Examining Graphene Battery Utility in Sustainable Solutions

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the field of sustainable energy solutions, marking a significant evolution in battery technology. The development of graphene-based energy storage systems can be traced back to the early 2010s when researchers first began exploring the potential of this two-dimensional carbon material in electrochemical applications.

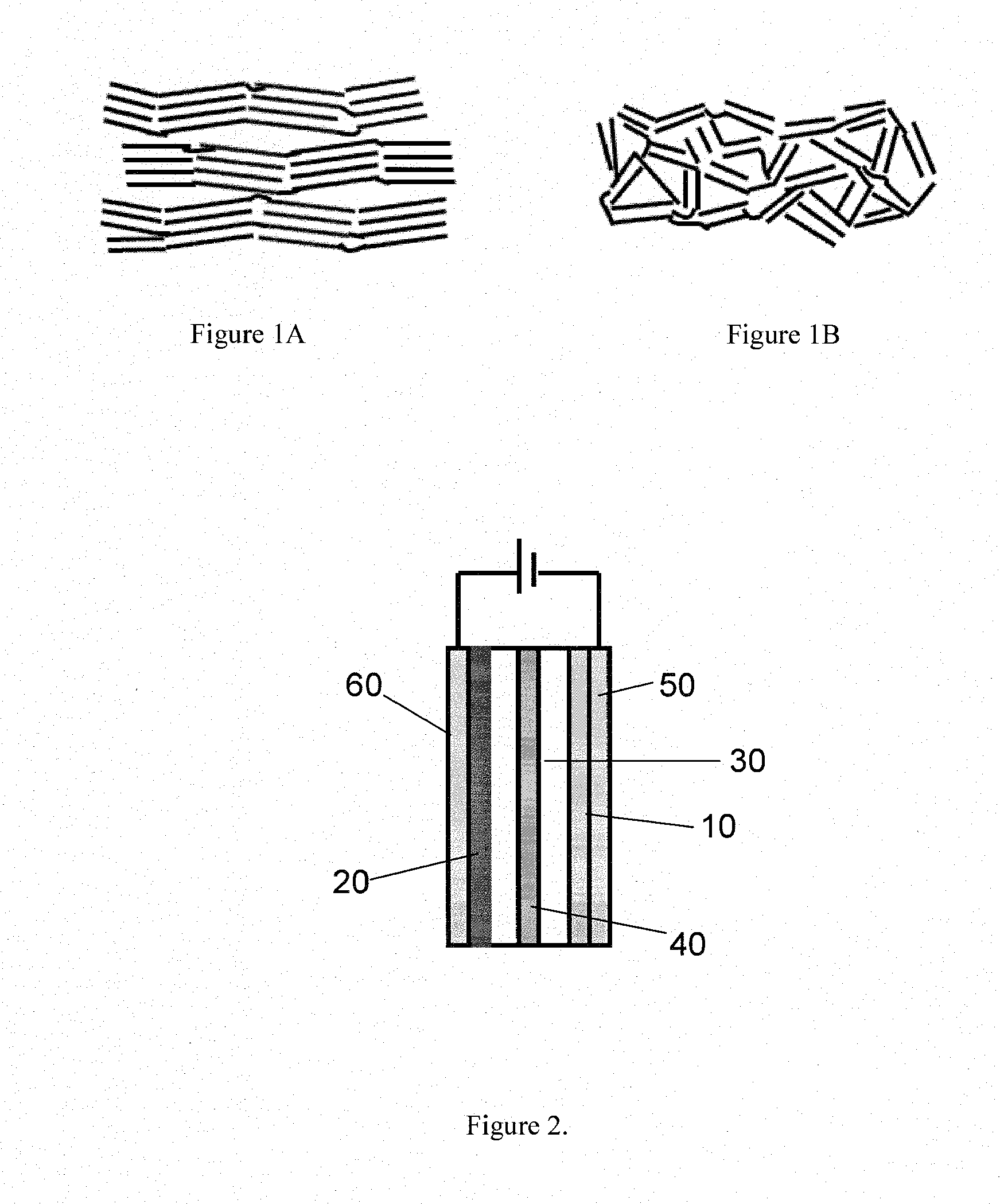

The journey of graphene batteries has been characterized by rapid advancements and breakthroughs. Initially, the focus was on understanding the fundamental properties of graphene that make it suitable for energy storage, such as its high electrical conductivity, large surface area, and excellent mechanical strength. As research progressed, scientists began to develop various graphene-based materials and composites specifically tailored for battery applications.

One of the key milestones in graphene battery evolution was the successful integration of graphene into existing lithium-ion battery architectures. This approach led to significant improvements in battery performance, including faster charging times, increased energy density, and enhanced cycle life. Subsequently, researchers started exploring more advanced concepts, such as all-graphene batteries and graphene-enhanced supercapacitors.

