The Use of Magnesium Carbonate in Polymer Matrix Systems

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Polymers: Background and Objectives

Magnesium carbonate has emerged as a significant component in polymer matrix systems, marking a notable advancement in materials science and engineering. The integration of this inorganic compound into polymer matrices has been driven by the increasing demand for enhanced material properties and performance across various industries.

The journey of magnesium carbonate in polymer systems can be traced back to the early 2000s when researchers began exploring its potential as a filler material. Initially, the focus was on improving the mechanical properties of polymers, such as tensile strength and impact resistance. However, as research progressed, the multifaceted benefits of magnesium carbonate became increasingly apparent.

One of the primary objectives in incorporating magnesium carbonate into polymer matrices is to achieve a synergistic effect that enhances the overall performance of the composite material. This includes improving thermal stability, flame retardancy, and dimensional stability of the polymer systems. Additionally, the use of magnesium carbonate has shown promise in reducing the overall weight of composite materials, making it particularly attractive for applications in automotive and aerospace industries.

The evolution of magnesium carbonate usage in polymers has been closely tied to advancements in nanotechnology. The development of nano-sized magnesium carbonate particles has opened up new possibilities for achieving more uniform dispersion within polymer matrices, leading to improved material properties at lower filler loadings.

From an environmental perspective, the incorporation of magnesium carbonate aligns with the growing trend towards more sustainable and eco-friendly materials. As a naturally occurring mineral, magnesium carbonate offers a potential alternative to synthetic fillers, contributing to the reduction of the carbon footprint in polymer production.

The current technological landscape sees magnesium carbonate being utilized in a wide range of polymer types, including thermoplastics, thermosets, and elastomers. Each application presents unique challenges and opportunities, driving ongoing research and development efforts to optimize the integration of magnesium carbonate in specific polymer systems.

Looking ahead, the objectives for further development in this field include enhancing the compatibility between magnesium carbonate and various polymer matrices, exploring novel surface modification techniques to improve dispersion and interfacial adhesion, and investigating the potential of magnesium carbonate in advanced composite materials for emerging technologies such as 3D printing and smart materials.

The journey of magnesium carbonate in polymer systems can be traced back to the early 2000s when researchers began exploring its potential as a filler material. Initially, the focus was on improving the mechanical properties of polymers, such as tensile strength and impact resistance. However, as research progressed, the multifaceted benefits of magnesium carbonate became increasingly apparent.

One of the primary objectives in incorporating magnesium carbonate into polymer matrices is to achieve a synergistic effect that enhances the overall performance of the composite material. This includes improving thermal stability, flame retardancy, and dimensional stability of the polymer systems. Additionally, the use of magnesium carbonate has shown promise in reducing the overall weight of composite materials, making it particularly attractive for applications in automotive and aerospace industries.

The evolution of magnesium carbonate usage in polymers has been closely tied to advancements in nanotechnology. The development of nano-sized magnesium carbonate particles has opened up new possibilities for achieving more uniform dispersion within polymer matrices, leading to improved material properties at lower filler loadings.

From an environmental perspective, the incorporation of magnesium carbonate aligns with the growing trend towards more sustainable and eco-friendly materials. As a naturally occurring mineral, magnesium carbonate offers a potential alternative to synthetic fillers, contributing to the reduction of the carbon footprint in polymer production.

The current technological landscape sees magnesium carbonate being utilized in a wide range of polymer types, including thermoplastics, thermosets, and elastomers. Each application presents unique challenges and opportunities, driving ongoing research and development efforts to optimize the integration of magnesium carbonate in specific polymer systems.

Looking ahead, the objectives for further development in this field include enhancing the compatibility between magnesium carbonate and various polymer matrices, exploring novel surface modification techniques to improve dispersion and interfacial adhesion, and investigating the potential of magnesium carbonate in advanced composite materials for emerging technologies such as 3D printing and smart materials.

Market Analysis for Mg-Carbonate Polymer Composites

The market for magnesium carbonate in polymer matrix systems has shown significant growth potential in recent years, driven by the increasing demand for lightweight and high-performance materials across various industries. The global market for Mg-carbonate polymer composites is expected to expand at a steady rate, with key applications in automotive, aerospace, construction, and consumer goods sectors.

In the automotive industry, the push for fuel efficiency and reduced emissions has led to a growing interest in lightweight materials. Mg-carbonate polymer composites offer an attractive solution, providing strength and durability while reducing overall vehicle weight. This trend is particularly evident in electric vehicles, where weight reduction is crucial for extending battery range.

