Magnesium Carbonate in Developing Chalk-Free Board Materials

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Chalk-free Boards: Background and Objectives

The development of chalk-free board materials represents a significant advancement in educational and presentation technology. Traditionally, blackboards and whiteboards have relied on chalk or markers, which often produce dust and require frequent cleaning. The use of magnesium carbonate in developing chalk-free board materials aims to address these issues and revolutionize the way we interact with writing surfaces.

Magnesium carbonate, a naturally occurring mineral compound, has gained attention in recent years for its potential applications in various industries. Its unique properties, including low toxicity, high stability, and excellent absorbency, make it an ideal candidate for innovative board materials. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional chalk and marker-based systems.

The primary objective of this research is to develop a new generation of writing surfaces that eliminate the need for consumable writing implements while maintaining or improving upon the functionality of traditional boards. By incorporating magnesium carbonate into the board material, researchers aim to create a surface that can be written on and erased repeatedly without the use of chalk or markers.

This technology has the potential to address several key challenges associated with conventional boards. Firstly, it could significantly reduce environmental impact by eliminating the need for disposable writing tools and cleaning products. Secondly, it may improve indoor air quality by reducing dust and volatile organic compounds often associated with chalk and markers. Lastly, it could offer cost savings for educational institutions and businesses by reducing the need for ongoing purchases of writing implements and cleaning supplies.

The development of chalk-free board materials using magnesium carbonate aligns with broader trends in sustainable and smart technologies. As the world moves towards more environmentally friendly and technologically advanced solutions, this research represents a convergence of material science, environmental consciousness, and educational technology.

Current research efforts are focused on optimizing the composition and manufacturing processes of these novel board materials. Scientists are exploring various formulations that combine magnesium carbonate with other compounds to achieve the desired writing and erasing properties. Additionally, researchers are investigating methods to enhance durability, improve contrast for better visibility, and ensure long-term stability of the writing surface.

As this technology continues to evolve, it is expected to have far-reaching implications beyond traditional educational settings. Potential applications may extend to interactive displays, smart home devices, and even outdoor signage. The success of this research could pave the way for a new era of sustainable, low-maintenance writing surfaces that meet the diverse needs of modern society.

Magnesium carbonate, a naturally occurring mineral compound, has gained attention in recent years for its potential applications in various industries. Its unique properties, including low toxicity, high stability, and excellent absorbency, make it an ideal candidate for innovative board materials. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional chalk and marker-based systems.

The primary objective of this research is to develop a new generation of writing surfaces that eliminate the need for consumable writing implements while maintaining or improving upon the functionality of traditional boards. By incorporating magnesium carbonate into the board material, researchers aim to create a surface that can be written on and erased repeatedly without the use of chalk or markers.

This technology has the potential to address several key challenges associated with conventional boards. Firstly, it could significantly reduce environmental impact by eliminating the need for disposable writing tools and cleaning products. Secondly, it may improve indoor air quality by reducing dust and volatile organic compounds often associated with chalk and markers. Lastly, it could offer cost savings for educational institutions and businesses by reducing the need for ongoing purchases of writing implements and cleaning supplies.

The development of chalk-free board materials using magnesium carbonate aligns with broader trends in sustainable and smart technologies. As the world moves towards more environmentally friendly and technologically advanced solutions, this research represents a convergence of material science, environmental consciousness, and educational technology.

Current research efforts are focused on optimizing the composition and manufacturing processes of these novel board materials. Scientists are exploring various formulations that combine magnesium carbonate with other compounds to achieve the desired writing and erasing properties. Additionally, researchers are investigating methods to enhance durability, improve contrast for better visibility, and ensure long-term stability of the writing surface.

As this technology continues to evolve, it is expected to have far-reaching implications beyond traditional educational settings. Potential applications may extend to interactive displays, smart home devices, and even outdoor signage. The success of this research could pave the way for a new era of sustainable, low-maintenance writing surfaces that meet the diverse needs of modern society.

Market Analysis for Eco-friendly Writing Surfaces

The market for eco-friendly writing surfaces has experienced significant growth in recent years, driven by increasing environmental awareness and the push for sustainable practices in educational and corporate settings. The global market for green writing surfaces, including chalk-free board materials, is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing traditional writing surface markets.

The demand for eco-friendly writing surfaces is particularly strong in the education sector, where schools and universities are actively seeking alternatives to traditional chalk boards. This shift is motivated by health concerns related to chalk dust and the desire for more versatile and low-maintenance writing solutions. The corporate sector also shows growing interest in sustainable writing surfaces for meeting rooms and collaborative spaces, aligning with broader corporate social responsibility initiatives.

