Magnesium Carbonate’s Use in Strengthening Recycled Paper Products

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MgCO3 in Paper Recycling: Background and Objectives

The use of magnesium carbonate (MgCO3) in strengthening recycled paper products represents a significant advancement in sustainable paper manufacturing. This technology has evolved from the broader field of paper recycling, which has been a focus of the paper industry for decades. The development of MgCO3 as a strengthening agent addresses the persistent challenge of maintaining paper quality and strength in recycled products.

Historically, recycled paper has suffered from reduced strength and quality compared to virgin paper due to the degradation of cellulose fibers during the recycling process. This limitation has restricted the use of recycled paper in high-performance applications. The introduction of MgCO3 as a strengthening agent aims to bridge this quality gap, potentially revolutionizing the recycled paper industry.

The primary objective of incorporating MgCO3 in recycled paper products is to enhance their mechanical properties, particularly tensile strength, burst strength, and folding endurance. By improving these characteristics, the technology seeks to expand the range of applications for recycled paper, making it a more viable alternative to virgin paper in various industries.

Another crucial goal is to increase the recycling efficiency of paper products. By strengthening recycled fibers, MgCO3 treatment may allow for more cycles of recycling before the paper becomes unusable, thus extending the lifecycle of paper resources and reducing the demand for virgin pulp.

The development of this technology aligns with global sustainability initiatives and the growing demand for eco-friendly products. As governments and consumers increasingly prioritize environmental conservation, the paper industry faces pressure to reduce its ecological footprint. MgCO3 treatment of recycled paper offers a potential solution that balances performance requirements with environmental considerations.

From a technical perspective, the use of MgCO3 in paper recycling involves complex interactions between the mineral and cellulose fibers. Understanding these interactions and optimizing the treatment process to achieve consistent results across different types of recycled paper are key objectives of ongoing research and development efforts.

As the technology progresses, researchers and industry professionals aim to refine the MgCO3 treatment process, making it more cost-effective and easier to integrate into existing paper recycling operations. This includes developing efficient methods for applying MgCO3 to recycled pulp and ensuring uniform distribution throughout the paper structure.

Historically, recycled paper has suffered from reduced strength and quality compared to virgin paper due to the degradation of cellulose fibers during the recycling process. This limitation has restricted the use of recycled paper in high-performance applications. The introduction of MgCO3 as a strengthening agent aims to bridge this quality gap, potentially revolutionizing the recycled paper industry.

The primary objective of incorporating MgCO3 in recycled paper products is to enhance their mechanical properties, particularly tensile strength, burst strength, and folding endurance. By improving these characteristics, the technology seeks to expand the range of applications for recycled paper, making it a more viable alternative to virgin paper in various industries.

Another crucial goal is to increase the recycling efficiency of paper products. By strengthening recycled fibers, MgCO3 treatment may allow for more cycles of recycling before the paper becomes unusable, thus extending the lifecycle of paper resources and reducing the demand for virgin pulp.

The development of this technology aligns with global sustainability initiatives and the growing demand for eco-friendly products. As governments and consumers increasingly prioritize environmental conservation, the paper industry faces pressure to reduce its ecological footprint. MgCO3 treatment of recycled paper offers a potential solution that balances performance requirements with environmental considerations.

From a technical perspective, the use of MgCO3 in paper recycling involves complex interactions between the mineral and cellulose fibers. Understanding these interactions and optimizing the treatment process to achieve consistent results across different types of recycled paper are key objectives of ongoing research and development efforts.

As the technology progresses, researchers and industry professionals aim to refine the MgCO3 treatment process, making it more cost-effective and easier to integrate into existing paper recycling operations. This includes developing efficient methods for applying MgCO3 to recycled pulp and ensuring uniform distribution throughout the paper structure.

Market Analysis for Enhanced Recycled Paper Products

The market for enhanced recycled paper products has been experiencing significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce waste and promote sustainability. The use of magnesium carbonate in strengthening recycled paper products represents a promising innovation in this sector, potentially addressing key challenges in the recycled paper industry.

