Examining Glass Fiber Reinforced Polypropylene Composites

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GFRPP Background and Objectives

Glass Fiber Reinforced Polypropylene (GFRPP) composites have emerged as a significant material innovation in the field of polymer composites over the past few decades. These composites combine the lightweight and versatile properties of polypropylene with the strength and stiffness of glass fibers, resulting in a material that offers superior mechanical properties and enhanced performance characteristics.

The development of GFRPP can be traced back to the 1960s when researchers began exploring ways to improve the mechanical properties of thermoplastics. The incorporation of glass fibers into polypropylene matrices marked a significant breakthrough, addressing the limitations of pure polypropylene in high-performance applications. Since then, GFRPP has undergone continuous evolution, driven by advancements in material science, processing technologies, and a growing demand for lightweight yet durable materials across various industries.

The primary objective of examining GFRPP composites is to further enhance their properties and expand their applications. This involves optimizing the interface between glass fibers and the polypropylene matrix, improving fiber distribution and orientation, and developing novel processing techniques. Researchers and industry professionals aim to achieve a balance between mechanical strength, impact resistance, thermal stability, and cost-effectiveness.

One of the key trends in GFRPP development is the focus on sustainability and recyclability. As environmental concerns gain prominence, there is a growing emphasis on creating GFRPP composites that can be easily recycled or reprocessed at the end of their lifecycle. This aligns with the broader industry shift towards circular economy principles and reduced environmental impact.

Another significant trend is the tailoring of GFRPP properties for specific applications. This includes developing grades with enhanced flame retardancy for automotive and construction applications, improved chemical resistance for industrial uses, and optimized surface finishes for aesthetic purposes in consumer products. The versatility of GFRPP allows for a wide range of modifications to meet diverse industry requirements.

The examination of GFRPP composites also extends to exploring hybrid systems, where glass fibers are combined with other reinforcing materials such as natural fibers or nanoparticles. These hybrid composites aim to synergize the benefits of different reinforcement types, potentially leading to materials with unprecedented property combinations.

As we delve deeper into the examination of GFRPP composites, the overarching goal is to push the boundaries of material performance while addressing the evolving needs of various industries. This includes improving the strength-to-weight ratio, enhancing long-term durability, and developing more efficient and cost-effective manufacturing processes. By understanding the fundamental science behind GFRPP and leveraging cutting-edge technologies, researchers and engineers strive to unlock new possibilities for this versatile composite material.

The development of GFRPP can be traced back to the 1960s when researchers began exploring ways to improve the mechanical properties of thermoplastics. The incorporation of glass fibers into polypropylene matrices marked a significant breakthrough, addressing the limitations of pure polypropylene in high-performance applications. Since then, GFRPP has undergone continuous evolution, driven by advancements in material science, processing technologies, and a growing demand for lightweight yet durable materials across various industries.

The primary objective of examining GFRPP composites is to further enhance their properties and expand their applications. This involves optimizing the interface between glass fibers and the polypropylene matrix, improving fiber distribution and orientation, and developing novel processing techniques. Researchers and industry professionals aim to achieve a balance between mechanical strength, impact resistance, thermal stability, and cost-effectiveness.

One of the key trends in GFRPP development is the focus on sustainability and recyclability. As environmental concerns gain prominence, there is a growing emphasis on creating GFRPP composites that can be easily recycled or reprocessed at the end of their lifecycle. This aligns with the broader industry shift towards circular economy principles and reduced environmental impact.

Another significant trend is the tailoring of GFRPP properties for specific applications. This includes developing grades with enhanced flame retardancy for automotive and construction applications, improved chemical resistance for industrial uses, and optimized surface finishes for aesthetic purposes in consumer products. The versatility of GFRPP allows for a wide range of modifications to meet diverse industry requirements.

The examination of GFRPP composites also extends to exploring hybrid systems, where glass fibers are combined with other reinforcing materials such as natural fibers or nanoparticles. These hybrid composites aim to synergize the benefits of different reinforcement types, potentially leading to materials with unprecedented property combinations.