Magnesium carbonate-based chalk-free board materials are emerging as a promising solution in this market. These materials offer several advantages over traditional chalk boards, including dust-free operation, improved visibility, and compatibility with a wide range of writing instruments. The potential for easy cleaning and long-term durability makes them attractive for both educational and corporate environments.

Geographically, North America and Europe lead in the adoption of eco-friendly writing surfaces, with Asia-Pacific showing the fastest growth rate. This regional variation is influenced by factors such as environmental regulations, educational budget allocations, and the pace of technological adoption in different markets.

Key market drivers include the increasing focus on indoor air quality, the rise of smart classrooms and interactive learning environments, and the growing emphasis on sustainability in procurement policies. The COVID-19 pandemic has further accelerated the demand for easily sanitizable surfaces, benefiting materials like magnesium carbonate-based boards.

However, the market faces challenges such as the higher initial cost of eco-friendly materials compared to traditional options and the need for education about their long-term benefits. Additionally, competition from digital writing solutions and interactive whiteboards presents both a threat and an opportunity for innovation in physical writing surfaces.

Looking ahead, the market for eco-friendly writing surfaces is expected to continue its growth trajectory. Innovations in material science, such as the development of more sustainable and cost-effective magnesium carbonate formulations, are likely to drive market expansion. The integration of smart features and compatibility with digital tools may also open new avenues for product development and market penetration in the evolving landscape of educational and corporate communication tools.

The demand for eco-friendly writing surfaces is particularly strong in the education sector, where schools and universities are actively seeking alternatives to traditional chalk boards. This shift is motivated by health concerns related to chalk dust and the desire for more versatile and low-maintenance writing solutions. The corporate sector also shows growing interest in sustainable writing surfaces for meeting rooms and collaborative spaces, aligning with broader corporate social responsibility initiatives.

Magnesium carbonate-based chalk-free board materials are emerging as a promising solution in this market. These materials offer several advantages over traditional chalk boards, including dust-free operation, improved visibility, and compatibility with a wide range of writing instruments. The potential for easy cleaning and long-term durability makes them attractive for both educational and corporate environments.

Geographically, North America and Europe lead in the adoption of eco-friendly writing surfaces, with Asia-Pacific showing the fastest growth rate. This regional variation is influenced by factors such as environmental regulations, educational budget allocations, and the pace of technological adoption in different markets.

Key market drivers include the increasing focus on indoor air quality, the rise of smart classrooms and interactive learning environments, and the growing emphasis on sustainability in procurement policies. The COVID-19 pandemic has further accelerated the demand for easily sanitizable surfaces, benefiting materials like magnesium carbonate-based boards.

However, the market faces challenges such as the higher initial cost of eco-friendly materials compared to traditional options and the need for education about their long-term benefits. Additionally, competition from digital writing solutions and interactive whiteboards presents both a threat and an opportunity for innovation in physical writing surfaces.

Looking ahead, the market for eco-friendly writing surfaces is expected to continue its growth trajectory. Innovations in material science, such as the development of more sustainable and cost-effective magnesium carbonate formulations, are likely to drive market expansion. The integration of smart features and compatibility with digital tools may also open new avenues for product development and market penetration in the evolving landscape of educational and corporate communication tools.

Current Challenges in Chalk-free Board Development

The development of chalk-free board materials using magnesium carbonate faces several significant challenges. One of the primary obstacles is achieving the right balance between writing performance and erasability. Traditional chalk-based boards rely on the friable nature of chalk to create visible marks, but magnesium carbonate-based alternatives must replicate this effect without compromising the board's surface integrity.

Another challenge lies in the formulation of the board material itself. Incorporating magnesium carbonate into a stable, durable matrix that can withstand repeated writing and erasing cycles is complex. The material must be sufficiently porous to allow for good adhesion of writing implements, yet robust enough to resist wear and tear over time. Achieving this delicate balance often requires extensive experimentation with different binder materials and manufacturing processes.

Durability is a critical concern in chalk-free board development. The surface must resist scratching, chipping, and degradation from various writing instruments and cleaning agents. This is particularly challenging when dealing with magnesium carbonate, as its properties can change under different environmental conditions, potentially affecting the board's long-term performance.

Color contrast and visibility present another set of challenges. Unlike traditional chalk, which naturally provides high contrast against dark backgrounds, magnesium carbonate-based materials must be carefully engineered to ensure that writing is clearly visible under various lighting conditions. This often involves developing specialized coatings or treatments that enhance contrast without compromising other performance characteristics.