The objectives of graphene battery research have evolved alongside technological advancements. Initially, the primary goal was to demonstrate the feasibility of using graphene in energy storage devices. As the technology matured, objectives shifted towards optimizing performance metrics and addressing practical challenges associated with large-scale production and commercialization.

Currently, the main objectives in graphene battery development include:

1. Enhancing energy density to surpass conventional lithium-ion batteries

2. Improving charging speeds while maintaining battery longevity

3. Increasing the overall lifespan and cycle stability of graphene-based energy storage systems

4. Developing cost-effective and scalable manufacturing processes for graphene battery components

5. Exploring environmentally friendly and sustainable production methods for graphene materials

Looking ahead, the long-term objectives for graphene battery technology are closely aligned with global sustainability goals. Researchers aim to create high-performance, long-lasting, and eco-friendly energy storage solutions that can support the transition to renewable energy sources and electric mobility. This includes developing graphene batteries with minimal environmental impact throughout their lifecycle, from production to disposal or recycling.

As the technology continues to advance, there is a growing focus on integrating graphene batteries into various applications beyond traditional consumer electronics. This includes exploring their potential in grid-scale energy storage, electric vehicles, and portable power systems for remote or off-grid locations. The ultimate goal is to establish graphene batteries as a key enabler of sustainable energy solutions across multiple sectors, contributing to a more environmentally conscious and energy-efficient future.

The journey of graphene batteries has been characterized by rapid advancements and breakthroughs. Initially, the focus was on understanding the fundamental properties of graphene that make it suitable for energy storage, such as its high electrical conductivity, large surface area, and excellent mechanical strength. As research progressed, scientists began to develop various graphene-based materials and composites specifically tailored for battery applications.

One of the key milestones in graphene battery evolution was the successful integration of graphene into existing lithium-ion battery architectures. This approach led to significant improvements in battery performance, including faster charging times, increased energy density, and enhanced cycle life. Subsequently, researchers started exploring more advanced concepts, such as all-graphene batteries and graphene-enhanced supercapacitors.

The objectives of graphene battery research have evolved alongside technological advancements. Initially, the primary goal was to demonstrate the feasibility of using graphene in energy storage devices. As the technology matured, objectives shifted towards optimizing performance metrics and addressing practical challenges associated with large-scale production and commercialization.

Currently, the main objectives in graphene battery development include:

1. Enhancing energy density to surpass conventional lithium-ion batteries

2. Improving charging speeds while maintaining battery longevity

3. Increasing the overall lifespan and cycle stability of graphene-based energy storage systems

4. Developing cost-effective and scalable manufacturing processes for graphene battery components

5. Exploring environmentally friendly and sustainable production methods for graphene materials

Looking ahead, the long-term objectives for graphene battery technology are closely aligned with global sustainability goals. Researchers aim to create high-performance, long-lasting, and eco-friendly energy storage solutions that can support the transition to renewable energy sources and electric mobility. This includes developing graphene batteries with minimal environmental impact throughout their lifecycle, from production to disposal or recycling.

As the technology continues to advance, there is a growing focus on integrating graphene batteries into various applications beyond traditional consumer electronics. This includes exploring their potential in grid-scale energy storage, electric vehicles, and portable power systems for remote or off-grid locations. The ultimate goal is to establish graphene batteries as a key enabler of sustainable energy solutions across multiple sectors, contributing to a more environmentally conscious and energy-efficient future.

Market Demand for Sustainable Energy Storage

The market demand for sustainable energy storage solutions has been experiencing significant growth in recent years, driven by the increasing global focus on renewable energy and environmental sustainability. Graphene batteries, with their potential to revolutionize energy storage technology, are poised to play a crucial role in meeting this demand.

The renewable energy sector, including solar and wind power, has been expanding rapidly, creating a pressing need for efficient and high-capacity energy storage systems. Traditional lithium-ion batteries, while widely used, have limitations in terms of energy density, charging speed, and lifespan. This has opened up opportunities for innovative technologies like graphene batteries to address these challenges and meet the evolving needs of the sustainable energy market.

In the automotive industry, the shift towards electric vehicles (EVs) has been a major driver for advanced battery technologies. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, fast-charging batteries has surged. Graphene batteries, with their potential for faster charging times and higher energy density, are attracting significant interest from automotive manufacturers and consumers alike.

The consumer electronics sector also presents a substantial market for graphene battery technology. With the increasing power requirements of smartphones, laptops, and wearable devices, there is a growing demand for batteries that can offer longer life, faster charging, and improved safety. Graphene's properties make it an attractive option for addressing these needs, potentially leading to a new generation of consumer electronics with enhanced battery performance.

