Research on transparent conductive films with enhanced thermal stability

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCF Development Background and Objectives

Transparent conductive films (TCFs) have emerged as critical components in modern optoelectronic devices, enabling the development of touchscreens, displays, solar cells, and various smart devices. The evolution of TCFs began in the 1990s with indium tin oxide (ITO) dominating the market due to its excellent combination of optical transparency and electrical conductivity. However, as technology advanced, the limitations of ITO became increasingly apparent, particularly its brittleness, limited flexibility, and most critically, its poor thermal stability at elevated temperatures.

The thermal stability challenge has become increasingly significant as modern devices operate in more demanding environments and manufacturing processes require higher temperature tolerances. When exposed to elevated temperatures, conventional TCFs often experience degradation in conductivity, optical properties, and mechanical integrity, severely limiting their application scope and reliability in next-generation devices.

The global push toward flexible, wearable, and high-performance electronics has accelerated the need for thermally stable TCFs. Industries ranging from automotive (for heated windshields and displays operating in extreme conditions) to aerospace and advanced manufacturing require TCFs that can maintain performance integrity across wide temperature ranges, sometimes exceeding 300°C during processing or operation.

Recent technological advancements have opened new pathways for enhancing the thermal stability of TCFs. These include novel material compositions, innovative fabrication techniques, and hybrid structures that combine different conductive materials to achieve synergistic properties. Materials science breakthroughs in nanomaterials, such as graphene, carbon nanotubes, metal nanowires, and conductive polymers, have shown promising potential to address the thermal stability limitations.

The primary objective of research in thermally stable TCFs is to develop films that maintain high transparency (>90%) and low sheet resistance (<100 Ω/sq) while withstanding temperatures above 200°C without significant performance degradation. Additionally, these advanced TCFs should maintain mechanical flexibility, chemical stability, and be compatible with large-scale, cost-effective manufacturing processes.

Another crucial goal is to reduce reliance on indium, a rare and increasingly expensive element, by developing alternative TCF materials and structures with enhanced thermal properties. This aligns with global sustainability initiatives and addresses supply chain vulnerabilities in the electronics industry.

The development of thermally stable TCFs represents a convergence point of materials science, nanotechnology, and electronic engineering. Success in this field would not only solve immediate technical challenges but could potentially enable entirely new device categories and applications previously limited by thermal constraints, thus driving innovation across multiple technology sectors.

The thermal stability challenge has become increasingly significant as modern devices operate in more demanding environments and manufacturing processes require higher temperature tolerances. When exposed to elevated temperatures, conventional TCFs often experience degradation in conductivity, optical properties, and mechanical integrity, severely limiting their application scope and reliability in next-generation devices.

The global push toward flexible, wearable, and high-performance electronics has accelerated the need for thermally stable TCFs. Industries ranging from automotive (for heated windshields and displays operating in extreme conditions) to aerospace and advanced manufacturing require TCFs that can maintain performance integrity across wide temperature ranges, sometimes exceeding 300°C during processing or operation.

Recent technological advancements have opened new pathways for enhancing the thermal stability of TCFs. These include novel material compositions, innovative fabrication techniques, and hybrid structures that combine different conductive materials to achieve synergistic properties. Materials science breakthroughs in nanomaterials, such as graphene, carbon nanotubes, metal nanowires, and conductive polymers, have shown promising potential to address the thermal stability limitations.

The primary objective of research in thermally stable TCFs is to develop films that maintain high transparency (>90%) and low sheet resistance (<100 Ω/sq) while withstanding temperatures above 200°C without significant performance degradation. Additionally, these advanced TCFs should maintain mechanical flexibility, chemical stability, and be compatible with large-scale, cost-effective manufacturing processes.

Another crucial goal is to reduce reliance on indium, a rare and increasingly expensive element, by developing alternative TCF materials and structures with enhanced thermal properties. This aligns with global sustainability initiatives and addresses supply chain vulnerabilities in the electronics industry.

The development of thermally stable TCFs represents a convergence point of materials science, nanotechnology, and electronic engineering. Success in this field would not only solve immediate technical challenges but could potentially enable entirely new device categories and applications previously limited by thermal constraints, thus driving innovation across multiple technology sectors.