Consumer demand for eco-friendly packaging and paper products has been steadily rising, with many customers willing to pay a premium for sustainable options. This trend is particularly evident in developed markets such as North America and Europe, where environmental concerns are more pronounced. The global recycled paper market was valued at approximately $42 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2026.

The packaging industry, which accounts for a significant portion of paper consumption, has been a major driver of demand for enhanced recycled paper products. With e-commerce continuing to expand, there is a growing need for sturdy, recyclable packaging materials that can withstand the rigors of shipping while maintaining eco-friendly credentials. The food and beverage industry has also shown increased interest in recycled paper products with improved strength and barrier properties.

Magnesium carbonate-enhanced recycled paper products have the potential to address several key market needs. These include improved strength and durability, better printability, and enhanced moisture resistance. Such improvements could expand the application range of recycled paper, making it suitable for more demanding uses where virgin paper is currently preferred.

The market for these enhanced products is likely to be particularly strong in industries where paper quality and performance are critical, such as publishing, high-end packaging, and certain industrial applications. Additionally, the construction industry has shown interest in recycled paper products with improved strength for applications like gypsum board facing.

However, the market adoption of magnesium carbonate-enhanced recycled paper products may face some challenges. Cost considerations are a significant factor, as the addition of magnesium carbonate could potentially increase production expenses. The market's price sensitivity, especially in sectors where margins are already thin, could impact widespread adoption.

Regulatory landscape and environmental certifications also play a crucial role in shaping market demand. As governments worldwide implement stricter regulations on waste management and recycling, products that can demonstrate improved recyclability and reduced environmental impact are likely to gain favor. Certifications such as FSC (Forest Stewardship Council) and recycled content labels can significantly influence purchasing decisions, especially in environmentally conscious markets.

In conclusion, the market for enhanced recycled paper products, particularly those strengthened with magnesium carbonate, shows promising growth potential. The intersection of environmental concerns, regulatory pressures, and technological advancements creates a favorable environment for innovation in this space. However, success in this market will depend on striking the right balance between performance improvements, cost-effectiveness, and environmental benefits.

Consumer demand for eco-friendly packaging and paper products has been steadily rising, with many customers willing to pay a premium for sustainable options. This trend is particularly evident in developed markets such as North America and Europe, where environmental concerns are more pronounced. The global recycled paper market was valued at approximately $42 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2026.

The packaging industry, which accounts for a significant portion of paper consumption, has been a major driver of demand for enhanced recycled paper products. With e-commerce continuing to expand, there is a growing need for sturdy, recyclable packaging materials that can withstand the rigors of shipping while maintaining eco-friendly credentials. The food and beverage industry has also shown increased interest in recycled paper products with improved strength and barrier properties.

Magnesium carbonate-enhanced recycled paper products have the potential to address several key market needs. These include improved strength and durability, better printability, and enhanced moisture resistance. Such improvements could expand the application range of recycled paper, making it suitable for more demanding uses where virgin paper is currently preferred.

The market for these enhanced products is likely to be particularly strong in industries where paper quality and performance are critical, such as publishing, high-end packaging, and certain industrial applications. Additionally, the construction industry has shown interest in recycled paper products with improved strength for applications like gypsum board facing.

However, the market adoption of magnesium carbonate-enhanced recycled paper products may face some challenges. Cost considerations are a significant factor, as the addition of magnesium carbonate could potentially increase production expenses. The market's price sensitivity, especially in sectors where margins are already thin, could impact widespread adoption.

Regulatory landscape and environmental certifications also play a crucial role in shaping market demand. As governments worldwide implement stricter regulations on waste management and recycling, products that can demonstrate improved recyclability and reduced environmental impact are likely to gain favor. Certifications such as FSC (Forest Stewardship Council) and recycled content labels can significantly influence purchasing decisions, especially in environmentally conscious markets.

