How transparent conductive films improve light transmission and conductivity balance

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCF Technology Background and Objectives

Transparent conductive films (TCFs) have emerged as a critical component in modern electronic devices, evolving significantly since their inception in the mid-20th century. Initially developed for military applications, these films have transitioned into mainstream consumer electronics, becoming essential elements in touchscreens, displays, photovoltaic cells, and various optoelectronic devices. The technological evolution of TCFs has been driven by the increasing demand for devices that combine transparency with electrical conductivity—properties that are inherently contradictory in most materials.

The fundamental challenge in TCF development lies in optimizing the balance between optical transparency and electrical conductivity. Traditional conductive materials like metals exhibit high conductivity but poor transparency, while transparent materials typically lack conductivity. This technological paradox has spurred decades of research aimed at developing materials and structures that can effectively reconcile these opposing properties.

Industry trends indicate a shift toward more flexible, durable, and cost-effective TCF solutions. The market has evolved from indium tin oxide (ITO) dominance to exploring alternative materials such as silver nanowires, carbon nanotubes, graphene, and conductive polymers. This diversification reflects both the limitations of traditional materials and the expanding application landscape requiring specialized performance characteristics.

The primary technical objective in TCF development is to achieve optimal performance metrics: sheet resistance below 100 Ω/sq combined with optical transparency exceeding 90% in the visible spectrum. Secondary objectives include enhancing mechanical flexibility, environmental stability, and developing scalable, cost-effective manufacturing processes that can support mass production while reducing reliance on scarce materials like indium.

Recent technological breakthroughs have focused on novel material compositions, innovative deposition techniques, and hierarchical nanostructures that can manipulate light-matter interactions at the nanoscale. These approaches aim to overcome the fundamental trade-off between transparency and conductivity by engineering materials that can simultaneously allow light transmission while providing efficient pathways for electrical conduction.

The global research landscape shows intensifying efforts to develop next-generation TCFs, with significant contributions from academic institutions, technology companies, and government research laboratories across North America, East Asia, and Europe. This collaborative ecosystem has accelerated innovation cycles, leading to rapid improvements in performance metrics and expanding the potential application domains for TCF technology.

Looking forward, TCF technology aims to enable emerging applications in flexible electronics, smart windows, transparent heaters, and electromagnetic interference shielding. The continued evolution of this technology will likely play a pivotal role in shaping the next generation of electronic devices, particularly as the industry moves toward more sustainable, flexible, and integrated solutions.

The fundamental challenge in TCF development lies in optimizing the balance between optical transparency and electrical conductivity. Traditional conductive materials like metals exhibit high conductivity but poor transparency, while transparent materials typically lack conductivity. This technological paradox has spurred decades of research aimed at developing materials and structures that can effectively reconcile these opposing properties.

Industry trends indicate a shift toward more flexible, durable, and cost-effective TCF solutions. The market has evolved from indium tin oxide (ITO) dominance to exploring alternative materials such as silver nanowires, carbon nanotubes, graphene, and conductive polymers. This diversification reflects both the limitations of traditional materials and the expanding application landscape requiring specialized performance characteristics.

The primary technical objective in TCF development is to achieve optimal performance metrics: sheet resistance below 100 Ω/sq combined with optical transparency exceeding 90% in the visible spectrum. Secondary objectives include enhancing mechanical flexibility, environmental stability, and developing scalable, cost-effective manufacturing processes that can support mass production while reducing reliance on scarce materials like indium.

Recent technological breakthroughs have focused on novel material compositions, innovative deposition techniques, and hierarchical nanostructures that can manipulate light-matter interactions at the nanoscale. These approaches aim to overcome the fundamental trade-off between transparency and conductivity by engineering materials that can simultaneously allow light transmission while providing efficient pathways for electrical conduction.

The global research landscape shows intensifying efforts to develop next-generation TCFs, with significant contributions from academic institutions, technology companies, and government research laboratories across North America, East Asia, and Europe. This collaborative ecosystem has accelerated innovation cycles, leading to rapid improvements in performance metrics and expanding the potential application domains for TCF technology.