Market Analysis for Thermally Stable TCFs

The transparent conductive film (TCF) market is experiencing robust growth driven by the expanding electronics industry, particularly in touch screens, displays, photovoltaics, and emerging flexible electronics. The global TCF market was valued at approximately $5.1 billion in 2022 and is projected to reach $8.7 billion by 2028, growing at a CAGR of 9.3% during the forecast period.

Thermally stable TCFs represent a high-value segment within this market, addressing critical performance limitations of conventional materials. Traditional indium tin oxide (ITO) films, while dominating with over 70% market share, suffer significant performance degradation at elevated temperatures, limiting their application in high-temperature environments such as automotive displays, aerospace electronics, and next-generation solar panels.

The demand for thermally stable TCFs is particularly strong in regions with established electronics manufacturing bases. Asia-Pacific leads with approximately 65% of the global market share, driven by extensive electronics manufacturing in China, South Korea, Japan, and Taiwan. North America and Europe follow with approximately 18% and 12% respectively, with demand primarily from premium automotive, aerospace, and specialized industrial applications.

By application segment, displays constitute the largest market for thermally stable TCFs (42%), followed by touch panels (28%), photovoltaics (17%), and emerging applications including smart windows and electromagnetic shielding (13%). The automotive sector represents the fastest-growing vertical market with 14.2% annual growth, driven by increasing integration of touch displays in vehicle interiors and the need for materials that can withstand harsh operating conditions.

Consumer electronics manufacturers are increasingly specifying enhanced thermal stability as a requirement for next-generation devices, particularly for foldable smartphones and wearable technology where operational temperatures can fluctuate significantly. This trend is reflected in procurement specifications from major OEMs that now commonly require TCFs to maintain over 90% of their electrical and optical properties after exposure to temperatures of 150-200°C.

The price premium for thermally stable TCFs currently ranges from 30-45% above conventional alternatives, presenting both a market barrier and opportunity. However, this premium is projected to decrease to 15-20% by 2026 as manufacturing processes mature and competition intensifies, potentially accelerating market adoption across more price-sensitive applications.

Market research indicates that end-users are willing to pay this premium primarily in applications where device failure would result in significant costs or safety concerns, highlighting the importance of application-specific market development strategies for thermally enhanced TCF technologies.

Thermally stable TCFs represent a high-value segment within this market, addressing critical performance limitations of conventional materials. Traditional indium tin oxide (ITO) films, while dominating with over 70% market share, suffer significant performance degradation at elevated temperatures, limiting their application in high-temperature environments such as automotive displays, aerospace electronics, and next-generation solar panels.

The demand for thermally stable TCFs is particularly strong in regions with established electronics manufacturing bases. Asia-Pacific leads with approximately 65% of the global market share, driven by extensive electronics manufacturing in China, South Korea, Japan, and Taiwan. North America and Europe follow with approximately 18% and 12% respectively, with demand primarily from premium automotive, aerospace, and specialized industrial applications.

By application segment, displays constitute the largest market for thermally stable TCFs (42%), followed by touch panels (28%), photovoltaics (17%), and emerging applications including smart windows and electromagnetic shielding (13%). The automotive sector represents the fastest-growing vertical market with 14.2% annual growth, driven by increasing integration of touch displays in vehicle interiors and the need for materials that can withstand harsh operating conditions.

Consumer electronics manufacturers are increasingly specifying enhanced thermal stability as a requirement for next-generation devices, particularly for foldable smartphones and wearable technology where operational temperatures can fluctuate significantly. This trend is reflected in procurement specifications from major OEMs that now commonly require TCFs to maintain over 90% of their electrical and optical properties after exposure to temperatures of 150-200°C.

The price premium for thermally stable TCFs currently ranges from 30-45% above conventional alternatives, presenting both a market barrier and opportunity. However, this premium is projected to decrease to 15-20% by 2026 as manufacturing processes mature and competition intensifies, potentially accelerating market adoption across more price-sensitive applications.

Market research indicates that end-users are willing to pay this premium primarily in applications where device failure would result in significant costs or safety concerns, highlighting the importance of application-specific market development strategies for thermally enhanced TCF technologies.

Current Challenges in TCF Thermal Stability

Despite significant advancements in transparent conductive film (TCF) technology, thermal stability remains a critical challenge that impedes broader application in next-generation devices. Current commercial TCFs, particularly indium tin oxide (ITO), exhibit performance degradation at temperatures exceeding 300°C, resulting in increased sheet resistance and reduced optical transparency. This limitation severely restricts their integration into manufacturing processes requiring high-temperature steps, such as display fabrication and photovoltaic cell production.