In conclusion, the market for enhanced recycled paper products, particularly those strengthened with magnesium carbonate, shows promising growth potential. The intersection of environmental concerns, regulatory pressures, and technological advancements creates a favorable environment for innovation in this space. However, success in this market will depend on striking the right balance between performance improvements, cost-effectiveness, and environmental benefits.

Current Challenges in Recycled Paper Strength

The recycled paper industry faces several significant challenges in maintaining and improving the strength of recycled paper products. One of the primary issues is the degradation of fiber quality through multiple recycling cycles. As paper fibers are recycled repeatedly, they become shorter and weaker, leading to a decrease in the overall strength of the final product. This fiber degradation is particularly problematic for high-grade paper products that require superior strength and durability.

Another challenge is the presence of contaminants in recycled paper feedstock. Ink particles, adhesives, and other non-fiber materials can interfere with fiber bonding and reduce the strength of recycled paper. These contaminants are often difficult to remove completely during the recycling process, necessitating advanced cleaning and screening technologies to minimize their impact on paper quality.

The variability in recycled paper feedstock composition also poses a significant challenge. Unlike virgin pulp, which has consistent properties, recycled paper sources can vary greatly in terms of fiber types, lengths, and quality. This inconsistency makes it difficult to maintain uniform strength properties across different batches of recycled paper products, leading to potential quality control issues and customer dissatisfaction.

Water retention is another critical challenge in recycled paper production. Recycled fibers tend to have a higher affinity for water compared to virgin fibers, which can lead to slower dewatering on the paper machine and increased energy consumption during the drying process. This not only affects production efficiency but can also impact the final strength of the paper due to changes in fiber bonding during the drying stage.

The limited availability of high-quality recycled fiber sources further compounds these challenges. As demand for recycled paper products increases, competition for premium recycled fiber intensifies, potentially leading to the use of lower-quality feedstock that further compromises paper strength.

Addressing these challenges requires innovative approaches to fiber treatment and paper strengthening. Traditional methods such as refining and chemical additives have limitations in their ability to restore fiber strength and overcome the inherent weaknesses of recycled paper. This has led to a growing interest in novel strengthening agents and technologies, including the exploration of inorganic compounds like magnesium carbonate, which shows promise in enhancing the mechanical properties of recycled paper products.

Another challenge is the presence of contaminants in recycled paper feedstock. Ink particles, adhesives, and other non-fiber materials can interfere with fiber bonding and reduce the strength of recycled paper. These contaminants are often difficult to remove completely during the recycling process, necessitating advanced cleaning and screening technologies to minimize their impact on paper quality.

The variability in recycled paper feedstock composition also poses a significant challenge. Unlike virgin pulp, which has consistent properties, recycled paper sources can vary greatly in terms of fiber types, lengths, and quality. This inconsistency makes it difficult to maintain uniform strength properties across different batches of recycled paper products, leading to potential quality control issues and customer dissatisfaction.

Water retention is another critical challenge in recycled paper production. Recycled fibers tend to have a higher affinity for water compared to virgin fibers, which can lead to slower dewatering on the paper machine and increased energy consumption during the drying process. This not only affects production efficiency but can also impact the final strength of the paper due to changes in fiber bonding during the drying stage.

The limited availability of high-quality recycled fiber sources further compounds these challenges. As demand for recycled paper products increases, competition for premium recycled fiber intensifies, potentially leading to the use of lower-quality feedstock that further compromises paper strength.

Addressing these challenges requires innovative approaches to fiber treatment and paper strengthening. Traditional methods such as refining and chemical additives have limitations in their ability to restore fiber strength and overcome the inherent weaknesses of recycled paper. This has led to a growing interest in novel strengthening agents and technologies, including the exploration of inorganic compounds like magnesium carbonate, which shows promise in enhancing the mechanical properties of recycled paper products.