Looking forward, TCF technology aims to enable emerging applications in flexible electronics, smart windows, transparent heaters, and electromagnetic interference shielding. The continued evolution of this technology will likely play a pivotal role in shaping the next generation of electronic devices, particularly as the industry moves toward more sustainable, flexible, and integrated solutions.

Market Demand Analysis for High-Performance TCFs

The global market for transparent conductive films (TCFs) has been experiencing robust growth, driven primarily by the expanding touchscreen display industry. As of recent market analyses, the TCF market is valued at over 5 billion USD with projections indicating a compound annual growth rate exceeding 8% through 2028. This growth trajectory is underpinned by increasing consumer demand for smartphones, tablets, wearable devices, and other touch-enabled electronics that require high-performance TCFs.

The demand for advanced TCFs is particularly pronounced in the consumer electronics sector, where manufacturers are constantly pushing for thinner, lighter, and more responsive devices. These applications require TCFs that can deliver exceptional optical transparency (typically above 90% in the visible spectrum) while maintaining electrical conductivity below 100 ohms per square. This delicate balance between transparency and conductivity represents the core market need that drives innovation in this space.

Emerging applications in flexible electronics, OLED displays, and solar cells are creating new market segments with specialized requirements for TCFs. The flexible electronics market, growing at nearly 15% annually, demands TCFs that can maintain performance integrity under repeated bending and folding conditions. Similarly, the OLED display industry requires TCFs with enhanced durability and consistent performance across varying environmental conditions.

Regional market analysis reveals that East Asia, particularly China, Japan, and South Korea, dominates TCF production and consumption, accounting for approximately 70% of the global market. This concentration aligns with the regional strength in electronics manufacturing. However, North America and Europe are showing increased demand driven by automotive applications, smart home devices, and renewable energy systems.

Industry surveys indicate that end-users are increasingly prioritizing TCFs with improved environmental sustainability profiles. This trend is reflected in growing demand for alternatives to traditional indium tin oxide (ITO) films, which face supply chain challenges due to the scarcity of indium. Materials such as silver nanowires, carbon nanotubes, graphene, and metal mesh are gaining market share as they offer comparable performance with potentially lower environmental impact.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers often prioritize performance over cost, emerging applications in building-integrated photovoltaics and automotive displays show greater price sensitivity, creating market opportunities for cost-effective TCF solutions that maintain adequate performance metrics.

The market is also witnessing increased demand for customized TCF solutions tailored to specific applications, driving manufacturers to develop more versatile production processes and expand their product portfolios to address diverse technical requirements across multiple industries.

The demand for advanced TCFs is particularly pronounced in the consumer electronics sector, where manufacturers are constantly pushing for thinner, lighter, and more responsive devices. These applications require TCFs that can deliver exceptional optical transparency (typically above 90% in the visible spectrum) while maintaining electrical conductivity below 100 ohms per square. This delicate balance between transparency and conductivity represents the core market need that drives innovation in this space.

Emerging applications in flexible electronics, OLED displays, and solar cells are creating new market segments with specialized requirements for TCFs. The flexible electronics market, growing at nearly 15% annually, demands TCFs that can maintain performance integrity under repeated bending and folding conditions. Similarly, the OLED display industry requires TCFs with enhanced durability and consistent performance across varying environmental conditions.

Regional market analysis reveals that East Asia, particularly China, Japan, and South Korea, dominates TCF production and consumption, accounting for approximately 70% of the global market. This concentration aligns with the regional strength in electronics manufacturing. However, North America and Europe are showing increased demand driven by automotive applications, smart home devices, and renewable energy systems.

Industry surveys indicate that end-users are increasingly prioritizing TCFs with improved environmental sustainability profiles. This trend is reflected in growing demand for alternatives to traditional indium tin oxide (ITO) films, which face supply chain challenges due to the scarcity of indium. Materials such as silver nanowires, carbon nanotubes, graphene, and metal mesh are gaining market share as they offer comparable performance with potentially lower environmental impact.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers often prioritize performance over cost, emerging applications in building-integrated photovoltaics and automotive displays show greater price sensitivity, creating market opportunities for cost-effective TCF solutions that maintain adequate performance metrics.