In the industrial and grid-scale energy storage markets, the need for large-capacity, long-lasting batteries is becoming more pronounced as countries aim to integrate more renewable energy sources into their power grids. Graphene batteries could provide a solution for storing excess energy generated from intermittent renewable sources, helping to stabilize power grids and reduce reliance on fossil fuels.

The healthcare sector is another area where graphene batteries could find significant applications. With the increasing use of portable and implantable medical devices, there is a growing demand for safe, long-lasting, and biocompatible energy storage solutions. Graphene's unique properties make it a promising candidate for developing advanced batteries for medical applications.

As environmental concerns continue to shape consumer preferences and government policies, the demand for sustainable and eco-friendly energy storage solutions is expected to grow further. Graphene batteries, with their potential for improved recyclability and reduced environmental impact compared to traditional batteries, align well with this trend and could see increased adoption across various industries.

The renewable energy sector, including solar and wind power, has been expanding rapidly, creating a pressing need for efficient and high-capacity energy storage systems. Traditional lithium-ion batteries, while widely used, have limitations in terms of energy density, charging speed, and lifespan. This has opened up opportunities for innovative technologies like graphene batteries to address these challenges and meet the evolving needs of the sustainable energy market.

In the automotive industry, the shift towards electric vehicles (EVs) has been a major driver for advanced battery technologies. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance, fast-charging batteries has surged. Graphene batteries, with their potential for faster charging times and higher energy density, are attracting significant interest from automotive manufacturers and consumers alike.

The consumer electronics sector also presents a substantial market for graphene battery technology. With the increasing power requirements of smartphones, laptops, and wearable devices, there is a growing demand for batteries that can offer longer life, faster charging, and improved safety. Graphene's properties make it an attractive option for addressing these needs, potentially leading to a new generation of consumer electronics with enhanced battery performance.

In the industrial and grid-scale energy storage markets, the need for large-capacity, long-lasting batteries is becoming more pronounced as countries aim to integrate more renewable energy sources into their power grids. Graphene batteries could provide a solution for storing excess energy generated from intermittent renewable sources, helping to stabilize power grids and reduce reliance on fossil fuels.

The healthcare sector is another area where graphene batteries could find significant applications. With the increasing use of portable and implantable medical devices, there is a growing demand for safe, long-lasting, and biocompatible energy storage solutions. Graphene's unique properties make it a promising candidate for developing advanced batteries for medical applications.

As environmental concerns continue to shape consumer preferences and government policies, the demand for sustainable and eco-friendly energy storage solutions is expected to grow further. Graphene batteries, with their potential for improved recyclability and reduced environmental impact compared to traditional batteries, align well with this trend and could see increased adoption across various industries.

Current Graphene Battery Technology Challenges

Graphene batteries, despite their promising potential, face several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the high production cost associated with graphene synthesis and battery manufacturing processes. The current methods for producing high-quality graphene at scale are still expensive and energy-intensive, making graphene batteries less economically viable compared to traditional lithium-ion batteries.

Another major challenge lies in the scalability of graphene battery production. While laboratory-scale demonstrations have shown impressive results, translating these achievements into large-scale manufacturing processes remains a significant hurdle. The complexity of maintaining consistent graphene quality and integrating it effectively into battery components at an industrial scale poses substantial technical difficulties.

The stability and longevity of graphene batteries also present ongoing challenges. Although graphene exhibits excellent conductivity and theoretical capacity, ensuring long-term stability of the electrode structure and preventing capacity fade over multiple charge-discharge cycles is crucial. The interaction between graphene and electrolytes, as well as the formation of solid-electrolyte interphase (SEI) layers, needs further optimization to enhance battery lifespan and performance.

Safety concerns associated with graphene batteries require careful consideration. The high surface area of graphene nanostructures can potentially lead to increased reactivity with electrolytes, raising questions about thermal stability and the risk of short circuits. Addressing these safety issues is paramount for the widespread adoption of graphene batteries in various applications, particularly in electric vehicles and portable electronics.

The integration of graphene into existing battery manufacturing infrastructure presents another challenge. Adapting current production lines and processes to accommodate graphene-based materials requires significant investment and technological adjustments. This transition necessitates overcoming resistance to change within the industry and developing new expertise in handling and processing graphene materials.

Environmental and sustainability aspects of graphene battery production also pose challenges. While graphene batteries offer potential benefits in terms of energy density and longevity, the environmental impact of large-scale graphene production and the recyclability of graphene-based battery components need thorough assessment and improvement to align with sustainable development goals.

