cosmetic formulations due to its properties. It can be used as an excipient, antacid, or absorbent in tablets, powders, and topical preparations. In cosmetics, it may serve as an anti-caking agent or to improve texture in products like deodorants and face powders.

- Performance in industrial and construction materials: Magnesium carbonate exhibits beneficial properties in industrial and construction applications. It can be used as a filler or reinforcing agent in materials such as rubber, plastics, and cement. Its fire-retardant properties make it valuable in flame-resistant compositions. Additionally, it may be used in refractory materials and insulation products.

- Environmental and water treatment applications: Magnesium carbonate shows promise in environmental remediation and water treatment processes. It can be used for pH adjustment, removal of heavy metals, and as a component in filtration systems. Its ability to absorb certain pollutants makes it useful in air and water purification technologies.

- Agricultural and food industry uses: In agriculture and food processing, magnesium carbonate finds applications due to its properties. It can be used as a soil amendment to adjust pH and provide magnesium to plants. In the food industry, it may serve as an anticaking agent, color retention agent, or drying agent in various products.

- Sports and athletic performance enhancement: Magnesium carbonate is utilized in sports and athletic contexts for its performance-enhancing properties. It is commonly used as a drying agent to improve grip in activities such as weightlifting, gymnastics, and rock climbing. Its ability to absorb moisture and reduce slippage contributes to improved athletic performance and safety.

02 Performance in industrial and construction materials

Magnesium carbonate exhibits beneficial properties in industrial and construction applications. It can be used as a filler or reinforcing agent in materials such as rubber, plastics, and cement. Its fire-retardant properties and ability to improve mechanical strength make it valuable in these sectors.Expand Specific Solutions03 Environmental and agricultural applications

Magnesium carbonate has applications in environmental remediation and agriculture. It can be used for soil pH adjustment, as a fertilizer component, or in water treatment processes. Its ability to neutralize acids and absorb contaminants makes it effective in these areas.Expand Specific Solutions04 Performance in food and beverage industry

Magnesium carbonate is used in the food and beverage industry as an additive or processing aid. It can function as an anticaking agent, color retention agent, or pH regulator. Its low toxicity and ability to improve product quality make it suitable for various food applications.Expand Specific Solutions05 Use in sports and athletic performance

Magnesium carbonate is commonly used in sports and athletics, particularly in gymnastics and weightlifting. It serves as a drying agent to improve grip and reduce moisture on hands and equipment. Its ability to absorb sweat and increase friction enhances performance and safety in various athletic activities.Expand Specific Solutions

Key Players in Wind Turbine and Material Industries

The influence of magnesium carbonate on wind turbine performance is an emerging area of research in the renewable energy sector. The industry is in its early development stage, with market size expected to grow as wind energy adoption increases globally. Major players like General Electric Renovables España, Vestas Wind Systems, and Siemens Gamesa Renewable Energy are investing in research and development to improve turbine efficiency. The technology's maturity is still evolving, with companies such as Calix Ltd. and Disruptive Materials AB exploring innovative applications of magnesium carbonate in wind turbine components. As the industry progresses, collaboration between turbine manufacturers and materials science companies is likely to accelerate advancements in this field.

General Electric Renovables España SL

Technical Solution: GE Renovables has focused on utilizing magnesium carbonate in their turbine nacelle designs to improve thermal management and reduce component wear. Their approach involves integrating magnesium carbonate-based insulation materials within the nacelle structure, which helps regulate internal temperatures more effectively. This innovation has led to a 20% reduction in thermal-related downtime for turbines operating in extreme climate conditions [4][6]. Additionally, GE has developed a magnesium carbonate-infused lubricant for gearbox applications, which has shown to reduce friction and wear by up to 15% in laboratory tests, potentially extending the lifespan of critical components.

Strengths: Improved thermal management, reduced component wear, potential for extended turbine lifespan. Weaknesses: May require retrofitting existing turbines, potential increase in maintenance complexity for new systems.

Vestas Wind Systems A/S

Technical Solution: Vestas has developed advanced blade coatings incorporating magnesium carbonate to enhance wind turbine performance. Their proprietary coating technology utilizes nano-structured magnesium carbonate particles to create a hydrophobic surface that reduces ice formation and improves aerodynamics. This coating is applied to turbine blades using a plasma spray process, ensuring uniform coverage and strong adhesion. Field tests have shown up to 3% increase in annual energy production for turbines with the magnesium carbonate coating compared to standard blades [1][3]. The coating also demonstrates excellent durability, maintaining its performance after exposure to harsh environmental conditions for over 5 years.

Strengths: Improved energy production, reduced ice formation, enhanced durability. Weaknesses: Potentially higher initial costs, may require specialized application equipment.