The market is also witnessing increased demand for customized TCF solutions tailored to specific applications, driving manufacturers to develop more versatile production processes and expand their product portfolios to address diverse technical requirements across multiple industries.

Current Challenges in Transparent Conductive Films

Despite significant advancements in transparent conductive film (TCF) technology, the fundamental trade-off between optical transparency and electrical conductivity remains a persistent challenge. This inherent inverse relationship creates a technical bottleneck where improving one property typically degrades the other. Current industry-standard materials like Indium Tin Oxide (ITO) face limitations in achieving optimal performance in both parameters simultaneously, particularly when applied to flexible substrates where conductivity deteriorates significantly upon bending.

Material stability presents another critical challenge, with many TCFs exhibiting performance degradation under environmental stressors such as humidity, temperature fluctuations, and UV exposure. This vulnerability significantly impacts long-term reliability in commercial applications, especially in outdoor settings or harsh industrial environments where consistent performance is essential.

Manufacturing scalability continues to impede widespread adoption of next-generation TCFs. Novel materials demonstrating superior laboratory performance often encounter significant barriers in transitioning to mass production. Complex fabrication processes, high temperature requirements, and specialized equipment needs contribute to elevated production costs that limit commercial viability.

The mechanical flexibility demands of modern electronics pose substantial challenges for traditional TCF materials. As the industry shifts toward foldable displays, wearable technology, and flexible photovoltaics, the need for TCFs that maintain conductivity under repeated bending and stretching has intensified. Current solutions often experience microfractures and conductivity losses when subjected to mechanical stress.

Material sourcing represents an increasingly significant concern, particularly regarding ITO's dependence on indium, which faces supply chain vulnerabilities due to geopolitical factors and limited natural reserves. This has accelerated the search for alternative materials with comparable performance characteristics but composed of more abundant elements.

Haze and optical quality issues persist in many alternative TCF technologies. Metal nanowire networks and certain carbon-based films often exhibit visible haze or color tinting that compromises display quality in high-end applications. Additionally, surface roughness in these alternatives can create integration challenges with other device components.

Integration compatibility with existing manufacturing infrastructure presents a substantial barrier to adoption. Many promising TCF technologies require specialized processing conditions that are incompatible with established production lines, necessitating significant capital investment for implementation. This compatibility gap slows industry transition to potentially superior materials despite their technical advantages.

Material stability presents another critical challenge, with many TCFs exhibiting performance degradation under environmental stressors such as humidity, temperature fluctuations, and UV exposure. This vulnerability significantly impacts long-term reliability in commercial applications, especially in outdoor settings or harsh industrial environments where consistent performance is essential.

Manufacturing scalability continues to impede widespread adoption of next-generation TCFs. Novel materials demonstrating superior laboratory performance often encounter significant barriers in transitioning to mass production. Complex fabrication processes, high temperature requirements, and specialized equipment needs contribute to elevated production costs that limit commercial viability.

The mechanical flexibility demands of modern electronics pose substantial challenges for traditional TCF materials. As the industry shifts toward foldable displays, wearable technology, and flexible photovoltaics, the need for TCFs that maintain conductivity under repeated bending and stretching has intensified. Current solutions often experience microfractures and conductivity losses when subjected to mechanical stress.

Material sourcing represents an increasingly significant concern, particularly regarding ITO's dependence on indium, which faces supply chain vulnerabilities due to geopolitical factors and limited natural reserves. This has accelerated the search for alternative materials with comparable performance characteristics but composed of more abundant elements.

Haze and optical quality issues persist in many alternative TCF technologies. Metal nanowire networks and certain carbon-based films often exhibit visible haze or color tinting that compromises display quality in high-end applications. Additionally, surface roughness in these alternatives can create integration challenges with other device components.

Integration compatibility with existing manufacturing infrastructure presents a substantial barrier to adoption. Many promising TCF technologies require specialized processing conditions that are incompatible with established production lines, necessitating significant capital investment for implementation. This compatibility gap slows industry transition to potentially superior materials despite their technical advantages.

