Evaluation of transparent conductive films under mechanical bending stress

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCF Bending Stress Background and Objectives

Transparent conductive films (TCFs) have evolved significantly over the past three decades, transitioning from laboratory curiosities to essential components in modern electronic devices. Initially developed in the 1980s primarily for electromagnetic shielding applications, TCFs have since become fundamental elements in touchscreens, flexible displays, solar cells, and various optoelectronic devices. The technological trajectory has been driven by increasing demands for devices with enhanced flexibility, transparency, and electrical conductivity.

The evolution of TCFs has been marked by several pivotal developments. Indium tin oxide (ITO) emerged as the industry standard in the 1990s due to its excellent combination of optical transparency and electrical conductivity. However, as electronic devices began incorporating flexible and bendable features in the early 2000s, ITO's inherent brittleness became a significant limitation, prompting research into alternative materials and structures.

Recent technological trends indicate a shift toward nanomaterial-based TCFs, including carbon nanotubes, graphene, metal nanowires, and conductive polymers. These materials offer promising mechanical flexibility while maintaining acceptable levels of transparency and conductivity. The industry has also witnessed advancements in hybrid structures that combine different materials to achieve optimal performance characteristics.

The primary objective of evaluating TCFs under mechanical bending stress is to develop films that maintain their electrical and optical properties when subjected to repeated flexing, folding, and stretching. This evaluation aims to establish standardized testing protocols and performance metrics that can accurately predict TCF behavior in real-world applications, particularly as the market for flexible electronics continues to expand.

Additionally, this technical research seeks to identify the fundamental failure mechanisms of TCFs under various bending conditions, including different radii of curvature, bending frequencies, and environmental factors. Understanding these mechanisms is crucial for designing more robust and durable transparent conductive materials.

The long-term goal is to establish design principles for next-generation TCFs that can withstand thousands of bending cycles without significant degradation in performance. This includes exploring novel material combinations, innovative fabrication techniques, and structural modifications that enhance mechanical resilience while preserving essential electrical and optical properties.

Furthermore, this research aims to bridge the gap between laboratory testing and commercial implementation by developing accelerated testing methodologies that can reliably predict TCF performance over extended periods of real-world use, thereby reducing development cycles and improving product reliability.

The evolution of TCFs has been marked by several pivotal developments. Indium tin oxide (ITO) emerged as the industry standard in the 1990s due to its excellent combination of optical transparency and electrical conductivity. However, as electronic devices began incorporating flexible and bendable features in the early 2000s, ITO's inherent brittleness became a significant limitation, prompting research into alternative materials and structures.

Recent technological trends indicate a shift toward nanomaterial-based TCFs, including carbon nanotubes, graphene, metal nanowires, and conductive polymers. These materials offer promising mechanical flexibility while maintaining acceptable levels of transparency and conductivity. The industry has also witnessed advancements in hybrid structures that combine different materials to achieve optimal performance characteristics.

The primary objective of evaluating TCFs under mechanical bending stress is to develop films that maintain their electrical and optical properties when subjected to repeated flexing, folding, and stretching. This evaluation aims to establish standardized testing protocols and performance metrics that can accurately predict TCF behavior in real-world applications, particularly as the market for flexible electronics continues to expand.

Additionally, this technical research seeks to identify the fundamental failure mechanisms of TCFs under various bending conditions, including different radii of curvature, bending frequencies, and environmental factors. Understanding these mechanisms is crucial for designing more robust and durable transparent conductive materials.

The long-term goal is to establish design principles for next-generation TCFs that can withstand thousands of bending cycles without significant degradation in performance. This includes exploring novel material combinations, innovative fabrication techniques, and structural modifications that enhance mechanical resilience while preserving essential electrical and optical properties.

Furthermore, this research aims to bridge the gap between laboratory testing and commercial implementation by developing accelerated testing methodologies that can reliably predict TCF performance over extended periods of real-world use, thereby reducing development cycles and improving product reliability.