As we delve deeper into the examination of GFRPP composites, the overarching goal is to push the boundaries of material performance while addressing the evolving needs of various industries. This includes improving the strength-to-weight ratio, enhancing long-term durability, and developing more efficient and cost-effective manufacturing processes. By understanding the fundamental science behind GFRPP and leveraging cutting-edge technologies, researchers and engineers strive to unlock new possibilities for this versatile composite material.

Market Analysis for GFRPP

The global market for Glass Fiber Reinforced Polypropylene (GFRPP) composites has experienced significant growth in recent years, driven by increasing demand across various industries. This market is expected to continue its upward trajectory due to the unique properties and versatile applications of GFRPP materials.

The automotive sector remains a key driver for GFRPP demand, as manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions. GFRPP components are increasingly used in interior parts, under-the-hood applications, and structural elements, offering a balance of strength, weight reduction, and cost-effectiveness.

The construction industry also presents substantial opportunities for GFRPP composites. These materials are gaining popularity in building and infrastructure projects due to their durability, corrosion resistance, and ease of installation. Applications include reinforced concrete, bridge decks, and prefabricated building components.

In the consumer goods sector, GFRPP is finding its way into a wide range of products, from household appliances to sporting equipment. The material's ability to combine strength with design flexibility makes it attractive for manufacturers looking to innovate and differentiate their products.

The electrical and electronics industry is another growing market for GFRPP composites. These materials are used in housings, connectors, and other components where electrical insulation and dimensional stability are crucial.

Geographically, Asia-Pacific leads the GFRPP market, with China and India being major contributors to growth. The region's expanding automotive and construction sectors, coupled with increasing industrialization, drive demand. North America and Europe also maintain significant market shares, particularly in high-tech applications and the automotive industry.

Market trends indicate a growing preference for sustainable and recyclable materials. This has led to increased research and development efforts in improving the recyclability of GFRPP composites, potentially opening new market opportunities and addressing environmental concerns.

The competitive landscape of the GFRPP market is characterized by a mix of large multinational corporations and specialized composite manufacturers. Key players are investing in technological advancements and capacity expansions to meet growing demand and maintain their market positions.

Challenges in the GFRPP market include fluctuating raw material prices, particularly for glass fibers and polypropylene resins. Additionally, competition from other composite materials and traditional materials like metals continues to shape market dynamics.

The automotive sector remains a key driver for GFRPP demand, as manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions. GFRPP components are increasingly used in interior parts, under-the-hood applications, and structural elements, offering a balance of strength, weight reduction, and cost-effectiveness.

The construction industry also presents substantial opportunities for GFRPP composites. These materials are gaining popularity in building and infrastructure projects due to their durability, corrosion resistance, and ease of installation. Applications include reinforced concrete, bridge decks, and prefabricated building components.

In the consumer goods sector, GFRPP is finding its way into a wide range of products, from household appliances to sporting equipment. The material's ability to combine strength with design flexibility makes it attractive for manufacturers looking to innovate and differentiate their products.

The electrical and electronics industry is another growing market for GFRPP composites. These materials are used in housings, connectors, and other components where electrical insulation and dimensional stability are crucial.

Geographically, Asia-Pacific leads the GFRPP market, with China and India being major contributors to growth. The region's expanding automotive and construction sectors, coupled with increasing industrialization, drive demand. North America and Europe also maintain significant market shares, particularly in high-tech applications and the automotive industry.

Market trends indicate a growing preference for sustainable and recyclable materials. This has led to increased research and development efforts in improving the recyclability of GFRPP composites, potentially opening new market opportunities and addressing environmental concerns.

The competitive landscape of the GFRPP market is characterized by a mix of large multinational corporations and specialized composite manufacturers. Key players are investing in technological advancements and capacity expansions to meet growing demand and maintain their market positions.