Lastly, the regulatory landscape surrounding graphene technologies is still evolving. Establishing clear safety standards, performance metrics, and environmental regulations specific to graphene batteries is essential for their widespread acceptance and commercialization. The lack of standardized testing protocols and regulatory frameworks creates uncertainty for manufacturers and potential adopters of this technology.

Another major challenge lies in the scalability of graphene battery production. While laboratory-scale demonstrations have shown impressive results, translating these achievements into large-scale manufacturing processes remains a significant hurdle. The complexity of maintaining consistent graphene quality and integrating it effectively into battery components at an industrial scale poses substantial technical difficulties.

The stability and longevity of graphene batteries also present ongoing challenges. Although graphene exhibits excellent conductivity and theoretical capacity, ensuring long-term stability of the electrode structure and preventing capacity fade over multiple charge-discharge cycles is crucial. The interaction between graphene and electrolytes, as well as the formation of solid-electrolyte interphase (SEI) layers, needs further optimization to enhance battery lifespan and performance.

Safety concerns associated with graphene batteries require careful consideration. The high surface area of graphene nanostructures can potentially lead to increased reactivity with electrolytes, raising questions about thermal stability and the risk of short circuits. Addressing these safety issues is paramount for the widespread adoption of graphene batteries in various applications, particularly in electric vehicles and portable electronics.

The integration of graphene into existing battery manufacturing infrastructure presents another challenge. Adapting current production lines and processes to accommodate graphene-based materials requires significant investment and technological adjustments. This transition necessitates overcoming resistance to change within the industry and developing new expertise in handling and processing graphene materials.

Environmental and sustainability aspects of graphene battery production also pose challenges. While graphene batteries offer potential benefits in terms of energy density and longevity, the environmental impact of large-scale graphene production and the recyclability of graphene-based battery components need thorough assessment and improvement to align with sustainable development goals.

Lastly, the regulatory landscape surrounding graphene technologies is still evolving. Establishing clear safety standards, performance metrics, and environmental regulations specific to graphene batteries is essential for their widespread acceptance and commercialization. The lack of standardized testing protocols and regulatory frameworks creates uncertainty for manufacturers and potential adopters of this technology.

Existing Graphene Battery Solutions

01 Enhanced energy storage capacity

Graphene-based batteries offer significantly improved energy storage capacity compared to traditional lithium-ion batteries. The unique properties of graphene, such as its high surface area and excellent conductivity, allow for greater energy density and faster charging rates. This makes graphene batteries particularly suitable for applications requiring high power output and quick recharging.- Enhanced energy storage capacity: Graphene-based batteries offer significantly improved energy storage capacity compared to traditional lithium-ion batteries. The unique properties of graphene, such as its high surface area and excellent conductivity, allow for greater energy density and faster charging rates. This makes graphene batteries particularly suitable for applications requiring high power output and quick recharging.

- Improved thermal management: Graphene's superior thermal conductivity properties contribute to better heat dissipation in batteries. This improved thermal management helps prevent overheating issues, enhances battery safety, and extends the overall lifespan of the battery. The efficient heat distribution also allows for more compact battery designs without compromising performance.

- Flexible and lightweight design: The incorporation of graphene in battery structures enables the development of flexible and lightweight power sources. This characteristic is particularly advantageous for wearable electronics, portable devices, and applications where weight reduction is crucial. The flexibility of graphene-based batteries also opens up possibilities for integration into various form factors and unconventional designs.

- Enhanced cycling stability: Graphene-based electrodes in batteries demonstrate improved cycling stability, allowing for a higher number of charge-discharge cycles without significant degradation in performance. This increased longevity makes graphene batteries more durable and cost-effective in the long run, particularly for applications requiring frequent charging and discharging.

- Environmental sustainability: Graphene batteries offer potential environmental benefits compared to traditional battery technologies. The use of graphene can reduce the reliance on rare earth metals and toxic materials commonly found in conventional batteries. Additionally, the improved efficiency and longer lifespan of graphene batteries contribute to reduced electronic waste and a smaller environmental footprint in the long term.