Market Analysis for Flexible Electronics

The flexible electronics market has been experiencing remarkable growth, driven by increasing demand for bendable, lightweight, and portable electronic devices. Current market valuations place the global flexible electronics sector at approximately $25 billion as of 2023, with projections indicating growth to reach $42 billion by 2027, representing a compound annual growth rate (CAGR) of 13.8%. This expansion is primarily fueled by applications in consumer electronics, healthcare monitoring devices, automotive displays, and wearable technology.

Transparent conductive films (TCFs) constitute a critical component within this ecosystem, serving as essential elements in touchscreens, displays, and photovoltaic cells that require both optical transparency and electrical conductivity under mechanical stress. The TCF segment alone accounts for roughly $5.7 billion of the flexible electronics market, with expectations to grow at a CAGR of 17.2% through 2028.

Consumer electronics remains the dominant application sector, comprising approximately 42% of the total market share. Smartphones and tablets with flexible displays have seen consumer adoption rates increase by 24% year-over-year, indicating strong market acceptance. Major manufacturers have reported that devices featuring bendable displays command premium pricing, with average selling prices 15-30% higher than their rigid counterparts.

The healthcare sector represents the fastest-growing segment for flexible electronics, expanding at 19.3% annually. Wearable health monitors utilizing TCFs have seen particularly strong adoption, with global shipments increasing by 32% in the past year. These devices benefit significantly from TCFs that maintain performance integrity under repeated bending cycles.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for 58% of global production capacity. However, North America leads in research innovation, generating 47% of patents related to mechanical stress resistance in TCFs. European markets show the highest premium segment growth at 16.2% annually, particularly in automotive applications.

Market challenges include price sensitivity, with TCF components typically representing 8-12% of total device manufacturing costs. Supply chain vulnerabilities have also emerged, with 76% of manufacturers reporting concerns about raw material availability for next-generation TCFs. Additionally, consumer expectations for durability have intensified, with market research indicating that 68% of end-users consider bend-resistance a critical purchasing factor for flexible devices.

Transparent conductive films (TCFs) constitute a critical component within this ecosystem, serving as essential elements in touchscreens, displays, and photovoltaic cells that require both optical transparency and electrical conductivity under mechanical stress. The TCF segment alone accounts for roughly $5.7 billion of the flexible electronics market, with expectations to grow at a CAGR of 17.2% through 2028.

Consumer electronics remains the dominant application sector, comprising approximately 42% of the total market share. Smartphones and tablets with flexible displays have seen consumer adoption rates increase by 24% year-over-year, indicating strong market acceptance. Major manufacturers have reported that devices featuring bendable displays command premium pricing, with average selling prices 15-30% higher than their rigid counterparts.

The healthcare sector represents the fastest-growing segment for flexible electronics, expanding at 19.3% annually. Wearable health monitors utilizing TCFs have seen particularly strong adoption, with global shipments increasing by 32% in the past year. These devices benefit significantly from TCFs that maintain performance integrity under repeated bending cycles.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for 58% of global production capacity. However, North America leads in research innovation, generating 47% of patents related to mechanical stress resistance in TCFs. European markets show the highest premium segment growth at 16.2% annually, particularly in automotive applications.

Market challenges include price sensitivity, with TCF components typically representing 8-12% of total device manufacturing costs. Supply chain vulnerabilities have also emerged, with 76% of manufacturers reporting concerns about raw material availability for next-generation TCFs. Additionally, consumer expectations for durability have intensified, with market research indicating that 68% of end-users consider bend-resistance a critical purchasing factor for flexible devices.

Current Challenges in TCF Mechanical Durability

Despite significant advancements in transparent conductive film (TCF) technology, mechanical durability remains a critical challenge that impedes widespread adoption in flexible electronics applications. The fundamental issue stems from the inherent brittleness of traditional TCF materials, particularly indium tin oxide (ITO), which exhibits catastrophic failure under repeated bending cycles. Crack propagation in these films typically initiates at stress concentration points and rapidly extends across the conductive network, leading to exponential increases in electrical resistance.