Challenges in the GFRPP market include fluctuating raw material prices, particularly for glass fibers and polypropylene resins. Additionally, competition from other composite materials and traditional materials like metals continues to shape market dynamics.

GFRPP Technical Challenges

Glass Fiber Reinforced Polypropylene (GFRPP) composites have gained significant attention in various industries due to their excellent mechanical properties and lightweight characteristics. However, several technical challenges persist in their development and application, hindering their widespread adoption and optimal performance.

One of the primary challenges in GFRPP composites is achieving strong interfacial adhesion between the glass fibers and the polypropylene matrix. The inherent incompatibility between the hydrophilic glass fibers and the hydrophobic polypropylene matrix leads to poor stress transfer and reduced overall mechanical properties. This issue necessitates the development of effective coupling agents and surface treatments to enhance the fiber-matrix interaction.

Another significant challenge is the uniform dispersion of glass fibers within the polypropylene matrix. Agglomeration of fibers can create stress concentration points, leading to premature failure and reduced mechanical performance. Achieving homogeneous fiber distribution requires optimized processing techniques and careful control of fiber length and orientation during the manufacturing process.

The thermal stability of GFRPP composites presents another technical hurdle. Polypropylene has a relatively low melting point, which limits the high-temperature applications of these composites. Improving the thermal resistance of the matrix while maintaining its desirable properties is crucial for expanding the application range of GFRPP composites in demanding environments.

Moisture absorption is a persistent issue in GFRPP composites, particularly in long-term applications. The hydrophilic nature of glass fibers can lead to water uptake, resulting in dimensional instability, reduced mechanical properties, and potential degradation of the fiber-matrix interface. Developing effective moisture barrier coatings or modifying the matrix to reduce water absorption is essential for enhancing the durability of these composites.

The recyclability and end-of-life management of GFRPP composites pose significant environmental challenges. The presence of glass fibers complicates the recycling process of polypropylene, making it difficult to separate and reuse the components effectively. Developing efficient recycling technologies and designing composites with improved recyclability are crucial for promoting sustainability in the use of these materials.

Balancing cost-effectiveness with performance enhancement remains an ongoing challenge in GFRPP composite development. While increasing fiber content generally improves mechanical properties, it also raises production costs and can lead to processing difficulties. Finding the optimal fiber content and developing cost-effective manufacturing processes are essential for the commercial viability of these composites.

One of the primary challenges in GFRPP composites is achieving strong interfacial adhesion between the glass fibers and the polypropylene matrix. The inherent incompatibility between the hydrophilic glass fibers and the hydrophobic polypropylene matrix leads to poor stress transfer and reduced overall mechanical properties. This issue necessitates the development of effective coupling agents and surface treatments to enhance the fiber-matrix interaction.

Another significant challenge is the uniform dispersion of glass fibers within the polypropylene matrix. Agglomeration of fibers can create stress concentration points, leading to premature failure and reduced mechanical performance. Achieving homogeneous fiber distribution requires optimized processing techniques and careful control of fiber length and orientation during the manufacturing process.

The thermal stability of GFRPP composites presents another technical hurdle. Polypropylene has a relatively low melting point, which limits the high-temperature applications of these composites. Improving the thermal resistance of the matrix while maintaining its desirable properties is crucial for expanding the application range of GFRPP composites in demanding environments.

Moisture absorption is a persistent issue in GFRPP composites, particularly in long-term applications. The hydrophilic nature of glass fibers can lead to water uptake, resulting in dimensional instability, reduced mechanical properties, and potential degradation of the fiber-matrix interface. Developing effective moisture barrier coatings or modifying the matrix to reduce water absorption is essential for enhancing the durability of these composites.

The recyclability and end-of-life management of GFRPP composites pose significant environmental challenges. The presence of glass fibers complicates the recycling process of polypropylene, making it difficult to separate and reuse the components effectively. Developing efficient recycling technologies and designing composites with improved recyclability are crucial for promoting sustainability in the use of these materials.