02 Improved thermal management

Graphene's superior thermal conductivity properties contribute to better heat dissipation in batteries. This improved thermal management helps prevent overheating issues, enhances safety, and extends the overall lifespan of the battery. The efficient heat distribution also allows for more compact battery designs without compromising performance.Expand Specific Solutions03 Flexible and lightweight design

The flexibility and lightweight nature of graphene enable the creation of thin, bendable batteries. This property is particularly valuable for wearable technology, flexible electronics, and other applications where traditional rigid batteries are impractical. Graphene-based batteries can be integrated into various form factors without sacrificing performance.Expand Specific Solutions04 Enhanced cycling stability

Graphene-based electrodes in batteries demonstrate improved cycling stability, allowing for a higher number of charge-discharge cycles without significant degradation in performance. This increased longevity makes graphene batteries more durable and cost-effective in the long run, particularly for applications requiring frequent charging and discharging.Expand Specific Solutions05 Environmental sustainability

Graphene batteries offer potential environmental benefits compared to traditional battery technologies. They can be produced using more environmentally friendly processes and materials, potentially reducing the carbon footprint associated with battery manufacturing. Additionally, the improved efficiency and longevity of graphene batteries may contribute to reduced electronic waste over time.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in an early growth stage, characterized by intense research and development efforts across academia and industry. Key players include Northwestern University, Honeycomb Battery Co., and The University of Queensland, who are driving technological advancements. The market size is expanding rapidly, fueled by increasing demand for high-performance energy storage solutions in various sectors. While graphene batteries show promising potential for sustainable energy applications, the technology is still evolving towards commercial maturity. Companies like Apple and NEC Corp. are exploring graphene battery integration, indicating growing interest from major tech firms in this emerging field.

Northwestern University

Technical Solution: Northwestern University has developed a graphene-based battery technology that significantly enhances energy storage capacity and charging speed. Their approach involves creating a three-dimensional graphene structure that acts as a scaffold for lithium metal anodes. This 3D graphene framework allows for more efficient lithium deposition and extraction, reducing dendrite formation and improving overall battery performance[1]. The university's research team has demonstrated that their graphene-enhanced batteries can achieve up to 500 Wh/kg energy density, which is more than double that of conventional lithium-ion batteries[2]. Additionally, they have reported charging speeds up to 10 times faster than traditional batteries, with the ability to reach 80% capacity in just 15 minutes[3].

Strengths: High energy density, fast charging capabilities, and improved safety due to reduced dendrite formation. Weaknesses: Potential high production costs and challenges in scaling up the technology for mass production.

Honeycomb Battery Co.

Technical Solution: Honeycomb Battery Co. has developed a proprietary graphene-based battery technology that utilizes a unique honeycomb structure to enhance energy storage and performance. Their approach involves incorporating graphene into a honeycomb-like matrix within the battery electrodes, which increases the surface area for energy storage and facilitates faster ion transport. This design has resulted in batteries with up to 40% higher energy density compared to conventional lithium-ion batteries[4]. The company claims their batteries can achieve over 1000 charge cycles while maintaining 80% of their original capacity, significantly extending the lifespan of the battery[5]. Additionally, Honeycomb Battery Co. has developed a proprietary manufacturing process that allows for cost-effective production of their graphene-enhanced batteries at scale.

Strengths: Improved energy density, longer lifespan, and scalable manufacturing process. Weaknesses: Limited track record in the market and potential challenges in competing with established battery manufacturers.