Current TCF materials face a performance trade-off triangle between optical transparency, electrical conductivity, and mechanical flexibility. While ITO delivers excellent transparency and conductivity, its ceramic nature results in mechanical failure at bend radii below 8mm, making it unsuitable for truly flexible applications. Alternative materials like silver nanowires and carbon nanotubes offer improved flexibility but struggle with long-term stability issues including oxidation, delamination, and junction resistance increases under mechanical stress.

The interface between the TCF and substrate presents another significant challenge. Adhesion failures during bending cycles create delamination points that accelerate material degradation. Current adhesion promotion techniques often compromise either the optical or electrical properties of the composite structure, highlighting the need for interface engineering solutions that maintain performance across all parameters.

Standardization of testing protocols represents a substantial hurdle in the field. The lack of universally accepted methods for evaluating mechanical durability makes cross-comparison between research results difficult. Various testing approaches—including static bend tests, dynamic cycling tests, and tensile strain measurements—produce different failure metrics, complicating technology assessment and benchmarking efforts.

Environmental factors compound these challenges, as humidity, temperature fluctuations, and UV exposure can dramatically accelerate mechanical degradation. The synergistic effects of these environmental stressors with mechanical bending remain poorly understood, creating reliability concerns for real-world applications where devices must withstand multiple simultaneous stresses.

Manufacturing scalability presents additional complications, as laboratory-scale fabrication methods that produce mechanically robust TCFs often cannot translate to high-volume production. Roll-to-roll compatible processes frequently introduce defects and non-uniformities that become failure initiation sites under mechanical stress, reducing overall durability in mass-produced films.

The development of predictive models for TCF mechanical failure remains in its infancy. Current analytical approaches struggle to accurately forecast performance degradation over thousands of bending cycles, limiting designers' ability to estimate product lifetimes. This modeling gap necessitates extensive empirical testing, significantly extending development timelines for flexible electronic products.

Current TCF materials face a performance trade-off triangle between optical transparency, electrical conductivity, and mechanical flexibility. While ITO delivers excellent transparency and conductivity, its ceramic nature results in mechanical failure at bend radii below 8mm, making it unsuitable for truly flexible applications. Alternative materials like silver nanowires and carbon nanotubes offer improved flexibility but struggle with long-term stability issues including oxidation, delamination, and junction resistance increases under mechanical stress.

The interface between the TCF and substrate presents another significant challenge. Adhesion failures during bending cycles create delamination points that accelerate material degradation. Current adhesion promotion techniques often compromise either the optical or electrical properties of the composite structure, highlighting the need for interface engineering solutions that maintain performance across all parameters.

Standardization of testing protocols represents a substantial hurdle in the field. The lack of universally accepted methods for evaluating mechanical durability makes cross-comparison between research results difficult. Various testing approaches—including static bend tests, dynamic cycling tests, and tensile strain measurements—produce different failure metrics, complicating technology assessment and benchmarking efforts.

Environmental factors compound these challenges, as humidity, temperature fluctuations, and UV exposure can dramatically accelerate mechanical degradation. The synergistic effects of these environmental stressors with mechanical bending remain poorly understood, creating reliability concerns for real-world applications where devices must withstand multiple simultaneous stresses.

Manufacturing scalability presents additional complications, as laboratory-scale fabrication methods that produce mechanically robust TCFs often cannot translate to high-volume production. Roll-to-roll compatible processes frequently introduce defects and non-uniformities that become failure initiation sites under mechanical stress, reducing overall durability in mass-produced films.

The development of predictive models for TCF mechanical failure remains in its infancy. Current analytical approaches struggle to accurately forecast performance degradation over thousands of bending cycles, limiting designers' ability to estimate product lifetimes. This modeling gap necessitates extensive empirical testing, significantly extending development timelines for flexible electronic products.