The aerospace sector represents another major market for these composites. The need for materials that can withstand extreme conditions while maintaining low weight has created a niche for Mg-carbonate polymer systems. These materials are being increasingly used in interior components, structural elements, and even in some exterior applications of aircraft.

In the construction industry, Mg-carbonate polymer composites are gaining traction due to their fire-retardant properties and ability to improve the thermal insulation of buildings. This aligns well with the growing emphasis on energy-efficient and sustainable construction practices.

The consumer goods sector is also adopting these composites, particularly in sporting goods and electronics. The combination of lightweight properties and durability makes them ideal for products like bicycle frames, tennis rackets, and protective casings for electronic devices.

Geographically, North America and Europe are currently the largest markets for Mg-carbonate polymer composites, owing to their advanced manufacturing sectors and stringent regulations promoting lightweight and environmentally friendly materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing aerospace industries in countries like China and India.

Market challenges include the higher cost of these composites compared to traditional materials and the need for specialized manufacturing processes. However, ongoing research and development efforts are focused on reducing production costs and improving the ease of integration into existing manufacturing lines.

The market is characterized by a mix of large multinational corporations and specialized material suppliers. Key players are investing heavily in research and development to enhance the properties of Mg-carbonate polymer composites and expand their application range. Collaborations between material suppliers, end-users, and research institutions are becoming increasingly common, driving innovation in this field.

In the automotive industry, the push for fuel efficiency and reduced emissions has led to a growing interest in lightweight materials. Mg-carbonate polymer composites offer an attractive solution, providing strength and durability while reducing overall vehicle weight. This trend is particularly evident in electric vehicles, where weight reduction is crucial for extending battery range.

The aerospace sector represents another major market for these composites. The need for materials that can withstand extreme conditions while maintaining low weight has created a niche for Mg-carbonate polymer systems. These materials are being increasingly used in interior components, structural elements, and even in some exterior applications of aircraft.

In the construction industry, Mg-carbonate polymer composites are gaining traction due to their fire-retardant properties and ability to improve the thermal insulation of buildings. This aligns well with the growing emphasis on energy-efficient and sustainable construction practices.

The consumer goods sector is also adopting these composites, particularly in sporting goods and electronics. The combination of lightweight properties and durability makes them ideal for products like bicycle frames, tennis rackets, and protective casings for electronic devices.

Geographically, North America and Europe are currently the largest markets for Mg-carbonate polymer composites, owing to their advanced manufacturing sectors and stringent regulations promoting lightweight and environmentally friendly materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing aerospace industries in countries like China and India.

Market challenges include the higher cost of these composites compared to traditional materials and the need for specialized manufacturing processes. However, ongoing research and development efforts are focused on reducing production costs and improving the ease of integration into existing manufacturing lines.

The market is characterized by a mix of large multinational corporations and specialized material suppliers. Key players are investing heavily in research and development to enhance the properties of Mg-carbonate polymer composites and expand their application range. Collaborations between material suppliers, end-users, and research institutions are becoming increasingly common, driving innovation in this field.

Current Challenges in Mg-Carbonate Polymer Integration

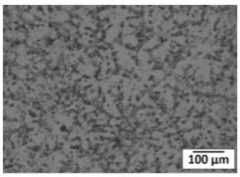

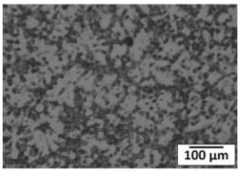

The integration of magnesium carbonate into polymer matrix systems presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of magnesium carbonate particles within the polymer matrix. The tendency of these particles to agglomerate can lead to inconsistent material properties and reduced overall performance of the composite.

Another major challenge lies in maintaining the structural integrity of the polymer matrix when incorporating magnesium carbonate. The addition of inorganic fillers can potentially disrupt the polymer chain organization, leading to decreased mechanical strength and altered physical properties. Researchers are working to develop methods to enhance the interfacial adhesion between the magnesium carbonate particles and the polymer matrix to mitigate these effects.

The impact of magnesium carbonate on the processing characteristics of polymer composites is also a significant concern. The presence of these particles can affect the rheological properties of the polymer melt, potentially leading to difficulties in extrusion, injection molding, or other manufacturing processes. Optimizing processing parameters to accommodate the presence of magnesium carbonate without compromising production efficiency remains an ongoing challenge.