Balancing cost-effectiveness with performance enhancement remains an ongoing challenge in GFRPP composite development. While increasing fiber content generally improves mechanical properties, it also raises production costs and can lead to processing difficulties. Finding the optimal fiber content and developing cost-effective manufacturing processes are essential for the commercial viability of these composites.

Current GFRPP Solutions

01 Composition and preparation of glass fiber reinforced polypropylene composites

Glass fiber reinforced polypropylene composites are prepared by combining polypropylene with glass fibers and other additives. The composition typically includes a specific ratio of polypropylene, glass fibers, and various modifiers to enhance properties such as strength, stiffness, and heat resistance. The preparation process often involves melt compounding and injection molding techniques.- Composition and preparation methods: Glass fiber reinforced polypropylene composites are prepared by combining polypropylene with glass fibers. Various methods are used to optimize the composition, including adjusting the ratio of components, selecting specific types of glass fibers, and incorporating additives to enhance properties. The preparation process may involve techniques such as melt blending, extrusion, or injection molding to ensure uniform distribution of fibers within the polymer matrix.

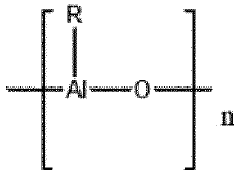

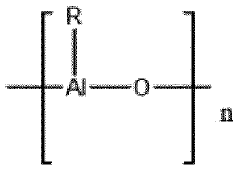

- Surface treatment of glass fibers: Surface treatment of glass fibers is crucial for improving the interfacial adhesion between the fibers and the polypropylene matrix. Various coupling agents, such as silane-based compounds, are used to modify the fiber surface. This treatment enhances the mechanical properties of the composite by promoting better stress transfer between the matrix and the reinforcement.

- Additives and modifiers: Different additives and modifiers are incorporated into glass fiber reinforced polypropylene composites to enhance specific properties. These may include compatibilizers to improve fiber-matrix adhesion, impact modifiers for increased toughness, flame retardants for fire resistance, and stabilizers to prevent degradation. The selection and optimization of these additives play a crucial role in tailoring the composite properties for specific applications.

- Processing techniques: Various processing techniques are employed to manufacture glass fiber reinforced polypropylene composites. These include injection molding, compression molding, extrusion, and pultrusion. Each technique offers specific advantages in terms of part geometry, fiber orientation, and production efficiency. The choice of processing method significantly influences the final properties and performance of the composite.

- Property enhancement and characterization: Research focuses on enhancing various properties of glass fiber reinforced polypropylene composites, such as mechanical strength, impact resistance, thermal stability, and dimensional stability. Advanced characterization techniques are used to analyze the microstructure, fiber distribution, and interfacial properties. This information is crucial for optimizing the composite formulation and processing parameters to achieve desired performance characteristics.

02 Surface treatment of glass fibers for improved adhesion

Surface treatment of glass fibers is crucial for enhancing the interfacial adhesion between the fibers and the polypropylene matrix. Various coupling agents and sizing materials are applied to the glass fiber surface to improve compatibility and bonding with the polymer. This results in better mechanical properties and overall performance of the composite.Expand Specific Solutions03 Incorporation of additives for enhanced properties

Additives are incorporated into glass fiber reinforced polypropylene composites to enhance specific properties. These may include impact modifiers, flame retardants, UV stabilizers, and antioxidants. The selection and combination of additives are tailored to meet specific performance requirements for different applications.Expand Specific Solutions04 Processing techniques for improved dispersion and orientation

Various processing techniques are employed to improve the dispersion of glass fibers within the polypropylene matrix and optimize fiber orientation. These techniques may include specialized extrusion methods, injection molding parameters, and post-processing treatments. The goal is to achieve uniform fiber distribution and alignment for enhanced mechanical properties.Expand Specific Solutions05 Recycling and sustainability of glass fiber reinforced polypropylene composites