The fundamental challenge lies in the microstructural changes that occur during thermal exposure. Crystalline TCFs experience grain boundary modifications, while amorphous structures undergo crystallization transitions that disrupt electron transport pathways. Additionally, thermal expansion coefficient mismatches between TCFs and substrate materials create mechanical stress during temperature fluctuations, leading to micro-crack formation and delamination issues that compromise electrical continuity.

Interface stability presents another significant hurdle, particularly in multilayer device architectures. High temperatures accelerate diffusion processes between adjacent layers, causing contamination that alters the TCF's electronic properties. This interfacial degradation is especially problematic in OLED displays and perovskite solar cells, where even minor chemical interactions can dramatically reduce device efficiency and operational lifetime.

For emerging alternative TCF materials, thermal stability challenges manifest differently. Metal nanowire networks (such as silver nanowires) suffer from accelerated oxidation and morphological changes at elevated temperatures, while carbon-based TCFs (graphene, carbon nanotubes) struggle with thermal expansion-induced defect formation. Conductive polymers like PEDOT:PSS demonstrate particularly poor thermal resilience, with significant conductivity loss occurring at temperatures as low as 150°C due to irreversible structural reorganization.

Manufacturing scalability compounds these challenges, as industrial processes often require TCFs to withstand repeated thermal cycling without performance degradation. Current solutions involving protective coatings or composite structures add complexity and cost to production while sometimes compromising the film's original transparency or flexibility advantages.

Environmental factors further exacerbate thermal stability issues, with humidity and oxygen exposure accelerating degradation mechanisms at elevated temperatures. This creates a complex reliability challenge where thermal stability must be considered within a broader environmental context rather than as an isolated parameter, necessitating comprehensive testing protocols that simulate real-world operating conditions.

Addressing these thermal stability challenges requires interdisciplinary approaches combining materials science, interface engineering, and advanced manufacturing techniques to develop next-generation TCFs capable of maintaining performance integrity across wider temperature ranges.

The fundamental challenge lies in the microstructural changes that occur during thermal exposure. Crystalline TCFs experience grain boundary modifications, while amorphous structures undergo crystallization transitions that disrupt electron transport pathways. Additionally, thermal expansion coefficient mismatches between TCFs and substrate materials create mechanical stress during temperature fluctuations, leading to micro-crack formation and delamination issues that compromise electrical continuity.

Interface stability presents another significant hurdle, particularly in multilayer device architectures. High temperatures accelerate diffusion processes between adjacent layers, causing contamination that alters the TCF's electronic properties. This interfacial degradation is especially problematic in OLED displays and perovskite solar cells, where even minor chemical interactions can dramatically reduce device efficiency and operational lifetime.

For emerging alternative TCF materials, thermal stability challenges manifest differently. Metal nanowire networks (such as silver nanowires) suffer from accelerated oxidation and morphological changes at elevated temperatures, while carbon-based TCFs (graphene, carbon nanotubes) struggle with thermal expansion-induced defect formation. Conductive polymers like PEDOT:PSS demonstrate particularly poor thermal resilience, with significant conductivity loss occurring at temperatures as low as 150°C due to irreversible structural reorganization.

Manufacturing scalability compounds these challenges, as industrial processes often require TCFs to withstand repeated thermal cycling without performance degradation. Current solutions involving protective coatings or composite structures add complexity and cost to production while sometimes compromising the film's original transparency or flexibility advantages.

Environmental factors further exacerbate thermal stability issues, with humidity and oxygen exposure accelerating degradation mechanisms at elevated temperatures. This creates a complex reliability challenge where thermal stability must be considered within a broader environmental context rather than as an isolated parameter, necessitating comprehensive testing protocols that simulate real-world operating conditions.

Addressing these thermal stability challenges requires interdisciplinary approaches combining materials science, interface engineering, and advanced manufacturing techniques to develop next-generation TCFs capable of maintaining performance integrity across wider temperature ranges.