Moisture sensitivity is another critical issue in Mg-carbonate polymer integration. Magnesium carbonate has hygroscopic properties, which can lead to water absorption in the composite material. This can result in dimensional instability, reduced mechanical properties, and potential degradation of the polymer matrix over time. Developing effective moisture barrier strategies or surface treatments for magnesium carbonate particles is crucial to address this challenge.

The long-term stability and durability of magnesium carbonate-polymer composites under various environmental conditions are also areas of concern. Factors such as temperature fluctuations, UV exposure, and chemical exposure can potentially accelerate the degradation of these composites. Researchers are investigating ways to enhance the long-term performance and reliability of these materials in diverse applications.

Lastly, the challenge of balancing cost-effectiveness with performance improvements remains a key consideration. While magnesium carbonate offers potential benefits in terms of flame retardancy, thermal stability, and mechanical reinforcement, the additional processing steps and potential modifications required to overcome integration challenges can increase production costs. Finding the optimal balance between enhanced material properties and economic viability is crucial for the widespread adoption of magnesium carbonate in polymer matrix systems.

Another major challenge lies in maintaining the structural integrity of the polymer matrix when incorporating magnesium carbonate. The addition of inorganic fillers can potentially disrupt the polymer chain organization, leading to decreased mechanical strength and altered physical properties. Researchers are working to develop methods to enhance the interfacial adhesion between the magnesium carbonate particles and the polymer matrix to mitigate these effects.

The impact of magnesium carbonate on the processing characteristics of polymer composites is also a significant concern. The presence of these particles can affect the rheological properties of the polymer melt, potentially leading to difficulties in extrusion, injection molding, or other manufacturing processes. Optimizing processing parameters to accommodate the presence of magnesium carbonate without compromising production efficiency remains an ongoing challenge.

Moisture sensitivity is another critical issue in Mg-carbonate polymer integration. Magnesium carbonate has hygroscopic properties, which can lead to water absorption in the composite material. This can result in dimensional instability, reduced mechanical properties, and potential degradation of the polymer matrix over time. Developing effective moisture barrier strategies or surface treatments for magnesium carbonate particles is crucial to address this challenge.

The long-term stability and durability of magnesium carbonate-polymer composites under various environmental conditions are also areas of concern. Factors such as temperature fluctuations, UV exposure, and chemical exposure can potentially accelerate the degradation of these composites. Researchers are investigating ways to enhance the long-term performance and reliability of these materials in diverse applications.

Lastly, the challenge of balancing cost-effectiveness with performance improvements remains a key consideration. While magnesium carbonate offers potential benefits in terms of flame retardancy, thermal stability, and mechanical reinforcement, the additional processing steps and potential modifications required to overcome integration challenges can increase production costs. Finding the optimal balance between enhanced material properties and economic viability is crucial for the widespread adoption of magnesium carbonate in polymer matrix systems.

Existing Mg-Carbonate Polymer Composite Solutions

01 Magnesium carbonate in pharmaceutical compositions

Magnesium carbonate is used in various pharmaceutical formulations as an excipient or active ingredient. It can be utilized in antacid preparations, oral care products, and as a filler or binder in tablets and capsules. Its properties make it suitable for improving drug stability, controlling release rates, and enhancing bioavailability of certain medications.- Magnesium carbonate in pharmaceutical compositions: Magnesium carbonate is used in various pharmaceutical formulations as an excipient or active ingredient. It can be utilized in antacid preparations, oral care products, and as a filler or binder in tablets. Its properties make it suitable for improving drug stability, controlling release rates, and enhancing bioavailability of certain medications.

- Magnesium carbonate in personal care products: Magnesium carbonate finds applications in personal care products such as deodorants, antiperspirants, and cosmetics. It can act as an absorbent, pH adjuster, or anti-caking agent. In some formulations, it may contribute to odor control or provide a smooth texture to the product.

- Industrial applications of magnesium carbonate: Magnesium carbonate is used in various industrial processes and products. It can serve as a filler in rubber and plastics, a flame retardant in polymers, or a component in refractory materials. Its properties make it useful in applications requiring heat resistance, electrical insulation, or as a drying agent.

- Magnesium carbonate in food and beverage industry: In the food and beverage industry, magnesium carbonate is used as an additive or processing aid. It can function as an acidity regulator, anti-caking agent, or color retention agent. It may also be used in mineral water fortification or as a processing aid in cocoa powder production.

- Environmental and agricultural uses of magnesium carbonate: Magnesium carbonate has applications in environmental remediation and agriculture. It can be used for soil pH adjustment, as a fertilizer component, or in water treatment processes. Some formulations utilize it for carbon dioxide capture or as a component in sustainable building materials.