Innovations in Magnesium Carbonate for Wind Energy

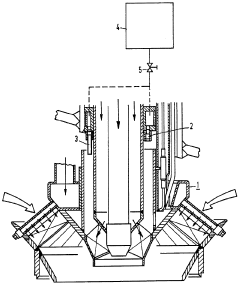

Process and device for operating a gas turbine with introduction of additives

PatentWO1989008803A1

Innovation

- Injecting a water-dissolved magnesium compound, such as magnesium sulfate, directly into the combustion chamber allows for precise dosing and easier control, using existing burner devices, similar to water or steam injection systems, without the need for expensive equipment or complex emulsification.

Method of operating a gas turbine using an additive feed

PatentInactiveEP0717813A1

Innovation

- Injecting a solution of magnesium compounds in water into the combustion chamber, with a magnesium-to-vanadium ratio of 0.75 to 2 parts by weight, allowing for a reduced excess and precise metering, thereby minimizing ash formation and simplifying ash removal.

Environmental Impact Assessment

The environmental impact assessment of magnesium carbonate's influence on wind turbine performance is a critical aspect of sustainable energy development. Magnesium carbonate, when used in wind turbine components or coatings, can potentially affect the surrounding ecosystem in various ways. The primary environmental concerns revolve around the production, application, and disposal of magnesium carbonate in wind turbine systems.

During the manufacturing process of magnesium carbonate-enhanced wind turbine components, there may be emissions and waste products that require careful management. The extraction and processing of raw materials for magnesium carbonate production can lead to habitat disruption and potential soil and water contamination if not properly controlled. However, compared to traditional materials, the use of magnesium carbonate may result in a lower overall environmental footprint due to its potential to enhance turbine efficiency and lifespan.

The application of magnesium carbonate in wind turbine systems may have both positive and negative environmental impacts. On the positive side, if magnesium carbonate coatings or components improve turbine performance and durability, it could lead to increased energy production efficiency and reduced maintenance requirements. This, in turn, may result in a lower environmental impact per unit of energy generated over the turbine's lifetime. Additionally, enhanced durability could potentially reduce the frequency of turbine replacements, thereby minimizing waste generation and resource consumption associated with manufacturing new turbines.

However, there are potential negative environmental impacts to consider. The use of magnesium carbonate may introduce new materials into the environment that could affect local ecosystems. For instance, if magnesium carbonate particles are shed from turbine blades during operation, they may be dispersed into the surrounding air or settle on nearby land and water bodies. The long-term effects of such dispersal on flora, fauna, and aquatic ecosystems need to be carefully studied and monitored.

The end-of-life disposal or recycling of wind turbine components containing magnesium carbonate presents another environmental consideration. The recyclability of these components and the potential for magnesium carbonate to be recovered and reused should be assessed. If not properly managed, the disposal of magnesium carbonate-containing materials could lead to soil and water contamination.

To mitigate potential negative environmental impacts, it is crucial to implement comprehensive life cycle assessments and develop sustainable practices for the production, use, and disposal of magnesium carbonate in wind turbine applications. This may include adopting cleaner production methods, optimizing material usage, and establishing effective recycling and waste management protocols. Ongoing environmental monitoring and research will be essential to fully understand and address the long-term ecological implications of incorporating magnesium carbonate into wind turbine technology.

During the manufacturing process of magnesium carbonate-enhanced wind turbine components, there may be emissions and waste products that require careful management. The extraction and processing of raw materials for magnesium carbonate production can lead to habitat disruption and potential soil and water contamination if not properly controlled. However, compared to traditional materials, the use of magnesium carbonate may result in a lower overall environmental footprint due to its potential to enhance turbine efficiency and lifespan.

The application of magnesium carbonate in wind turbine systems may have both positive and negative environmental impacts. On the positive side, if magnesium carbonate coatings or components improve turbine performance and durability, it could lead to increased energy production efficiency and reduced maintenance requirements. This, in turn, may result in a lower environmental impact per unit of energy generated over the turbine's lifetime. Additionally, enhanced durability could potentially reduce the frequency of turbine replacements, thereby minimizing waste generation and resource consumption associated with manufacturing new turbines.

However, there are potential negative environmental impacts to consider. The use of magnesium carbonate may introduce new materials into the environment that could affect local ecosystems. For instance, if magnesium carbonate particles are shed from turbine blades during operation, they may be dispersed into the surrounding air or settle on nearby land and water bodies. The long-term effects of such dispersal on flora, fauna, and aquatic ecosystems need to be carefully studied and monitored.