Current Solutions for Transmission-Conductivity Trade-off

01 Carbon nanotube-based transparent conductive films

Carbon nanotubes (CNTs) can be used to create transparent conductive films with balanced light transmission and electrical conductivity properties. These films can be fabricated through various methods such as solution processing or direct growth. The unique structure of carbon nanotubes allows for high electrical conductivity while maintaining good optical transparency. The performance can be further enhanced by controlling the density, alignment, and purity of the nanotubes.- Carbon nanotube-based transparent conductive films: Carbon nanotubes (CNTs) can be used to create transparent conductive films with balanced light transmission and electrical conductivity properties. These films can be fabricated through various methods such as solution processing or direct growth. The unique structure of carbon nanotubes allows for high electrical conductivity while maintaining good optical transparency. The performance can be further enhanced by controlling the density, alignment, and purity of the nanotubes.

- Metal nanowire transparent conductors: Metal nanowires, particularly silver nanowires, offer an excellent balance between transparency and conductivity for transparent conductive films. These nanowires form a percolating network that allows electrical current to flow while leaving sufficient open space for light to pass through. The performance can be optimized by controlling nanowire dimensions, density, and junction resistance. Post-treatment processes such as annealing or pressing can further improve the conductivity without significantly reducing transparency.

- Indium tin oxide (ITO) and alternative metal oxides: Indium tin oxide (ITO) has been widely used as a transparent conductive material due to its good balance of optical transparency and electrical conductivity. However, due to the scarcity and cost of indium, alternative metal oxides such as aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), and indium-free compositions are being developed. These materials can be deposited using various techniques including sputtering, chemical vapor deposition, and sol-gel methods to achieve the desired balance of properties.

- Composite and hybrid transparent conductive materials: Composite and hybrid materials combine different types of conductive components to achieve an optimal balance between transparency and conductivity. These may include combinations of metal nanowires with graphene, carbon nanotubes with conductive polymers, or metal oxides with metallic grids. The synergistic effects between different materials can lead to enhanced performance that exceeds what can be achieved with single-component systems. Additionally, these composites often offer improved mechanical flexibility and durability.

- Structural and process optimization techniques: Various structural and process optimization techniques can be employed to enhance the balance between light transmission and conductivity in transparent conductive films. These include patterning of conductive materials into mesh or grid structures, multilayer architectures with anti-reflection properties, doping strategies to increase carrier concentration, and post-processing treatments such as plasma treatment or chemical modification. The film thickness can also be carefully controlled to find the optimal point where conductivity is sufficient while maintaining maximum transparency.

02 Metal nanowire transparent conductive films

Metal nanowires, particularly silver nanowires, offer an excellent balance between transparency and conductivity for transparent conductive films. These nanowires form a percolating network that allows electrical current to flow while leaving sufficient open space for light to pass through. The performance of these films can be optimized by controlling nanowire dimensions, density, and junction resistance. Post-treatment processes such as annealing or pressing can further improve the conductivity without significantly reducing transparency.Expand Specific Solutions03 Indium tin oxide (ITO) alternatives for transparent conductors

Various materials are being developed as alternatives to traditional indium tin oxide (ITO) for transparent conductive applications. These include doped metal oxides, conductive polymers, and hybrid materials. These alternatives aim to overcome ITO's limitations such as brittleness, indium scarcity, and high processing temperatures while maintaining the balance between optical transparency and electrical conductivity. Material composition, deposition methods, and post-processing techniques are key factors in optimizing this balance.Expand Specific Solutions04 Multilayer and composite structures for enhanced performance

Multilayer and composite structures can be designed to achieve superior balance between transparency and conductivity compared to single-material films. These structures typically combine different functional layers, each optimized for specific properties. For example, a highly conductive layer may be sandwiched between transparent protective layers, or conductive materials may be embedded in a transparent matrix. This approach allows for independent optimization of optical and electrical properties, resulting in better overall performance.Expand Specific Solutions05 Surface treatment and doping techniques