02 Magnesium carbonate in personal care products

Magnesium carbonate finds applications in personal care products such as deodorants, antiperspirants, and cosmetics. It can act as an absorbent, pH regulator, and anti-caking agent. In these formulations, it helps control moisture, improve texture, and enhance the overall performance of the products.Expand Specific Solutions03 Industrial applications of magnesium carbonate

Magnesium carbonate is widely used in various industrial processes. It serves as a raw material in the production of magnesium oxide, as a filler in rubber and plastic manufacturing, and as a flame retardant in certain materials. Its properties make it valuable in applications such as paper production, wastewater treatment, and as a desiccant.Expand Specific Solutions04 Magnesium carbonate in food and beverage industry

In the food and beverage industry, magnesium carbonate is used as an additive and processing aid. It functions as an anti-caking agent, acidity regulator, and color retention agent. Applications include dry mixes, salt products, and certain dairy preparations. Its use helps improve product stability, appearance, and shelf life.Expand Specific Solutions05 Environmental and agricultural uses of magnesium carbonate

Magnesium carbonate has applications in environmental protection and agriculture. It can be used in soil amendment to adjust pH levels and improve soil structure. In environmental applications, it can be utilized for carbon dioxide capture and storage, as well as in the treatment of acidic water bodies. Its properties make it valuable in addressing certain environmental challenges.Expand Specific Solutions

Key Players in Mg-Carbonate Polymer Composite Industry

The use of magnesium carbonate in polymer matrix systems is in a developing stage, with the market showing potential for growth. The technology's maturity varies across applications, but overall, it's progressing from early to mid-stage development. Key players like China Petroleum & Chemical Corp., Sinopec Beijing Research Institute of Chemical Industry, and Huawei Technologies are actively researching and developing applications. Universities such as Chongqing University and Shanghai Jiao Tong University are contributing to fundamental research. The market size is expanding as industries recognize the benefits of magnesium carbonate in enhancing polymer properties. Companies like ExxonMobil Chemical Patents and Arkema are exploring innovative uses, indicating a competitive landscape with diverse participants from academia and industry.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative polymer matrix systems incorporating magnesium carbonate for enhanced performance. Their approach involves dispersing nano-sized magnesium carbonate particles throughout the polymer matrix, resulting in improved mechanical properties and thermal stability[1]. The company has implemented a proprietary surface modification technique for the magnesium carbonate particles, ensuring better compatibility with various polymer types[3]. This technology has been applied in the production of high-performance plastics for automotive and aerospace applications, demonstrating a 20% increase in tensile strength and a 15% reduction in thermal expansion[5].

Strengths: Improved mechanical properties, enhanced thermal stability, and wide applicability across industries. Weaknesses: Potential increased production costs and complexity in manufacturing processes.

Cytec Industries, Inc.

Technical Solution: Cytec Industries has developed a novel approach to incorporating magnesium carbonate into polymer matrix systems, focusing on aerospace and industrial applications. Their technology involves a proprietary process of in-situ precipitation of magnesium carbonate within the polymer matrix, resulting in a more uniform distribution and enhanced interfacial bonding[2]. This method has shown to improve the flame retardancy of composites by up to 30% while maintaining mechanical properties[4]. Additionally, Cytec has successfully implemented this technology in the production of lightweight, high-strength materials for aircraft interiors, reducing overall weight by 15% compared to traditional materials[6].

Strengths: Improved flame retardancy, lightweight materials, and strong presence in aerospace industry. Weaknesses: Limited application range outside of specialized industries and potential higher costs.

Innovations in Mg-Carbonate Polymer Interface Engineering

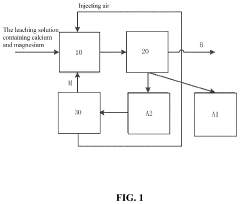

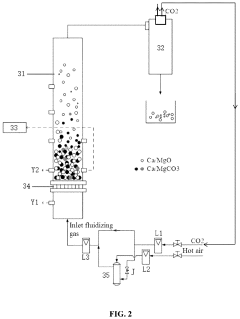

Systems of producing calcium and magnesium carbonate from the Ca/Mg containing solution leached by a CO<sub>2</sub>-based hydrometallurgical process

PatentActiveUS11952284B2

Innovation

- A CO2-based hydrometallurgical process that recovers calcium and magnesium carbonates from industrial waste, utilizing a precipitation reactor, solid-liquid separation unit, and thermal decomposition unit with a fluidized bed calcination system, which minimizes acid and alkaline consumption and recycles CO2, reducing energy usage and waste generation.