Current Approaches to Enhance TCF Thermal Stability

01 Metal oxide-based transparent conductive films with enhanced thermal stability

Metal oxide-based transparent conductive films, particularly those containing indium tin oxide (ITO), zinc oxide, or other doped metal oxides, demonstrate superior thermal stability at high temperatures. These films maintain their optical transparency and electrical conductivity even after heat treatment. The addition of specific dopants or the use of multi-layer structures can further enhance the thermal resistance properties, making them suitable for applications requiring exposure to elevated temperatures.- Metal oxide-based transparent conductive films with enhanced thermal stability: Metal oxide-based transparent conductive films, particularly those containing indium tin oxide (ITO), zinc oxide, or other doped metal oxides, demonstrate superior thermal stability at high temperatures. These films maintain their optical transparency and electrical conductivity even after heat treatment processes. The addition of specific dopants or the use of multi-layer structures can further enhance the thermal resistance properties, making them suitable for applications requiring exposure to elevated temperatures.

- Carbon-based transparent conductive films with thermal durability: Carbon-based materials such as graphene, carbon nanotubes (CNTs), and carbon nanosheets can be formulated into transparent conductive films with excellent thermal stability. These materials maintain their electrical properties at high temperatures due to the strong carbon-carbon bonds. Various fabrication methods including chemical vapor deposition, solution processing, and transfer techniques can be employed to create these thermally stable films, which are particularly valuable for flexible electronics operating in variable temperature environments.

- Polymer-metal composite films for improved thermal resistance: Composite films combining conductive polymers with metallic nanostructures offer enhanced thermal stability compared to conventional transparent conductors. The polymer matrix provides mechanical support while the metallic components ensure electrical conductivity. These composites can withstand thermal cycling and maintain transparency and conductivity at elevated temperatures. Special additives and cross-linking agents can be incorporated to further improve the thermal durability of these composite films.

- Protective coatings and encapsulation for thermal stabilization: Applying protective coatings or encapsulation layers to transparent conductive films significantly enhances their thermal stability. These protective layers, which may include silicon dioxide, aluminum oxide, or specialized polymers, shield the conductive layer from oxidation and degradation at high temperatures. Multi-layer encapsulation approaches can provide both thermal and environmental protection while maintaining the optical and electrical properties of the underlying conductive film.

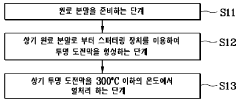

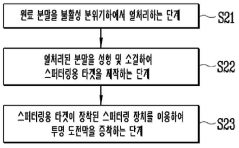

- Novel fabrication methods for thermally stable transparent conductors: Advanced fabrication techniques such as atomic layer deposition, pulsed laser deposition, and solution-based processes can produce transparent conductive films with superior thermal stability. These methods allow precise control over film composition, thickness, and microstructure, which are critical factors affecting thermal performance. Post-deposition treatments including annealing under controlled atmospheres and surface modification can further enhance the thermal durability of these films while maintaining their transparency and conductivity.

02 Carbon-based transparent conductive films with thermal durability

Carbon-based materials such as graphene, carbon nanotubes (CNTs), and carbon nanosheets can be formulated into transparent conductive films with excellent thermal stability. These materials maintain their electrical properties at high temperatures due to the strong carbon-carbon bonds. Various fabrication methods including chemical vapor deposition, solution processing, and transfer techniques can be employed to create these thermally stable films, which are particularly valuable for flexible electronics and high-temperature applications.Expand Specific Solutions03 Polymer-metal composite films for improved thermal resistance

Composite films combining conductive polymers with metallic nanostructures offer enhanced thermal stability compared to conventional transparent conductors. The polymer matrix provides mechanical support while the metallic components ensure electrical conductivity. These composites can withstand thermal cycling and maintain transparency and conductivity at elevated temperatures. Special additives and cross-linking agents can be incorporated to further improve the thermal durability of these composite films.Expand Specific Solutions04 Protective coatings and encapsulation for thermal stabilization

Applying protective coatings or encapsulation layers to transparent conductive films significantly enhances their thermal stability. These protective layers, which may include silicon dioxide, aluminum oxide, or specialized polymers, shield the conductive film from oxidation and degradation at high temperatures. The encapsulation techniques can be tailored to specific environmental conditions while maintaining the optical and electrical properties of the underlying conductive film.Expand Specific Solutions05 Novel fabrication methods for thermally stable transparent conductors