Methodologies for TCF Bending Stress Evaluation

01 Carbon nanotube-based transparent conductive films

Carbon nanotubes (CNTs) are used to create transparent conductive films with excellent mechanical flexibility and resistance to bending stress. These films maintain their electrical conductivity even under repeated bending conditions due to the inherent flexibility of carbon nanotubes. The incorporation of CNTs in polymer matrices creates composite films that combine transparency with mechanical durability, making them suitable for flexible electronic devices.- Carbon nanotube-based transparent conductive films: Carbon nanotubes (CNTs) are used to create transparent conductive films with excellent mechanical flexibility and resistance to bending stress. These films maintain their electrical conductivity even under repeated bending cycles due to the inherent flexibility of carbon nanotubes. The incorporation of CNTs into polymer matrices creates composite films that combine transparency with mechanical durability, making them suitable for flexible electronic applications.

- Metal nanowire networks for flexible transparent conductors: Metal nanowire networks, particularly silver nanowires, provide a solution for creating transparent conductive films that can withstand mechanical bending stress. These networks maintain electrical conductivity under deformation due to their mesh-like structure that allows for movement during bending. The nanowires can be embedded in flexible substrates or polymer matrices to enhance their mechanical properties while maintaining optical transparency.

- Indium tin oxide (ITO) modifications for improved flexibility: Traditional indium tin oxide (ITO) films are modified to improve their resistance to mechanical bending stress. Techniques include creating patterned or segmented ITO structures, reducing film thickness, incorporating buffer layers, or depositing ITO on flexible substrates. These modifications help overcome the inherent brittleness of ITO while maintaining its excellent transparency and conductivity properties for use in flexible displays and touch panels.

- Graphene-based transparent conductive films: Graphene is utilized to create transparent conductive films with superior mechanical flexibility. The single-atom thickness and sp² bonding of graphene provide exceptional mechanical properties, allowing the films to withstand severe bending stress without degradation in electrical performance. Various methods of graphene synthesis and transfer are employed to create films that combine high optical transparency, electrical conductivity, and mechanical durability.

- Composite and hybrid transparent conductive structures: Hybrid structures combining different conductive materials are developed to enhance resistance to mechanical bending stress. These composites may include combinations of metal grids with conductive polymers, oxide/metal/oxide multilayers, or nanostructured materials embedded in flexible matrices. The synergistic properties of these hybrid structures provide improved mechanical flexibility while maintaining high transparency and conductivity for applications in flexible electronics.

02 Metal nanowire networks for flexible transparent conductors

Metal nanowire networks, particularly silver nanowires, provide a solution for creating transparent conductive films that can withstand mechanical bending stress. These networks maintain electrical conductivity while being bent or flexed due to the ability of the nanowires to slide against each other without breaking. The films exhibit high optical transparency and can be fabricated on flexible substrates, making them ideal for foldable displays and flexible electronics.Expand Specific Solutions03 Indium tin oxide (ITO) modifications for improved flexibility

Traditional indium tin oxide (ITO) films are modified to improve their resistance to mechanical bending stress. These modifications include creating patterned or segmented ITO structures, reducing film thickness, or incorporating ITO into composite structures. These approaches help overcome the inherent brittleness of ITO while maintaining its excellent optical transparency and electrical conductivity properties, extending its use to flexible display applications.Expand Specific Solutions04 Graphene-based transparent conductive films

Graphene is utilized to create transparent conductive films with superior mechanical properties under bending stress. The two-dimensional structure of graphene provides exceptional flexibility while maintaining high electrical conductivity and optical transparency. These films can be subjected to extreme bending conditions without significant degradation in performance, making them suitable for next-generation flexible and wearable electronic devices.Expand Specific Solutions05 Composite and hybrid transparent conductive structures