Recycling and sustainability aspects of glass fiber reinforced polypropylene composites are addressed through various methods. These include mechanical recycling, chemical recycling, and the development of bio-based or recyclable alternatives for certain components. Efforts are made to improve the recyclability and reduce the environmental impact of these composites.Expand Specific Solutions

Key GFRPP Manufacturers

The market for Glass Fiber Reinforced Polypropylene Composites is in a growth phase, driven by increasing demand in automotive, aerospace, and construction industries. The global market size is projected to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with key players like Borealis AG, ExxonMobil, and SABIC leading innovation. These companies are focusing on developing high-performance composites with improved strength-to-weight ratios and enhanced thermal and chemical resistance. Emerging players like Kingfa Sci. & Tech. and Shanghai PRET Composites are also making significant strides in product development and market expansion, particularly in the Asia-Pacific region.

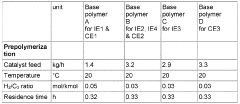

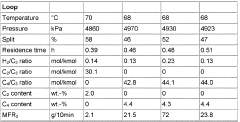

Borealis AG

Technical Solution: Borealis AG has developed a proprietary technology for producing glass fiber reinforced polypropylene (GFRPP) composites with enhanced mechanical properties. Their process involves a specialized sizing treatment for glass fibers, which improves fiber-matrix adhesion and results in composites with up to 30% higher tensile strength compared to conventional GFRPP[1]. The company also utilizes a novel compounding technique that ensures uniform fiber distribution and minimizes fiber breakage during processing, leading to improved impact resistance and dimensional stability of the final products[2]. Borealis' GFRPP composites incorporate their Borstar® technology, which allows for precise control of polymer architecture and enables the production of materials with tailored properties for specific applications[3].

Strengths: Superior mechanical properties, improved fiber-matrix adhesion, and customizable material characteristics. Weaknesses: Potentially higher production costs due to specialized treatments and processes, and limited to polypropylene-based composites.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a proprietary technology for producing high-performance glass fiber reinforced polypropylene (GFRPP) composites. Their approach involves the use of specially formulated polypropylene grades with optimized molecular weight distribution and tacticity, which enhance the interaction between the polymer matrix and glass fibers[1]. The company employs a unique compatibilization technique that improves the interfacial adhesion between the fibers and the matrix, resulting in composites with up to 25% higher flexural modulus compared to standard GFRPP[2]. ExxonMobil's process also incorporates a controlled cooling strategy during molding, which minimizes internal stresses and warpage in the final products, leading to improved dimensional stability and surface finish[3].

Strengths: Enhanced mechanical properties, improved dimensional stability, and superior surface quality. Weaknesses: May require specialized equipment for processing, and potentially higher raw material costs due to custom-formulated polypropylene grades.

GFRPP Core Technologies

Glass fiber reinforced polypropylene composition

PatentPendingEP4299668A1

Innovation

- A glass fiber reinforced polypropylene composition is developed, comprising 40-55 wt.% propylene-1-butene or ethylene-propylene random copolymer, 20-40 wt.% high pressure polyethylene acrylate copolymer, 10-30 wt.% short glass fibers, and 0.5-2.5 wt.% coupling agent, with optional units derived from vinyl-trimethoxy-silane, and a slip agent, to achieve improved tensile strength and strain at break, suitable for replacing leather-polymer composites.

Glass fiber reinforced polypropylene composition

PatentWO2024003279A1

Innovation

- A glass fiber reinforced polypropylene composition is developed with a specific formulation including 40-55 wt.% propylene-1-butene or ethylene-propylene random copolymer, 20-40 wt.% high pressure polyethylene acrylate copolymer, 10-30 wt.% short glass fibers, and a coupling agent, along with a slip agent, to achieve improved tensile strength and elongation, and is used to replace leather-polymer composites.

Environmental Impact of GFRPP

Glass Fiber Reinforced Polypropylene (GFRPP) composites have gained significant attention in various industries due to their excellent mechanical properties and lightweight nature. However, the environmental impact of these materials throughout their lifecycle is a growing concern that requires careful examination.