Innovative fabrication techniques such as atomic layer deposition, pulsed laser deposition, and solution-based processes can produce transparent conductive films with superior thermal stability. These methods allow precise control over film composition, thickness, and microstructure, which directly influence thermal performance. Post-treatment processes including annealing under controlled atmospheres and surface modification can further enhance the thermal durability of these films while maintaining their transparency and conductivity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The transparent conductive film market with enhanced thermal stability is currently in a growth phase, driven by increasing demand in display technologies, touch panels, and photovoltaics. The global market size is estimated to reach $8-10 billion by 2025, with a CAGR of approximately 8-10%. Technological maturity varies across different approaches, with established players like Nitto Denko, LG Chem, and Eastman Chemical leading in traditional ITO-based solutions. Emerging companies such as C3 Nano and Advanced Nano Products are pioneering nanowire and nanoparticle technologies, while research institutions like Ningbo Institute of Industrial Technology and University of Luxembourg are advancing next-generation materials. Japanese firms including Toyobo, Kuraray, and Kaneka demonstrate strong expertise in high-performance polymer substrates essential for thermally stable transparent conductors, creating a competitive landscape balanced between established technologies and innovative alternatives.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed innovative transparent conductive films using silver nanowire (AgNW) technology with proprietary heat-resistant polymer matrices. Their approach involves embedding AgNWs in specialized polymer composites that maintain structural integrity at temperatures exceeding 200°C. The company has implemented a multi-layer film structure where a protective overcoat with thermal stabilizing additives shields the conductive layer from oxidation and thermal degradation. Additionally, Nitto's process includes a unique annealing treatment that creates stronger junctions between nanowires, significantly improving thermal stability while maintaining over 90% optical transparency and sheet resistance below 50 ohms/square even after extended high-temperature exposure. Their films incorporate UV-blocking components to prevent polymer degradation and utilize cross-linking agents that activate at elevated temperatures to reinforce the film structure during thermal stress.

Strengths: Superior thermal stability in harsh environments; excellent optical clarity maintained after thermal cycling; strong adhesion to various substrates; scalable manufacturing process. Weaknesses: Higher production costs compared to conventional ITO films; potential silver migration issues in extremely humid conditions; limited flexibility compared to some competing nanomaterial-based solutions.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a hybrid transparent conductive film technology combining metal mesh structures with conductive polymers for enhanced thermal stability. Their proprietary approach utilizes a precisely engineered metal grid pattern (typically silver or copper) embedded within a thermally-resistant polymer matrix, creating a film that maintains conductivity at temperatures up to 250°C. The company employs a specialized nano-imprinting process to create ultra-fine metal patterns (linewidths below 2μm) that remain invisible to the naked eye while providing excellent conductivity. LG Chem's films incorporate proprietary heat-stabilizing additives that prevent oxidation of the metal components and degradation of the polymer matrix during thermal cycling. Their multi-layer structure includes a protective overcoat with ceramic nanoparticles that act as thermal barriers, distributing heat more evenly across the film surface and preventing localized hotspots that could compromise performance. The films maintain over 88% transparency and sheet resistance below 30 ohms/square even after 1000 hours at elevated temperatures.

Strengths: Exceptional thermal stability combined with high conductivity; excellent optical properties with minimal haze; compatible with flexible display applications; established mass production capabilities. Weaknesses: Complex manufacturing process requiring specialized equipment; higher material costs than traditional solutions; potential for visible patterns under certain lighting conditions.

Key Patents and Innovations in Heat-Resistant TCFs

Thermal stability transparent conductive thin film and method for preparing thermal stability transparent conductive thin film

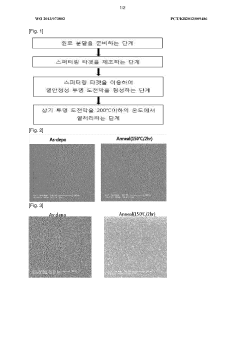

PatentActiveKR1020110054863A

Innovation

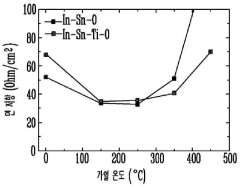

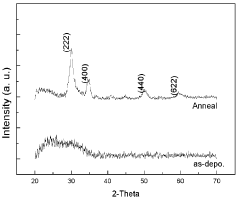

- A transparent conductive film composed of indium oxide and tin oxide with added titanium, preferably in the form of titanium oxide or metal titanium, is crystallized at a relatively low temperature (300°C or lower) using a sputtering process, ensuring stable resistivity values.