Existing MgCO3 Application Methods in Paper

01 Magnesium carbonate as a strength enhancer in cement compositions

Magnesium carbonate is utilized as an additive in cement compositions to improve strength and durability. It can enhance the compressive strength of concrete and mortar, making it suitable for various construction applications. The incorporation of magnesium carbonate can also contribute to improved resistance against environmental factors.- Magnesium carbonate as a strength enhancer in cement compositions: Magnesium carbonate is utilized as an additive in cement compositions to improve strength and durability. It can enhance the compressive strength of concrete and mortar, making it suitable for various construction applications. The addition of magnesium carbonate can also contribute to improved resistance against environmental factors.

- Magnesium carbonate in pharmaceutical formulations: Magnesium carbonate is employed in pharmaceutical compositions to enhance the strength and stability of tablets and other dosage forms. It can act as a binding agent, improving the mechanical properties of the formulation. Additionally, it may contribute to the controlled release of active ingredients in certain drug delivery systems.

- Magnesium carbonate in sports and fitness applications: In sports and fitness contexts, magnesium carbonate is used to improve grip strength and reduce moisture. It is commonly applied as a powder on hands or equipment to enhance performance in activities such as weightlifting, rock climbing, and gymnastics. The compound's ability to absorb sweat and increase friction contributes to its effectiveness in these applications.

- Magnesium carbonate in material reinforcement: Magnesium carbonate is utilized as a reinforcing agent in various materials, including plastics, rubbers, and composites. It can enhance the mechanical properties, such as tensile strength and impact resistance, of these materials. The incorporation of magnesium carbonate can lead to improved durability and performance in end products.

- Magnesium carbonate in fire-resistant compositions: Magnesium carbonate is employed in fire-resistant and flame-retardant compositions. It can contribute to increased thermal stability and fire resistance in various materials and coatings. The compound's properties make it suitable for applications in building materials, textiles, and other products where fire safety is a concern.

02 Magnesium carbonate in pharmaceutical formulations

Magnesium carbonate is employed in pharmaceutical formulations to enhance the strength and stability of tablets and capsules. It acts as a binding agent and can improve the mechanical properties of the final dosage form. Additionally, it may contribute to controlled release properties in certain formulations.Expand Specific Solutions03 Magnesium carbonate in refractory materials

Magnesium carbonate is used in the production of refractory materials to enhance their strength and heat resistance. It can improve the thermal stability and mechanical properties of refractory bricks and other high-temperature applications. The incorporation of magnesium carbonate can lead to increased durability in extreme conditions.Expand Specific Solutions04 Magnesium carbonate in composite materials

Magnesium carbonate is utilized as a filler in composite materials to enhance their strength and mechanical properties. It can improve the stiffness, impact resistance, and dimensional stability of polymer-based composites. The addition of magnesium carbonate may also contribute to flame retardancy in certain applications.Expand Specific Solutions05 Magnesium carbonate in food and beverage applications

Magnesium carbonate is used in food and beverage applications to improve product stability and texture. It can act as an anti-caking agent, acidity regulator, and color retention aid. In some cases, it may contribute to the structural integrity of certain food products, enhancing their overall quality and shelf life.Expand Specific Solutions

Key Players in Paper Recycling Industry

The market for magnesium carbonate in strengthening recycled paper products is in an early growth stage, with increasing demand driven by sustainability trends in the packaging industry. The global market size is estimated to be in the hundreds of millions of dollars, with potential for significant expansion. Technologically, the application is still developing, with companies like Nippon Paper Industries, Arakawa Chemical, and UPM-Kymmene leading research efforts. Smaller specialized firms such as Disruptive Materials AB are also making strides in innovative magnesium carbonate formulations. While the technology shows promise, further optimization is needed to achieve widespread commercial adoption in paper recycling processes.

Nippon Paper Industries Co., Ltd.