The production of GFRPP composites involves energy-intensive processes, particularly in the manufacturing of glass fibers and polypropylene. The extraction of raw materials for glass fibers, such as silica sand and limestone, can lead to habitat disruption and soil erosion. Additionally, the melting and drawing processes for glass fiber production consume substantial amounts of energy, contributing to greenhouse gas emissions.

Polypropylene, derived from petroleum, raises concerns about resource depletion and the carbon footprint associated with its production. The compounding process, where glass fibers are mixed with polypropylene, also requires energy and may involve the use of additives that could have environmental implications.

During the use phase, GFRPP composites generally have a positive environmental impact due to their lightweight properties, especially in automotive applications. The reduced weight leads to improved fuel efficiency and lower emissions over the vehicle's lifespan. However, the durability of GFRPP can be a double-edged sword from an environmental perspective. While it extends product life, it also means these materials persist in the environment for extended periods.

End-of-life management of GFRPP composites presents significant challenges. Recycling these materials is complex due to the difficulty in separating the glass fibers from the polymer matrix. Current recycling methods often result in downcycling, where the recycled material has lower quality and limited applications compared to the original composite.

Incineration of GFRPP waste can recover energy but may release harmful emissions if not properly controlled. Landfilling, while common, is not an environmentally friendly option as these materials do not biodegrade and occupy valuable land space for extended periods.

Recent research has focused on developing more sustainable alternatives, such as natural fiber reinforced composites and improved recycling technologies. Efforts are also being made to optimize production processes to reduce energy consumption and emissions. Life Cycle Assessment (LCA) studies are increasingly being conducted to quantify the environmental impacts of GFRPP composites across their entire lifecycle, providing valuable insights for improvement.

In conclusion, while GFRPP composites offer significant performance benefits, their environmental impact remains a complex issue. Balancing the material's advantages with its environmental footprint requires ongoing research, innovation in production and recycling technologies, and a holistic approach to lifecycle management.

The production of GFRPP composites involves energy-intensive processes, particularly in the manufacturing of glass fibers and polypropylene. The extraction of raw materials for glass fibers, such as silica sand and limestone, can lead to habitat disruption and soil erosion. Additionally, the melting and drawing processes for glass fiber production consume substantial amounts of energy, contributing to greenhouse gas emissions.

Polypropylene, derived from petroleum, raises concerns about resource depletion and the carbon footprint associated with its production. The compounding process, where glass fibers are mixed with polypropylene, also requires energy and may involve the use of additives that could have environmental implications.

During the use phase, GFRPP composites generally have a positive environmental impact due to their lightweight properties, especially in automotive applications. The reduced weight leads to improved fuel efficiency and lower emissions over the vehicle's lifespan. However, the durability of GFRPP can be a double-edged sword from an environmental perspective. While it extends product life, it also means these materials persist in the environment for extended periods.

End-of-life management of GFRPP composites presents significant challenges. Recycling these materials is complex due to the difficulty in separating the glass fibers from the polymer matrix. Current recycling methods often result in downcycling, where the recycled material has lower quality and limited applications compared to the original composite.

Incineration of GFRPP waste can recover energy but may release harmful emissions if not properly controlled. Landfilling, while common, is not an environmentally friendly option as these materials do not biodegrade and occupy valuable land space for extended periods.

Recent research has focused on developing more sustainable alternatives, such as natural fiber reinforced composites and improved recycling technologies. Efforts are also being made to optimize production processes to reduce energy consumption and emissions. Life Cycle Assessment (LCA) studies are increasingly being conducted to quantify the environmental impacts of GFRPP composites across their entire lifecycle, providing valuable insights for improvement.

In conclusion, while GFRPP composites offer significant performance benefits, their environmental impact remains a complex issue. Balancing the material's advantages with its environmental footprint requires ongoing research, innovation in production and recycling technologies, and a holistic approach to lifecycle management.