Transparent conductive film having superior thermal stability, target for transparent conductive film, and method for manufacturing transparent conductive film

PatentWO2013073802A1

Innovation

- A transparent conductive film and target composition comprising indium oxide and tantalum oxide, with optional dopants from specific groups, are used to achieve crystallization at low temperatures, ensuring stable resistivity and thermal stability, and a method involving co-precipitation and sintering to form a high-density target with ultrafine synthetic powder for efficient film formation.

Material Science Advancements for TCF Applications

Recent advancements in material science have significantly propelled the development of transparent conductive films (TCFs) with enhanced thermal stability. The evolution of these materials has been driven by the increasing demand for flexible electronics, touchscreens, and photovoltaic devices that can withstand elevated temperatures without performance degradation.

Traditional indium tin oxide (ITO) films, while offering excellent optical transparency and electrical conductivity, exhibit limited thermal stability above 300°C, restricting their application in high-temperature processing environments. This limitation has catalyzed research into alternative materials and composite structures that maintain performance under thermal stress.

Metal nanowire networks, particularly those based on silver and copper, have emerged as promising alternatives due to their inherent flexibility and conductivity. Recent innovations in surface passivation techniques have addressed their oxidation susceptibility at high temperatures. Researchers have developed core-shell structures where nanowires are encapsulated with thermally resistant oxides, significantly improving stability up to 400-500°C while maintaining over 90% transparency.

Carbon-based materials represent another frontier in thermally stable TCFs. Graphene, with its exceptional thermal conductivity (approximately 5000 W/m·K) and intrinsic stability, has been successfully incorporated into hybrid structures. The challenge of graphene's limited conductivity has been addressed through chemical doping and the development of graphene-metal composite films that demonstrate stability at temperatures exceeding 600°C.

Metal oxide frameworks have also seen substantial progress, with aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) showing improved thermal resilience compared to conventional ITO. These materials maintain their optoelectronic properties at temperatures up to 500°C, making them suitable for high-temperature applications such as concentrated solar power systems.

Polymer-inorganic hybrid materials represent the cutting edge of TCF development. By combining thermally resistant polymers like polyimide with inorganic conductive components, researchers have created composite films that offer both flexibility and thermal stability. These hybrids utilize the polymer matrix to protect the conductive elements from oxidation while maintaining structural integrity at elevated temperatures.

The integration of self-healing mechanisms into TCF materials marks a revolutionary approach to thermal stability. These systems incorporate microencapsulated conductive materials that release and repair damaged conductive pathways when triggered by thermal stress, effectively extending the operational lifetime of the films under cyclic thermal conditions.

Traditional indium tin oxide (ITO) films, while offering excellent optical transparency and electrical conductivity, exhibit limited thermal stability above 300°C, restricting their application in high-temperature processing environments. This limitation has catalyzed research into alternative materials and composite structures that maintain performance under thermal stress.

Metal nanowire networks, particularly those based on silver and copper, have emerged as promising alternatives due to their inherent flexibility and conductivity. Recent innovations in surface passivation techniques have addressed their oxidation susceptibility at high temperatures. Researchers have developed core-shell structures where nanowires are encapsulated with thermally resistant oxides, significantly improving stability up to 400-500°C while maintaining over 90% transparency.

Carbon-based materials represent another frontier in thermally stable TCFs. Graphene, with its exceptional thermal conductivity (approximately 5000 W/m·K) and intrinsic stability, has been successfully incorporated into hybrid structures. The challenge of graphene's limited conductivity has been addressed through chemical doping and the development of graphene-metal composite films that demonstrate stability at temperatures exceeding 600°C.

Metal oxide frameworks have also seen substantial progress, with aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) showing improved thermal resilience compared to conventional ITO. These materials maintain their optoelectronic properties at temperatures up to 500°C, making them suitable for high-temperature applications such as concentrated solar power systems.

Polymer-inorganic hybrid materials represent the cutting edge of TCF development. By combining thermally resistant polymers like polyimide with inorganic conductive components, researchers have created composite films that offer both flexibility and thermal stability. These hybrids utilize the polymer matrix to protect the conductive elements from oxidation while maintaining structural integrity at elevated temperatures.