Technical Solution: Nippon Paper Industries has developed a proprietary technology for incorporating magnesium carbonate into recycled paper products to enhance their strength and durability. Their process involves adding finely ground magnesium carbonate particles during the paper recycling process, which helps to fill voids and strengthen fiber bonds. This results in recycled paper with improved tensile strength, tear resistance, and dimensional stability[1][3]. The company has also implemented a controlled precipitation method to create uniform magnesium carbonate nanoparticles that can be evenly distributed throughout the paper matrix, further enhancing its structural integrity[2].

Strengths: Improved paper strength and quality, efficient use of recycled materials. Weaknesses: Potential increase in production costs, may require modifications to existing paper manufacturing processes.

Omya International AG

Technical Solution: Omya International AG has developed an advanced magnesium carbonate-based filler system specifically designed for strengthening recycled paper products. Their technology involves surface-treating magnesium carbonate particles to enhance their compatibility with cellulose fibers, resulting in improved bonding and strength characteristics. Omya's process also includes a precise particle size distribution control, which allows for optimal packing of the filler particles within the paper structure[4]. This approach not only enhances the mechanical properties of recycled paper but also improves its printability and optical properties[5]. The company has reported strength improvements of up to 15% in recycled paperboard products using their magnesium carbonate filler system[6].

Strengths: Multifunctional improvement in paper properties, versatile application across various paper grades. Weaknesses: May require specialized equipment for implementation, potential impact on paper recycling processes.

Innovative MgCO3 Incorporation Techniques

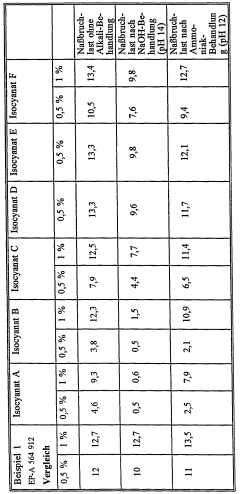

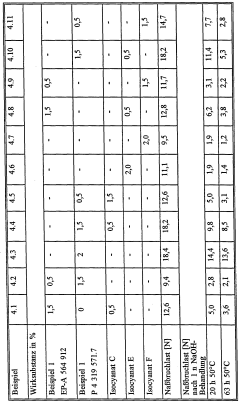

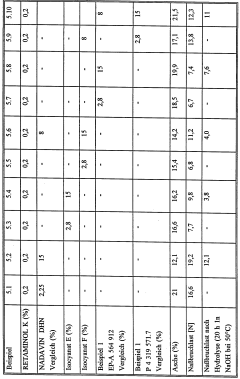

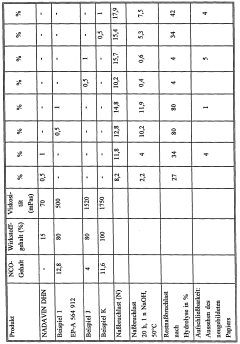

Process for producing structurally resistant paper

PatentWO1996035019A1

Innovation

- Water-emulsifiable compounds with isocyanate groups bridged via ester and/or amide groups are used as dry and wet strength agents, allowing for terminable strengthening of paper by treating paper stock or finished sheets with specific isocyanate mixtures, which can be reversed for recycling.

Recovery of high value materials from industrial waste

PatentWO2014000055A1

Innovation

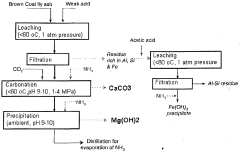

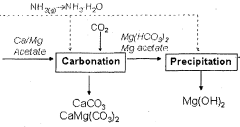

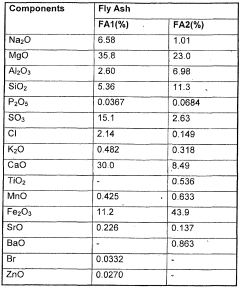

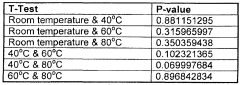

- A process involving leaching, carbonation, and precipitation using ammonium acetate to extract calcium and magnesium from fly ash, converting CO2 into stable mineral carbonates, thereby producing high-value magnesium products and reducing greenhouse gas emissions.