Hybrid and composite structures combine different conductive materials to create transparent films with enhanced resistance to mechanical bending stress. These structures may include combinations of metal grids with conductive polymers, oxide/metal/oxide multilayers, or conductive materials embedded in flexible polymer matrices. The synergistic effect of these combinations results in films that maintain conductivity under bending while providing high optical transparency and mechanical durability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The transparent conductive film (TCF) market under mechanical bending stress is currently in a growth phase, driven by increasing demand for flexible electronics. The global market size is expanding rapidly, expected to reach significant valuation as applications in flexible displays, touch panels, and wearable devices proliferate. Technologically, the field shows varying maturity levels across different approaches. Companies like Nitto Denko, TDK, and FUJIFILM lead with advanced polymer-based solutions, while Shantou Goworld Display and LX Hausys focus on specialized display applications. Emerging players such as InkTec and Shenzhen Huake Chuangzhi are advancing silver nanowire technologies, offering promising alternatives to traditional ITO films. Academic-industry collaborations involving South China University of Technology and Donghua University are accelerating innovation in next-generation flexible TCFs with enhanced mechanical durability.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed advanced transparent conductive films (TCFs) specifically engineered to withstand mechanical bending stress through their proprietary ELECRYSTA™ technology. Their solution incorporates silver nanowire networks embedded in flexible polymer matrices that maintain conductivity even after thousands of bending cycles. The company employs a unique multi-layer structure with a buffer layer between the conductive material and substrate to minimize strain concentration during bending. Their evaluation methodology includes cyclic bending tests at various radii (2-10mm) while simultaneously measuring resistance changes in real-time, allowing for precise characterization of performance degradation under mechanical stress. Nitto's films demonstrate less than 5% resistance increase after 100,000 bending cycles at a 5mm radius, making them suitable for foldable display applications.

Strengths: Superior flexibility retention with minimal resistance change during repeated bending; proprietary buffer layer technology effectively distributes mechanical stress. Weaknesses: Higher production costs compared to conventional ITO films; limited transparency in certain wavelength ranges which may affect optical performance in specialized applications.

Toyobo Co., Ltd.

Technical Solution: Toyobo has pioneered COSMOSHINE™ transparent conductive films specifically designed for flexible electronics applications requiring high bend durability. Their technical approach utilizes a hybrid structure combining metal mesh patterns with conductive polymers (PEDOT:PSS) to create films that maintain conductivity under extreme bending conditions. The company's evaluation protocol subjects films to dynamic mechanical testing under controlled environmental conditions, measuring both electrical resistance changes and optical properties simultaneously during bending stress application. Their proprietary stress-distribution layer technology prevents crack propagation by dispersing mechanical forces across the film surface. Toyobo's films maintain over 90% of their initial conductivity after 200,000 bending cycles at a 3mm radius, with transmittance exceeding 88% across the visible spectrum, making them ideal for wearable electronics and flexible displays.

Strengths: Exceptional durability under repeated bending with minimal performance degradation; balanced optical and electrical properties maintained under stress. Weaknesses: Higher cost structure compared to traditional conductive films; requires specialized handling during manufacturing integration processes.

Critical Patents in Flexible TCF Technology

Transparent electroconductive film and manufacturing method therefor

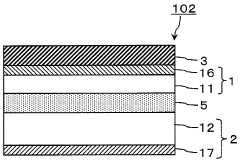

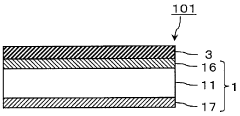

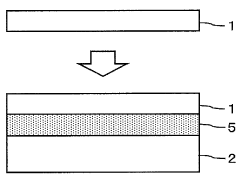

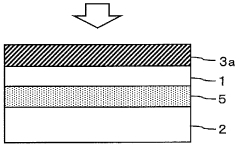

PatentWO2012090735A1

Innovation

- A transparent conductive film with a crystalline ITO layer formed on a flexible substrate, where compressive residual stress is applied during heat treatment to achieve dimensional changes of -0.3% to -1.5% and residual stress of 0.4 to 2 GPa, enhancing hitting properties and bending resistance.

Transparent conductive film and method for manufacturing the same

PatentInactiveJP2017228534A

Innovation

- Development of a transparent conductive film with compressive residual stress (0.4 to 2 GPa) in the crystalline indium-tin complex oxide layer, significantly improving bending characteristics and flexure resistance under heavy load.

- Transformation of amorphous indium-tin complex oxide into crystalline structure through controlled heating process while imparting compressive stress, creating a film with superior mechanical properties.