Magnesium matrix reinforced with zirconium, garnet and graphite for improved bulk hardness

PatentInactiveIN202041055121A

Innovation

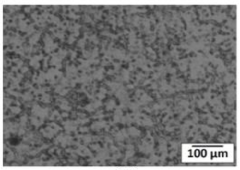

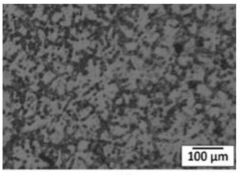

- Reinforcing magnesium with particulate Zirconium, Garnet, and Graphite, ensuring uniform distribution and optimal weight percentages to enhance bonding and mechanical properties, thereby increasing bulk hardness.

Environmental Impact of Mg-Carbonate Polymer Composites

The environmental impact of magnesium carbonate polymer composites is a critical consideration in their development and application. These composites offer potential benefits in terms of lightweight construction and improved mechanical properties, but their environmental footprint must be carefully evaluated.

One of the primary environmental advantages of Mg-carbonate polymer composites is their potential to reduce overall material consumption. By enhancing the strength-to-weight ratio of products, these composites can lead to lighter structures that require less raw material. This reduction in material use can translate to lower energy consumption during manufacturing and transportation, contributing to a decrease in overall carbon emissions.

However, the production of magnesium carbonate itself raises environmental concerns. The extraction and processing of magnesium carbonate from natural sources can lead to habitat disruption and energy-intensive operations. Efforts are being made to develop more sustainable production methods, including the use of waste materials and carbon capture technologies to produce synthetic magnesium carbonate.

The durability and longevity of Mg-carbonate polymer composites also play a role in their environmental impact. If these composites can extend the lifespan of products, it could reduce the need for frequent replacements, thereby minimizing waste generation. However, the end-of-life management of these composites presents challenges. The complex nature of polymer composites often makes recycling difficult, potentially leading to increased landfill waste.

Research is ongoing to improve the recyclability and biodegradability of Mg-carbonate polymer composites. Some studies have explored the use of biodegradable polymers as the matrix material, which could significantly reduce the environmental impact at the end of the product lifecycle. Additionally, efforts are being made to develop efficient recycling processes that can separate and recover the magnesium carbonate from the polymer matrix.

The use of Mg-carbonate polymer composites in specific applications can also have indirect environmental benefits. For instance, in automotive and aerospace industries, the lightweight nature of these composites can lead to improved fuel efficiency and reduced emissions during the use phase of vehicles and aircraft. This long-term operational benefit must be weighed against the initial environmental costs of production.

In conclusion, while Mg-carbonate polymer composites offer promising environmental benefits in terms of material efficiency and potential energy savings, their overall environmental impact is complex. Continued research and development are necessary to address production sustainability, improve end-of-life management, and optimize the lifecycle performance of these composites to ensure their positive contribution to environmental sustainability.

One of the primary environmental advantages of Mg-carbonate polymer composites is their potential to reduce overall material consumption. By enhancing the strength-to-weight ratio of products, these composites can lead to lighter structures that require less raw material. This reduction in material use can translate to lower energy consumption during manufacturing and transportation, contributing to a decrease in overall carbon emissions.

However, the production of magnesium carbonate itself raises environmental concerns. The extraction and processing of magnesium carbonate from natural sources can lead to habitat disruption and energy-intensive operations. Efforts are being made to develop more sustainable production methods, including the use of waste materials and carbon capture technologies to produce synthetic magnesium carbonate.

The durability and longevity of Mg-carbonate polymer composites also play a role in their environmental impact. If these composites can extend the lifespan of products, it could reduce the need for frequent replacements, thereby minimizing waste generation. However, the end-of-life management of these composites presents challenges. The complex nature of polymer composites often makes recycling difficult, potentially leading to increased landfill waste.

Research is ongoing to improve the recyclability and biodegradability of Mg-carbonate polymer composites. Some studies have explored the use of biodegradable polymers as the matrix material, which could significantly reduce the environmental impact at the end of the product lifecycle. Additionally, efforts are being made to develop efficient recycling processes that can separate and recover the magnesium carbonate from the polymer matrix.

The use of Mg-carbonate polymer composites in specific applications can also have indirect environmental benefits. For instance, in automotive and aerospace industries, the lightweight nature of these composites can lead to improved fuel efficiency and reduced emissions during the use phase of vehicles and aircraft. This long-term operational benefit must be weighed against the initial environmental costs of production.