Environmental stability is a significant hurdle in chalk-free board development. Magnesium carbonate can be sensitive to humidity and temperature fluctuations, which can affect its writing and erasing properties. Developing a board material that maintains consistent performance across a wide range of environmental conditions is crucial for widespread adoption, especially in diverse educational and professional settings.

Cost-effectiveness and scalability pose additional challenges. While magnesium carbonate is relatively abundant, the processes required to incorporate it into high-performance board materials can be complex and expensive. Developing manufacturing techniques that are both economically viable and capable of producing consistent, high-quality products at scale is essential for market success.

Lastly, meeting regulatory standards and ensuring product safety add another layer of complexity to chalk-free board development. Materials used in educational and professional environments must comply with strict safety regulations, including low VOC emissions and fire resistance. Balancing these requirements with performance and cost considerations requires careful material selection and extensive testing.

Another challenge lies in the formulation of the board material itself. Incorporating magnesium carbonate into a stable, durable matrix that can withstand repeated writing and erasing cycles is complex. The material must be sufficiently porous to allow for good adhesion of writing implements, yet robust enough to resist wear and tear over time. Achieving this delicate balance often requires extensive experimentation with different binder materials and manufacturing processes.

Durability is a critical concern in chalk-free board development. The surface must resist scratching, chipping, and degradation from various writing instruments and cleaning agents. This is particularly challenging when dealing with magnesium carbonate, as its properties can change under different environmental conditions, potentially affecting the board's long-term performance.

Color contrast and visibility present another set of challenges. Unlike traditional chalk, which naturally provides high contrast against dark backgrounds, magnesium carbonate-based materials must be carefully engineered to ensure that writing is clearly visible under various lighting conditions. This often involves developing specialized coatings or treatments that enhance contrast without compromising other performance characteristics.

Environmental stability is a significant hurdle in chalk-free board development. Magnesium carbonate can be sensitive to humidity and temperature fluctuations, which can affect its writing and erasing properties. Developing a board material that maintains consistent performance across a wide range of environmental conditions is crucial for widespread adoption, especially in diverse educational and professional settings.

Cost-effectiveness and scalability pose additional challenges. While magnesium carbonate is relatively abundant, the processes required to incorporate it into high-performance board materials can be complex and expensive. Developing manufacturing techniques that are both economically viable and capable of producing consistent, high-quality products at scale is essential for market success.

Lastly, meeting regulatory standards and ensuring product safety add another layer of complexity to chalk-free board development. Materials used in educational and professional environments must comply with strict safety regulations, including low VOC emissions and fire resistance. Balancing these requirements with performance and cost considerations requires careful material selection and extensive testing.

Existing Magnesium Carbonate-based Solutions

01 Chalk-free magnesium carbonate production methods

Various methods are employed to produce chalk-free magnesium carbonate, including precipitation techniques and purification processes. These methods aim to eliminate chalk impurities and create high-quality magnesium carbonate suitable for diverse applications.- Chalk-free magnesium carbonate production methods: Various methods are employed to produce chalk-free magnesium carbonate, including precipitation techniques and controlled crystallization processes. These methods aim to create high-purity magnesium carbonate without chalk impurities, resulting in a product with improved properties for specific applications.

- Applications of chalk-free magnesium carbonate: Chalk-free magnesium carbonate finds applications in diverse industries, such as pharmaceuticals, cosmetics, and food additives. Its purity and specific properties make it suitable for use in products where chalk contamination would be undesirable, including antacids, toothpaste, and dietary supplements.

- Chalk-free magnesium carbonate in sports and fitness: In sports and fitness applications, chalk-free magnesium carbonate is used as a grip enhancer and moisture absorber. It provides improved hand grip for activities such as weightlifting, rock climbing, and gymnastics without leaving residue typically associated with traditional chalk.

- Formulation and processing of chalk-free magnesium carbonate: Specific formulation and processing techniques are employed to maintain the chalk-free nature of magnesium carbonate. These may include controlled particle size distribution, surface treatments, and blending with other materials to enhance its properties while preserving its chalk-free characteristics.

- Environmental and sustainability aspects: The production and use of chalk-free magnesium carbonate may have environmental and sustainability implications. Research focuses on developing eco-friendly production methods, reducing energy consumption, and exploring sustainable sources of raw materials for manufacturing chalk-free magnesium carbonate.