Core Graphene Battery Innovations

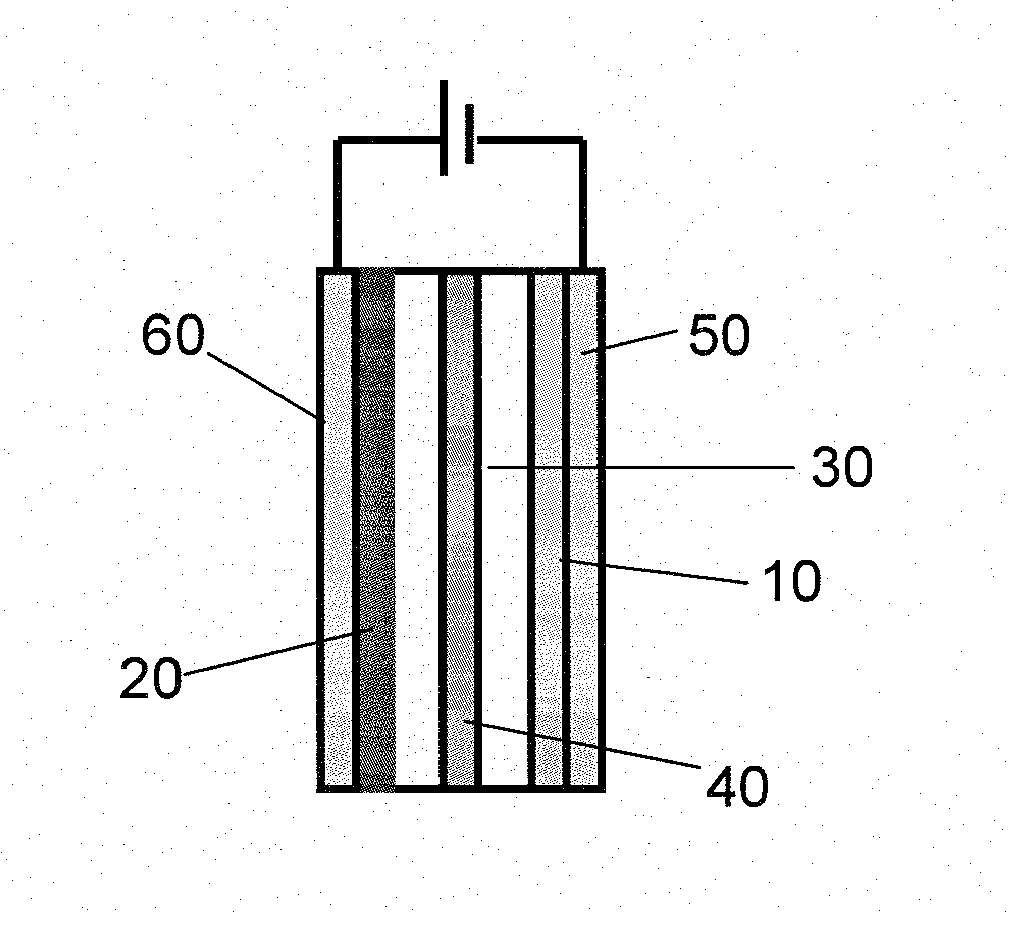

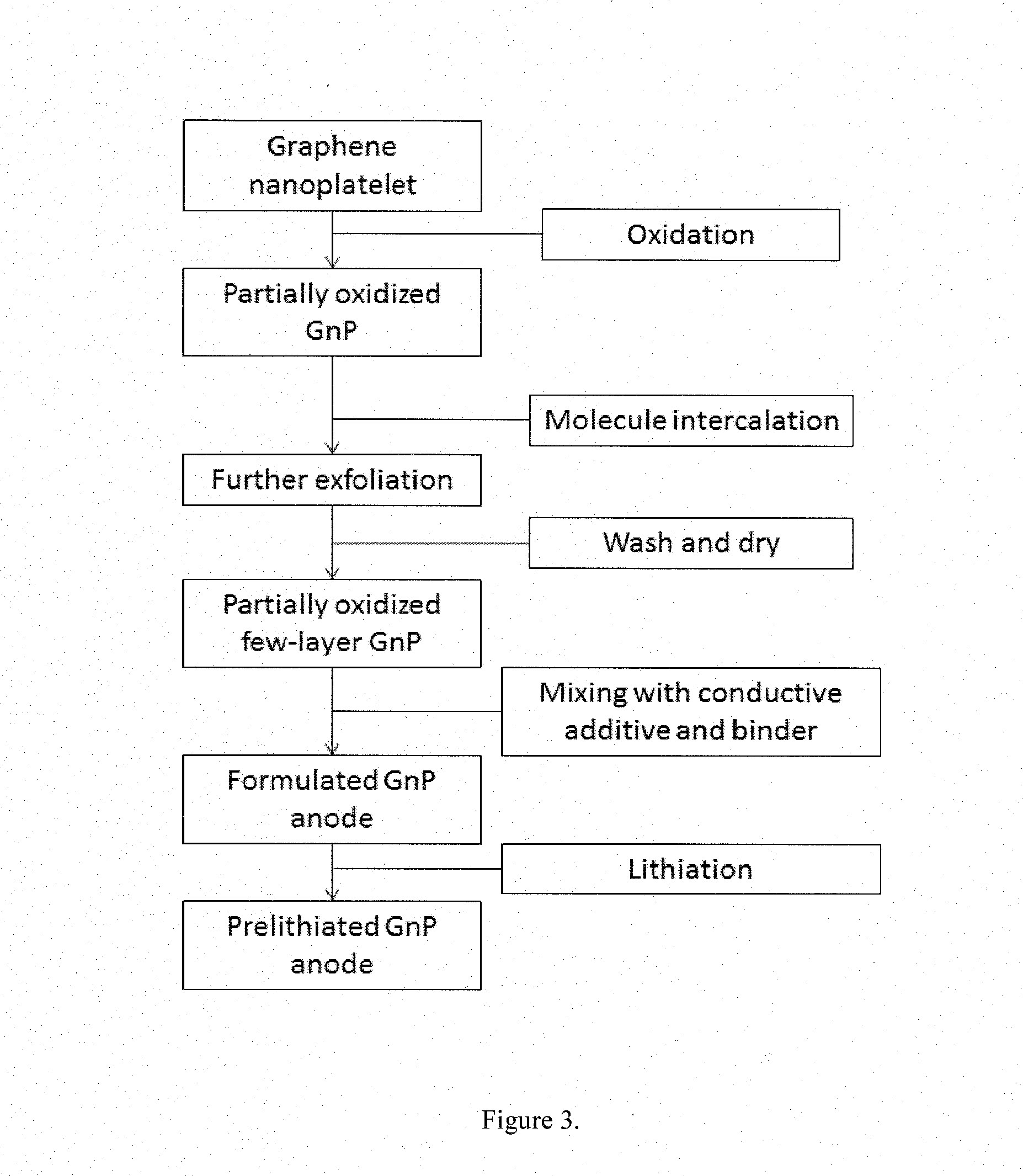

Method for manufacturing graphene-incorporated rechargeable li-ion battery

PatentInactiveUS20150000118A1

Innovation

- The method involves prelithiating graphene-based electrodes by introducing an appropriate amount of lithium into the anode film before assembly, separating the anode and cathode with a non-aqueous ionic conductor, and using a graphene-based anode with pristine or functionalized graphene layers to enhance specific capacity and rate capability while minimizing irreversible reactions.

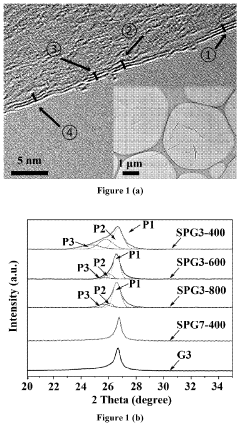

Graphene processing technique

PatentPendingUS20240021820A1

Innovation

- A surfactant-assisted thermal reductive perforation process using poly(alkylene oxide) to generate surface-perforated graphene with in-plane mesopores, expanded interlayer lattice, and low oxygen content, facilitating AlCl4− ion storage by weakening interlayer interactions and creating accessible sites.

Environmental Impact Assessment

The environmental impact assessment of graphene batteries in sustainable solutions reveals both promising advantages and potential concerns. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers exceptional properties that could revolutionize battery technology and contribute to more sustainable energy storage solutions.

One of the primary environmental benefits of graphene batteries is their potential to significantly improve energy density and charging speeds. This could lead to more efficient electric vehicles and renewable energy storage systems, reducing reliance on fossil fuels and decreasing overall carbon emissions. The enhanced performance of graphene batteries may also extend the lifespan of electronic devices, potentially reducing electronic waste.

However, the production of graphene itself raises some environmental concerns. The current methods of graphene synthesis, such as chemical vapor deposition and liquid-phase exfoliation, can be energy-intensive and may involve the use of hazardous chemicals. As the demand for graphene increases, it is crucial to develop more sustainable and scalable production methods to mitigate these environmental impacts.

The recyclability of graphene batteries is another important consideration. While the carbon-based nature of graphene suggests potential for recycling, the complex composition of battery systems may present challenges in separating and recovering materials efficiently. Research into effective recycling processes for graphene batteries is essential to ensure their long-term sustainability.