GFRPP Testing Standards

Glass Fiber Reinforced Polypropylene (GFRPP) composites are widely used in various industries due to their excellent mechanical properties and lightweight characteristics. To ensure the quality and performance of these materials, standardized testing methods are essential. Several international organizations have developed comprehensive testing standards for GFRPP composites.

The American Society for Testing and Materials (ASTM) has established numerous standards specifically for GFRPP testing. ASTM D3039 is a widely used standard for determining the tensile properties of polymer matrix composite materials reinforced by high-modulus fibers. This test method provides valuable information on the material's strength, modulus, and ultimate elongation.

For flexural properties, ASTM D790 is commonly employed. This standard test method measures the flexural strength and modulus of GFRPP composites, which are crucial parameters for applications requiring bending resistance. Additionally, ASTM D6272 offers an alternative four-point bending test method for determining flexural properties.

The International Organization for Standardization (ISO) has also developed relevant standards for GFRPP testing. ISO 527-4 specifies the test conditions for determining the tensile properties of isotropic and orthotropic fiber-reinforced plastic composites. This standard is particularly useful for assessing the mechanical behavior of GFRPP under uniaxial tensile stress.

Impact resistance is another critical property of GFRPP composites. ASTM D256 and ISO 179 provide standardized methods for measuring the impact strength of these materials. These tests help evaluate the material's ability to withstand sudden loads and resist crack propagation.

For thermal properties, ASTM E1269 and ISO 11357 outline procedures for determining the specific heat capacity and glass transition temperature of GFRPP composites using differential scanning calorimetry (DSC). These thermal characteristics are essential for understanding the material's behavior under various temperature conditions.

Environmental resistance testing is crucial for GFRPP composites used in outdoor applications. ASTM G154 and ISO 4892 describe accelerated weathering tests that simulate the effects of sunlight, heat, and moisture on the material's properties. These standards help predict the long-term performance of GFRPP composites in real-world environments.

Fatigue testing is essential for applications involving cyclic loading. ASTM D3479 provides guidelines for tension-tension fatigue testing of polymer matrix composite materials. This standard helps assess the material's resistance to repeated loading and unloading cycles, which is critical for many structural applications.

The American Society for Testing and Materials (ASTM) has established numerous standards specifically for GFRPP testing. ASTM D3039 is a widely used standard for determining the tensile properties of polymer matrix composite materials reinforced by high-modulus fibers. This test method provides valuable information on the material's strength, modulus, and ultimate elongation.

For flexural properties, ASTM D790 is commonly employed. This standard test method measures the flexural strength and modulus of GFRPP composites, which are crucial parameters for applications requiring bending resistance. Additionally, ASTM D6272 offers an alternative four-point bending test method for determining flexural properties.

The International Organization for Standardization (ISO) has also developed relevant standards for GFRPP testing. ISO 527-4 specifies the test conditions for determining the tensile properties of isotropic and orthotropic fiber-reinforced plastic composites. This standard is particularly useful for assessing the mechanical behavior of GFRPP under uniaxial tensile stress.

Impact resistance is another critical property of GFRPP composites. ASTM D256 and ISO 179 provide standardized methods for measuring the impact strength of these materials. These tests help evaluate the material's ability to withstand sudden loads and resist crack propagation.

For thermal properties, ASTM E1269 and ISO 11357 outline procedures for determining the specific heat capacity and glass transition temperature of GFRPP composites using differential scanning calorimetry (DSC). These thermal characteristics are essential for understanding the material's behavior under various temperature conditions.

Environmental resistance testing is crucial for GFRPP composites used in outdoor applications. ASTM G154 and ISO 4892 describe accelerated weathering tests that simulate the effects of sunlight, heat, and moisture on the material's properties. These standards help predict the long-term performance of GFRPP composites in real-world environments.

Fatigue testing is essential for applications involving cyclic loading. ASTM D3479 provides guidelines for tension-tension fatigue testing of polymer matrix composite materials. This standard helps assess the material's resistance to repeated loading and unloading cycles, which is critical for many structural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!