02 Applications of chalk-free magnesium carbonate

Chalk-free magnesium carbonate finds applications in various industries, including pharmaceuticals, cosmetics, and food additives. Its purity and specific properties make it suitable for use in products where chalk contamination is undesirable.Expand Specific Solutions03 Characterization and quality control of chalk-free magnesium carbonate

Techniques for characterizing and ensuring the quality of chalk-free magnesium carbonate are essential. These may include spectroscopic methods, particle size analysis, and purity testing to confirm the absence of chalk and other impurities.Expand Specific Solutions04 Formulations incorporating chalk-free magnesium carbonate

Various formulations incorporate chalk-free magnesium carbonate as a key ingredient. These may include pharmaceutical preparations, dietary supplements, and industrial products where the purity and specific properties of magnesium carbonate are crucial.Expand Specific Solutions05 Environmental and sustainability aspects of chalk-free magnesium carbonate

The production and use of chalk-free magnesium carbonate may have environmental implications. Research in this area focuses on sustainable production methods, recycling processes, and the overall environmental impact of using this material in various applications.Expand Specific Solutions

Key Players in Chalk-free Board Industry

The research on using Magnesium Carbonate in developing chalk-free board materials is in its early stages, with the market showing potential for growth. The industry is transitioning from traditional chalk-based materials to more sustainable alternatives. Key players like DuPont de Nemours, Inc., Omya International AG, and Premier Magnesia, LLC are investing in R&D to develop innovative solutions. The technology is still evolving, with companies such as Carbon Upcycling Technologies, Inc. exploring eco-friendly approaches. As environmental concerns drive demand for chalk-free alternatives, the market is expected to expand, attracting both established manufacturers and emerging startups.

Premier Magnesia, LLC

Technical Solution: Premier Magnesia has developed a proprietary process for producing high-purity magnesium carbonate for use in chalk-free board materials. Their method involves the controlled precipitation of magnesium carbonate from magnesium-rich brines, resulting in fine particles with uniform size distribution[1]. The company has optimized the particle morphology to enhance binding properties and reduce dusting. Their magnesium carbonate is treated with surface modifiers to improve its compatibility with various binder systems used in board production[3]. Premier Magnesia's technology allows for the incorporation of up to 40% magnesium carbonate in board formulations without compromising strength or durability[5].

Strengths: High-purity product, controlled particle size, enhanced binding properties. Weaknesses: Potentially higher production costs, limited to magnesium-rich brine sources.

Omya International AG

Technical Solution: Omya has developed a range of functionalized calcium carbonate (FCC) products that can be used in combination with magnesium carbonate for chalk-free board materials. Their patented process involves surface modification of calcium carbonate particles to improve compatibility with magnesium carbonate and other board components[2]. Omya's technology allows for a synergistic blend of calcium and magnesium carbonates, optimizing the balance between cost-effectiveness and performance. The company has also developed specialized dispersants to ensure uniform distribution of the carbonate particles within the board matrix, enhancing overall material properties[4]. Omya's approach enables the production of boards with up to 70% total carbonate content, significantly reducing the need for traditional binders[6].

Strengths: Cost-effective solution, high filler content, versatile application. Weaknesses: May require adjustments to existing production processes, potential for increased water sensitivity.

Innovative Applications of Magnesium Carbonate

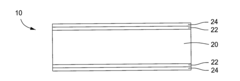

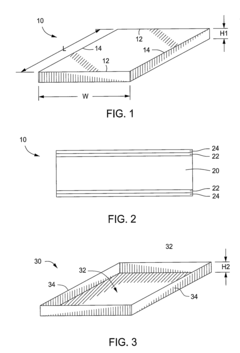

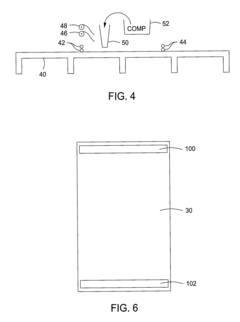

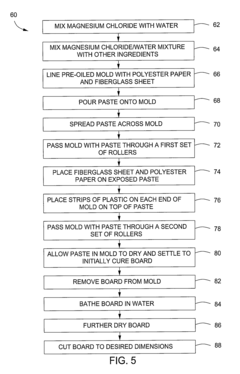

Magnesium oxide-based construction board

PatentActiveUS7998547B2

Innovation

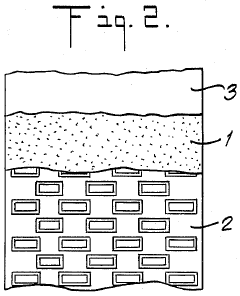

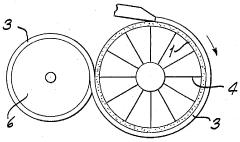

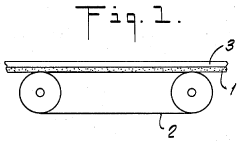

- A construction board composed of magnesium oxide, magnesium chloride, a binding agent, perlite, recycled board scraps, water, fiberglass, and polypropylene sheets, fabricated using a method involving mixing magnesium chloride with water, forming a paste, and passing it through rollers to achieve the desired thickness and durability.