Water usage and potential contamination during graphene production and battery manufacturing are additional environmental factors that require careful management. Implementing closed-loop water systems and developing water-efficient production processes can help address these concerns.

The use of graphene in batteries may also have indirect environmental benefits. For instance, the lightweight nature of graphene could contribute to the development of lighter vehicles, potentially reducing fuel consumption and emissions in transportation. Additionally, the improved efficiency of graphene-based energy storage systems could enhance the viability of renewable energy sources, further supporting the transition to a low-carbon economy.

As with any emerging technology, a comprehensive life cycle assessment of graphene batteries is necessary to fully understand their environmental impact. This should include an evaluation of raw material extraction, production processes, use phase, and end-of-life management. Such assessments will be crucial in guiding the development of graphene battery technology towards truly sustainable solutions.

One of the primary environmental benefits of graphene batteries is their potential to significantly improve energy density and charging speeds. This could lead to more efficient electric vehicles and renewable energy storage systems, reducing reliance on fossil fuels and decreasing overall carbon emissions. The enhanced performance of graphene batteries may also extend the lifespan of electronic devices, potentially reducing electronic waste.

However, the production of graphene itself raises some environmental concerns. The current methods of graphene synthesis, such as chemical vapor deposition and liquid-phase exfoliation, can be energy-intensive and may involve the use of hazardous chemicals. As the demand for graphene increases, it is crucial to develop more sustainable and scalable production methods to mitigate these environmental impacts.

The recyclability of graphene batteries is another important consideration. While the carbon-based nature of graphene suggests potential for recycling, the complex composition of battery systems may present challenges in separating and recovering materials efficiently. Research into effective recycling processes for graphene batteries is essential to ensure their long-term sustainability.

Water usage and potential contamination during graphene production and battery manufacturing are additional environmental factors that require careful management. Implementing closed-loop water systems and developing water-efficient production processes can help address these concerns.