Environmental Impact Assessment

The use of magnesium carbonate in strengthening recycled paper products has significant environmental implications that warrant careful consideration. This process aims to enhance the quality and durability of recycled paper, potentially increasing its lifespan and reducing the need for virgin paper production. However, the environmental impact of this technique must be thoroughly assessed across multiple dimensions.

Firstly, the sourcing and production of magnesium carbonate should be examined. While it is a naturally occurring mineral, its extraction and processing can have environmental consequences, including habitat disruption, energy consumption, and potential emissions. The scale of magnesium carbonate production required for widespread application in the paper industry could exacerbate these impacts.

The incorporation of magnesium carbonate into recycled paper may affect the recyclability of the final product. It is crucial to evaluate whether paper treated with magnesium carbonate can be effectively recycled again without compromising quality or requiring additional processing steps. Any reduction in recyclability could offset the initial environmental benefits of strengthening recycled paper.

Water usage and effluent management are key considerations in paper production. The addition of magnesium carbonate may alter water requirements or affect the composition of wastewater from paper mills. Potential changes in water treatment processes and the environmental fate of magnesium-containing effluents must be carefully assessed.

Energy consumption during the paper strengthening process is another critical factor. If the incorporation of magnesium carbonate requires additional energy inputs, this could impact the overall carbon footprint of recycled paper production. However, if the strengthened paper reduces the need for multiple recycling cycles or virgin paper production, it may lead to net energy savings over the product lifecycle.

The end-of-life scenario for magnesium carbonate-treated paper products must also be considered. While improved durability may extend the useful life of paper products, the ultimate disposal or decomposition of these materials could have different environmental implications compared to untreated recycled paper.

Potential benefits of this technology include reduced deforestation pressure, lower overall resource consumption, and decreased waste generation if stronger recycled paper products can replace virgin paper in more applications. However, these benefits must be weighed against any additional environmental burdens introduced by the magnesium carbonate treatment process.

A comprehensive life cycle assessment (LCA) would be essential to fully understand the environmental trade-offs of using magnesium carbonate in recycled paper strengthening. This assessment should compare the environmental impacts of strengthened recycled paper against both conventional recycled paper and virgin paper products across all stages of production, use, and disposal.

Firstly, the sourcing and production of magnesium carbonate should be examined. While it is a naturally occurring mineral, its extraction and processing can have environmental consequences, including habitat disruption, energy consumption, and potential emissions. The scale of magnesium carbonate production required for widespread application in the paper industry could exacerbate these impacts.

The incorporation of magnesium carbonate into recycled paper may affect the recyclability of the final product. It is crucial to evaluate whether paper treated with magnesium carbonate can be effectively recycled again without compromising quality or requiring additional processing steps. Any reduction in recyclability could offset the initial environmental benefits of strengthening recycled paper.

Water usage and effluent management are key considerations in paper production. The addition of magnesium carbonate may alter water requirements or affect the composition of wastewater from paper mills. Potential changes in water treatment processes and the environmental fate of magnesium-containing effluents must be carefully assessed.

Energy consumption during the paper strengthening process is another critical factor. If the incorporation of magnesium carbonate requires additional energy inputs, this could impact the overall carbon footprint of recycled paper production. However, if the strengthened paper reduces the need for multiple recycling cycles or virgin paper production, it may lead to net energy savings over the product lifecycle.

The end-of-life scenario for magnesium carbonate-treated paper products must also be considered. While improved durability may extend the useful life of paper products, the ultimate disposal or decomposition of these materials could have different environmental implications compared to untreated recycled paper.

Potential benefits of this technology include reduced deforestation pressure, lower overall resource consumption, and decreased waste generation if stronger recycled paper products can replace virgin paper in more applications. However, these benefits must be weighed against any additional environmental burdens introduced by the magnesium carbonate treatment process.

A comprehensive life cycle assessment (LCA) would be essential to fully understand the environmental trade-offs of using magnesium carbonate in recycled paper strengthening. This assessment should compare the environmental impacts of strengthened recycled paper against both conventional recycled paper and virgin paper products across all stages of production, use, and disposal.