Process for manufacturing magnesium carbonate board

PatentInactiveUS4242163A

Innovation

- A process involving the mixing of neutral magnesium carbonate suspension with fibrous materials and active magnesia, followed by dehydration, lamination, and heat curing, using a less porous carrier and vacuum filtration to control water content and enhance adherence between layers, effectively increasing the board's specific gravity and structural strength.

Environmental Impact Assessment

The use of Magnesium Carbonate in developing chalk-free board materials presents both environmental challenges and opportunities. This assessment examines the potential impacts on ecosystems, resource consumption, and overall sustainability.

Magnesium Carbonate production involves mining and processing, which can lead to habitat disruption and biodiversity loss in extraction areas. However, the scale of impact is generally smaller compared to traditional chalk mining operations. Proper site selection and restoration practices can significantly mitigate these effects.

The manufacturing process of chalk-free board materials using Magnesium Carbonate typically requires less energy compared to traditional chalk-based products. This reduction in energy consumption translates to lower greenhouse gas emissions, contributing positively to climate change mitigation efforts. Additionally, the production process generates fewer particulate emissions, improving local air quality around manufacturing facilities.

Water usage in Magnesium Carbonate-based board production is generally lower than in traditional methods. This reduced water footprint is particularly beneficial in water-stressed regions. However, careful management of wastewater from the production process is crucial to prevent potential contamination of local water bodies.

The durability and longevity of chalk-free board materials can lead to reduced waste generation over time. These materials are often more resistant to wear and degradation, potentially extending the lifecycle of the products. This durability contributes to resource conservation by reducing the frequency of replacement and disposal.

Recycling and end-of-life considerations for Magnesium Carbonate-based board materials are generally favorable. The materials can often be recycled or repurposed more easily than traditional chalk-based products, reducing the burden on landfills and promoting a circular economy approach.

Transportation-related emissions may be reduced if Magnesium Carbonate sources are closer to manufacturing facilities compared to traditional chalk sources. This localization of raw material sourcing can contribute to a smaller carbon footprint in the supply chain.

The shift to chalk-free board materials may also indirectly benefit indoor air quality in educational and office environments. The reduction of chalk dust can lead to improved respiratory health for users, although this benefit is more related to occupational health than direct environmental impact.

In conclusion, while the use of Magnesium Carbonate in chalk-free board materials does have some environmental impacts, particularly in the extraction phase, it generally offers a more sustainable alternative to traditional chalk-based products. The benefits in terms of reduced energy consumption, lower emissions, improved resource efficiency, and better end-of-life management outweigh the potential negative impacts when proper environmental management practices are implemented throughout the product lifecycle.

Magnesium Carbonate production involves mining and processing, which can lead to habitat disruption and biodiversity loss in extraction areas. However, the scale of impact is generally smaller compared to traditional chalk mining operations. Proper site selection and restoration practices can significantly mitigate these effects.

The manufacturing process of chalk-free board materials using Magnesium Carbonate typically requires less energy compared to traditional chalk-based products. This reduction in energy consumption translates to lower greenhouse gas emissions, contributing positively to climate change mitigation efforts. Additionally, the production process generates fewer particulate emissions, improving local air quality around manufacturing facilities.

Water usage in Magnesium Carbonate-based board production is generally lower than in traditional methods. This reduced water footprint is particularly beneficial in water-stressed regions. However, careful management of wastewater from the production process is crucial to prevent potential contamination of local water bodies.

The durability and longevity of chalk-free board materials can lead to reduced waste generation over time. These materials are often more resistant to wear and degradation, potentially extending the lifecycle of the products. This durability contributes to resource conservation by reducing the frequency of replacement and disposal.

Recycling and end-of-life considerations for Magnesium Carbonate-based board materials are generally favorable. The materials can often be recycled or repurposed more easily than traditional chalk-based products, reducing the burden on landfills and promoting a circular economy approach.