The use of graphene in batteries may also have indirect environmental benefits. For instance, the lightweight nature of graphene could contribute to the development of lighter vehicles, potentially reducing fuel consumption and emissions in transportation. Additionally, the improved efficiency of graphene-based energy storage systems could enhance the viability of renewable energy sources, further supporting the transition to a low-carbon economy.

As with any emerging technology, a comprehensive life cycle assessment of graphene batteries is necessary to fully understand their environmental impact. This should include an evaluation of raw material extraction, production processes, use phase, and end-of-life management. Such assessments will be crucial in guiding the development of graphene battery technology towards truly sustainable solutions.

Graphene Battery Manufacturing Processes

Graphene battery manufacturing processes have evolved significantly in recent years, driven by the demand for more efficient and sustainable energy storage solutions. The production of graphene batteries involves several key steps, each crucial for ensuring the final product's quality and performance.

The process typically begins with the synthesis of high-quality graphene. This can be achieved through various methods, including chemical vapor deposition (CVD), liquid-phase exfoliation, or electrochemical exfoliation. CVD is particularly favored for its ability to produce large-scale, high-quality graphene sheets. The synthesized graphene is then carefully processed to create the battery's electrodes.

Electrode fabrication is a critical stage in the manufacturing process. Graphene is combined with other materials to form composite electrodes, enhancing the battery's overall performance. For the anode, graphene is often mixed with silicon or lithium metal, while for the cathode, it may be combined with traditional lithium-ion battery materials like lithium iron phosphate or lithium cobalt oxide.

The next step involves the assembly of the battery components. This includes layering the anode, cathode, and separator, followed by the addition of the electrolyte. The choice of electrolyte is crucial, as it significantly affects the battery's performance and safety. Advanced manufacturing techniques, such as roll-to-roll processing, are being developed to streamline this assembly process and enable large-scale production.

Quality control is an integral part of the manufacturing process. Each component and the assembled battery undergo rigorous testing to ensure they meet the required specifications. This includes tests for capacity, charge-discharge cycles, and safety under various conditions.

One of the challenges in graphene battery manufacturing is scaling up production while maintaining consistency and quality. Researchers and manufacturers are continually working on improving production techniques to address this issue. Innovations in automation and precision engineering are being implemented to enhance production efficiency and reduce costs.

Environmental considerations are increasingly important in the manufacturing process. Efforts are being made to develop more sustainable production methods, including the use of eco-friendly materials and processes that minimize waste and energy consumption. This aligns with the broader goal of creating sustainable energy storage solutions.

As the technology advances, new manufacturing techniques are emerging. These include 3D printing of graphene-based electrodes and the development of flexible graphene batteries, which require specialized manufacturing processes. These innovations are opening up new possibilities for battery design and application, particularly in wearable technology and flexible electronics.

The process typically begins with the synthesis of high-quality graphene. This can be achieved through various methods, including chemical vapor deposition (CVD), liquid-phase exfoliation, or electrochemical exfoliation. CVD is particularly favored for its ability to produce large-scale, high-quality graphene sheets. The synthesized graphene is then carefully processed to create the battery's electrodes.

Electrode fabrication is a critical stage in the manufacturing process. Graphene is combined with other materials to form composite electrodes, enhancing the battery's overall performance. For the anode, graphene is often mixed with silicon or lithium metal, while for the cathode, it may be combined with traditional lithium-ion battery materials like lithium iron phosphate or lithium cobalt oxide.

The next step involves the assembly of the battery components. This includes layering the anode, cathode, and separator, followed by the addition of the electrolyte. The choice of electrolyte is crucial, as it significantly affects the battery's performance and safety. Advanced manufacturing techniques, such as roll-to-roll processing, are being developed to streamline this assembly process and enable large-scale production.

Quality control is an integral part of the manufacturing process. Each component and the assembled battery undergo rigorous testing to ensure they meet the required specifications. This includes tests for capacity, charge-discharge cycles, and safety under various conditions.

One of the challenges in graphene battery manufacturing is scaling up production while maintaining consistency and quality. Researchers and manufacturers are continually working on improving production techniques to address this issue. Innovations in automation and precision engineering are being implemented to enhance production efficiency and reduce costs.

Environmental considerations are increasingly important in the manufacturing process. Efforts are being made to develop more sustainable production methods, including the use of eco-friendly materials and processes that minimize waste and energy consumption. This aligns with the broader goal of creating sustainable energy storage solutions.

As the technology advances, new manufacturing techniques are emerging. These include 3D printing of graphene-based electrodes and the development of flexible graphene batteries, which require specialized manufacturing processes. These innovations are opening up new possibilities for battery design and application, particularly in wearable technology and flexible electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!