Cost-Benefit Analysis of MgCO3 Usage

The cost-benefit analysis of using magnesium carbonate (MgCO3) in strengthening recycled paper products is a crucial aspect of evaluating its potential implementation in the paper industry. This analysis considers both the economic and environmental factors associated with MgCO3 usage.

From an economic perspective, the primary cost considerations include the procurement of MgCO3, integration of the material into existing production processes, and potential equipment modifications. The current market price of MgCO3 ranges from $200 to $400 per ton, depending on quality and quantity. Implementation costs may vary significantly based on the scale of production and the extent of process modifications required.

However, these costs must be weighed against the potential benefits. The use of MgCO3 can lead to improved paper strength, potentially reducing the amount of virgin fiber needed in recycled paper products. This could result in substantial cost savings, as virgin fiber is typically more expensive than recycled fiber. Additionally, the enhanced strength properties may allow for the production of lighter-weight paper products, reducing material costs and transportation expenses.

Environmental benefits also play a significant role in the cost-benefit analysis. The reduced need for virgin fiber translates to fewer trees harvested, contributing to forest conservation efforts. Furthermore, the improved recyclability of paper products strengthened with MgCO3 can lead to increased recycling rates and reduced waste in landfills.

Energy consumption is another factor to consider. While the integration of MgCO3 may require some additional energy in the production process, the overall energy savings from reduced virgin fiber processing and potentially lower drying requirements could offset this increase.

In terms of product quality, the improved strength and durability of recycled paper products enhanced with MgCO3 could lead to higher customer satisfaction and potentially command premium pricing in certain market segments. This could contribute to increased revenue and market share for companies adopting this technology.

Long-term cost implications should also be evaluated. As environmental regulations become more stringent, the use of MgCO3 in recycled paper products could position companies favorably, potentially avoiding future compliance costs or penalties associated with less sustainable practices.

It's important to note that the cost-benefit ratio may vary depending on the specific application and scale of production. Pilot studies and small-scale implementations can provide valuable data for more accurate cost-benefit analyses tailored to individual company needs and market conditions.

From an economic perspective, the primary cost considerations include the procurement of MgCO3, integration of the material into existing production processes, and potential equipment modifications. The current market price of MgCO3 ranges from $200 to $400 per ton, depending on quality and quantity. Implementation costs may vary significantly based on the scale of production and the extent of process modifications required.

However, these costs must be weighed against the potential benefits. The use of MgCO3 can lead to improved paper strength, potentially reducing the amount of virgin fiber needed in recycled paper products. This could result in substantial cost savings, as virgin fiber is typically more expensive than recycled fiber. Additionally, the enhanced strength properties may allow for the production of lighter-weight paper products, reducing material costs and transportation expenses.

Environmental benefits also play a significant role in the cost-benefit analysis. The reduced need for virgin fiber translates to fewer trees harvested, contributing to forest conservation efforts. Furthermore, the improved recyclability of paper products strengthened with MgCO3 can lead to increased recycling rates and reduced waste in landfills.

Energy consumption is another factor to consider. While the integration of MgCO3 may require some additional energy in the production process, the overall energy savings from reduced virgin fiber processing and potentially lower drying requirements could offset this increase.

In terms of product quality, the improved strength and durability of recycled paper products enhanced with MgCO3 could lead to higher customer satisfaction and potentially command premium pricing in certain market segments. This could contribute to increased revenue and market share for companies adopting this technology.

Long-term cost implications should also be evaluated. As environmental regulations become more stringent, the use of MgCO3 in recycled paper products could position companies favorably, potentially avoiding future compliance costs or penalties associated with less sustainable practices.

It's important to note that the cost-benefit ratio may vary depending on the specific application and scale of production. Pilot studies and small-scale implementations can provide valuable data for more accurate cost-benefit analyses tailored to individual company needs and market conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!