Transportation-related emissions may be reduced if Magnesium Carbonate sources are closer to manufacturing facilities compared to traditional chalk sources. This localization of raw material sourcing can contribute to a smaller carbon footprint in the supply chain.

The shift to chalk-free board materials may also indirectly benefit indoor air quality in educational and office environments. The reduction of chalk dust can lead to improved respiratory health for users, although this benefit is more related to occupational health than direct environmental impact.

In conclusion, while the use of Magnesium Carbonate in chalk-free board materials does have some environmental impacts, particularly in the extraction phase, it generally offers a more sustainable alternative to traditional chalk-based products. The benefits in terms of reduced energy consumption, lower emissions, improved resource efficiency, and better end-of-life management outweigh the potential negative impacts when proper environmental management practices are implemented throughout the product lifecycle.

Cost-Benefit Analysis of Magnesium Carbonate Boards

The cost-benefit analysis of magnesium carbonate boards reveals a complex interplay of economic factors that must be carefully considered. Initial production costs for these innovative chalk-free boards are generally higher than traditional alternatives due to the specialized materials and manufacturing processes required. The primary raw material, magnesium carbonate, while abundant, may incur higher extraction and processing costs compared to conventional chalk-based materials.

However, the long-term benefits of magnesium carbonate boards can potentially outweigh these initial expenses. Their durability and resistance to wear significantly extend the product lifespan, reducing replacement frequency and associated costs over time. This longevity factor is particularly advantageous in high-use environments such as schools, offices, and conference facilities.

The chalk-free nature of these boards also presents substantial indirect cost savings. Traditional chalk boards generate dust that can damage electronic equipment, necessitate more frequent cleaning, and potentially impact indoor air quality. By eliminating these issues, magnesium carbonate boards can reduce maintenance costs, prolong the life of nearby electronics, and potentially decrease health-related expenses in sensitive environments.

From a market perspective, the premium quality and innovative features of magnesium carbonate boards may command higher prices, potentially offsetting the increased production costs. As environmental and health concerns continue to grow, the eco-friendly attributes of these boards could drive increased demand, leading to economies of scale in production and further cost reductions.

Energy efficiency in the manufacturing process is another critical factor. While initial setup may require significant investment, optimized production methods for magnesium carbonate boards could lead to reduced energy consumption in the long run, contributing to both cost savings and environmental benefits.

The recyclability of magnesium carbonate boards also factors into the cost-benefit equation. Unlike some traditional board materials, these boards can be more easily recycled at the end of their lifecycle, potentially reducing waste management costs and aligning with circular economy principles.

In conclusion, while the upfront costs of magnesium carbonate boards may be higher, the long-term economic benefits, coupled with environmental advantages, present a compelling case for their adoption. As production techniques evolve and market demand increases, the cost-benefit ratio is likely to improve further, making these innovative boards an increasingly attractive option for various applications.

However, the long-term benefits of magnesium carbonate boards can potentially outweigh these initial expenses. Their durability and resistance to wear significantly extend the product lifespan, reducing replacement frequency and associated costs over time. This longevity factor is particularly advantageous in high-use environments such as schools, offices, and conference facilities.

The chalk-free nature of these boards also presents substantial indirect cost savings. Traditional chalk boards generate dust that can damage electronic equipment, necessitate more frequent cleaning, and potentially impact indoor air quality. By eliminating these issues, magnesium carbonate boards can reduce maintenance costs, prolong the life of nearby electronics, and potentially decrease health-related expenses in sensitive environments.

From a market perspective, the premium quality and innovative features of magnesium carbonate boards may command higher prices, potentially offsetting the increased production costs. As environmental and health concerns continue to grow, the eco-friendly attributes of these boards could drive increased demand, leading to economies of scale in production and further cost reductions.

Energy efficiency in the manufacturing process is another critical factor. While initial setup may require significant investment, optimized production methods for magnesium carbonate boards could lead to reduced energy consumption in the long run, contributing to both cost savings and environmental benefits.

The recyclability of magnesium carbonate boards also factors into the cost-benefit equation. Unlike some traditional board materials, these boards can be more easily recycled at the end of their lifecycle, potentially reducing waste management costs and aligning with circular economy principles.

In conclusion, while the upfront costs of magnesium carbonate boards may be higher, the long-term economic benefits, coupled with environmental advantages, present a compelling case for their adoption. As production techniques evolve and market demand increases, the cost-benefit ratio is likely to improve further, making these innovative boards an increasingly attractive option for various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!