The integration of self-healing mechanisms into TCF materials marks a revolutionary approach to thermal stability. These systems incorporate microencapsulated conductive materials that release and repair damaged conductive pathways when triggered by thermal stress, effectively extending the operational lifetime of the films under cyclic thermal conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of transparent conductive films (TCFs) with enhanced thermal stability extends beyond their technical performance, encompassing their entire lifecycle from raw material extraction to disposal. Traditional TCFs often rely on indium tin oxide (ITO), which presents significant environmental concerns due to the scarcity of indium and energy-intensive mining processes. The extraction of indium generates substantial carbon emissions and can lead to habitat destruction and water pollution in mining regions.

Manufacturing processes for thermally stable TCFs typically require high-temperature treatments and chemical etching, which consume considerable energy and utilize potentially hazardous chemicals. However, recent advancements in low-temperature fabrication methods for thermally stable alternatives such as silver nanowire networks, graphene, and metal mesh structures have demonstrated reduced energy requirements by up to 40% compared to conventional ITO processing.

Lifecycle assessments of thermally enhanced TCFs reveal that their extended operational lifespan significantly reduces the environmental burden associated with device replacement and electronic waste generation. Devices incorporating these films can withstand higher operating temperatures without degradation, potentially extending product lifetimes by 30-50% in high-temperature environments such as automotive displays and outdoor electronic signage.

The recyclability of TCF materials varies considerably. Metal-based conductive films offer better recovery potential than composite organic-inorganic structures. Research indicates that silver nanowire-based films can achieve recycling rates of up to 85% of the precious metal content, while carbon-based alternatives like graphene offer inherently lower toxicity profiles but present challenges in separation from substrate materials.

Emerging sustainable approaches include the development of bio-based transparent conductors derived from cellulose nanofibers and conductive polymers, which demonstrate promising thermal stability while reducing dependence on rare earth elements. These materials show potential for biodegradability, with laboratory studies indicating decomposition rates of 60-70% within six months under industrial composting conditions.

Water consumption represents another critical environmental consideration, with conventional TCF manufacturing processes requiring 200-300 liters per square meter of film produced. Solution-based processing methods for alternative TCFs have demonstrated water requirement reductions of up to 70%, particularly for polymer-based conductive films with thermal stabilizing additives.

The transition toward more environmentally sustainable TCFs necessitates holistic approaches that balance thermal performance requirements with reduced environmental footprints. This includes designing for disassembly, implementing closed-loop manufacturing systems, and developing standardized methods for assessing the environmental impact of emerging TCF technologies throughout their complete lifecycle.

Manufacturing processes for thermally stable TCFs typically require high-temperature treatments and chemical etching, which consume considerable energy and utilize potentially hazardous chemicals. However, recent advancements in low-temperature fabrication methods for thermally stable alternatives such as silver nanowire networks, graphene, and metal mesh structures have demonstrated reduced energy requirements by up to 40% compared to conventional ITO processing.

Lifecycle assessments of thermally enhanced TCFs reveal that their extended operational lifespan significantly reduces the environmental burden associated with device replacement and electronic waste generation. Devices incorporating these films can withstand higher operating temperatures without degradation, potentially extending product lifetimes by 30-50% in high-temperature environments such as automotive displays and outdoor electronic signage.

The recyclability of TCF materials varies considerably. Metal-based conductive films offer better recovery potential than composite organic-inorganic structures. Research indicates that silver nanowire-based films can achieve recycling rates of up to 85% of the precious metal content, while carbon-based alternatives like graphene offer inherently lower toxicity profiles but present challenges in separation from substrate materials.

Emerging sustainable approaches include the development of bio-based transparent conductors derived from cellulose nanofibers and conductive polymers, which demonstrate promising thermal stability while reducing dependence on rare earth elements. These materials show potential for biodegradability, with laboratory studies indicating decomposition rates of 60-70% within six months under industrial composting conditions.

Water consumption represents another critical environmental consideration, with conventional TCF manufacturing processes requiring 200-300 liters per square meter of film produced. Solution-based processing methods for alternative TCFs have demonstrated water requirement reductions of up to 70%, particularly for polymer-based conductive films with thermal stabilizing additives.

The transition toward more environmentally sustainable TCFs necessitates holistic approaches that balance thermal performance requirements with reduced environmental footprints. This includes designing for disassembly, implementing closed-loop manufacturing systems, and developing standardized methods for assessing the environmental impact of emerging TCF technologies throughout their complete lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!