Various surface treatments and doping techniques can be employed to improve the balance between transparency and conductivity in transparent conductive films. These include chemical doping, plasma treatment, acid treatment, and functionalization with various compounds. Such modifications can enhance charge carrier concentration or mobility without significantly affecting optical properties. Additionally, surface treatments can improve film stability, adhesion to substrates, and compatibility with other materials in device structures.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The transparent conductive film (TCF) market is in a growth phase, driven by increasing demand for touch screens, displays, and photovoltaic applications. The market is projected to expand significantly due to the proliferation of electronic devices requiring balanced light transmission and conductivity properties. Companies like Nitto Denko, LG Display, and Sony Group are leading innovation in this space, with Japanese firms dominating the competitive landscape. Technological maturity varies across different TCF types, with established players like Sumitomo Metal Mining and Mitsubishi Materials focusing on traditional ITO films, while emerging companies such as CHASM Advanced Materials and Beijing Zenithnano Technology are developing next-generation solutions using nanomaterials like carbon nanotubes and silver nanowires to overcome the inherent brittleness-conductivity trade-off of conventional materials.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed advanced transparent conductive films using silver nanowire (AgNW) technology that achieves exceptional balance between optical transparency and electrical conductivity. Their proprietary manufacturing process creates a uniform network of ultra-thin silver nanowires embedded in polymer matrices, allowing for light transmission rates exceeding 90% while maintaining sheet resistance below 100 ohms/square. The company has further enhanced performance through multi-layer film structures where each layer is optimized for specific functions - the top layer provides protection against environmental factors, the middle layer contains the conductive nanowire network, and the bottom layer ensures strong adhesion to various substrates. This approach allows precise control over the trade-off between conductivity and transparency by adjusting nanowire density and dimensions.

Strengths: Superior flexibility compared to ITO films, enabling use in foldable displays; excellent durability with resistance to repeated bending; scalable roll-to-roll manufacturing process reduces production costs. Weaknesses: Higher cost compared to some competing technologies; potential for silver migration under certain environmental conditions; requires specialized handling during integration.

Sony Group Corp.

Technical Solution: Sony has developed proprietary transparent conductive film technology based on a composite structure of conductive polymers and metal nanowires. Their approach utilizes PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) as a conductive polymer matrix with embedded silver nanowires to create a synergistic effect that enhances both conductivity and transparency. The company's manufacturing process involves solution-based deposition followed by specialized post-treatments that optimize the interface between the polymer and nanowires, reducing junction resistance. This hybrid structure achieves sheet resistance of approximately 20 ohms/square while maintaining optical transparency above 89%. Sony has further refined this technology by incorporating graphene oxide interlayers that improve adhesion to various substrates and enhance environmental stability. Their latest innovation involves patterned deposition techniques that create invisible conductive grids optimized for touch sensor applications in their display products.

Strengths: Excellent flexibility and adhesion to various substrates; compatible with roll-to-roll manufacturing for cost-effective production; superior environmental stability compared to pure polymer conductors. Weaknesses: Higher sheet resistance compared to pure metal-based solutions; potential for degradation under prolonged UV exposure; requires careful control of processing conditions to ensure consistent performance.

Core Innovations in TCF Material Science

Method for improving light transmittance and reducing sheet resistance of transparent conductive film containing metal oxide, silver and metal oxide capable of simultaneously improving light transmittance and conductive properties

PatentActiveTW202429490A

Innovation

- Using ultraviolet laser annealing with specific power density (280-700 W/mm²) to improve both light transmittance and conductivity of metal oxide/silver/metal oxide transparent conductive films.

- Implementing a precise scanning methodology with controlled speed (200-500 mm/s) and strategic gaps between adjacent laser action areas to optimize film properties.

- Achieving superior performance metrics (85% light transmittance with only 5.35 ohms/unit area sheet resistance) through controlled laser processing rather than traditional annealing methods.