In conclusion, while Mg-carbonate polymer composites offer promising environmental benefits in terms of material efficiency and potential energy savings, their overall environmental impact is complex. Continued research and development are necessary to address production sustainability, improve end-of-life management, and optimize the lifecycle performance of these composites to ensure their positive contribution to environmental sustainability.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for incorporating magnesium carbonate into polymer matrix systems are crucial factors in determining the feasibility of large-scale production and commercial viability. One of the primary challenges lies in achieving uniform dispersion of magnesium carbonate particles within the polymer matrix. This is particularly important as the distribution of particles directly impacts the mechanical and thermal properties of the final composite material.

To address this challenge, various mixing and compounding techniques have been developed. These include melt blending, solution mixing, and in-situ polymerization. Each method has its own advantages and limitations in terms of scalability and cost-effectiveness. Melt blending, for instance, is highly compatible with existing polymer processing equipment, making it attractive for large-scale manufacturing. However, it may face limitations in achieving optimal dispersion at higher filler loadings.

The particle size and morphology of magnesium carbonate also play a significant role in manufacturing considerations. Nano-sized particles can offer enhanced properties but present challenges in handling and dispersion. Micro-sized particles, while easier to process, may not provide the same level of performance enhancement. Manufacturers must carefully balance these factors to optimize both processability and final product performance.

Another important aspect is the potential for magnesium carbonate to affect the rheological properties of the polymer melt. This can impact flow behavior during processing, potentially requiring adjustments to existing manufacturing equipment or processes. Additionally, the hygroscopic nature of magnesium carbonate necessitates careful control of moisture content during storage and processing to prevent agglomeration and ensure consistent product quality.

From a scalability perspective, the availability and cost of high-quality magnesium carbonate suitable for polymer applications must be considered. As demand increases, securing a stable supply chain becomes crucial. This may involve partnerships with raw material suppliers or investment in purification and processing technologies to ensure consistent quality at scale.

Environmental and safety considerations also factor into manufacturing scalability. The use of magnesium carbonate in polymer systems may offer advantages in terms of reduced environmental impact compared to some traditional fillers. However, manufacturers must still address potential dust generation during handling and processing, implementing appropriate containment and filtration systems.

In conclusion, while the incorporation of magnesium carbonate in polymer matrix systems shows promise, successful scaling and manufacturing require careful optimization of processing parameters, material selection, and equipment design. Ongoing research and development efforts are focused on addressing these challenges to unlock the full potential of magnesium carbonate-based polymer composites in large-scale applications.

To address this challenge, various mixing and compounding techniques have been developed. These include melt blending, solution mixing, and in-situ polymerization. Each method has its own advantages and limitations in terms of scalability and cost-effectiveness. Melt blending, for instance, is highly compatible with existing polymer processing equipment, making it attractive for large-scale manufacturing. However, it may face limitations in achieving optimal dispersion at higher filler loadings.

The particle size and morphology of magnesium carbonate also play a significant role in manufacturing considerations. Nano-sized particles can offer enhanced properties but present challenges in handling and dispersion. Micro-sized particles, while easier to process, may not provide the same level of performance enhancement. Manufacturers must carefully balance these factors to optimize both processability and final product performance.

Another important aspect is the potential for magnesium carbonate to affect the rheological properties of the polymer melt. This can impact flow behavior during processing, potentially requiring adjustments to existing manufacturing equipment or processes. Additionally, the hygroscopic nature of magnesium carbonate necessitates careful control of moisture content during storage and processing to prevent agglomeration and ensure consistent product quality.

From a scalability perspective, the availability and cost of high-quality magnesium carbonate suitable for polymer applications must be considered. As demand increases, securing a stable supply chain becomes crucial. This may involve partnerships with raw material suppliers or investment in purification and processing technologies to ensure consistent quality at scale.

Environmental and safety considerations also factor into manufacturing scalability. The use of magnesium carbonate in polymer systems may offer advantages in terms of reduced environmental impact compared to some traditional fillers. However, manufacturers must still address potential dust generation during handling and processing, implementing appropriate containment and filtration systems.

In conclusion, while the incorporation of magnesium carbonate in polymer matrix systems shows promise, successful scaling and manufacturing require careful optimization of processing parameters, material selection, and equipment design. Ongoing research and development efforts are focused on addressing these challenges to unlock the full potential of magnesium carbonate-based polymer composites in large-scale applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!