- Precise control of dimensional change (-0.3% to -1.5%) in the transparent conductive layer during heating process to optimize the mechanical properties of the final film.

Materials Science Advancements for TCF Flexibility

Recent advancements in materials science have significantly contributed to enhancing the flexibility of transparent conductive films (TCFs). Traditional TCF materials like indium tin oxide (ITO) exhibit inherent brittleness, limiting their application in flexible electronics. The development of novel nanomaterials and composite structures has revolutionized this field, enabling TCFs to withstand mechanical stress without compromising electrical conductivity or optical transparency.

Carbon-based materials, particularly graphene and carbon nanotubes (CNTs), represent a breakthrough in flexible TCF technology. These materials demonstrate exceptional mechanical properties with Young's modulus values exceeding 1 TPa, allowing them to endure repeated bending cycles without structural degradation. Graphene's two-dimensional structure provides unique advantages, as it can be deformed up to 20% strain while maintaining electrical conductivity.

Metal nanowire networks, especially those based on silver (AgNWs), have emerged as another promising solution. These networks form percolation pathways that maintain conductivity even under significant deformation. Recent research has focused on optimizing nanowire dimensions and network density to achieve an optimal balance between transparency, conductivity, and flexibility. AgNW films with wire diameters below 30 nm have demonstrated remarkable resilience to bending radii as small as 1 mm.

Composite structures combining multiple materials have shown superior performance compared to single-material TCFs. PEDOT:PSS polymer composites integrated with metallic nanowires or carbon nanomaterials create synergistic effects, where the polymer matrix absorbs mechanical stress while the conductive components maintain electrical pathways. These hybrid systems can withstand thousands of bending cycles with minimal increase in sheet resistance.

Surface modification techniques have further enhanced TCF flexibility. Treatments such as acid etching, plasma modification, and the application of specialized adhesion layers improve interfacial bonding between TCFs and substrates. These modifications distribute mechanical stress more evenly across the film-substrate interface, preventing delamination and crack propagation during bending.

Substrate engineering represents another critical advancement. Ultra-thin glass (< 100 μm), specialized polyimides, and elastomeric materials like PDMS provide platforms with inherent flexibility. The development of neutral plane engineering, where TCFs are positioned at the neutral mechanical plane of the device stack, minimizes strain during bending, significantly extending operational lifetime under mechanical stress.

Carbon-based materials, particularly graphene and carbon nanotubes (CNTs), represent a breakthrough in flexible TCF technology. These materials demonstrate exceptional mechanical properties with Young's modulus values exceeding 1 TPa, allowing them to endure repeated bending cycles without structural degradation. Graphene's two-dimensional structure provides unique advantages, as it can be deformed up to 20% strain while maintaining electrical conductivity.

Metal nanowire networks, especially those based on silver (AgNWs), have emerged as another promising solution. These networks form percolation pathways that maintain conductivity even under significant deformation. Recent research has focused on optimizing nanowire dimensions and network density to achieve an optimal balance between transparency, conductivity, and flexibility. AgNW films with wire diameters below 30 nm have demonstrated remarkable resilience to bending radii as small as 1 mm.

Composite structures combining multiple materials have shown superior performance compared to single-material TCFs. PEDOT:PSS polymer composites integrated with metallic nanowires or carbon nanomaterials create synergistic effects, where the polymer matrix absorbs mechanical stress while the conductive components maintain electrical pathways. These hybrid systems can withstand thousands of bending cycles with minimal increase in sheet resistance.

Surface modification techniques have further enhanced TCF flexibility. Treatments such as acid etching, plasma modification, and the application of specialized adhesion layers improve interfacial bonding between TCFs and substrates. These modifications distribute mechanical stress more evenly across the film-substrate interface, preventing delamination and crack propagation during bending.

Substrate engineering represents another critical advancement. Ultra-thin glass (< 100 μm), specialized polyimides, and elastomeric materials like PDMS provide platforms with inherent flexibility. The development of neutral plane engineering, where TCFs are positioned at the neutral mechanical plane of the device stack, minimizes strain during bending, significantly extending operational lifetime under mechanical stress.