Transparent conductive film for optoelectronic device

PatentInactiveUS20120222885A1

Innovation

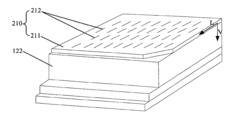

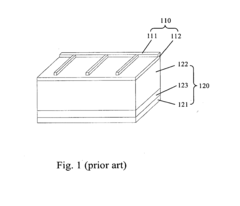

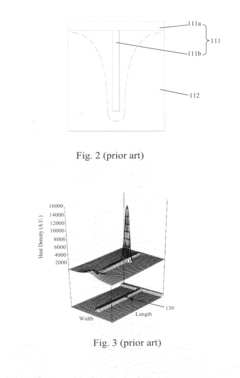

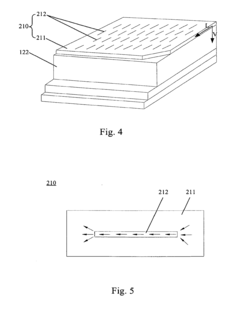

- A transparent conductive film with a plurality of separate conductors disposed on its surface, arranged to collect electrical current and reduce internal resistance, allowing for a thinner film without impairing performance, and featuring conductors that extend along current flow directions, are arranged in rows or concentric circles to improve current and heat uniformity.

Sustainability Aspects of TCF Manufacturing

The manufacturing of transparent conductive films (TCFs) presents significant environmental and sustainability challenges that must be addressed as these materials become increasingly vital in modern electronics. Traditional TCF production methods often involve energy-intensive processes and environmentally harmful chemicals, particularly when using indium tin oxide (ITO), the industry standard material.

Resource scarcity represents a primary sustainability concern, as indium is a rare earth element with limited global reserves. Current extraction and processing methods generate substantial waste and environmental degradation. The manufacturing process typically requires high temperatures exceeding 300°C, resulting in considerable energy consumption and associated carbon emissions.

Alternative TCF materials offer promising sustainability improvements. Carbon-based materials such as graphene and carbon nanotubes can be produced using less energy-intensive methods and abundant carbon sources. Metal nanowire networks, particularly those using silver or copper, can be fabricated using solution-based processes at lower temperatures, significantly reducing energy requirements.

Recent advancements in green manufacturing techniques have demonstrated substantial progress. Roll-to-roll processing enables continuous production with reduced material waste, while solution-based deposition methods operate at near-ambient temperatures, dramatically lowering energy consumption. Additionally, water-based processing systems are replacing toxic organic solvents in certain TCF production methods.

Life cycle assessment (LCA) studies indicate that newer TCF technologies can reduce environmental impact by 40-60% compared to traditional ITO manufacturing. However, end-of-life considerations remain challenging, as the composite nature of many TCFs complicates recycling efforts. The electronics industry is increasingly exploring design-for-recycling approaches that facilitate material recovery.

Regulatory frameworks worldwide are evolving to address these sustainability concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop TCFs with reduced environmental impact. Similarly, initiatives like the Responsible Minerals Initiative are promoting sustainable sourcing practices throughout the supply chain.

Future sustainability improvements will likely focus on closed-loop manufacturing systems, bio-based precursor materials, and ambient-temperature processing techniques. These innovations promise to further reduce the environmental footprint of TCF production while maintaining the critical balance between light transmission and conductivity that makes these materials essential for modern electronic devices.

Resource scarcity represents a primary sustainability concern, as indium is a rare earth element with limited global reserves. Current extraction and processing methods generate substantial waste and environmental degradation. The manufacturing process typically requires high temperatures exceeding 300°C, resulting in considerable energy consumption and associated carbon emissions.

Alternative TCF materials offer promising sustainability improvements. Carbon-based materials such as graphene and carbon nanotubes can be produced using less energy-intensive methods and abundant carbon sources. Metal nanowire networks, particularly those using silver or copper, can be fabricated using solution-based processes at lower temperatures, significantly reducing energy requirements.

Recent advancements in green manufacturing techniques have demonstrated substantial progress. Roll-to-roll processing enables continuous production with reduced material waste, while solution-based deposition methods operate at near-ambient temperatures, dramatically lowering energy consumption. Additionally, water-based processing systems are replacing toxic organic solvents in certain TCF production methods.

Life cycle assessment (LCA) studies indicate that newer TCF technologies can reduce environmental impact by 40-60% compared to traditional ITO manufacturing. However, end-of-life considerations remain challenging, as the composite nature of many TCFs complicates recycling efforts. The electronics industry is increasingly exploring design-for-recycling approaches that facilitate material recovery.