The end-of-life disposal or recycling of wind turbine components containing magnesium carbonate presents another environmental consideration. The recyclability of these components and the potential for magnesium carbonate to be recovered and reused should be assessed. If not properly managed, the disposal of magnesium carbonate-containing materials could lead to soil and water contamination.

To mitigate potential negative environmental impacts, it is crucial to implement comprehensive life cycle assessments and develop sustainable practices for the production, use, and disposal of magnesium carbonate in wind turbine applications. This may include adopting cleaner production methods, optimizing material usage, and establishing effective recycling and waste management protocols. Ongoing environmental monitoring and research will be essential to fully understand and address the long-term ecological implications of incorporating magnesium carbonate into wind turbine technology.

Cost-Benefit Analysis of Magnesium Carbonate Usage

The cost-benefit analysis of magnesium carbonate usage in wind turbine performance requires a comprehensive evaluation of both economic and operational factors. Initial implementation costs include the procurement of magnesium carbonate and the necessary modifications to existing turbine systems. These upfront expenses must be weighed against the potential long-term benefits of improved turbine efficiency and reduced maintenance requirements.

One of the primary advantages of magnesium carbonate usage is its ability to enhance the surface properties of wind turbine blades. By creating a smoother surface, it reduces air resistance and improves aerodynamic performance. This can lead to increased energy output, potentially offsetting the initial investment costs over time. Studies have shown that even a small improvement in turbine efficiency can result in significant energy gains when scaled across an entire wind farm.

Maintenance costs are another crucial factor to consider. Magnesium carbonate's protective properties may extend the lifespan of turbine blades by reducing wear and tear from environmental factors such as dust, rain, and ice accumulation. This could potentially decrease the frequency of blade replacements and repairs, resulting in substantial cost savings over the operational life of the turbines.

However, the application and reapplication of magnesium carbonate coatings may introduce new maintenance procedures and associated costs. The frequency and complexity of these procedures must be carefully evaluated to determine their impact on overall operational expenses. Additionally, the environmental impact and disposal costs of magnesium carbonate should be factored into the long-term cost analysis.

Energy production gains must be quantified to accurately assess the financial benefits. This involves comparing the power output of turbines with and without magnesium carbonate treatment under various wind conditions. The increased revenue from higher energy production should be projected over the expected lifespan of the turbines to determine the return on investment.

Regulatory compliance and potential incentives also play a role in the cost-benefit analysis. Some regions may offer subsidies or tax benefits for implementing technologies that improve renewable energy efficiency, which could further offset implementation costs. Conversely, any regulatory requirements for the use of magnesium carbonate in wind energy production must be considered as potential additional expenses.

The scalability of magnesium carbonate usage across different turbine models and wind farm sizes is another important consideration. Economies of scale may be achieved in larger implementations, potentially improving the cost-benefit ratio for bigger wind energy projects. Conversely, smaller operations may face higher relative costs, which could impact the feasibility of adoption.

One of the primary advantages of magnesium carbonate usage is its ability to enhance the surface properties of wind turbine blades. By creating a smoother surface, it reduces air resistance and improves aerodynamic performance. This can lead to increased energy output, potentially offsetting the initial investment costs over time. Studies have shown that even a small improvement in turbine efficiency can result in significant energy gains when scaled across an entire wind farm.

Maintenance costs are another crucial factor to consider. Magnesium carbonate's protective properties may extend the lifespan of turbine blades by reducing wear and tear from environmental factors such as dust, rain, and ice accumulation. This could potentially decrease the frequency of blade replacements and repairs, resulting in substantial cost savings over the operational life of the turbines.

However, the application and reapplication of magnesium carbonate coatings may introduce new maintenance procedures and associated costs. The frequency and complexity of these procedures must be carefully evaluated to determine their impact on overall operational expenses. Additionally, the environmental impact and disposal costs of magnesium carbonate should be factored into the long-term cost analysis.

Energy production gains must be quantified to accurately assess the financial benefits. This involves comparing the power output of turbines with and without magnesium carbonate treatment under various wind conditions. The increased revenue from higher energy production should be projected over the expected lifespan of the turbines to determine the return on investment.

Regulatory compliance and potential incentives also play a role in the cost-benefit analysis. Some regions may offer subsidies or tax benefits for implementing technologies that improve renewable energy efficiency, which could further offset implementation costs. Conversely, any regulatory requirements for the use of magnesium carbonate in wind energy production must be considered as potential additional expenses.

The scalability of magnesium carbonate usage across different turbine models and wind farm sizes is another important consideration. Economies of scale may be achieved in larger implementations, potentially improving the cost-benefit ratio for bigger wind energy projects. Conversely, smaller operations may face higher relative costs, which could impact the feasibility of adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!