Standardization of Mechanical Testing Protocols

The standardization of mechanical testing protocols for transparent conductive films (TCFs) represents a critical foundation for reliable evaluation of their performance under bending stress. Current testing methodologies exhibit significant variations across research institutions and manufacturers, leading to inconsistent results and challenges in comparative analysis. A unified approach to mechanical testing would enable more accurate benchmarking and accelerate technological advancement in flexible electronics.

The primary parameters requiring standardization include bending radius, bending cycles, bending frequency, and environmental conditions during testing. For bending radius, we propose a tiered classification system with categories for extreme (<1mm), high (1-5mm), moderate (5-10mm), and mild (>10mm) bending stress scenarios. This classification aligns with practical applications ranging from foldable displays to curved automotive interfaces.

Bending cycle standardization should incorporate both short-term resilience testing (100-1,000 cycles) and long-term durability assessment (10,000-1,000,000 cycles). The testing frequency requires careful consideration, as high-frequency testing may introduce thermal effects that confound pure mechanical stress evaluation. Our analysis suggests 0.5-1 Hz as an optimal frequency range for standard testing protocols.

Environmental condition standardization must address temperature, humidity, and atmospheric pressure during testing. We recommend conducting tests at 23±2°C and 50±5% relative humidity as baseline conditions, with additional testing at application-specific environmental extremes. This approach ensures both reproducibility and practical relevance of test results.

In-situ measurement techniques represent another critical aspect requiring standardization. Real-time monitoring of electrical resistance during bending provides more valuable insights than pre/post measurements alone. Optical monitoring systems that simultaneously track crack formation and propagation alongside electrical performance changes should be incorporated into standardized protocols.

The development of reference materials with known mechanical properties would significantly enhance test calibration across different laboratories. These reference materials should include standard TCF samples with certified bending performance characteristics, enabling equipment validation and cross-laboratory result verification.

Implementation of these standardized protocols would facilitate meaningful comparison between emerging TCF technologies, accelerate material optimization processes, and provide manufacturers with reliable metrics for quality control. International standards organizations including IEC, ASTM, and ISO have expressed interest in adopting comprehensive mechanical testing frameworks for flexible electronic components.

The primary parameters requiring standardization include bending radius, bending cycles, bending frequency, and environmental conditions during testing. For bending radius, we propose a tiered classification system with categories for extreme (<1mm), high (1-5mm), moderate (5-10mm), and mild (>10mm) bending stress scenarios. This classification aligns with practical applications ranging from foldable displays to curved automotive interfaces.

Bending cycle standardization should incorporate both short-term resilience testing (100-1,000 cycles) and long-term durability assessment (10,000-1,000,000 cycles). The testing frequency requires careful consideration, as high-frequency testing may introduce thermal effects that confound pure mechanical stress evaluation. Our analysis suggests 0.5-1 Hz as an optimal frequency range for standard testing protocols.

Environmental condition standardization must address temperature, humidity, and atmospheric pressure during testing. We recommend conducting tests at 23±2°C and 50±5% relative humidity as baseline conditions, with additional testing at application-specific environmental extremes. This approach ensures both reproducibility and practical relevance of test results.

In-situ measurement techniques represent another critical aspect requiring standardization. Real-time monitoring of electrical resistance during bending provides more valuable insights than pre/post measurements alone. Optical monitoring systems that simultaneously track crack formation and propagation alongside electrical performance changes should be incorporated into standardized protocols.

The development of reference materials with known mechanical properties would significantly enhance test calibration across different laboratories. These reference materials should include standard TCF samples with certified bending performance characteristics, enabling equipment validation and cross-laboratory result verification.

Implementation of these standardized protocols would facilitate meaningful comparison between emerging TCF technologies, accelerate material optimization processes, and provide manufacturers with reliable metrics for quality control. International standards organizations including IEC, ASTM, and ISO have expressed interest in adopting comprehensive mechanical testing frameworks for flexible electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!