Regulatory frameworks worldwide are evolving to address these sustainability concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop TCFs with reduced environmental impact. Similarly, initiatives like the Responsible Minerals Initiative are promoting sustainable sourcing practices throughout the supply chain.

Future sustainability improvements will likely focus on closed-loop manufacturing systems, bio-based precursor materials, and ambient-temperature processing techniques. These innovations promise to further reduce the environmental footprint of TCF production while maintaining the critical balance between light transmission and conductivity that makes these materials essential for modern electronic devices.

TCF Integration in Emerging Applications

Transparent conductive films (TCFs) are rapidly expanding beyond traditional display applications into diverse emerging fields, creating new integration challenges and opportunities. In the realm of flexible electronics, TCFs are enabling the development of bendable displays, wearable health monitors, and foldable smartphones by providing consistent conductivity even under mechanical stress. The integration process requires specialized lamination techniques that maintain the delicate balance between transparency and conductivity while ensuring adhesion to flexible substrates.

Smart architectural applications represent another frontier, with TCFs being incorporated into smart windows and building-integrated photovoltaics. These applications demand TCFs with exceptional durability against environmental factors while maintaining optical clarity and electrical performance over decades rather than years. Integration methods have evolved to include direct deposition on glass during manufacturing processes, creating seamless connections with building management systems.

The automotive sector has embraced TCFs for advanced applications including heads-up displays, smart mirrors, and defrosting windshields. Integration challenges in this domain center around meeting stringent safety standards while withstanding extreme temperature variations and vibration. Manufacturers have developed specialized edge connection technologies that maintain reliability under these demanding conditions.

In biomedical devices, TCFs are finding novel applications in transparent biosensors, smart contact lenses, and implantable monitoring systems. The integration process for these applications requires biocompatible encapsulation techniques that preserve both electrical functionality and optical transparency while ensuring patient safety. Recent innovations include gradient-patterned TCFs that optimize conductivity in specific regions while maximizing transparency elsewhere.

The emerging field of augmented reality (AR) and virtual reality (VR) presents perhaps the most demanding integration challenges for TCFs. These applications require exceptionally high transparency (>95%) combined with sufficient conductivity for touch sensing and display functionality, all while maintaining minimal haze. Integration solutions include multi-layer TCF structures with specialized anti-reflection coatings and patterned conductivity zones that optimize performance for specific device regions.

As these diverse applications continue to evolve, TCF integration techniques are becoming increasingly specialized, with manufacturers developing application-specific films and connection technologies that address the unique requirements of each emerging field.

Smart architectural applications represent another frontier, with TCFs being incorporated into smart windows and building-integrated photovoltaics. These applications demand TCFs with exceptional durability against environmental factors while maintaining optical clarity and electrical performance over decades rather than years. Integration methods have evolved to include direct deposition on glass during manufacturing processes, creating seamless connections with building management systems.

The automotive sector has embraced TCFs for advanced applications including heads-up displays, smart mirrors, and defrosting windshields. Integration challenges in this domain center around meeting stringent safety standards while withstanding extreme temperature variations and vibration. Manufacturers have developed specialized edge connection technologies that maintain reliability under these demanding conditions.

In biomedical devices, TCFs are finding novel applications in transparent biosensors, smart contact lenses, and implantable monitoring systems. The integration process for these applications requires biocompatible encapsulation techniques that preserve both electrical functionality and optical transparency while ensuring patient safety. Recent innovations include gradient-patterned TCFs that optimize conductivity in specific regions while maximizing transparency elsewhere.

The emerging field of augmented reality (AR) and virtual reality (VR) presents perhaps the most demanding integration challenges for TCFs. These applications require exceptionally high transparency (>95%) combined with sufficient conductivity for touch sensing and display functionality, all while maintaining minimal haze. Integration solutions include multi-layer TCF structures with specialized anti-reflection coatings and patterned conductivity zones that optimize performance for specific device regions.

As these diverse applications continue to evolve, TCF integration techniques are becoming increasingly specialized, with manufacturers developing application-specific films and connection technologies that address the unique requirements of each emerging field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!